Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Maintenance Schedule For Substation

Caricato da

Sajid ShaikhDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Maintenance Schedule For Substation

Caricato da

Sajid ShaikhCopyright:

Formati disponibili

OPERATION AND COMPREHENSIVE MAINTENANCE FOR SUB-STATION ELIGIBILITY CONDITIONS

1. The firm shall have establishment and maintenance setup located at Mumbai or

suburban Mumbai. The firm shall have Solvency certificate from the Bankers for a minimum of Rs. 20 lakhs, latest Chartered Accountants Certificate, valid Electrical Contractors licence and round the clock fixed and Mobile telephone number.

2.

a) Registered Electrical Contractors of BSNL/CPWD/MES subject to their financial limits corresponding to the estimated cost of work for 12 months. OR b) Registered Electrical Contractors of highest class in State PWD. AND a) Firms who have carried out satisfactorily at least 1 work (Cost of the work shall not be less than 75% of 12 months estimated cost) of Maintenance in MTNL/BSNL comprising of either Sub station or Engine Alternator service as part of scope of work. Also firm's aggregate turn over for the last 3 years shall not be less than Rs. 50 lakhs reckoned from date of notice inviting tender.

1. The firm shall have following valid certificates/ registration:i. Sales Tax/ VAT registration certificate. ii. EPF registration. iii. ESIC registration. iv. Works Contract registration number and address of WC Tax Assessing Authority as a proof of their establishment in Mumbai/ Navi Mumbai region. v. Service Tax registration.

SUB-STATION MAINTENANCE DOCUMENT

1. Scope of Maintenance: Ensuring that HT Panel, Transformer, LT panels, capacitor panels & out door structure as well as connecting cables/ducts, constituting the substation are maintained in healthy & clean condition, Monitoring on continuous basis power factor & peak load and ensuring that these are maintained within limits to avoid penalty. To perform maintenance tasks as per schedule given below. To disconnect total electric supply and or individual loads in case of emergent situation to avoid/ limit damage. To ensure continuous power supply and in case of breakdowns take steps to ensure restoration at the earliest. 2. Tasks to be performed within first 15 days Identify a persons(s) with necessary competence to be responsible for substation maintenance The person(s) deputed for substation job should Know how to treat the persons suffering from electric shock/ burn etc. Be able to operate fire extinguisher. Make himself familiar with the distribution scheme the switches controlling various loads and also importance. Clearly understand what is to be done in case of an emergency. This should be done in consultation with Engineer In-charge. Carry out general inspection with a view to identify shortcoming if any in the sub stations installation. Check all the switches & meters for proper operation Check availability and working of fire extinguishers at earmarked locations. Check operation and calibration of all the safety devices like relays and fuses. Check the earthing system for the proper earth values & continuity of earthing system. Check insulation value of oil in all the equipments. Carry out megger test.

Check oil level in all the equipment to ensure proper levels. Check power factor meter, maximum demand meter for proper functioning Check the tripping of the HT Panel including batteries etc. for proper functioning. Check all the electrical connections for proper tightness. All results of above inspection to be recorded and brought to the notice of Engineer-inCharge specially highlighting shortcomings for necessary action. All rectification, replacements, calibration and testing costs at the time of taking over the maintenance at beginning shall be borne by the department. 3. Special conditions If anything adverse is noticed during the daily check the matter will be reported to the EE (E) / DE (Bldg) and wherever necessary corrective measures should be taken immediately. The firm shall make up any penalty on account of power factor/ maximum demand. On receipt of breakdown call, the firm has to restore power supply immediately, not later than 8 hours, if necessary making alternate arrangement. The regular maintenance and thorough checking shall be done by the agency within 24 hours. All materials required for repair, replacements including transformer oil should be the responsibility of the firm without any extra cost. In case of total burn out of transformer beyond repairs, department shall arrange for replacement. The decision about beyond repairs shall rests with Engineer in charge. However the installation, testing and commissioning including electrical inspection shall be responsibility of the firm. Tests are to be carried out before handing over the maintenance as per the yearly test schedule attached. The agency will be responsible for all rectification, replacements, calibration and testing costs and hand over the installation to the new agency in healthy condition. In case the same agency continues for operation and maintenance of the installation, the agency will carryout these activities as per the maintenance schedule.

MAINTENANCE SCHEDULE FOR CAST RESIN TRANSFORMER

Sr. No. 1 2 3 4 5 6

Inspection Frequency Hourly Hourly Hourly Hourly After every tap change/ half yearly Daily

Items to be inspected Ambient Temperature Winding Temperature Load (Amperes) Incoming voltage HT tap links WTI (Winding Temperature Indicator) WTR (Winding Temperature Relay) Enclosure & marshalling box

Inspection Notes Check ambient temperature Check WTI temperature Check load current Check against rated figures Check that links are fully tightened and locked Check RTD for healthiness Check alarm & trip thermisters for healthiness (a) Check for cowebs, dust, dirt deposits (b) Painting (a) Check for cowebs, dust, dirt deposits (b) Painting Check for tightness of nut bolts Check for tightness of core bolts/ tie rod nuts Check earth resistance Check ratio (Refer to manufacturer if necessary) Side covers, cable boxes, marshalling box (a) Check relays, its contacts, their operation (b) Check alarm/ trip circuit operation for alarm Motor bearing (a) Examine for dirt deposits (b) Examine for cracks/ damages

Half yearly

Half yearly

Core & coil assembly

9 10 11 12 13 14

Half yearly Yearly Yearly Yearly Yearly Yearly

HT/ LT connections Core & coil assembly Earth resistance Transformer Enclosure Relays, its alarm & trip contacts, their circuits

15 16

Yearly (or as found necessary) Yearly

Cooling fan (only for forced air cooled CRT) HT/LT bushings

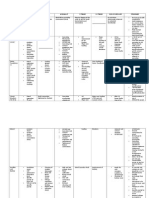

12.00 AM 3.00 AM 6.00 AM 9.00 AM 12.00 PM 3.00 PM 6.00 PM 9.00 PM Permissible range Ambient temp. 85% 0f full load current +/- 5% of 415 Volts 105C (Dry type)65 oC (Oil) 85% 0f full load current +/- 5% of 415 Volts Voltage Oil/ Winding (Dry type) Temperature Current Voltage Current Hours 105C (Dry type)65 oC (Oil) Oil/ Winding (Dry type)Temperature 0.9 PF KWh KVAh PF MD

RECORD OF MEASUREMENTS FOR SUBSTATION - 3 HOURLY (BY OPERATOR) DEPT.MV PANEL EB PANEL Incomer-1 TR-1 Incomer-2 TR-2

Date

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29

(Check for premises, doors and OCB etc.)

General cleanliness

X'MER

(Check colour of active agent)

Dehydrating breather

(Check for local heating, unusual smell / noise)

OCB tank

Oil

(Check for leaks.)

(Check for healthiness)

Auxiliary fuses

RECORD OF DAILY CHECKS (BY OPERATOR)

HT PANEL

(Check for healthiness)

Alarm and circuit indicating

Month :-

(Check for satisfactory operation)

Indicating and measuring instruments

Battery

(Check for voltage and sp. gravity)

30 31

RECORD OF WEEKLY CHECKS (BY OPERATOR)

Year :Item to be inspected :- Oil level of Transformer Inspection note :- Check against oil level mark Weeks Month

January February March April May June July August September October November December

Remark s

RECORD OF MONTHLY CHECKS (BY OPERATOR) Year :Months Sl. Items to be Fe Ma Ma Au No De Inspection Note Jan Apr Jun Jul Sep Oct No. Inspected b r y g v c LT PANEL 1 Connections Check for tightness and over heating, unusual smell or noise 2 Busbar/Cable Examine joints insulators, busbar contacts, cable joints etc for overall condition 3 Indicating and Check for measuring satisfactory instruments operation 4 Earthing Check for proper earthing LT CIRCUIT BREAKER 1 General Check for conditions premises, doors and locks etc. 2 Connections Check for tightness and over heating 3 Load Check for load conditions and match the CT ratings 4 Busbar/Cable Examine joints insulators, busbar contacts, cable joints etc for overall condition 5 Alarm and Check for indicating continuity and circuit proper operation 6 Indicating and Check for measuring satisfactory instruments operation 7 Earthing Check for proper earthing EARTH STATION 1 Earth pits Watering of pits 2 Connections Tighten them CONTACTORS 1 Connections Check for tightness of elect & mech. Joints

RECORD OF QUARTERLY CHECKS (BY AMC) Year :Sl. Items to be Inspected Inspection Note No. TRANSFORMER 1 Oil Check dielectric strength (>30 KV/mm) & pH value ( 5.5) 2 Bushing Examine for cracks and dirt deposits 3 Connections Examine for looseness 4 Explosion vent Examine the packing HT PANEL 1 Cleaning Remove all loose external dirt with dry cloth 2 Operating mechanisms Check for trouble free operation 3 4 5 6 7 Interlocking device Isolating contacts / Shutters Cable boxes Check for healthy operation Check for proper functioning Check for sealing arrangements for filling holes and compound for cracks Check for signs of damage Check for any deterioration Check for alignment and pressure Remove all loose external dirt with dry cloth Check for tightness Check for trouble free operation Check for healthy operation Check for proper functioning Check for etc. Check for Check for Check for Check for carbon formation, damage signs of damage any deterioration alignment and pressure settings & operation 1

Quarter 2 3 4

Insulators Aux. contacts/ switches/fuses 8 Contacts LT CIRCUIT BREAKER 1 Cleaning 2 3 4 5 6 Fastening and clamps Operating mechanisms Interlocking device Isolating contacts / Shutters Arc chutes

7 Insulators 8 Aux. contacts/ switches 9 Contacts 10 CTs & relays LT PANEL 1 Cleaning 2 3 4 5 6 7 Fastening and clamps Operating mechanisms Interlocking device SFU/FSU Isolating contacts / Shutters Aux. contacts/switches

Remove all loose external dirt with dry cloth Check for tightness Check for trouble free operation Check for healthy operation Check for operation & tightness Check for proper functioning Check for any deterioration

Sl. Items to be Inspected No.

Inspection Note

CAPACITOR PANEL

1 2 3 4 5 6 7 Connections Check for tightness, corrosion and breakage Busbar/Cable joints Examine insulators, busbar contacts, cable joints etc for overall condition Indicating and measuring Check for satisfactory operation instruments Capacitors Check for leakages & contacts External fuses Check for condition Insulation Measure insulation resistance between phases and phase to earth Automatic power factor Check for setting and operation relay Poles Fastening and clamps Insulators and fittings Conductors and earth wire Jumpers and other accessories Air break switch Check for damages, erosion and corrosion, leaning due to overloading etc. Check for tightness Check for cracks, flash over marks and tilting Check for proper supports, intactness, sag, joints etc. Check for proper supports , clearances , proper insulation and loose joints etc. Check for proper functioning, over heating, pitting on the contacts, earth connections, locking arrangement, complete fitting of male and female contacts, arcing horns etc. Check for deterioration of porcelain, intactness of line and earth connection, indication of fused or spark over etc. Check for tightness Check for over heating marks, damage to insulation through over heating, contactor hum/chattering

OUTDOOR STRUCTURE 1 2 3 4 5 6

Lightning arresters

8 Earthing system CONTACTORS 1 Contacts

RECORD OF YEARLY CHECKS (BY AMC) Sl. Items to be No. Inspected TRANSFORMER 1 Gasket joints 2 Cable boxes 3 4 5 6 HT 1 2 3 Earth resistance Insulation resistance Temperature indication Paint work PANEL Earth resistance CTs & PTs Oil level & quality Inspection Note Examine for tightness Check for sealing arrangements for filling holes and compound for cracks Check for value, earth connections Check for healthiness of insulation Check pockets of thermometer Check overall painting 1 2 3 4 5

Check for value, earth connections Check for satisfactory functioning Examine for dielectric strength & oil level in tank LT CIRCUIT BREAKER (MCCB) 1 Contacts Clean the contacts with a piece of cloth dipped in Carbon tetra Chloride and TrichloroEthyline (for corrosive atmosphere) 2 Contacts After major fault clearance, contact buttons should be cleaned with fine emery paper, after that with piece of cloth dipped in Carbon tetra Chloride and TrichloroEthyline LT PANEL 1 Rubber mats Check for condition 2 Insulators Check for signs of damage 3 Contacts Check for alignment and pressure 4 CTs & relays Check for settings & operation 5 Insulation Measure insulation resistance between phases and phase to earth 6 Earthing Check for earth resistance 7 Control wiring, fuses, Check for continuity & healthiness protection RELAYS/METERS/CT/PT 1 Relays Check for settings, functioning rotating mechanism etc. 2 Control wiring, fuses, Check for continuity & healthiness protection 3 Meters Check for functioning 4 CTs & PTs Check for ratio 5 Insulation Measure insulation resistance between phases and phase to earth EARTH STATION 1 Earth resistance Check for value

YEARLY TESTING OF INSTALLATION

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. Test for any sign(s) of overloading in respect of H.T. & L.T. equipments Check for existence of any unauthorized temporary installation. Check whether the transformer oil samples are being tested periodically and results recorded in a register. Check whether earth resistance is being measured periodically and results recorded in register. Check where lighting arrestors have been provided near the transformer for protection against lightning. Check the condition of service lines, cables, wires, circuit breakers, isolating switches, protective recording & integrating apparatus and such other fittings. Check if Danger Notice plates in the local language and of the type approved by the electrical inspector are affixed as per rules permanently in conspicuous position. Check safety measures on live lines and apparatus. Check whether all circuits and apparatus are so arranged that there is no danger of any part(s) becoming accidentally charged by any voltage beyond the limits of voltage for which it is intended. Check if first aid boxes or cupboards conspicuously marked and properly equipped are provided and maintained. Check where staff trained in first aid treatment. Check if instructions in HINDI, ENGLISH and MARATHI for restoration of persons suffering from electric shock have been affixed in conspicuous place. Check insulation resistance between conductors and earth in Meg. Ohms. Check if all conductor and apparatus i/c live parts thereof are inaccessible. Check the method adopted to guard L.V. circuits in transformer becoming accidentally charged above its/their normal voltage. Check if trenches inside substation containing cable are filled with non-inflammable material or completely covered with noninflammable slabs. In case of metal sheathed electrical supply lines check whether the metal sheath connected with earth properly. Check provisions made for immediate and automatic discharge of every static condenser on disconnection of supply. Check every guard wire been properly earthed at each point at which its electrical continuity is broken.

ANNEXURE I A. Details to be supplied before starting the work 1 2 3 4 5 6 Name of the Agency (with Office address) Name of Proprietor/partners Telephone No.(s)of the firm Name & address of the Supervisor 24 Hours contact No. Particulars of the Licence/ Registration

: : : : : :

B.

Detail of staff to be posted at site. Sr. No. Name and Address EPF no. of Operator

Annexure - II COMPLAINT REGISTER Dated Signature of Firm Representative

Sr. No.

Date & Time of complaint

Nature of complaint

Location

Time & Date of attending complaint

Cause of fault

Material used

Dated Signature of complainant

ANNEXURE III Programme for Periodical Maintenance for the month of __________ Name of contractor: __________________ Agreement No. : _____________________ Name of Division: _________________ Location: __________________ Sr. No. Name of Service Maintenance activity with requirements of materials Remark

(Contractor)

SDE / DE

ANNEXURE IV Actual Periodical Maintenance carried out in the month of __________ Name of contractor: __________________ Agreement No. : _____________________ Name of Sub Division: _________________ Location: __________________ Sr. No. Name of service Periodical maintenance actually carried out Results satisfactory/ unsatisfactory

Remarks

(Contractor)

SDE / DE

ANNEXURE V LOG BOOK OF SUBSTATION (INDOOR) DATE : __________ H. T. Voltage In KV R Y 08.0 0 11.0 0 14.0 0 17.0 0 20.0 0 23.0 0 02.0 0 05.0 0 HT Current In Amp. Incoming Transformer I Voltage R Y Y B B R Current R Y B Tem p in C

Transformer II

Voltage R Y Y B B R Current R Y B Tem p in C MD in KVA

Total Power Kwh ( a) Kvah (b) P.F. (a/b)

Remarks

TIME

Y B R Y B B R

i) Record no. & duration of Mains failure on each day. Details of maintenance like, heating of silica gel, dehydration of transformer oil, servicing of LT. ACBs, replacement of HRC fuses, indication lamps & contacts of contactors, etc. iii) Record of earth resistance.

ANNEXURE VI LOG BOOK OF SUBSTATION (OUTDOOR) DATE: __________ Transformer I TIME Voltage RY 08.0 0 11.0 0 14.0 0 17.0 0 20.0 0 23.0 0 02.0 0 05.0 0 YB BR R Current Y B Tem p in C RY Voltage YB BR R

Transformer II

Current Y B Tem p in C MD in KVA

Total Power Kwh ( a) Kvah (b) P.F. (a/b)

Remarks

i) Record no. & duration of Mains failure on each day. ii) Details of maintenance like, heating of silica gel, dehydration of transformer oil, servicing of LT ACBs. iii) Record of earth resistance.

Note: 1. Log book shall be checked daily by the Technician/JTO in- charge. 2. Log book shall be checked and reviewed by SDE in-charge at least once in a week. 3. Log book shall be checked and reviewed by DE in-charge at least once in a fortnight.

Potrebbero piacerti anche

- Standard Operating Procedure - Fire Extinguishers - V01 - 10092010Documento8 pagineStandard Operating Procedure - Fire Extinguishers - V01 - 10092010Karthik MandyaNessuna valutazione finora

- Electrical Safety Auditing Checkpoints: Compliance To Statutory RulesDocumento8 pagineElectrical Safety Auditing Checkpoints: Compliance To Statutory RulesSoumya Mukherjee100% (3)

- Knowledge is "Real Power": Introduction to Power QualityDa EverandKnowledge is "Real Power": Introduction to Power QualityNessuna valutazione finora

- Electrical Maintenance ManualDocumento2 pagineElectrical Maintenance Manualkurnia_te3769Nessuna valutazione finora

- Inspection of MCC - EEPDocumento3 pagineInspection of MCC - EEPwaseemNessuna valutazione finora

- Equipme NT Daily/Weely Monthly Annually 5 Years 10 Years Non-Scheduled StandardDocumento4 pagineEquipme NT Daily/Weely Monthly Annually 5 Years 10 Years Non-Scheduled StandardmuhammadfurQanmirzaNessuna valutazione finora

- Building Management System - WikipediaDocumento3 pagineBuilding Management System - WikipediaBRGRNessuna valutazione finora

- Building Maintenance PlanDocumento4 pagineBuilding Maintenance PlanhafizahNessuna valutazione finora

- Okken Solution GuideDocumento26 pagineOkken Solution GuideShailesh ChettyNessuna valutazione finora

- UPS MaintenanceDocumento3 pagineUPS MaintenancedescslamNessuna valutazione finora

- AdvertDocumento9 pagineAdvertjoseph katongoNessuna valutazione finora

- SOP - PowerDocumento32 pagineSOP - PowerpothanNessuna valutazione finora

- Video Intercom Solution and Cabling SpecificationsDocumento20 pagineVideo Intercom Solution and Cabling SpecificationsSaid GedeonNessuna valutazione finora

- Comprehensive Electrical System Maintenance ChecklistsDocumento5 pagineComprehensive Electrical System Maintenance ChecklistsAshwinSiddaramaiahNessuna valutazione finora

- Annual Maintenance Contract ProposalDocumento5 pagineAnnual Maintenance Contract ProposalJofren FuentesNessuna valutazione finora

- 8BK88PLUSDocumento8 pagine8BK88PLUSSwapnil PatilNessuna valutazione finora

- Electrical Safety Audit Services SiteSelfiesDocumento31 pagineElectrical Safety Audit Services SiteSelfiesAniruddhaNessuna valutazione finora

- ZLAC8015Documento9 pagineZLAC8015THANAWATNessuna valutazione finora

- Fire Detection and Alarm System QCDD Form (Record of Completion)Documento3 pagineFire Detection and Alarm System QCDD Form (Record of Completion)Ronie PaduaNessuna valutazione finora

- Maintenance of Low Voltage Circuit BreakersDocumento2 pagineMaintenance of Low Voltage Circuit BreakersJuvencio MolinaNessuna valutazione finora

- Power Cable Jointing: Novatex Limited SOP / E&I / 17Documento3 paginePower Cable Jointing: Novatex Limited SOP / E&I / 17OSAMANessuna valutazione finora

- Example Recommended Spare Parts - DRAFTDocumento5 pagineExample Recommended Spare Parts - DRAFTvoNessuna valutazione finora

- Hvac CVDocumento2 pagineHvac CVsarfaraz055Nessuna valutazione finora

- Electrical Safety PDFDocumento16 pagineElectrical Safety PDFARPITA KUMARINessuna valutazione finora

- Air Handling Unit PDFDocumento16 pagineAir Handling Unit PDFizani_idrisNessuna valutazione finora

- Facilities Maintenance Training ReportDocumento2 pagineFacilities Maintenance Training ReportdmugalloyNessuna valutazione finora

- Method Statement For Conduits WiringDocumento8 pagineMethod Statement For Conduits WiringÖmeralp SakNessuna valutazione finora

- Conditioning Monitoring of TransformerDocumento5 pagineConditioning Monitoring of TransformerAnonymous lEmZKBXiv100% (1)

- DOC-01-031 - AFP-3030 Installation Manual (AUS) Rev ADocumento52 pagineDOC-01-031 - AFP-3030 Installation Manual (AUS) Rev AMohamed RafihNessuna valutazione finora

- 11KV Network Manual - V.0Documento232 pagine11KV Network Manual - V.0Shaharyar Waliullah0% (1)

- Lightning Protection Malaysia 2011Documento41 pagineLightning Protection Malaysia 2011Mohd Lutfi MahaliNessuna valutazione finora

- Fire Alarm MaintenanceDocumento2 pagineFire Alarm Maintenancesamantha1966Nessuna valutazione finora

- Preventive Maintenance PresentationDocumento15 paginePreventive Maintenance Presentationabhinav2018100% (2)

- Elec QTDDocumento46 pagineElec QTDdibyendu65Nessuna valutazione finora

- Lightning Protection SystemDocumento19 pagineLightning Protection SystemKarthik MandyaNessuna valutazione finora

- Digital Meters - Newtek Electricals, Multifunction Energy Meters, VAF Meter, Smart MeterDocumento18 pagineDigital Meters - Newtek Electricals, Multifunction Energy Meters, VAF Meter, Smart MeterNewtek ElectricalsNessuna valutazione finora

- MDB Specs PDFDocumento9 pagineMDB Specs PDFAbdElrahman AhmedNessuna valutazione finora

- SOP-08 Thermocouple - DTC CalibrationDocumento9 pagineSOP-08 Thermocouple - DTC CalibrationPandu BirumakovelaNessuna valutazione finora

- Panel Board ShortCircuit RatingsDocumento2 paginePanel Board ShortCircuit RatingsuddinnadeemNessuna valutazione finora

- Improving Electrical Safety Management-TNB PDFDocumento24 pagineImproving Electrical Safety Management-TNB PDFSopi LabuNessuna valutazione finora

- D.G MaintenanceDocumento8 pagineD.G MaintenanceshaikamirulhasanNessuna valutazione finora

- Schneider RM6 - MV Medium Voltage Compact Switchboard (Ring Main UnitDocumento31 pagineSchneider RM6 - MV Medium Voltage Compact Switchboard (Ring Main UnitNOELGREGORIONessuna valutazione finora

- Fault Diagnostic in MDB Panels PDFDocumento2 pagineFault Diagnostic in MDB Panels PDFkkn1234Nessuna valutazione finora

- ATS Sequence of OperationDocumento1 paginaATS Sequence of OperationnooruddinkhanNessuna valutazione finora

- NT-Series UPS Installation and Commissioning Check ListDocumento20 pagineNT-Series UPS Installation and Commissioning Check ListWalter AchayaNessuna valutazione finora

- Transfix User GuideDocumento19 pagineTransfix User GuidesantoshkumarNessuna valutazione finora

- Installation Operation & Maintenance of 33kV & 11kV SwitchgearDocumento23 pagineInstallation Operation & Maintenance of 33kV & 11kV SwitchgearSaff MdNessuna valutazione finora

- Isometer Bender PDFDocumento40 pagineIsometer Bender PDFpttung0% (1)

- DG & EB Check ListDocumento43 pagineDG & EB Check ListRamesh MariyappaNessuna valutazione finora

- Check List For The Commissioning of DTS SystemDocumento2 pagineCheck List For The Commissioning of DTS SystemmohammadNessuna valutazione finora

- Scope of Electrical AuditDocumento2 pagineScope of Electrical AuditSumit Sharma100% (1)

- Electrical Preventative MaintenanceDocumento30 pagineElectrical Preventative MaintenanceMohsin AttaNessuna valutazione finora

- LV Dielectric TestingDocumento2 pagineLV Dielectric TestingwaseemsamsodienNessuna valutazione finora

- Why Is Thermography Testing of Electrical Panel Important?Documento13 pagineWhy Is Thermography Testing of Electrical Panel Important?Itz AleshaGachaverse100% (1)

- Notifier AFP 3030 NZ Programming Manual 1-59Documento59 pagineNotifier AFP 3030 NZ Programming Manual 1-59Anonymous Tiapta4Nessuna valutazione finora

- Electrical Installation Condition ReportDocumento9 pagineElectrical Installation Condition ReportSullam SyamsunNessuna valutazione finora

- Circuit Breaker Maintenance FormDocumento1 paginaCircuit Breaker Maintenance FormSamuel NdopuNessuna valutazione finora

- Maharashtra State Electricity Distribution Co. LTD.: (Opted For Go-Green)Documento2 pagineMaharashtra State Electricity Distribution Co. LTD.: (Opted For Go-Green)Sajid ShaikhNessuna valutazione finora

- A Comparison of Hip and Knee Torques Produced During A MaximalDocumento42 pagineA Comparison of Hip and Knee Torques Produced During A MaximalMohit DodejaNessuna valutazione finora

- Muscular System - Structure - Function - Movement PDFDocumento48 pagineMuscular System - Structure - Function - Movement PDFjohn ryan piolNessuna valutazione finora

- Airfryer Recipe Book1Documento38 pagineAirfryer Recipe Book1personnelniosNessuna valutazione finora

- AC RC ScheduleDocumento12 pagineAC RC ScheduleSajid ShaikhNessuna valutazione finora

- Spinal Cord DetailDocumento2 pagineSpinal Cord DetailSajid ShaikhNessuna valutazione finora

- Spinal Cord DetailDocumento2 pagineSpinal Cord DetailSajid ShaikhNessuna valutazione finora

- Works Manual 2012Documento460 pagineWorks Manual 2012Hannah Selvan100% (1)

- Test Schedule On Fire AlarmDocumento3 pagineTest Schedule On Fire AlarmSajid ShaikhNessuna valutazione finora

- Bootloader3 PDFDocumento18 pagineBootloader3 PDFsaravananNessuna valutazione finora

- Lab 3.1 - Configuring and Verifying Standard ACLsDocumento9 pagineLab 3.1 - Configuring and Verifying Standard ACLsRas Abel BekeleNessuna valutazione finora

- Optimizing AOD Refractory PerformanceDocumento10 pagineOptimizing AOD Refractory PerformanceJulio PurezaNessuna valutazione finora

- Sample Chapter - Oil and Gas Well Drilling Technology PDFDocumento19 pagineSample Chapter - Oil and Gas Well Drilling Technology PDFDavid John100% (1)

- Network Command - HPUXDocumento5 pagineNetwork Command - HPUXRashid NihalNessuna valutazione finora

- A Simulation-Based Process Model For Managing Complex Design ProcessDocumento13 pagineA Simulation-Based Process Model For Managing Complex Design ProcessMetehan AgacaNessuna valutazione finora

- DC Power Supply and Voltage RegulatorsDocumento73 pagineDC Power Supply and Voltage RegulatorsRalph Justine NevadoNessuna valutazione finora

- Nomad Pro Operator ManualDocumento36 pagineNomad Pro Operator Manualdavid_stephens_29Nessuna valutazione finora

- Acuvim II Profibus Modules Users Manual v1.10Documento36 pagineAcuvim II Profibus Modules Users Manual v1.10kamran719Nessuna valutazione finora

- Packages in JavaDocumento4 paginePackages in JavaKummeta KeerthiNessuna valutazione finora

- GTG - TFA Belt DrivenDocumento2 pagineGTG - TFA Belt Drivensuan170Nessuna valutazione finora

- Orthographic Views in Multiview Drawings: Autocad 2015 Tutorial: 2D Fundamentals 5-1Documento30 pagineOrthographic Views in Multiview Drawings: Autocad 2015 Tutorial: 2D Fundamentals 5-1Uma MageshwariNessuna valutazione finora

- CSS Lab ManualDocumento32 pagineCSS Lab ManualQaif AmzNessuna valutazione finora

- RTL8139D DataSheetDocumento60 pagineRTL8139D DataSheetRakesh NettemNessuna valutazione finora

- Syllabus EMSE6760 DDLDocumento4 pagineSyllabus EMSE6760 DDLlphiekickmydogNessuna valutazione finora

- Completing The Square PDFDocumento10 pagineCompleting The Square PDFgreg heffleyNessuna valutazione finora

- BSIT Nov Dec 2012 2nd CycleDocumento59 pagineBSIT Nov Dec 2012 2nd CyclePiyush PriyankNessuna valutazione finora

- Practice Question ElectricityDocumento3 paginePractice Question ElectricityIvan SetyawanNessuna valutazione finora

- Fractal Cities - A Geometry of Form and Function PDFDocumento432 pagineFractal Cities - A Geometry of Form and Function PDFDavid Diaz100% (1)

- CCNA2 Lab 7 3 8 enDocumento6 pagineCCNA2 Lab 7 3 8 enapi-3809703100% (1)

- Fitting Fundamentals: For SewersDocumento21 pagineFitting Fundamentals: For SewersLM_S_S60% (5)

- Ecoflam Burners 2014 enDocumento60 pagineEcoflam Burners 2014 enanonimppNessuna valutazione finora

- 307-01 Automatic Transmission 10 Speed - Description and Operation - DescriptionDocumento12 pagine307-01 Automatic Transmission 10 Speed - Description and Operation - DescriptionCARLOS LIMADANessuna valutazione finora

- Chapter 19. TemperatureDocumento41 pagineChapter 19. TemperatureNguyên Nguyễn SơnNessuna valutazione finora

- MOVIDRIVE-B Lab7Documento6 pagineMOVIDRIVE-B Lab7GrungeokêNessuna valutazione finora

- Parts Manual Z-45Documento240 pagineParts Manual Z-45John Forero PinzonNessuna valutazione finora

- Magnetism NotesDocumento14 pagineMagnetism Notesapi-277818647Nessuna valutazione finora

- Dover Artificial Lift - Hydraulic Lift Jet Pump BrochureDocumento8 pagineDover Artificial Lift - Hydraulic Lift Jet Pump BrochurePedro Antonio Mejia Suarez100% (1)

- Types of Solids 1Documento16 pagineTypes of Solids 1Fern BaldonazaNessuna valutazione finora

- Lab Assignment - 2: CodeDocumento8 pagineLab Assignment - 2: CodeKhushal IsraniNessuna valutazione finora