Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

IOSRJEN (WWW - Iosrjen.org) IOSR Journal of Engineering

Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

IOSRJEN (WWW - Iosrjen.org) IOSR Journal of Engineering

Copyright:

Formati disponibili

IOSR Journal of Engineering (IOSRJEN)

ISSN: 2250-3021 Volume 2, Issue 8 (August 2012), PP 159-165

www.iosrjen.org

www.iosrjen.org 159 | P a g e

Evaluation of Gold-Coated Stainless Steel Bipolar Plates for Fuel

Cell Applications

Ching Chiang Hwang

1

, Ing-Bang Huang

2*

1

Department of Biotechnology, Mingdao University, Taiwan

2

*Department of Materials Science and Engineering, National Formosa University, Huwei, Yulin, 63201,

Taiwan (corresponding author)

Abstract: - In this study, the computer-aided design and manufacturing (CAD / CAM) technology were applied

to develop and produce stainless steel bipolar plates for DMFC (direct methanol fuel cell). Effects of surface

modification on the cell performance were investigated. Surface modification of the stainless steel polar plate

was made by electroless gold plating method. A DMFC consisting of gold coated stainless steel as anode and

uncoated stainless steel as cathode was assembled and evaluated. The methanol crossover rate (Rc) of the

proton exchange membrane (PEM) was decreased by about 43%, the efficiency (Ef) of DMFC increased about

4.3% and amounts of methanol electro-oxidation at the cathode side (Mco ) were decreased by about 17%, as

compared to uncoated anode polar plates. These measurements were determined by the transient current and

mathematical analysis.

Keywords: - Direct methanol fuel cell; Bipolar plates; Crossover rate; Methanol

I. INTRODUCTION

Bipolar plates, which are a type of multifunctional component, are one of the most important

components in a PEMFC stack. The main functions of bipolar plates are to distribute and separate the cathodic

and anodic reactant gases and to collect and transmit electric current. Usually, bipolar plates are fabricated from

graphite, carbon composites and metallic materials, among which, metallic materials are most attractive owing

to good mechanical properties and chemical stability, electrical conductivity and thermal conductivity and good

machining properties. Metallic materials which can be recycled, such as titanium, aluminum, stainless steel,

have been tested as possible candidates for bipolar plates. Unfortunately, metals are prone to corrosion and the

resulting metal ions can readily migrate to, and poison, the membrane in a PEMFC environment. The dissolved

metal ions can lower the ionic conductivity of the membrane and the performance of the PEMFC. Furthermore,

any corrosion layer lowers the electrical conductivity of the bipolar plate, and increase potential loss because of

higher electrical resistance. Hence, in order to act as suitable materials for bipolar plates, metals should have

both very high corrosion resistance and high electrical conductivity [1, 2].

. In order to improve the corrosion resistance and electrical conductivity of the bare substrate, several

coating material and processes have been proposed [1, 2]. Gold (Au) has been studied as a coating material on

stainless steel substrate by some researchers. Gold has high excellent corrosion resistance and electrical

conductivity, and the use of very thin gold coating on bare substrate has proven very successful [3, 4].

Methanol crossover, which causes significant voltage loss and waste of fuel, is a serious problem in

DMFC. Thus, it has attracted attention worldwide. Several methods have been used to measure methanol

crossover in DMFC [5-10]. Pukrushpan et al. determined methanol crossover rates by continuously measuring

the concentration of CH3OH, CO and CO2 in the exhaust gas of the cathode [5]. Narayanan et al. measured the

methanol crossover rates by estimating the carbon dioxide content of the cathode exit stream. Crossover rates

were reported as an equivalent current density of methanol oxidation [6]. Amphlett directly measured methanol

flux rates across Nafion membranes by an electrochemical method using a flooded electrolyte cell with two

compartments separated by a membrane, with various concentrations of methanol [7]. A potentiometric method

reported by Prakash et al. [8] showed that the slope (dE/dt) of the E versus t (time) curve is proportional to the

crossover rate. The CH3OH crossover rate was calculated from the time required to reach the equilibrium

concentration of CH3OH on either side of the polymer electrolyte membrane. Han and Liu determined the

methanol crossover rates by measuring the carbon dioxide concentration at the cathode exit in real time [9]. Kin

et al. proposed a relatively easy method for estimating the methanol crossover rate of a proton exchange

membrane (PEM) and the efficiency of a direct methanol fuel cell (DMFC) by using current transient analysis

[10]. However, the mathematical expression should be modified in order to satisfy the practical application

condition.

In this study, computer-aided design and manufacturing (CAD / CAM) technology were applied to

develop and produce bipolar plates composed of type 304 stainless steel for DMFC application. Surface

modification of the 304 stainless steel was made by electroless Au-plating. Methanol crossover from the anode

Evaluation of Gold-Coated Stainless Steel Bipolar Plates for Fuel Cell Applications

www.iosrjen.org 160 | P a g e

to the cathode through the Nafion PEM detrimentally influenced the performance of direct methanol fuel cells.

The methanol crossover rate of PEM, the efficiency of DMFC and the amount of methanol electro-oxidation at

cathode side were estimated by measuring the transient voltage and current at the DMFC when methanol was

introduced into the anode.

II. MATHEMATICAL

Before carrying out mathematical analysis, the following terms must be defined. MT: total amount of

methanol charged (mole); Mao: amount of methanol electro-oxidized at anode side (mole); Mmo: amount of

bipolar plates corrosion oxidation at anode side (mole); Mco: amount of crossover methanol electro-oxidized at

cathode side (mole); Ef: efficiency of DMFC (%); RC: crossover rate (mol cm-2 s-1); t: time required for

electro-oxidation current to fall from I to zero (s); A: active area of electro-oxidation (cm2 ); I: current (A); n:

number of electrons exchanged; F: Faradays constant (96480A s mol-1).

A relatively easy method for estimating the methanol crossover rate of proton exchange membrane

(PEM) and the efficiency of direct methanol fuel cell (DMFC) has already been proposed [10]. However, the

mathematical expression must be modified in order to be using this method under in the practical application

conditions; the modified equations are expressed as follows:

0 ) 1 ( = A t R E M M M

c f T o a T

(1)

where,

% 100

=

co T

o a

f

M M

M

E

(2)

The net charge quantity during the operating of a direct methanol fuel cell when methanol is introduced

into the anode can be expressed by the following equation,

mo co

o

a

FM M M F Idt 2 ) ( 6 + =

}

(3)

at the right hand side of Eq. (3), the first term, , stands for the net oxidation charge quantity of methanol

on the anode side and the amount of methanol crossover on the cathode side. The second term, , indicates the

corrosion charge quantity of the metal bipolar plates on the anode side. In four experiments under identical

operating conditions, but with different charging volumes of methanol solution, Eq. (1) becomes the following

simultaneous equations:

=

=

=

=

0 ) 1 (

0 ) 1 (

0 ) 1 (

0 ) 1 (

4 4 4 4 4

3 3 3 3 3

2 2 2 2 2

1 1 1 1 1

A t R E M M M

A t R E M M M

A t R E M M M

A t R E M M M

c f T ao T

c f T o a T

c f T o a T

c f T o a T

(4)

After rearranging, we get:

= +

= +

= +

= +

}

}

}

}

F

dt I

t

M M A t R E M

F

dt I

t

M M A t R E M

F

dt I

t

M M A t R E M

F

dt I

t

M M A t R E M

CO mo C f T

CO mo C f T

CO mo C f T

CO mo C f T

6

0

3

1

6

0

3

1

6

0

3

1

6

0

3

1

4

4

4 4 4

3

3

3 3 3

2

2

2 2 2

1

1

1 1 1

(5)

Evaluation of Gold-Coated Stainless Steel Bipolar Plates for Fuel Cell Applications

www.iosrjen.org 161 | P a g e

Even though of there are four unknown parameters Mmo ,Mco, Ef and RC in Eq.(5) however, the value

of parameter Mmo can be set to zero since the corrosion current of the stainless steel plate is much lower when

the stainless steel bipolar plate used on the anode side for DMFC. In this study, Eq. (5) can be reduced as

follows:

=

=

=

}

}

}

F

dt I

t

M A t R E M

F

dt I

t

M A t R E M

F

dt I

t

M A t R E M

CO C f T

CO C f T

CO C f T

6

0

6

0

6

0

3

3

3 3 3

2

2

2 2 2

1

1

1 1 1

(6)

The above simultaneous equations can be transformed into matrix form as

A x = b (7)

Where

, ,

And

The simultaneous equations can be easily solved by the inverse matrix:

b A X

1

=

(8)

The methanol crossover rate of PEM (Rc), the efficiency of DMFC (Ef), and the amount of methanol

electro-oxidation on the cathode side can be easily computed from Eq. (8) using Microsoft Excel.

III. EXPERIMENTAL

3.1 Computer-aided design and manufacturing of the DMFC device

The direct methanol fuel cell device consists of two supporting plates (PMMA), stainless steel bipolar

plates and a membrane electrode assembly (MEA). The CAD / CAM software I-DEAS was employed to

conduct 3D solid modeling design, as shown in Fig. 1. Bipolar plates were designed with the mirror symmetry

which enables the positive and negative stacking. All the holes on the plate should be aligned with each other

after stacking, as shown in Fig. 2. Stainless steel bipolar plates were manufactured by a Japanese Mitsubishi

laser cutting machine (3500W ML3015LVPlus).

The DMFC device has two supporting plates. The first plate has a 50 mm 50 mm opening square slot

for air inlet which can be made entirely by laser cutting. The other plate, with a 50mm 50mm 7mm square

slot, acts as methanol fuel tank. A groove was made around the square slot for placing a rubber ring to prevent

leakage of methanol fuel. There are two holes at the top of square slot for injecting methanol fuel. These slots

Evaluation of Gold-Coated Stainless Steel Bipolar Plates for Fuel Cell Applications

www.iosrjen.org 162 | P a g e

also act as an air outlet. The CAD/CAM software SmartCAM was employed to process the tool path planning

and manufacturing simulation.

Figure.1. 3D solid modeling design of DMFC device: supporting plates, stainless steel bipolar plates and MEA.

Figure.2. Dimensions of bipolar plate

3.2 Electroless gold plating

In this study, type 304 stainless steel plates were chosen as the bipolar plates of a DMFC. Before

electroless plating, the stainless steel plates were polished on 200, 600, 800, 1000 and 1200 grit silicon carbide

papers and a final polish with 1.0m alumina powder. The polished plates were thoroughly cleaned with

distilled water in an ultrasonic bath for 15 min and dried with air before passing through the procedure of the

eletroless method. The operating conditions and steps of this method are illustrated in Fig. 3.

Fig.3. Flow chart of preparing the gold - plating by an electroless method.

Evaluation of Gold-Coated Stainless Steel Bipolar Plates for Fuel Cell Applications

www.iosrjen.org 163 | P a g e

3.3 Cell performance testing

The experimental system uses a DMFC that includes an anode chamber for the electrochemical

oxidation of the methanol, a cathode chamber for the electrochemical reduction of oxygen and a membrane

electrode assembly (MEA) arranged between the anode and the cathode. On the anode side, the bare and coated

SS304 stainless steels served as anode polar plates, respectively. On the cathode side, the bare SS304 stainless

steel served as cathode polar plate only. A load unit was connected to the DMFC. An aqueous solution of the

methanol was fed to the anode chamber while the load unit was operated at 10 in a loading state, enabling the

methanol to crossover to the cathode, where it was oxidized. The transient voltage and current were measured

using a digital-meter and the methanol crossover rate, the efficiency of direct methanol fuel cell (DMFC) and

the amount of methanol electro-oxidation on the cathode side were determined from the transient current

analysis. In this work, the membrane electrode assembly (MEA) was made according to the method proposed by

Kin et al. [10].

The fuel chamber (0.7 cm thick with an area of 25 cm2) was filled with 1.1 cm3, 3.3 cm3 and 4.4 cm3

10 vol.% aqueous methanol solution, for the first, second and third measurements, respectively. All tests were

performed at an ambient temperature of 25 and at atmospheric pressure. The voltage and current of the DMFC

were monitored for approximately 36 h to ensure a stable approach to zero current.

IV. RESULTS AND DISCUSSION

Figs. 4 - 7 show the changes of transient voltage and current of the DMFC with time after each

measurement was performed at a different charging volume (1.1 cm3, 3.3 cm3 and 4.4 cm3) with a particular

fuel solution of 10 Vol.% methanol in water when Au-coated and uncoated SS304 stainless steels served as

anode polar plates, respectively. We compared the cell voltage and current response of the DMFC with the Au-

coated and uncoated stainless steels serving as anode polar plates, respectively. When the Au-coated stainless

steel served as the anode polar plate, we found higher cell voltage and current values than in the case of the

uncoated stainless steel. These values can be attributed to the decreased crossover rate (Rc), increased efficiency

(Ef) and decreased amounts of methanol electro-oxidation on the cathode side (Mco ), which are derived below.

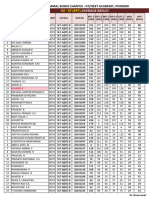

The data in Table 1 were used to calculate the crossover rate (R

c

), the efficiency (E

f

) and the amount of

methanol electro-oxidation of the cathode side (M

co

) at various fuel charging volumes in the three tests. Through

the transient current results and mathematical analysis of Eq. (8) computed using Microsoft Excel, the

crossover rates (R

c

), efficiency (E

f

) and amounts of methanol electro-oxidation on the cathode side (M

co

) are

determined to be 5.9mol cm

-2

hr

-1

and 10.4mol cm

-2

hr

-1

, 22.1% and 17.8%, 27

and 32.5

mmol

as shown in Table

2

for the coated and uncoated anode polar plates, respectively. It is obvious that the crossover rate (R

c

) of the

coated anode polar plate decreased by about 43%, the efficiency (E

f

) increased by about 4.3% and the amount of

methanol electro-oxidation on the cathode side (M

co

) decreased by about 17% in comparison to the results of the

uncoated anode polar plate. These results reveal the effects of surface modification on methanol crossover,

efficiency and the amount of methanol electro-oxidation on the cathode side of a DMFC.

Figure. 4. Voltage transients monitored during electro-oxidation using 10 vol. % methanol solution for DMFC

with Au-coated anode polar plate : (A) 1.1 cm3, (B) 3.3 cm3 , and (C) 4.4 cm3

Evaluation of Gold-Coated Stainless Steel Bipolar Plates for Fuel Cell Applications

www.iosrjen.org 164 | P a g e

Figure. 5. Current transients monitored during electro-oxidation using 10 vol. % methanol solution for DMFC

with Au-coated anode polar plate : (A) 1.1 cm3, (B) 3.3 cm3, and (C) 4.4 cm3

Figure. 6. Voltage transients monitored during electro-oxidation using 10 vol. % methanol solution for DMFC

with uncoated anode polar plate: (A) 1.1 cm3, (B) 3.3 cm3, and (C) 4.4 cm3

Figure. 7. Current transients monitored during electro-oxidation using 10 vol. % methanol solution for DMFC

with uncoated anode polar plate: (A) 1.1 cm3, (B) 3.3 cm3, and (C) 4.4 cm3

Evaluation of Gold-Coated Stainless Steel Bipolar Plates for Fuel Cell Applications

www.iosrjen.org 165 | P a g e

V. CONCLUSION

In this study, a stainless steel bipolar plate was designed and fabricated using computer-aided design and

manufacturing (CAD / CAM) technology. Surface modification of the stainless steel bipolar plate was made by

the electroless Au-plating method. The methanol crossover rate of the proton exchange membrane (PEM)

decreased by about 43%, the efficiency of DMFC increased by about 4.3% and the amount of methanol electro-

oxidation on the cathode side was decreased by about 17%, in comparison to the results of the uncoated anode

polar plates. These findings were determined by transient current and mathematical analysis.

REFERENCES

[1] J. Kim, S.M. Lee, S. Srinivasan, et al., Modeling of proton exchange membrane fuel cell performance with an empirical equation,,

Journal of Electrochemistry Society, Vol. 142, No.8, 1995, pp.26702674.

[2] J.H. Lee, T.R. Lalk, Modeling fuel cell stack systems, Journal Power Sources, Vol. 73, 1998, pp. 229241.

[3] W. Yoon, X. Huang, P. Fazzino, K. L. Reifsnider, M. A. Akkaoui,Evaluation of coated metallic bipolar plates for polymer electrolyte

membrane fuel cells Journal of Power Sources ,Vol. 179, 2008, No.1 ,pp. 265-273.

[4] A. Kumar, M. Ricketts, S. Hirano,Ex situ evaluation of nanometer range gold coating on stainless steel substrate for automotive

polymer electrolyte membrane fuel cell bipolar plate Journal of Power Sources , Vol.195, 2010, No.5, pp.1401-1407.

[5] Jay T. Pukrushpan, G.Anna, Modeling and control for PEM fuel cell stack system, in: Proceeding of the American Control

Conference, Anchorage, AK, 2002, pp. 31173122.

[6] S. R. Narayanan, A. Kindler, B. Jeffries-Nakamura, W. Chun, H. Frank, M. Smart, T. I. Valdez, S. Surampudi, G. Halpert, J. Kosek ,

C. Cropley, Proceedings of Annual Battery Conference on Applications and Advances ,Vol. 11, 1996, 113.

[7] J.C. Amphlett, R.F. Mann, B.A. Peppley, A practical PEM fuel cell model for simulating vehicle power sources, battery conference

on applications and advances, in: Proceedings of the tenth annual1995, pp. 221226.

[8] N. Munichandraiah, K. McGrath, G. Prakash, R. Aniszfeld, G. Olah, A potentiometric method of monitoring methanol crossover

through polymer electrolyte membranes of direct methanol fuel cells Journal of Power Sources, Vol.117, No1-2, 2003, 98-101.

[9] Jiahua Han, Hongtan Liu, Real time measurements of methanol crossover in a DMFC Journal of Power Sources,Vol, 164,No.1,

2007, pp. 166-173.

[10] T. H. Kin, W. Y. Shieh, C. C. Yang, George Yu,Estimating the methanol crossover rate of PEM and the efficiency of DMFC via a

current transient analysis Pages Journal of Power Sources, Vol. 161,No.2, 2006, pp.1183-1186.

Potrebbero piacerti anche

- MMSE Adaptive Receiver vs. Rake Receiver Performance Evaluation For UWB Signals Over Multipath Fading ChannelDocumento13 pagineMMSE Adaptive Receiver vs. Rake Receiver Performance Evaluation For UWB Signals Over Multipath Fading ChannelIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- The Experimental Study On The Compatibility Relationship of Polymer and Oil LayerDocumento5 pagineThe Experimental Study On The Compatibility Relationship of Polymer and Oil LayerIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Application of The Multi-Curve Reconstruction Technology in Seismic InversionDocumento4 pagineApplication of The Multi-Curve Reconstruction Technology in Seismic InversionIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Random Fixed Point Theoremsin Metric Space: Balaji R Wadkar, Ramakant Bhardwaj, Basantkumar SinghDocumento9 pagineRandom Fixed Point Theoremsin Metric Space: Balaji R Wadkar, Ramakant Bhardwaj, Basantkumar SinghIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Study On Logging Interpretation Model and Its Application For Gaotaizi Reservoir of L OilfieldDocumento6 pagineStudy On Logging Interpretation Model and Its Application For Gaotaizi Reservoir of L OilfieldIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Introduction To Accounting Professional Judgment ManipulationDocumento3 pagineIntroduction To Accounting Professional Judgment ManipulationIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Effectiveness in Addressing The Sustainability and Environmental Issue Involving Use of Coal Ash As Partial Replacement of Cement in ConcreteDocumento6 pagineEffectiveness in Addressing The Sustainability and Environmental Issue Involving Use of Coal Ash As Partial Replacement of Cement in ConcreteIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- The Identification of Lithologic Traps in Nanpu Sag D3 Member of Gaonan RegionDocumento5 pagineThe Identification of Lithologic Traps in Nanpu Sag D3 Member of Gaonan RegionIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- "Sign Language Translator": Mr. Sangam Mhatre, Mrs. Siuli DasDocumento4 pagine"Sign Language Translator": Mr. Sangam Mhatre, Mrs. Siuli DasIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Construction of Self-Regulated EFL Micro-Course Learning: Zhongwen LiuDocumento4 pagineConstruction of Self-Regulated EFL Micro-Course Learning: Zhongwen LiuIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Strength Properties of Commercially Produced Clay Bricks in Six Different Locations/ States in NigeriaDocumento10 pagineStrength Properties of Commercially Produced Clay Bricks in Six Different Locations/ States in NigeriaIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Modeling and Design of Hybrid Power Plants: Ahmed KH A. E. AlkhezimDocumento5 pagineModeling and Design of Hybrid Power Plants: Ahmed KH A. E. AlkhezimIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Constructions Quality Versus Bad Components in Jordanian CementDocumento3 pagineConstructions Quality Versus Bad Components in Jordanian CementIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Validating The Theories of Urban Crime in The City of RaipurDocumento10 pagineValidating The Theories of Urban Crime in The City of RaipurIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- The Research of Source System On Chang 6 Sand Formation in Ansai OilfieldDocumento5 pagineThe Research of Source System On Chang 6 Sand Formation in Ansai OilfieldIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Detecting Spammers in Youtube: A Study To Find Spam Content in A Video PlatformDocumento5 pagineDetecting Spammers in Youtube: A Study To Find Spam Content in A Video PlatformIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Genetic Analysis of Low Resistivity Reservoir: Gang Wang, Kai Shao, Yuxi CuiDocumento3 pagineGenetic Analysis of Low Resistivity Reservoir: Gang Wang, Kai Shao, Yuxi CuiIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Assessment of The Life Quality of Urban Areas Residents (The Case Study of The City of Fahraj)Documento6 pagineAssessment of The Life Quality of Urban Areas Residents (The Case Study of The City of Fahraj)IOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Bose-Einstein Condensation Controlled by (HOP+OLP) Trapping PotentialsDocumento5 pagineBose-Einstein Condensation Controlled by (HOP+OLP) Trapping PotentialsIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Symbolism As A Modernist Featurein A Passage To India: Ahmad Jasim Mohammad, Suhairsaad Al-DeenDocumento4 pagineSymbolism As A Modernist Featurein A Passage To India: Ahmad Jasim Mohammad, Suhairsaad Al-DeenIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Oil and Water Layer Identification by Dual-Frequency Resistivity LoggingDocumento4 pagineOil and Water Layer Identification by Dual-Frequency Resistivity LoggingIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Yingtai Area in Songliao Basin As The Main Layer Tight Oil "Dessert" Reservoir PredictionDocumento4 pagineYingtai Area in Songliao Basin As The Main Layer Tight Oil "Dessert" Reservoir PredictionIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Application of Cloud Transformation Technology in Predicting Reservoir PropertyDocumento4 pagineApplication of Cloud Transformation Technology in Predicting Reservoir PropertyIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Characteristic of Cracks in Tight Sandstone Reservoir: Ming Yan Yunfeng Zhang Jie Gao Ji GaoDocumento4 pagineCharacteristic of Cracks in Tight Sandstone Reservoir: Ming Yan Yunfeng Zhang Jie Gao Ji GaoIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Classification of Fault Condensed Belt and Faults Development Characteristics in Xingbei Region, Daqing PlacanticlineDocumento5 pagineClassification of Fault Condensed Belt and Faults Development Characteristics in Xingbei Region, Daqing PlacanticlineIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Analysis of Distribution and Effection of Oil-Water: Yue FeiDocumento6 pagineAnalysis of Distribution and Effection of Oil-Water: Yue FeiIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Introduction To Voltaic CellsDocumento5 pagineIntroduction To Voltaic CellsFlash MobNessuna valutazione finora

- CMT 560 Potentiostat GalvanostatDocumento15 pagineCMT 560 Potentiostat Galvanostatnurinadlina.jpkmawarNessuna valutazione finora

- CHE Lab Electrochemical Cells 12thDocumento6 pagineCHE Lab Electrochemical Cells 12thNicolocoNessuna valutazione finora

- Lab Report: Electrochemistry and Electrode PotentialDocumento12 pagineLab Report: Electrochemistry and Electrode PotentialAnna Tongco100% (2)

- Electrochemical Polymerization of Aniline in Presence of Tio NanoparticlesDocumento6 pagineElectrochemical Polymerization of Aniline in Presence of Tio NanoparticlesIndra JemainNessuna valutazione finora

- 02 ElectrochemistryDocumento14 pagine02 ElectrochemistryTangent ChauhanNessuna valutazione finora

- Laporan Korosi Kelompok 14 (Asis 7x)Documento10 pagineLaporan Korosi Kelompok 14 (Asis 7x)Fadilah MuhammadNessuna valutazione finora

- Xii-Iit & NeetDocumento17 pagineXii-Iit & Neet420oivasNessuna valutazione finora

- UN Test Manual Lithium Battery RequirementsDocumento10 pagineUN Test Manual Lithium Battery Requirementsvenkata_gaddamNessuna valutazione finora

- 2022 CJC H2 CHEM Prelim P1 QP W Ans FINALDocumento32 pagine2022 CJC H2 CHEM Prelim P1 QP W Ans FINALYanqiao LiNessuna valutazione finora

- Galvanic Cell Lab Report 2Documento6 pagineGalvanic Cell Lab Report 2nityaNessuna valutazione finora

- Lab Report Stage 3 Team 2Documento10 pagineLab Report Stage 3 Team 2Danna Chapa CantúNessuna valutazione finora

- The Use of Electrical Resistivity As NDT Method For PDFDocumento94 pagineThe Use of Electrical Resistivity As NDT Method For PDFeid elsayedNessuna valutazione finora

- E4500 Complete ManualDocumento170 pagineE4500 Complete Manualnang ndutNessuna valutazione finora

- Topic 9 Redox Booklet C ANSWERS 2014 (Amended Sept 2015)Documento39 pagineTopic 9 Redox Booklet C ANSWERS 2014 (Amended Sept 2015)mickey mouseNessuna valutazione finora

- Jwfp-Ugsp-Prs-Pro-001 Inspection Test Plan Rev 0 (Approved)Documento7 pagineJwfp-Ugsp-Prs-Pro-001 Inspection Test Plan Rev 0 (Approved)Ika D'YheaNessuna valutazione finora

- Hydrometallurgy 2009 PDFDocumento497 pagineHydrometallurgy 2009 PDFPatricio Leonardo83% (6)

- 2016, Chem. Unit 1&2 Practice QuestionDocumento12 pagine2016, Chem. Unit 1&2 Practice Questionabdilema16Nessuna valutazione finora

- A Review of Electrochemical Macro-To Micro-Hole Drilling ProcessesDocumento16 pagineA Review of Electrochemical Macro-To Micro-Hole Drilling ProcessesMaitry DaveNessuna valutazione finora

- IX Phy Ch10 Gravitation ChapterNotesDocumento8 pagineIX Phy Ch10 Gravitation ChapterNotesGKJK2530Nessuna valutazione finora

- Volume 9 BioelectrochemistryDocumento605 pagineVolume 9 BioelectrochemistrySandraMeirellesNessuna valutazione finora

- Redox ReactionDocumento11 pagineRedox ReactionAmeya GuptaNessuna valutazione finora

- Chemistry Notes Puspanjali PDFDocumento85 pagineChemistry Notes Puspanjali PDFDURGA PRASADNessuna valutazione finora

- Che 101Documento5 pagineChe 101Laba ListicNessuna valutazione finora

- Application of Electro Chemical Machining For MateDocumento7 pagineApplication of Electro Chemical Machining For MateJeny ThoriumNessuna valutazione finora

- Runge, Jude M. - Enhancing Anodic Aluminum Oxide For Bonding ApplicationsDocumento13 pagineRunge, Jude M. - Enhancing Anodic Aluminum Oxide For Bonding ApplicationsLuis Gustavo PachecoNessuna valutazione finora

- Sensing Technology: Current Status and Future Trends IIDocumento265 pagineSensing Technology: Current Status and Future Trends IIaraaraNessuna valutazione finora

- Computational Screening of Cathode Coatings For Solid-State BatteriesDocumento35 pagineComputational Screening of Cathode Coatings For Solid-State Batteriestolentino.jason1222Nessuna valutazione finora

- CBSE Project Physics Dry Battery ChargerDocumento12 pagineCBSE Project Physics Dry Battery ChargersddNessuna valutazione finora

- Chapter 18 ElectrochemistryDocumento21 pagineChapter 18 ElectrochemistryRizza Mae RaferNessuna valutazione finora