Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Quality Beyond Regulatory Requirements

Caricato da

Pradeep Mishra0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

80 visualizzazioni5 pagineMedicalMetricsinc. (MMI) had an existing quality management system (qms) but it was missing a framework to help drive organization-wide improvement. It implemented ISO 9001:2008 quality management systems - requirements. MMI is a provider of independent imaging core lab services for clinical trials.

Descrizione originale:

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoMedicalMetricsinc. (MMI) had an existing quality management system (qms) but it was missing a framework to help drive organization-wide improvement. It implemented ISO 9001:2008 quality management systems - requirements. MMI is a provider of independent imaging core lab services for clinical trials.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

80 visualizzazioni5 pagineQuality Beyond Regulatory Requirements

Caricato da

Pradeep MishraMedicalMetricsinc. (MMI) had an existing quality management system (qms) but it was missing a framework to help drive organization-wide improvement. It implemented ISO 9001:2008 quality management systems - requirements. MMI is a provider of independent imaging core lab services for clinical trials.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 5

Making the Case for Quality

Imaging Core Lab Takes Quality Beyond

Regulatory Requirements With ISO 9001

MedicalMetricsInc.(MMI),

hadanexistingquality

managementsystem

structuredtomeetFDA

regulations,butitwas

missingaframeworkto

helpdriveorganization-

wideimprovement.

MMIworkedwithan

externalconsultanttocreate

anintegratedmanagement

systemafusionof

regulatoryrequirements

withtheISO9001

frameworkandreceived

certificationtothestandard

inlessthansevenmonths.

MMIcontinuestomake

itsqualitymanagement

systemstrongerafter

passingtheaudit.

ThoughMMIscertification

isrecent,itisalready

seeingimprovementstothe

timelinessofdeliverablesto

clinicaltrialsponsors.MMI

alsoreportsanincreasein

qualityawarenessfromthe

ISO9001implementation

andhasreceivedpositive

feedbackfromsponsors.

At a Glance

As a 30-person imaging core lab, Medical Metrics Inc. (MMI) works hard to get the job done. But some-

times, getting the job done leaves room for little else. Although it had been operating under an existing

quality management system (QMS) structured to meet Food and Drug Administration (FDA) regulations,

increasing efficiency was considered outside the scope of regulatory agency requirements

1

. MMI found it

lacked an organization-wide framework in place to analyze and improve the business. Thats why MMI

decided to implement ISO 9001:2008 Quality management systems Requirementsto not only get the

job done, but to get the job done better.

About Medical Metrics Inc.

MMI is a provider of independent imaging core lab services for

clinical trials of medical devices, drugs, and biologics based in

Houston, TX. Since 2000, the company has partnered with

clinical trial sponsors on more than 300 investigations and

research studies across a wide range of therapeutic areas. Its

services include imaging protocol development, medical image

management, expert image review, and scientific interpretation.

MMIs areas of expertise include orthopedics, spine, neurology,

cardiology, and vascular medicine. MMI supports domestic and

multinational clinical trials ranging from early-phase clinical

testing to post-approval surveillance. Participation in regulated

studies has resulted in numerous product approvals, including

several first to market products.

Why ISO 9001?

In addition to regulatory requirements, MMI must meet the

quality system standards of large multinational organizations

that have stringent vendor evaluation programs.

Before taking on new studies, trial sponsors (MMIs customers)

require MMI to complete supplier questionnaires. MMI found

almost every questionnaire included a question as to whether

MMI was ISO 9001 certified. While MMIs interest in ISO

9001 certification was not imposed by a sponsor, compliance to

the standard would give the lab an edge in the industry.

by Megan Schmidt

June 2012

ASQ www.asq.org Page 1 of 5

MRIrelaxationmapofarticularcartilage.

MRIvisualizationofdiscnucleus.

Skeleton Management System

MMI had an existing quality system infrastructure in place based

on 21 CFR Part 812, 21 CFR Part 820, and 21 CFR Part 11 regu-

lations because of MMIs clinical trial participation and because it

utilized proprietary technology for analyzing radiographic images.

The existing system underwent several FDA visits and numerous

sponsor audits that contributed to continual improvement, but this

improvement was primarily limited to software validation and

data management. What was missing was a company-wide frame-

work to identify real and potential deficiencies to improve upon.

Knowing that it lacked the internal expertise to implement ISO

9001 and not wanting to delay services to clients, MMI selected

external consultant Gretchen McAuliffe, principal consultant of

Labtopia, to lead the project. In McAuliffes initial discussions

with MMI, they contemplated two separate quality systemsone

based on FDA regulations and one based on ISO 9001. She pro-

posed a structure where ISO 9001 encompassed the entire

organization, forming an umbrella quality system that included

all FDA regulatory requirements.

Rapid Certification

MMI planned to achieve ISO certification in less than seven

months, an aggressive timeline guided by a clear project

schedule (Figure 1).

Senior management supported ISO 9001 certification from the

beginning and elevated the project to an organizational priority.

Tom Martin, president and CEO, felt ISO 9001 certification

would communicate the companys customer focus and a com-

mitment to continual improvement. Without a comprehensive

QMS, we cannot be sure that we are meeting our customers

needs. We also cannot be sure that we are working on the right

things without understanding the overall organization and how

it is performing in our customers eyes. The quality system

helps us focus on what is important, Martin said.

ISO 9001:2008 is an international management standard based

on eight quality principles:

Customer focus

Leadership

Involvement of people

Process approach

System approach to management

Continual improvement

Factual approach to decision making

Mutually beneficial supplier relationships

Certification to ISO 9001 means that an independent authority

has assessed and approved an organizations management sys-

tem against the standard.

ASQ www.asq.org Page 2 of 5

Milestone Deadline Tasks

BusinessProcesses May31,2011 Defineandmapbusinessprocesses.

Training May31,2011 ConductISO9001:2008overviewtrainingwithstaff.

Metrics June15,2011 Definebusiness/departmentmetricsforkeybusinessprocesses.

Metrics June30,2011 Haveinplacemechanismtotrackinformationforkeybusinessmetrics.

Documentation July31,2011 Revise/draftSOPs.

August31,2011 Revise/draftworkinstructions.

August31,2011 Draftqualitymanual(s).

SOPTraining August31,2011 Trainallpersonnelonjob-relatedprocedures/processes.

InternalAudit September10,2011 Completeinternalaudit.

QualitySystemsOverviewTraining September15,2011 Trainpersonnelonanoverviewofthequalitymanagementsystem.

RegistrarAudit September30,2011 Stage1registraraudit.

CorrectiveActions October31,2011 Closeallcorrectiveactionsfromaudit.

ManagementReview(MR)* October31,2011 Conductfirstquarterlymanagementreviewwithinputsofpreviousquarterquality

objectives/metrics.

* Quarterly MRs were conducted prior to starting the ISO 9001 project; however, they did

not include all the inputs required by the standard. They also did not review any metrics.

RegistrarAudit November30,2011 Stage2registraraudit.

CertificateinHand! January2012

Figure 1: MMIs project schedule for achieving ISO certification

ASQ www.asq.org Page 3 of 5

MMI attributes its rapid certification to weekly QMS meetings

for the core implementation teamwhich consisted of senior

management, department managers, and the consultantto

discuss the status of tasks and to identify areas where addi-

tional resources were required to meet goals. MMI created

time to focus on the quality system, discussed issues and

delays, and allocated resources when necessary so bumps

wouldnt become roadblocks.

Since ISO 9001 was a new way to do business, MMI also

involved more staff to actively participate in implementing the

quality management system than it would have historically.

This helped send the message across the organization that qual-

ity is no longer solely the responsibility of the quality

management representative.

McAuliffe explained that preparing MMI for ISO 9001 was a

change management issue. The organization readily embraced

the QMS, but lacked the discipline or understanding on how

and when to use the system (i.e., documenting a complaint,

entering a nonconformance, etc). Throughout the implementa-

tion, McAuliffe trained staff on how a QMS functions and what

its requirements are, and made sure they were kept informed of

developments to procedures and processes.

Implementation Milestones

McAuliffe said since a quality system infrastructure was in

place, implementing ISO 9001 and integrating it with the FDA

requirements was essentially taking what was there and mak-

ing it better and more automated. MMIs integrated

management system is shown in Figure 2.

21 CFR Part 820 QSR

Management commitment

and customer focus

Quality planning

Quality management system

Management review*

Quality policy and objectives

Control of documents* and records*

Management responsibility

processes

D&D planning

Inputs/Outputs

Design review

Verication and validation

Change control

Design and development

related processes

Project requirements

Contract review

Customer related

processes

Purchasing

Product project life cycle

Consulting project life cycle

Monitoring and measuring

equipment

Data management

Product realization processes

Customer satisfaction (inc. complaints*)

Internal audits*

Control of nonconforming material

Improvement (CA/PA)*

Statistical techniques

Measurement, analysis, and

improvement processes

Human resources

Training*

Infrastructure

Work environment

Resource management processes

*Indicates QSR requirement

relevant to 510(k) software

Software

Requirements

Requirements Customer

Deliverables

Feedback

Figure 2: MMI quality management system overview

ASQ www.asq.org Page 4 of 5

Highlights from MMIs ISO 9001 implementation include:

Gap analysis

One of MMIs first steps toward ISO 9001 compliance was to

conduct a gap analysis to reveal areas for improvement in the

existing system. In many cases, processes and requirements had

already been defined, but documentation was either outdated or

the processes did not always reflect current operations. Because

of this, much of the existing documentation had to be rewritten.

Processes and documentation

A document control structure was established early in the jour-

ney using an alpha-numeric numbering system. McAuliffe and

the management team created common document templates

that were used to collaborate with process owners in defining

and documenting processes. The companys business develop-

ment and technical services groups experienced the most

process development.

Quality policy and objectives

MMI had an existing quality policy that was broadened to include

ISO 9001 requirements, such as continual improvement. This

spring boarded improvements to MMIs quality objectives.

Quality objectives were largely driven by customer satisfaction,

and MMI felt this focus was the best way to continue. However,

MMI needed to establish parameters around where

and how objectives would be tracked, the fre-

quency of measurement, goals, and when metrics

would be reviewed. For most of the objectives,

MMI added new fields to the existing customer

relationship management (CRM) system so perfor-

mance was more visible.

Defining customer requirements

Customer requirements were already clearly

defined under the existing system. MMI operates

under a schedule of work for each project. The

schedules are akin to project plans and typically

entail 15 to 20 pages of documents outlining the

scope of work, which is defined by the sponsors

clinical protocol, which receives FDA approval.

Using and improving the QMS

With design and development of the QMS com-

pleted, the next step was to continually improve it

based on internal and external feedback. Senior

management began holding weekly quality meet-

ings to review complaints and nonconformances.

An internal audit also provided a more formal and comprehen-

sive assessment of opportunities to improve.

To seek external feedback, MMI shared its QMS with sponsors.

The quality manual proved to be an especially useful tool to

show sponsors how MMI does businessits conformance to

ISO 9001 and regulatory requirements.

MMI also implemented a customer satisfaction survey. Initially,

a beta survey was sent to 20 contacts that MMI identified as

friends of MMI. MMI used feedback from the pilot to adjust the

survey accordingly before sending it to all existing customers.

Results

MMI reached its goal of attaining ISO 9001:2008 certification

in less than seven monthsthe final, stage 2 audit from ABS

Quality Evaluations occurred in November 2011 and MMIs

ISO 9001 certificate was in hand by early January 2012.

Because its certification is recent and the QMS is still in its

infancy, MMI said the bottom-line impact has yet to be fully

evaluated. However, MMI saw improvements to two of its key

metrics during third and fourth quarters of 2011more than

90percent of its deliverables to sponsors were on time and

more than 90 percent of its business proposal submissions were

on time. McAuliffe anticipates that MMI will further refine its

objectives and see improvements as the company continues to

Validity of this certificate is based on the periodic audits of the management systemdefined by the above scope and is contingent upon prompt, written

notification to ABS Quality Evaluations, Inc. of significant changes to the management systemor components thereof.

ABS Quality Evaluations, Inc. 16855 Northchase Drive, Houston, TX 77060, U.S.A.

Validity of this certificate may be confirmed at www.abs-qe.com/cert_validation.

Copyright 2003 ABS Quality Evaluations, Inc.. All rights reserved.

ABS QuaIity EvaIuations

Certificate Of Conformance

has been assessed by ABS Quality Evaluations, nc. and found to be in conformance with the requirements set forth by:

This is to certify that the Quality Management System of:

MedicaI Metrics, Inc.

2121 Sage Road

Suite 300

Houston, TX 77056

U.S.A.

ISO 9001:2008

The Quality Management System is applicable to:

Certificate No: 46605

Effective Date: 06 January 2012

Expiration Date: 05 January 2015

Issue Date: 06 January 2012

Alex Weisselberg, President

DESIGN AND DELIVERY OF IMAGE MANAGEMENT, RADIOLOGIC REVIEW, AND CONSULTING SERVICES TO THE CLINICAL TRIAL INDUSTRY

ABSQualityEvaluationsInc.auditedMedicalMetricsqualitymanagementsystemand

foundthatitisinconformancetotherequirementsinISO9001:2008.MedicalMetrics

receivedacertificateofconformancefromtheregistrar.Thecertificatedemonstratesthat

athirdpartyhasverifiedtheorganizationscompliancetothestandard.

ASQ www.asq.org Page 5 of 5

set the bar higher.Its about learning to

crawl before we can walk, McAuliffe said.

Management review meetings are an inte-

gral part of monitoring, evaluating, and

improving a QMS. McAuliffe said the

results of the companys first management

review meetings were a bit shocking to

senior management. Having the results

for performance on key criteria was an

eye-opening experience. Often, I find com-

panies cannot see the forest through the

trees, and having the actual hard data,

which is a clear indicator of performance,

is critical to quality improvement, she

said. Once senior management saw where

the actual issues were, they were able to

implement corrective actions and saw

remarkable improvement over the next quarter.

Information from key, identified objectives and metrics are

reported to the board of directors during quarterly meetings.

Our first report to the board was in January 2012 and it has

been about educating the board members about the metrics, how

and why we chose them, and how and why we are improving

these processes, Martin explained. Going forward, we expect

that the board may have further input on what types of quality

metrics the organization will require.

Personnel are kept informed of monthly and quarterly objectives

through a quality bulletin. It includes results of recent audits,

upcoming audits, performance metrics, and minor procedural

notifications.

Continuing Commitment to Quality

In 2012, MMI will further define and refine its processes and

develop metrics to make them more granularespecially those

that involve multiple, interacting departments. There are still

some key business processes that the lab plans to further docu-

ment and develop into standard operating procedures. The

company plans to involve customers as it further develops its

QMS. MMI is currently working with a key customer to further

develop a process for delivering data. This program will eventu-

ally be evaluated by a second tier of customers before becoming

a standard practice at MMI.

Another goal of MMI is to use its Web-based CRM to manage

multiple aspects of the business, including the QMS. The pri-

mary reason for this move is that the CRM has the capability to

integrate workflow, email notifications to personnel, and it will

allow for a substantial improvement in reporting. Likewise, the

CRM will help MMI meet the 21 CFR Part 11 requirement and

will be able to be validated, which is a regulatory requirement

for the customer complaint and corrective

and preventive action (CAPA) system.

Plans are under way to integrate some

processes, such as quality and production,

into its CRM. The CRM serves as the

daily project dashboard. Fully linking the

QMS with the CRM will allow personnel

to review quality action items, CAPAs,

and complaints as a matter of their daily

business. This will allow issues to be visi-

ble to everyone in the organization and

will reinforce that the QMS is not a sepa-

rate entity.

While MMI has come a long way in a

short amount of time, ISO 9001 certifica-

tion is just the beginning to a new way of

doing business.

Registration was just the start, now we have to manage,

improve, and develop the system, Martin said.

For More Information

To learn more about MMI and the services it provides,

contact Michelle Council, director of business development

at 713-850-7500 x211 or mcouncil@medicalmetrics.com or

visit www.medicalmetrics.com.

For more information about MMIs ISO 9001 implementation,

contact Gretchen McAuliffe of Labtopia at 281-619-2600 or

gmcauliffe@labtopiainc.com.

Read more articles about quality applications in the healthcare

sector at asq.org/healthcare-use/library/overview.html.

Learn about ISO 9001 at asq.org/learn-about-quality/iso-

9000/overview/overview.html.

Reference

1. http://www.fda.gov/downloads/MedicalDevices/

DeviceRegulationandGuidance/PostmarketRequirements/

QualitySystemsRegulations/UCM134625.pdf

About the Author

Megan Schmidt is an ASQ staff writer.

Tell Your Story!

The ASQ Knowledge Center features individuals and

organizations with quality success stories to tell.

Contact knowledgecenter@asq.org for more information.

Three-dimensionalreconstructionofspinal

anatomy.

Potrebbero piacerti anche

- Module-1-ISO 13485-DocumentDocumento7 pagineModule-1-ISO 13485-Documentsri manthNessuna valutazione finora

- Quality Management System Software A Complete Guide - 2019 EditionDa EverandQuality Management System Software A Complete Guide - 2019 EditionNessuna valutazione finora

- Presented By: Varish Tripathi Mnnit Allahabad REG. NO. - 2018PR07 Faculty - Dr. S.B Mishra SirDocumento22 paginePresented By: Varish Tripathi Mnnit Allahabad REG. NO. - 2018PR07 Faculty - Dr. S.B Mishra Sirvarish3Nessuna valutazione finora

- Process Approach A Complete Guide - 2019 EditionDa EverandProcess Approach A Complete Guide - 2019 EditionNessuna valutazione finora

- MDSAP AU P0008.006 - Audit Time - Determination - 0424 Posted FINALDocumento15 pagineMDSAP AU P0008.006 - Audit Time - Determination - 0424 Posted FINALHARESH NIRMALNessuna valutazione finora

- Introduction To CGMP Compliance CourseDocumento111 pagineIntroduction To CGMP Compliance CourseHend maarofNessuna valutazione finora

- The APIC Audit ProgrammeDocumento19 pagineThe APIC Audit ProgrammeshdphNessuna valutazione finora

- Quality Management in Health Care: Concepts, Principles and StandardsDocumento8 pagineQuality Management in Health Care: Concepts, Principles and StandardsMartin BringasNessuna valutazione finora

- Quality Systems For Pharmacovigilance SME Workshop "Focus On Pharmacovigilance" 19 April 2012, EMA LondonDocumento20 pagineQuality Systems For Pharmacovigilance SME Workshop "Focus On Pharmacovigilance" 19 April 2012, EMA LondonHala MohamedNessuna valutazione finora

- Final Document: Global Harmonization Task ForceDocumento26 pagineFinal Document: Global Harmonization Task ForceChaNessuna valutazione finora

- A Case Study of A Quality System Implementation in A Small Manufacturing FirmDocumento15 pagineA Case Study of A Quality System Implementation in A Small Manufacturing Firmaudithan100% (1)

- ISO 13485-2016 Raga PresentationDocumento17 pagineISO 13485-2016 Raga PresentationSuresh AnandNessuna valutazione finora

- Sample Job Description QMR PDFDocumento2 pagineSample Job Description QMR PDFHilario AlinabonNessuna valutazione finora

- Applying The ISO 9001 Process Approach and Service Blueprint To Hospital Management SystemsDocumento16 pagineApplying The ISO 9001 Process Approach and Service Blueprint To Hospital Management SystemsFelipe Andrés Montaner OlivaresNessuna valutazione finora

- 15 - M. PH Drugs Regulatory AffairsDocumento10 pagine15 - M. PH Drugs Regulatory AffairsMehak LubanaNessuna valutazione finora

- Iso and Quality Ob 3 RAWDocumento25 pagineIso and Quality Ob 3 RAWsagarsam001Nessuna valutazione finora

- Clause 8 - ExplanationDocumento33 pagineClause 8 - Explanations_agali2413Nessuna valutazione finora

- Guide To Agile Design and Development For Medical Devices-AMDD-Greenlight-GuruDocumento40 pagineGuide To Agile Design and Development For Medical Devices-AMDD-Greenlight-Gururemliw101Nessuna valutazione finora

- Iso13485 QM01 Scope PDFDocumento4 pagineIso13485 QM01 Scope PDFQuality and Safety Consultants Co.Nessuna valutazione finora

- GLP Protocols and Study Conduct-It Just Takes A Little PlanningDocumento11 pagineGLP Protocols and Study Conduct-It Just Takes A Little PlanningSofia BlazevicNessuna valutazione finora

- Krishnamurti-This Matter of Culture ChapterDocumento4 pagineKrishnamurti-This Matter of Culture Chapterysbrar2008Nessuna valutazione finora

- White Paper On UNIDO's GMP Roadmap ConceptDocumento24 pagineWhite Paper On UNIDO's GMP Roadmap Conceptiabureid7460Nessuna valutazione finora

- Embracing Agile PracticesDocumento4 pagineEmbracing Agile PracticesnikitoNessuna valutazione finora

- GU - Routine Testing of Lab Balances - ENDocumento8 pagineGU - Routine Testing of Lab Balances - ENsyifaurrohmah100% (1)

- QMR Job DescriptionaDocumento3 pagineQMR Job Descriptionabondjamesbondus100% (1)

- Business Process Management BPMDocumento19 pagineBusiness Process Management BPMwafaa ech-chaitamiNessuna valutazione finora

- M.pharm. Quality Assurance SyllabusDocumento19 pagineM.pharm. Quality Assurance SyllabusDang Anh DuyNessuna valutazione finora

- Process Approach of ISODocumento19 pagineProcess Approach of ISOFouzan Soniwala100% (1)

- MDSAP PresentationDocumento31 pagineMDSAP PresentationAditya C KNessuna valutazione finora

- Excipact StandardsDocumento96 pagineExcipact Standardselighi100% (1)

- Medical Device Quality Systems Manual: A Small Entity Compliance GuideDocumento468 pagineMedical Device Quality Systems Manual: A Small Entity Compliance GuideScott BeachNessuna valutazione finora

- Good Documentation and Quality Management PrinciplesDocumento11 pagineGood Documentation and Quality Management PrinciplesNana AdomakoNessuna valutazione finora

- QM Project ReportDocumento6 pagineQM Project ReportRupesh Kumar ChaturvediNessuna valutazione finora

- Ich Q7Documento69 pagineIch Q7Mehdi AhmadiNessuna valutazione finora

- ISO 9001 2015 Mock AuditDocumento15 pagineISO 9001 2015 Mock AuditMadan R HonnalagereNessuna valutazione finora

- Scope Training Exchange Information Between PV Assessors PV Inspectors Best Practice Guidance enDocumento39 pagineScope Training Exchange Information Between PV Assessors PV Inspectors Best Practice Guidance ensthug25100% (1)

- FDA 483 and Warning LetterDocumento38 pagineFDA 483 and Warning LetterOmar FaruqNessuna valutazione finora

- ECPD - DT03 - ISO 13485 - 2016 LA - Day 3 Daily TestDocumento5 pagineECPD - DT03 - ISO 13485 - 2016 LA - Day 3 Daily TestSandeep kulkarniNessuna valutazione finora

- Isr 13485 Delta ChecklistDocumento11 pagineIsr 13485 Delta ChecklistMs. ThuNessuna valutazione finora

- Module 01Documento100 pagineModule 01Essam ZatoutNessuna valutazione finora

- Canadian Safety and Effectiveness Requirements (Cser)Documento9 pagineCanadian Safety and Effectiveness Requirements (Cser)aymohamad2020Nessuna valutazione finora

- PDF - Js ViewerDocumento15 paginePDF - Js ViewerDavid Maycotte-CervantesNessuna valutazione finora

- MC Ds Mastercontrol AuditDocumento3 pagineMC Ds Mastercontrol AuditManish PatelNessuna valutazione finora

- Quality Control ElementsDocumento53 pagineQuality Control ElementsMariaCarlaMañagoNessuna valutazione finora

- Checklist of Mandatory Documentation Required by ISO 13485:2016Documento17 pagineChecklist of Mandatory Documentation Required by ISO 13485:2016Gonzalo MazaNessuna valutazione finora

- Supplier Auditpak 2000Documento52 pagineSupplier Auditpak 2000Adrian AustinNessuna valutazione finora

- What Is ISODocumento26 pagineWhat Is ISOISO Consultant NomanNessuna valutazione finora

- AAMI Quality Systems White Paper: Comparison of 21 CFR Part 820 To ISO 13485:2016Documento28 pagineAAMI Quality Systems White Paper: Comparison of 21 CFR Part 820 To ISO 13485:2016Hong XuyenNessuna valutazione finora

- Dydacomp's Multichannel Order Manager 7i Setup GuideDocumento312 pagineDydacomp's Multichannel Order Manager 7i Setup GuideDydacompNessuna valutazione finora

- As ISO 10993.5-2002 Biological Evaluation of Medical Devices Tests For in Vitro CytotoxicityDocumento8 pagineAs ISO 10993.5-2002 Biological Evaluation of Medical Devices Tests For in Vitro CytotoxicitySAI Global - APACNessuna valutazione finora

- RecordsDocumento23 pagineRecordsPamela Acosta GerraNessuna valutazione finora

- Astm E2097 - 1 (En)Documento5 pagineAstm E2097 - 1 (En)Rahul SamalaNessuna valutazione finora

- Guide For Quality System Manual Internal Audit: ApprovedDocumento9 pagineGuide For Quality System Manual Internal Audit: ApprovedMan Peatman ManpeatmanNessuna valutazione finora

- Comparison Matrix ISO 13485 To 21CFR820 R4Documento64 pagineComparison Matrix ISO 13485 To 21CFR820 R4Tomasz Wojtera100% (1)

- ISO 13485 Lead Auditor Two Page BrochureDocumento2 pagineISO 13485 Lead Auditor Two Page BrochurePECBCERTIFICATIONNessuna valutazione finora

- Astm GuideDocumento2 pagineAstm GuideVijay BhosaleNessuna valutazione finora

- f5763552 Microsoft Word - Uncertainty Analysis Guideline 2012dDocumento21 paginef5763552 Microsoft Word - Uncertainty Analysis Guideline 2012dkuma4321Nessuna valutazione finora

- 3 Product StewardshipDocumento24 pagine3 Product StewardshiphamidNessuna valutazione finora

- Warning Letter - Deficiencies in Validation and OOS - ECA AcademyDocumento2 pagineWarning Letter - Deficiencies in Validation and OOS - ECA AcademyDeepakNessuna valutazione finora

- Dissertation Adoption of Enterprise Resource Planning Erp in VietnamDocumento30 pagineDissertation Adoption of Enterprise Resource Planning Erp in VietnamAr Puneet AroraNessuna valutazione finora

- Lidos Inst GBDocumento46 pagineLidos Inst GBpublinet fssNessuna valutazione finora

- Hitz Work and PayDocumento2 pagineHitz Work and Paynajergodfred12Nessuna valutazione finora

- InstallationDocumento2 pagineInstallationAlona AcotNessuna valutazione finora

- Graphic Design Assignment 1Documento4 pagineGraphic Design Assignment 1Amita MaddhesiyaNessuna valutazione finora

- BSCS Rating DocumentDocumento19 pagineBSCS Rating Documentnagesh100% (1)

- 2a - LTE and RAN Products Update For Mobifone PDFDocumento29 pagine2a - LTE and RAN Products Update For Mobifone PDFSamuel WebbNessuna valutazione finora

- Intro To CCNA SecurityDocumento52 pagineIntro To CCNA SecurityRatnesh KumarNessuna valutazione finora

- Key InterlockDocumento2 pagineKey InterlockJohar ShamNessuna valutazione finora

- SXE10 ECU PinoutDocumento13 pagineSXE10 ECU PinoutLeiden O'Sullivan100% (2)

- Radius: Remote Authentication Dial in User Service (RADIUS) Is A NetworkingDocumento6 pagineRadius: Remote Authentication Dial in User Service (RADIUS) Is A NetworkingVandana SharmaNessuna valutazione finora

- Coordinating Parallel Hierarchical Storage ManagemDocumento16 pagineCoordinating Parallel Hierarchical Storage ManagemAdane AbateNessuna valutazione finora

- CPA System REST API Specification 3.5.7Documento121 pagineCPA System REST API Specification 3.5.7demuziovarioxf.syw.240.0Nessuna valutazione finora

- Failure Analysis Report DT2368 Stopper Frame LooseDocumento10 pagineFailure Analysis Report DT2368 Stopper Frame LooseEng PLM ACPNessuna valutazione finora

- Mos Word 2016 ObjectiveDocumento12 pagineMos Word 2016 ObjectiveĐình ToànNessuna valutazione finora

- CD M&W 2008 Ed - Sect 2 - CD Valves and PrefiltersDocumento12 pagineCD M&W 2008 Ed - Sect 2 - CD Valves and PrefiltersThamaraiselvan RamadossNessuna valutazione finora

- Breakout Box Owners Manual 3DDocumento7 pagineBreakout Box Owners Manual 3Dcacampbell3Nessuna valutazione finora

- Applicability Guide PDFDocumento2 pagineApplicability Guide PDFtriplbingaziNessuna valutazione finora

- Handbook For Sap PP in S/4HANADocumento477 pagineHandbook For Sap PP in S/4HANArahmani83% (6)

- Nav1 Eplan2Documento2 pagineNav1 Eplan2Jemar lucidoNessuna valutazione finora

- Use Case ModelingDocumento31 pagineUse Case ModelingpacharneajayNessuna valutazione finora

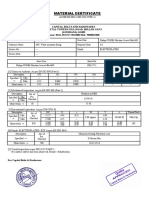

- CBH-22-167 Din 7985 Pan Combi MS M6 X 16 BZP 4.6Documento1 paginaCBH-22-167 Din 7985 Pan Combi MS M6 X 16 BZP 4.6qualityNessuna valutazione finora

- Installation of TransformerDocumento24 pagineInstallation of TransformerMariel A. ReyesNessuna valutazione finora

- Prima Efficiency Across BoundariesDocumento9 paginePrima Efficiency Across Boundariescosty_transNessuna valutazione finora

- Ergonomics Research Papers PDFDocumento2 pagineErgonomics Research Papers PDFChris0% (1)

- ShipParticular STM-004Documento8 pagineShipParticular STM-004RF NoiseeNessuna valutazione finora

- An Elementary Textbook of Physics Sound - R. W. StewartDocumento161 pagineAn Elementary Textbook of Physics Sound - R. W. StewartJonak SandilyaNessuna valutazione finora

- Report K97DRN180L4 V 131458937418208242Documento1 paginaReport K97DRN180L4 V 131458937418208242Yogesh GuptaNessuna valutazione finora

- Campus RecruitmentDocumento7 pagineCampus RecruitmentAnzil100% (2)

- Catalog C-1 AccumulatorsDocumento12 pagineCatalog C-1 AccumulatorsTrg SiltarNessuna valutazione finora

- The Coaching Habit: Say Less, Ask More & Change the Way You Lead ForeverDa EverandThe Coaching Habit: Say Less, Ask More & Change the Way You Lead ForeverValutazione: 4.5 su 5 stelle4.5/5 (186)

- The First Minute: How to start conversations that get resultsDa EverandThe First Minute: How to start conversations that get resultsValutazione: 4.5 su 5 stelle4.5/5 (57)

- The 7 Habits of Highly Effective PeopleDa EverandThe 7 Habits of Highly Effective PeopleValutazione: 4 su 5 stelle4/5 (2565)

- Scaling Up: How a Few Companies Make It...and Why the Rest Don't, Rockefeller Habits 2.0Da EverandScaling Up: How a Few Companies Make It...and Why the Rest Don't, Rockefeller Habits 2.0Valutazione: 5 su 5 stelle5/5 (1)

- How to Lead: Wisdom from the World's Greatest CEOs, Founders, and Game ChangersDa EverandHow to Lead: Wisdom from the World's Greatest CEOs, Founders, and Game ChangersValutazione: 4.5 su 5 stelle4.5/5 (95)

- Summary of Noah Kagan's Million Dollar WeekendDa EverandSummary of Noah Kagan's Million Dollar WeekendValutazione: 5 su 5 stelle5/5 (1)

- How to Talk to Anyone at Work: 72 Little Tricks for Big Success Communicating on the JobDa EverandHow to Talk to Anyone at Work: 72 Little Tricks for Big Success Communicating on the JobValutazione: 4.5 su 5 stelle4.5/5 (36)

- Transformed: Moving to the Product Operating ModelDa EverandTransformed: Moving to the Product Operating ModelValutazione: 4 su 5 stelle4/5 (1)

- Only the Paranoid Survive: How to Exploit the Crisis Points That Challenge Every CompanyDa EverandOnly the Paranoid Survive: How to Exploit the Crisis Points That Challenge Every CompanyValutazione: 3.5 su 5 stelle3.5/5 (122)

- Spark: How to Lead Yourself and Others to Greater SuccessDa EverandSpark: How to Lead Yourself and Others to Greater SuccessValutazione: 4.5 su 5 stelle4.5/5 (132)

- Unlocking Potential: 7 Coaching Skills That Transform Individuals, Teams, & OrganizationsDa EverandUnlocking Potential: 7 Coaching Skills That Transform Individuals, Teams, & OrganizationsValutazione: 4.5 su 5 stelle4.5/5 (28)

- Transformed: Moving to the Product Operating ModelDa EverandTransformed: Moving to the Product Operating ModelValutazione: 4 su 5 stelle4/5 (1)

- The Power of People Skills: How to Eliminate 90% of Your HR Problems and Dramatically Increase Team and Company Morale and PerformanceDa EverandThe Power of People Skills: How to Eliminate 90% of Your HR Problems and Dramatically Increase Team and Company Morale and PerformanceValutazione: 5 su 5 stelle5/5 (22)

- Billion Dollar Lessons: What You Can Learn from the Most Inexcusable Business Failures of the Last Twenty-five YearsDa EverandBillion Dollar Lessons: What You Can Learn from the Most Inexcusable Business Failures of the Last Twenty-five YearsValutazione: 4.5 su 5 stelle4.5/5 (52)

- Superminds: The Surprising Power of People and Computers Thinking TogetherDa EverandSuperminds: The Surprising Power of People and Computers Thinking TogetherValutazione: 3.5 su 5 stelle3.5/5 (7)

- 25 Ways to Win with People: How to Make Others Feel Like a Million BucksDa Everand25 Ways to Win with People: How to Make Others Feel Like a Million BucksValutazione: 5 su 5 stelle5/5 (36)

- Radical Candor by Kim Scott - Book Summary: Be A Kickass Boss Without Losing Your HumanityDa EverandRadical Candor by Kim Scott - Book Summary: Be A Kickass Boss Without Losing Your HumanityValutazione: 4.5 su 5 stelle4.5/5 (40)

- The 7 Habits of Highly Effective People: 30th Anniversary EditionDa EverandThe 7 Habits of Highly Effective People: 30th Anniversary EditionValutazione: 5 su 5 stelle5/5 (337)

- Coach the Person, Not the Problem: A Guide to Using Reflective InquiryDa EverandCoach the Person, Not the Problem: A Guide to Using Reflective InquiryValutazione: 5 su 5 stelle5/5 (64)

- 7 Principles of Transformational Leadership: Create a Mindset of Passion, Innovation, and GrowthDa Everand7 Principles of Transformational Leadership: Create a Mindset of Passion, Innovation, and GrowthValutazione: 5 su 5 stelle5/5 (52)

- The 4 Disciplines of Execution: Revised and Updated: Achieving Your Wildly Important GoalsDa EverandThe 4 Disciplines of Execution: Revised and Updated: Achieving Your Wildly Important GoalsValutazione: 4.5 su 5 stelle4.5/5 (48)

- The Introverted Leader: Building on Your Quiet StrengthDa EverandThe Introverted Leader: Building on Your Quiet StrengthValutazione: 4.5 su 5 stelle4.5/5 (35)

- Leadership Skills that Inspire Incredible ResultsDa EverandLeadership Skills that Inspire Incredible ResultsValutazione: 4.5 su 5 stelle4.5/5 (11)

- The E-Myth Revisited: Why Most Small Businesses Don't Work andDa EverandThe E-Myth Revisited: Why Most Small Businesses Don't Work andValutazione: 4.5 su 5 stelle4.5/5 (709)

- The 12 Week Year: Get More Done in 12 Weeks than Others Do in 12 MonthsDa EverandThe 12 Week Year: Get More Done in 12 Weeks than Others Do in 12 MonthsValutazione: 4.5 su 5 stelle4.5/5 (411)

- The Little Big Things: 163 Ways to Pursue ExcellenceDa EverandThe Little Big Things: 163 Ways to Pursue ExcellenceNessuna valutazione finora

- The Lean Product Playbook: How to Innovate with Minimum Viable Products and Rapid Customer FeedbackDa EverandThe Lean Product Playbook: How to Innovate with Minimum Viable Products and Rapid Customer FeedbackValutazione: 4.5 su 5 stelle4.5/5 (81)