Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Heating and Cooling of Circular Saws: K KT KTT

Caricato da

te2makanza5279Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Heating and Cooling of Circular Saws: K KT KTT

Caricato da

te2makanza5279Copyright:

Formati disponibili

Heating and Cooling of Circular Saws

Bruce Lehmann, Ph.D., P.Eng.

Cal Saw Canada

Introduction

Temperature differences between the rim and the eye of a circular saw have major effects on saw

stiffness. Even small differences of say 10 C are significant, yet this can be created by only a

small fraction of the power produced at the tooth tip or when the blades rubs against the wood.

However, there are also mechanisms to take away large amounts of heat away from the blade.

This paper discusses where and how much heat is developed, how if flows through the saw, and

how the heat leaves. The end result is a model that calculates the temperature distribution in the

saw blade. Such information is needed to understand how to design and operate circular saws.

Also, new materials such as stainless steel and cermet tips have different thermal properties that

need to be investigated.

Effects of Temperature on Circular Saws

The problem of temperature changes in circular saws is that the rim usually gets hotter than the

rest of the saw, causing a loss of stiffness and resulting in an increase in sawing deviation. If T

is the temperature difference between the rim and the eye, then the stiffness is affected as

follows:

k k t k t T

0

3

1

where t is the plate thickness. From this equation the relative change in stiffness due a

temperature change is

k t T

k t

k

k

T

t

1

0

3

1

0

2

_

,

which can be interpreted to mean that thinner saws are more sensitive to temperature differences

than thinker saws. Given the industry trend to thinner saws, which have lower stiffness to begin

with, the need to understand and control how heat moves through the saw is more critical.

Furthermore, as will be shown below, thickness has a significant effect on hear slow.

Heat Flow Concepts

Heat has a source, it flows through materials, and is absorbed or dissipated. Since it takes time

for heat to move, time is part of the discussion of heat flow in saws.

For a piece of material of mass, m, surface area, A, the change in temperature during a time

period is

( ) T

Q

mC

hA

mC

T T

_

,

Q is the amount of heat from some source. Note that the larger the mass the larger the

temperature rise. The value of C, the thermal capacity of the material, is larger for materials that

can absorb more heat for a given temperature increase. The second term represents the loss of

heat to the surrounding air or cooling water. T is the temperature of the material, and T

is the

temperature of the surrounding air. The convection coeeficient, h, accounts for how fast the air

flows over the surface or the amount of water that adheres to and spins off the blade surface.

Heat is taken away faster as the surface area increases and the difference between the

temperature of the material and the surroundings increases.

Another aspect of heat flow is conduction through the material. Heat flows from one point to

another when there is a difference in temperature between the two points. The amount of heat is

proportional to the cross-sectional area that the heat must flow through and inversely

proportional to the distance between the points. Mathematically, the change in temperature at

Point 1 during a time period is

( )

T

ka

mC x

T T

2 1

Model of Heat Flow in a Circular Saw

The drawing below shows how the heat flow model partitions the plate into rings, each with its

own mass, and surface area. Note that this model assumes all the heat flow to be radial. For the

rotation speeds of operating saws, the temperature around the saw can be assumed to be uniform

[Hauptmann and Ramsey]

Figure 1. Lumped-mass model of heat flow through a circular saw.

Mass of node n = m

n

= t(R

n+1

2

R

n

2

)

Surface area of node n = A

n

= 2(R

n+1

2

R

n

2

)

Conduction area of node n = a

n

= 2t R

n

Temperature of node n at time interval i = T

i,n

Time = i

To calculate the temperature of each node, the following equation is solved:

( ) ( ) ( ) T T

m C

Q

ka

R

T T

ka

R

T T hA T T

i n i n

m

i n

n

n

i n i n

n

n

i n i n n i n +

+

+

_

,

+ +

1

]

1 1

1

1

1 1 , , , , , , , ,

The same model can be extended to include the teeth by dividing the tooth into segments as

shown above.

Heat Sources

In sawing the sources of heat are all caused by friction, such as friction:

at the tooth tip (face, back and flanks)

from sawdust spillage

from rubbing with the wood surface

from jammed slivers

from tight guides.

An estimate of how much heat is generated at the tooth tip can be found from the Merchant

model of cutting forces by calculating the heat from the chip sliding over the face of the tooth.

Figure 2. Cutting force model.

The friction force on the face of the tooth is:

F F

F

Cos Sin

f N

T

+

The power lost to friction is

P F V

f f c

and the power driving the saw is

P F V

T

The fraction of power that ends up in heat is

P

P

V

V Cos Sin

f

c

c

_

,

_

,

For a friction coefficient of 0.35, a hook angle of 30, and assuming V = V

c

, then the ratio is

equal to 0.34, which is a significant about. The amount of heat that goes into the tooth rather

than the sawdust is unknown at this time, but given that wood is a very poor conductor of heat

compared to steel or tungsten carbide, a first approximation would be to assume all of the heat

from the cutting action goes into the teeth.. In contrast, in metal cutting about 20% of the heat

goes into the tool, 65% into the chip, and 15% into the workpiece [ ].

The heat from the rubbing due to a jammed sliver in the guide, assuming a contact force of say,

50N (about 10lb), a friction coefficient of 0.3, and a blade surface speed of 40m/s, is

P = (2)(0.3)(50N)(40m/s)

= 1.2 KW

Heat Sinks

The air flowing around a spinning circular saw can carry away a large amount of heat. The

model includes a formula for the convection coefficient, h, developed by Kreith [ ] that

accounts for laminar (smooth) and turbulent air flow depending upon the rotation speed and the

size of the saw. See Figure 3. Typical values of the convection coefficient are:

Near eye h = 5 W/m

2

C

Near rim h = 85 W/m

2

C

When water is used for cooling, especially with guides, the value of the convection coefficient

could be 5 to 10 times that of air cooling. (These numbers are based on a comparison to

experimental data from other industries using water cooling.)

Figure 3. Convection coefficient for laminar and turbulent air flow around a spinning disk.

Thermal Properties of Materials

The thermal properties of the materials involved in sawing are given in the table below.

Density Heat

Capacity

Thermal

Conductivity

Diffusivity

C C k = k/C

Material Kg/m

3

KJ/kgC KJ/m

3

C W/mC m

2

/s x 10

9

Wood 420 2.5 1050 0.10 95

Steel 7800 0.42 3280 36 11000

Stainless Steel 7880 0.46 3625 25 6900

Inconel 8500 0.42 3570 16 4480

Air 1.18 1.0 1.18 0.026 22000

Water 993 4.2 4170 0.62 149

Tungsten Carbide 14700 0.24 3528 63 17850

Cermet 6400 - - 15 -

These properties, especially the diffusivity, determine how fast heat flow through a material.

The lower the diffusivity value, the slower the temperature will change, or more precisely, the

slower the heat will spread to the surrounding material. As an example, heat will flow through a

steel saw 60% faster than through a stainless steel saw. See Figure 4.

If most of the heat enters the saw though the tooth tips a low diffusivity is beneficial because the

heat will stay in the teeth, resulting in less heating of the rim of the saw. Furthermore, because

the tooth temperatures will be higher, more heat will be carried off by convection around the

teeth.

0.0

10.0

20.0

30.0

40.0

50.0

0.0000 0.0500 0.1000 0.1500 0.2000 0.2500 0.3000 0.3500 0.4000 0.4500 0.5000

Radial Position (m)

T

e

m

p

e

r

a

t

u

r

e

a

b

o

v

e

A

m

b

i

e

n

t

(

C

)

Gullet Bottom

Steel

Stainless Steel

Iconel

Figure 4. Effect of material properties on temperature. 2KW at tooth tip for 100 seconds.

The other important thermal property is the heat capacity, C. The larger the heat capacity, the

small the temperature rise for a given amount of heat input. Figure 5 shows the temperature

distribution for steel, stainless steel and Inconel saws for a heat input in the body of the saw,

possibly due to a sliver.

The value of C also affects the rate that the saw heats or cools. For example, see Figure 6,

where the rim of the saw is heated for 10 seconds and then allowed to cool.

0.0

10.0

20.0

30.0

40.0

50.0

0.0000 0.0500 0.1000 0.1500 0.2000 0.2500 0.3000 0.3500 0.4000 0.4500 0.5000

Radial Position (m)

T

e

m

p

e

r

a

t

u

r

e

a

b

o

v

e

A

m

b

i

e

n

t

(

C

)

500 W Heat Input

Iconel

Stainless Steel

Steel

Figure 5. Effect on material properties on temperatures due to a sliver.

0.0

2.0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

18.0

20.0

0 2 4 6 8 10 12 14 16 18 20

Time (sec)

T

e

m

p

e

r

a

t

u

r

e

a

b

o

v

e

A

m

b

i

e

n

t

(

C

)

Rim temperature for a 500 W heat input at the rim. Heating for

10 sec followed by 10 sec of cooling.

Figure 6. Heating and cooling of a steel saw.

0.0

2.0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

0 10 20 30 40 50 60 70 80

Time (sec)

T

e

m

p

e

r

a

t

u

r

e

a

b

o

v

e

A

m

b

i

e

n

t

(

C

)

Temperature at the gullet bottom. Alternating 10 sec of

heating at the gullet bottom followed by 10 sec of cooling.

Figure 7. Temperature at the gullet bottom due to repeated heating and cooling cycles as would occur during

production.

In Figure 6 only one heating and cooling cycle is shown. In production, boards may be separated

by only a few seconds, which may not be enough time for the blade to completely cool. The

result is a gradual increase in blade temperature, eventually reaching a sustained amount, as

shown in Figure 7.The implication is that more cooling is required as the board piece-count is

increased, even if the feed speed remains the same.

Effect of Plate Thickness

Reducing the plate thickness has two effects on heat flow:

1. The thermal resistance to heat conduction is higher because the cross-sectional area for

the heat to flow through is smaller.

2. The amount of mass available to absorb heat is smaller, resulting in higher temperatures.

In the case of heat conduction, the two effects exactly cancel each other resulting in the same

temperature distribution for plates of different thicknesses.

The differences in plate temperature for different thicknesses occurs because the heat inputs do

not decrease in proportion to decreases in plate thickness. For instance, heating at the tooth tip is

proportional to the kerf, not the plate thickness; and the heat from a sliver is not affected by plate

thickness. As a result, thin blades heat more because they have less mass to absorb the heat.

Conclusions

1. The stiffness of thin saws is much more sensitive to a temperature rise at the rim.

Furthermore, because thin saws have less mass to absorb heat, more more care is needed

to avoid heat getting into the saw in the first place, and to providing adequate cooling.

2. Alternate plate materials such as stainless steel improve the thermal response of the saw

because it can absorb more heat and the heat stays in the teeth rather than moving into the

rim of the saw.

3. The amount of heat entering the saw through the tooth tips is on the order of 30% of the

arbor power. On the other hand, the cooling effect of the air flowing around the rotating

saw takes most of the heat away. Furthermore, water spray can absorb about five times

as much heat as does air cooling.

4. Heating and cooling times for circular saws is measured in seconds, not micro-seconds or

minutes. More heat and thinner saws result in faster heating. More external cooling and

thinner saws result in faster cooling.

References

1. E.G. Hauptmann and H Ramsey, Temperature distribution in a rotating thin disk.

Appl. Sci. Res. 20. pp 436-443, 1969.

2. F. Kreith., Principles of Heat Transfer, 2

nd

Ed. Intl Textbook Co., Scranton, 1965

3. B.L. Juneja and G.S. Sekhon. Fundementals of Metal Cutting and Machine Tools.

John Wiley & Sons, Toronto.

4. C.D. Mote. Unsymetrical Transient Heat Condition: Rotating Disk Applications. J.

Eng. Ind. 1970. pp. 181-190.

0.0

10.0

20.0

30.0

40.0

50.0

0.0000 0.0500 0.1000 0.1500 0.2000 0.2500 0.3000 0.3500 0.4000 0.4500 0.5000

Radial Position (m)

T

e

m

p

e

r

a

t

u

r

e

a

b

o

v

e

A

m

b

i

e

n

t

(

C

)

2 mm thick

3 mm thick

500 W for 50 sec.

Figure 8. Effect of plate thickness on temperature.

Potrebbero piacerti anche

- Heat Transfer Lab Experiment ReportDocumento5 pagineHeat Transfer Lab Experiment ReportMuhammed Rafi K M67% (3)

- 4.1.3 Step-by-Step CalculationDocumento11 pagine4.1.3 Step-by-Step Calculationmohamed nizal100% (1)

- Cryoquip VaporizersDocumento2 pagineCryoquip VaporizersASDF AFDS0% (1)

- Thermal Design of Heat ExchangersDocumento24 pagineThermal Design of Heat ExchangersWira NugrohoNessuna valutazione finora

- Method of Calculating The Cooling Rate in HAZ During WeldingDocumento6 pagineMethod of Calculating The Cooling Rate in HAZ During WeldingahmedNessuna valutazione finora

- Solutions Manual to accompany Engineering Materials ScienceDa EverandSolutions Manual to accompany Engineering Materials ScienceValutazione: 4 su 5 stelle4/5 (1)

- Transport Phenomena 3 4 2012 HeatDocumento59 pagineTransport Phenomena 3 4 2012 HeatSiti HannaNessuna valutazione finora

- LPG Cargo Measurement and Calculation Procedure PDFDocumento3 pagineLPG Cargo Measurement and Calculation Procedure PDFJohn Green100% (3)

- LEED Green Associate Practice ExamDocumento21 pagineLEED Green Associate Practice ExamuclabruintizedNessuna valutazione finora

- Examples of Fire Safety Engineering Calculations.Documento18 pagineExamples of Fire Safety Engineering Calculations.Sam Wing HongNessuna valutazione finora

- Tugas Metalurgi Las - Heat Flow in WeldingDocumento4 pagineTugas Metalurgi Las - Heat Flow in WeldingRhidiyan Waroko100% (4)

- Analysis of Temperature Loss of Hot Metal During Hot Rolling Process at Steel PlantDocumento7 pagineAnalysis of Temperature Loss of Hot Metal During Hot Rolling Process at Steel PlantIJMERNessuna valutazione finora

- Simulation and Study of Shell and Tube Type Heat EDocumento9 pagineSimulation and Study of Shell and Tube Type Heat EILEENVIRUSNessuna valutazione finora

- HMT KKK Unit 1, 2Documento73 pagineHMT KKK Unit 1, 2Siddharth GarkhailNessuna valutazione finora

- Solucion Cap 7Documento7 pagineSolucion Cap 7karen20yarNessuna valutazione finora

- Steady State Temperature Distribution of Cast Resin Dry Type Transformer Based On New Thermal Model Using Finite Element MethodDocumento5 pagineSteady State Temperature Distribution of Cast Resin Dry Type Transformer Based On New Thermal Model Using Finite Element MethodAnonymous sAmJfcVNessuna valutazione finora

- Thermal Loading in Cutting Tools: 2.1 Heat Generation in The Contact SurfacesDocumento15 pagineThermal Loading in Cutting Tools: 2.1 Heat Generation in The Contact SurfacesJaimeFeijooNessuna valutazione finora

- 3.044 Problem Set 1: Heat Conduction Due Monday February 14, 2005Documento3 pagine3.044 Problem Set 1: Heat Conduction Due Monday February 14, 2005Carlos CastilloNessuna valutazione finora

- Thermal Design Consideration For Surface Mount LayoutsDocumento16 pagineThermal Design Consideration For Surface Mount LayoutsRicardoNessuna valutazione finora

- Transient Temperature Field of A Friction Pair inDocumento4 pagineTransient Temperature Field of A Friction Pair inluong van toiNessuna valutazione finora

- Transient Temperature Distribution in A Steel Rod Subjected To Friction WeldingDocumento11 pagineTransient Temperature Distribution in A Steel Rod Subjected To Friction WeldingMuhammad Fatka FirmansyahNessuna valutazione finora

- Heat Transfer Thru ConductionDocumento6 pagineHeat Transfer Thru Conductionsammar_10Nessuna valutazione finora

- Edge Heater Rev4 Jan 03Documento12 pagineEdge Heater Rev4 Jan 03Claire HamantNessuna valutazione finora

- Title Mist Intensified Cooling in SpotDocumento8 pagineTitle Mist Intensified Cooling in SpotCahya WaskitaNessuna valutazione finora

- Final Lab ManualDocumento135 pagineFinal Lab ManualManicharanNessuna valutazione finora

- Me - 312, Hmt-Lec-Week 5Documento21 pagineMe - 312, Hmt-Lec-Week 5Ahsan JunaidNessuna valutazione finora

- March 7 Homework Solutions: Mechanical Engineering 375 Heat TransferDocumento5 pagineMarch 7 Homework Solutions: Mechanical Engineering 375 Heat TransferFadelPrawiraErwinNessuna valutazione finora

- HMT Lab ManualDocumento33 pagineHMT Lab ManualMahikant JhaNessuna valutazione finora

- BA Graville-Chapter 3Documento36 pagineBA Graville-Chapter 3Bhavana ValetiNessuna valutazione finora

- Difference Between Bi ND NuDocumento6 pagineDifference Between Bi ND NuIzuchucku JohnNessuna valutazione finora

- (ME-2505) Lab 1Documento9 pagine(ME-2505) Lab 1Ruman Hossain RonyNessuna valutazione finora

- HMT DAVV PracticalDocumento21 pagineHMT DAVV PracticalNarendraNessuna valutazione finora

- Thermal Conductvity Matal RodDocumento7 pagineThermal Conductvity Matal RodTheOPGarriXNessuna valutazione finora

- Thermal Analysis of Electrical Machines Limits and Heat Transfer PrinciplesDocumento2 pagineThermal Analysis of Electrical Machines Limits and Heat Transfer PrinciplesAnonymous sAmJfcVNessuna valutazione finora

- Casting Forming & Casting, Forming &: Welding WeldingDocumento25 pagineCasting Forming & Casting, Forming &: Welding WeldingWen LiNessuna valutazione finora

- HMT Chapter 1Documento118 pagineHMT Chapter 1Venugopal kulkarniNessuna valutazione finora

- Wakefield Heat SinkDocumento23 pagineWakefield Heat SinkNiko KraljNessuna valutazione finora

- Heat Transfer LabDocumento17 pagineHeat Transfer Labgauravojha1000Nessuna valutazione finora

- Numerical Simulation of The Temperaturbe Filed in fixed-TIG Welding PoolDocumento5 pagineNumerical Simulation of The Temperaturbe Filed in fixed-TIG Welding PoolRaul MamaniNessuna valutazione finora

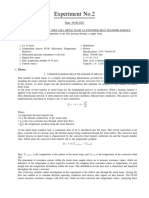

- Experiment No.2: Date: 30-08-2023Documento4 pagineExperiment No.2: Date: 30-08-2023navneetservNessuna valutazione finora

- Lecture Notes For CO2 (Part 3) : 1-D Steady State Heat ConductionDocumento28 pagineLecture Notes For CO2 (Part 3) : 1-D Steady State Heat ConductionhahahaNessuna valutazione finora

- Temperature Distributions in Solids and in Laminar FlowDocumento4 pagineTemperature Distributions in Solids and in Laminar FlowSambasiva Rao KaturiNessuna valutazione finora

- Thermal Analysis On Butt Welded Aluminium Alloy AA7075 Plate Using FEMDocumento5 pagineThermal Analysis On Butt Welded Aluminium Alloy AA7075 Plate Using FEMInnovative Research PublicationsNessuna valutazione finora

- 01 Thermal Expansion of MatterDocumento6 pagine01 Thermal Expansion of MatterElay DyNessuna valutazione finora

- Experiment - 5: AIM: Study and Calculate The Efficiency of Fin in Natural and Forced ConvectionDocumento17 pagineExperiment - 5: AIM: Study and Calculate The Efficiency of Fin in Natural and Forced ConvectionRushabh PatelNessuna valutazione finora

- HT ManualDocumento42 pagineHT ManualAbhimanyu BhagatNessuna valutazione finora

- Delhi Technological University: Heat and Mass Transfer (ME-302) Group: M4Documento190 pagineDelhi Technological University: Heat and Mass Transfer (ME-302) Group: M4Subhash SharmaNessuna valutazione finora

- Heat Has Critical Influences On Machining. To Some Extent, It Can Increase Tool Wear andDocumento8 pagineHeat Has Critical Influences On Machining. To Some Extent, It Can Increase Tool Wear andPassmore DubeNessuna valutazione finora

- PHY12 Report 1Documento7 paginePHY12 Report 1Paul JavenNessuna valutazione finora

- HTHP 1073 - V1Documento15 pagineHTHP 1073 - V1Triều Huỳnh NhậtNessuna valutazione finora

- MAK 302L Experiment 3 Extended Surface Heat Transfer 1. PurposeDocumento5 pagineMAK 302L Experiment 3 Extended Surface Heat Transfer 1. PurposeYEe FaNgNessuna valutazione finora

- CHE 402 - FR Heat Loss in Bare and Lagged PipesDocumento8 pagineCHE 402 - FR Heat Loss in Bare and Lagged PipesHirizza Junko YamamotoNessuna valutazione finora

- Experiment 1Documento30 pagineExperiment 1goku geshNessuna valutazione finora

- Experimental and Three Dimensional Finite Element Analysis of Thermal History of Oxy-Acetylene Line Heating ProcessDocumento6 pagineExperimental and Three Dimensional Finite Element Analysis of Thermal History of Oxy-Acetylene Line Heating Processalvaromviegas_191514Nessuna valutazione finora

- HT ReportDocumento10 pagineHT Reportsankalp agarwalNessuna valutazione finora

- R07 Set No. 2Documento8 pagineR07 Set No. 2bhaskar5377Nessuna valutazione finora

- Optimizing Dimension of Heat Sinks Plate db461907Documento5 pagineOptimizing Dimension of Heat Sinks Plate db461907Al Hussein CoulibalyNessuna valutazione finora

- Lee DiskDocumento4 pagineLee DiskAmit DipankarNessuna valutazione finora

- Trial Physics STPM Sem 3 2013 TerengganuDocumento7 pagineTrial Physics STPM Sem 3 2013 TerengganuZuraini Arshad100% (1)

- 1st PU Physics Model QP 4 PDFDocumento9 pagine1st PU Physics Model QP 4 PDFPrasad C M50% (4)

- Toyoshima, Miyahara - 1975 - Catalysis and Coordinative Active Sites On Sulfurated Unsaturation ofDocumento7 pagineToyoshima, Miyahara - 1975 - Catalysis and Coordinative Active Sites On Sulfurated Unsaturation ofDOUGLAS RAMON RODRIGUEZ ORDOÑEZNessuna valutazione finora

- History of Tio2Documento2 pagineHistory of Tio2Nutnicha Manee-inNessuna valutazione finora

- Grade 6 Science Fun Activity 1 AnswersDocumento8 pagineGrade 6 Science Fun Activity 1 AnswersbinduNessuna valutazione finora

- CHEE 3369 Fall 2018 HW#4 - SolutionsDocumento5 pagineCHEE 3369 Fall 2018 HW#4 - Solutionsjmoh100% (1)

- Test Unit ME HOD NO.: C Lorific Val e A TM D2 0 18 0 5 Kin. Vi Osity 122° P C T A M D445Documento1 paginaTest Unit ME HOD NO.: C Lorific Val e A TM D2 0 18 0 5 Kin. Vi Osity 122° P C T A M D445Yogesh ChaudhariNessuna valutazione finora

- Development of Biogas Compression System For Using in HouseholdDocumento6 pagineDevelopment of Biogas Compression System For Using in Householdanand sahuNessuna valutazione finora

- Ra410202 Non Conventional Energy Sources Set1Documento2 pagineRa410202 Non Conventional Energy Sources Set1Srinivasa Rao G100% (1)

- s6 Physics p1 BugandaDocumento7 pagines6 Physics p1 BugandaWafula EricNessuna valutazione finora

- Mastery Test in Science 8Documento2 pagineMastery Test in Science 8Myrille SabenacioNessuna valutazione finora

- 02 Activity Sheet 1 NSTP (Dela Peña)Documento2 pagine02 Activity Sheet 1 NSTP (Dela Peña)Princess Diane Dela PeñaNessuna valutazione finora

- Module 7 Volnerabilities of Different Elements Exposed To HazardsDocumento9 pagineModule 7 Volnerabilities of Different Elements Exposed To HazardsJinky AydallaNessuna valutazione finora

- Coefficitent of Friction LabDocumento2 pagineCoefficitent of Friction LabMelissa DanowskiNessuna valutazione finora

- Physics - 61 - Week - 5 - Exercises and Solved Problems PDFDocumento2 paginePhysics - 61 - Week - 5 - Exercises and Solved Problems PDFSebastian SmytheNessuna valutazione finora

- Atomic Numbers, Protons, Neutrons and Electrons: Name DateDocumento1 paginaAtomic Numbers, Protons, Neutrons and Electrons: Name Datenoob noobNessuna valutazione finora

- Small Hydropower Plants in Generation in The Rural Area of The West and Southwest of Paraná State-BrazilDocumento13 pagineSmall Hydropower Plants in Generation in The Rural Area of The West and Southwest of Paraná State-BrazilJoão VítorNessuna valutazione finora

- Handout - 2 - Physical States of MatterDocumento12 pagineHandout - 2 - Physical States of MatterHarun ÖzdemirNessuna valutazione finora

- CEP14 Lec1 The Water CycleDocumento10 pagineCEP14 Lec1 The Water CycleJulius Christian PerezNessuna valutazione finora

- F. M. 1Documento3 pagineF. M. 1Aashish PardeshiNessuna valutazione finora

- NCSC Activity Guide BookDocumento202 pagineNCSC Activity Guide BookAMIT AGARWAL100% (3)

- Jee Main-2023 - Important Replica QS - PhysicsDocumento106 pagineJee Main-2023 - Important Replica QS - PhysicsAryan GuptaNessuna valutazione finora

- Problem Set 3Documento1 paginaProblem Set 3engineerNessuna valutazione finora

- Hydrology Dissertation IdeasDocumento8 pagineHydrology Dissertation IdeasBuyWritingPaperElgin100% (1)

- Topic - 5 - and - 15 - Mixed - Questions ChemistryDocumento12 pagineTopic - 5 - and - 15 - Mixed - Questions ChemistryRanem Ahmed Nasser Al ShibaniNessuna valutazione finora

- GIS 1st Unit - PDF.WWW - Chennaiuniversity.net - NotesDocumento32 pagineGIS 1st Unit - PDF.WWW - Chennaiuniversity.net - NotesvanamgouthamNessuna valutazione finora

- CLASS-9TH (A&B) EarthquakeDocumento4 pagineCLASS-9TH (A&B) EarthquakeAimanNessuna valutazione finora