Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Wpt-III Lab Report 1

Caricato da

Rafid RatulDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Wpt-III Lab Report 1

Caricato da

Rafid RatulCopyright:

Formati disponibili

Experiment No: 01 Name of the Experiment: Dyeing of Cotton with Pigments. Theory: Actually pigments are not dyes.

They are organic or inorganic coloring substances and have no affinity to fibers. According to the definition proposed by colored pigments manufacturers association pigments are colored, black, white or fluorescent particulate organic and inorganic solids which usually are insoluble in and essentially physically and chemically un affected by the vehicles or substrate in which they are incorporated. They alter appearance by selective absorption and or by scattering of light. Pigments are usually dispersed in vehicles or substrates for application as for instance in inks, paints, plastics or other polymeric materials. Pigments retain a crystal or particulate structure throughout the coloration process. Generally, the finely divided pigments provide negative surface charge when dispersed in water. This negative surface charge has been put to good use in textile coloration for attracting the pigment particles to fiber surfaces on which cationic groups have been attached. In pigmentation of textiles, there is no chemical reaction happening between the fiber and the pigment. Since pigment has no attraction to the fibers, thus the fibers are treated with a suitable cationizing agent for creating an attraction of anionic pigment to fibers. This process is called cationic pretreatment. Mainly pigments are used in printing and woven dyeing and to color garments without actually dyeing them. Pigment dyeing on garments is very popular and common in textile coloration field. The pigments are simply set on the surface of the fiber and held on with aid of binders. By putting color only on the surface of a garment, a washed out, faded look similar to denim jeans can be created.

Object: To dye fabric using pigments. To acquire knowledge over pigments.

Apparatus: 1) Beaker 2) Heater 3) Agitator 4) Chemicals 5) Thermometer 6) Oven

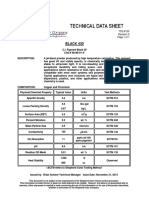

Recipe: Step Material M:L Pigments Binder Fixer Acetic Acid Leveling Agent pH Temperature Time Temperature Time Amount 1 : 30 3% 25 gm/l 7 gm/l 3 gm/l 3 gm/l Less than 6 80 90 C 45 60 minutes 140 C 3 5 minutes

Dyeing

After treatment

Recipe Calculation: Here, M : L ratio is given as 1 : 30. Our fabric weight was 4 gm which needs 120 ml water during dyeing process according to the M : L ratio. Now, the amount of pigments, chemicals, auxiliaries are calculated bellow.

Pigment required, 5% of fabric weight =

= 0.2 gm

At each 1000 ml water, required amount of Binder is 25 ml So, At 120 ml water, required amount of Binder is = At each 1000 ml water, required amount of Fixer is 7 ml So, At 120 ml water, required amount of Fixer is = = 0.84 ml

= 3 ml

At each 1000 ml water, required amount of Leveling Agent is 3 ml So, At 120 ml water, required amount of Leveling Agent = At each 1000 ml water, required amount of Acetic Acid is 3 ml So, At 120 ml water, required amount of Acetic Acid = = 0.36 ml = 0.36 ml

All the calculations is done on the basis of recipe given earlier. Actual amount which was used for dyeing may vary slightly due to few measurement errors or as per need.

Working Procedure: At first we wash all the beakers and dye bath well and weigh the fabric in order to complete necessary calculation to get the required amount of water and other chemicals for dyeing. Then we measured and poured necessary amount of water into the dye bath along with required amount of pigments and acetic acid. Then we heated the bath until the temperature reached 40 C and kept heating for about 10 minutes. At this point, we added the fabric into the dye bath that was to be dyed by pigment. After that, we continued heating until the temperature reached 60 C. At this point, we added Binder and leveling agent to the dye liquor and continued heating at 60 C for about 10 minutes. After that, we added fixer to the dye liquor. Then we, increased the heating and raised the temperature up to 80C at which temperature, heating is continued for about 60 minutes. At the end, we drained the dye liquor and dipped the fabric into clean water without rinsing or washing it. Then, we put the fabric into the oven where it is placed to dry up at about 140 C for about 5 minutes. At last, we got the fabric out of the oven and cut it into pieces for making samples of the experiment for each member of the group. Dyeing Curve:

Fig: Dyeing Curve for dyeing of cotton fabric with pigments

Precaution: The temperature at various stages of dyeing should be controlled carefully. There should be enough dyeing time given in order to get a good quality dye. Fabric should not be raised over dyeing liquor as it can cause uneven dyeing. Fabric is not washed after dyeing, however, it was dipped into fresh water to get rid of extra dye liquor.

Conclusion: We used red pigments for dyeing. Due to its natural tendency to wash away from the fabric, we had to use a fixing agent to bind the color onto the fabric so that it can have better color fastness. We obtained a red color which became a slightly lighter shade after drying.

SAMPLE

Potrebbero piacerti anche

- National Textile University Faculty of Engineering & TechnologyDocumento8 pagineNational Textile University Faculty of Engineering & TechnologyShahan AkhtarNessuna valutazione finora

- National Textile University Faculty of Engineering & TechnologyDocumento11 pagineNational Textile University Faculty of Engineering & TechnologyShahan Akhtar100% (1)

- Pigment DyeingDocumento3 paginePigment DyeingPawan KinnalNessuna valutazione finora

- Methods of ColorationDocumento11 pagineMethods of ColorationFerdous Khan RubelNessuna valutazione finora

- Dyeing of Synthetic FibersDocumento15 pagineDyeing of Synthetic FibersHaqiqat AliNessuna valutazione finora

- Dying of Fabric Final Final FinalDocumento20 pagineDying of Fabric Final Final FinalCHINMAY UPADHYAYA X-DNessuna valutazione finora

- Assignment 2 ChemesteryDocumento26 pagineAssignment 2 ChemesterySIDDHARTH KOTHARINessuna valutazione finora

- Chemistry Investigatory Project On Dyeing of FabricsDocumento19 pagineChemistry Investigatory Project On Dyeing of FabricsAditi100% (2)

- Chemical Classification of PigmentsDocumento6 pagineChemical Classification of PigmentsPoison EmuNessuna valutazione finora

- Chemistryinvestigatoryproject 170821161814Documento18 pagineChemistryinvestigatoryproject 170821161814Arush TiwariNessuna valutazione finora

- Disperse DyesDocumento23 pagineDisperse DyesPratik Minj100% (3)

- Chemistry Isc Class12 ProjectDocumento18 pagineChemistry Isc Class12 ProjectRuhi Bhatt100% (2)

- Dyeing of Polyester Fabric With Disperse DyesDocumento4 pagineDyeing of Polyester Fabric With Disperse DyesKushagradhi Debnath100% (1)

- BalarajDocumento28 pagineBalarajApoorv MohanNessuna valutazione finora

- Dyeing Faults & RemediesDocumento13 pagineDyeing Faults & RemediesSHEIKH SADI100% (1)

- Defects in Dyeing With Reactive DyesDocumento6 pagineDefects in Dyeing With Reactive DyesvinayakasisNessuna valutazione finora

- TP Expirment No. 5 Direct DyeingDocumento4 pagineTP Expirment No. 5 Direct DyeingTolenuf AbeyaNessuna valutazione finora

- Chemistry Thesis Back UpDocumento11 pagineChemistry Thesis Back Upseeman madheshNessuna valutazione finora

- Lab Report On: Dip Dyeing Process On Twill FabricDocumento6 pagineLab Report On: Dip Dyeing Process On Twill FabricIMAMA HOSSAIN SOBUJNessuna valutazione finora

- Garment Surface Ornamentation (GSO) : - Wet Processing and Their Importance Desizing Scouring Mercerization BleachingDocumento68 pagineGarment Surface Ornamentation (GSO) : - Wet Processing and Their Importance Desizing Scouring Mercerization BleachingGulumaNessuna valutazione finora

- Apparel DyeingDocumento21 pagineApparel DyeingUmme Hafsa OpurbaNessuna valutazione finora

- Application Methods of Reactive Dyeing - Textile LearnerDocumento12 pagineApplication Methods of Reactive Dyeing - Textile LearnerAnas ZidaneNessuna valutazione finora

- Wet Processing Technology LAb DocumentDocumento3 pagineWet Processing Technology LAb DocumentSanjana Islam Nilima0% (1)

- Chemidtry PracticalDocumento12 pagineChemidtry PracticalaasifNessuna valutazione finora

- 2nd Lab ReportDocumento13 pagine2nd Lab Reportali hasan100% (1)

- St. Joseph'S Co-Ed School, Bhopal: Chemistry Investigatory ProjectDocumento15 pagineSt. Joseph'S Co-Ed School, Bhopal: Chemistry Investigatory ProjectHimanshu DubeyNessuna valutazione finora

- Dyeing With Polyester Using HTHP BEAM DYEING MACHINEDocumento4 pagineDyeing With Polyester Using HTHP BEAM DYEING MACHINESivakumar KNessuna valutazione finora

- Chemistry Investigatory ProjectDocumento18 pagineChemistry Investigatory ProjectDinesh Singh Choudhary0% (1)

- High Temp Dyeing Method On Polyester FabricDocumento2 pagineHigh Temp Dyeing Method On Polyester FabricrashidtexNessuna valutazione finora

- Lab Report: 1st: National Textile University FSDDocumento6 pagineLab Report: 1st: National Textile University FSDFizzah Rauf 0041Nessuna valutazione finora

- Dying of FabricDocumento14 pagineDying of FabricCHINMAY UPADHYAYA X-DNessuna valutazione finora

- Chemistry Investigatory ProjectDocumento9 pagineChemistry Investigatory Projectanon_32709488156% (16)

- Chemistry ProjectDocumento15 pagineChemistry ProjectHadiqua FaiyazNessuna valutazione finora

- Toaz - Info Chemistry Investigatory Project On Dyeing of Fabrics For Class 12 PRDocumento19 pagineToaz - Info Chemistry Investigatory Project On Dyeing of Fabrics For Class 12 PRmukesh kumarNessuna valutazione finora

- Printing DefectsDocumento4 paginePrinting DefectsShrishti GuptaNessuna valutazione finora

- Deying TemperatureDocumento12 pagineDeying TemperatureIrtza ArainNessuna valutazione finora

- Carrier Dyeing Method of Disperse DyeDocumento2 pagineCarrier Dyeing Method of Disperse DyerashidtexNessuna valutazione finora

- Chemistry Investigatory Project 2023-24Documento20 pagineChemistry Investigatory Project 2023-24sucharitafin17Nessuna valutazione finora

- CHEM Project Final XCMDocumento17 pagineCHEM Project Final XCMBargav KrishnaNessuna valutazione finora

- Chemistry Project On Dyeing of Fabrics Class XIIDocumento17 pagineChemistry Project On Dyeing of Fabrics Class XIIAnonymous 0PdDjJNessuna valutazione finora

- 11 Preparation of Vegetable DyeDocumento13 pagine11 Preparation of Vegetable Dyejesinthafrancis100% (1)

- CHM Invst - PRJDocumento20 pagineCHM Invst - PRJtksjubs13Nessuna valutazione finora

- Two Stage Two Bath With Disperse/reactive Dyes at High TemperatureDocumento4 pagineTwo Stage Two Bath With Disperse/reactive Dyes at High Temperaturenasimul haqueNessuna valutazione finora

- Dyeing - FinalDocumento60 pagineDyeing - Finaldaniel leulsegedNessuna valutazione finora

- Selection and Types of Dyes: Dyeing An IntroductionDocumento8 pagineSelection and Types of Dyes: Dyeing An IntroductionrajaNessuna valutazione finora

- Chemistry Investigatory Project Class 12Documento17 pagineChemistry Investigatory Project Class 12Rosalin Acharya XIIC 15100% (1)

- What Is MercerizingDocumento4 pagineWhat Is MercerizingSojid khanNessuna valutazione finora

- Lab ReportDocumento6 pagineLab ReportTanzila NusratNessuna valutazione finora

- Textile AssignmentDocumento8 pagineTextile AssignmentMahmudul Hasan Khan40% (5)

- Direct DyeDocumento4 pagineDirect DyeEusha NightangelNessuna valutazione finora

- Dyeing of Fabrics: Session 2019-2020Documento16 pagineDyeing of Fabrics: Session 2019-2020Jashan PahwaNessuna valutazione finora

- Chemistry ProjectDocumento13 pagineChemistry ProjectVardhman Shrivastava100% (1)

- Precaution Manual For Colour Blooming Auxiliaries Applications On Textiles.Documento12 paginePrecaution Manual For Colour Blooming Auxiliaries Applications On Textiles.L.N.CHEMICAL INDUSTRY100% (1)

- KENDRIYA VIDYALAYA NIRMAL ChemDocumento11 pagineKENDRIYA VIDYALAYA NIRMAL ChemganeshchandraroutrayNessuna valutazione finora

- Dying of Cotton Fabric With Reactive Dye (Hot Brand) .Documento5 pagineDying of Cotton Fabric With Reactive Dye (Hot Brand) .Redwan Ibn MahbubNessuna valutazione finora

- ManDocumento13 pagineManShubham KumarNessuna valutazione finora

- Lab ReportDocumento7 pagineLab ReportMoklesur RahmanNessuna valutazione finora

- Textile and Fabric Arts Dictionary: Grow Your VocabularyDa EverandTextile and Fabric Arts Dictionary: Grow Your VocabularyNessuna valutazione finora

- Learn How to Paint Portraits of People In Watercolor For the Absolute BeginnersDa EverandLearn How to Paint Portraits of People In Watercolor For the Absolute BeginnersNessuna valutazione finora

- Black 430 TDS PDFDocumento1 paginaBlack 430 TDS PDFSimon WilliargoNessuna valutazione finora

- ASTM D4214-07. Standard Test Methods For Evaluating The Degree of Chalking of Exterior Paint Films.Documento5 pagineASTM D4214-07. Standard Test Methods For Evaluating The Degree of Chalking of Exterior Paint Films.yansi100% (1)

- Colorants For Plastics BASFDocumento29 pagineColorants For Plastics BASFGleidiston Zattoni100% (1)

- The Weathering Magazine 01Documento80 pagineThe Weathering Magazine 01Darcco Fakafel91% (34)

- REVIGO 2017 Original Colours of Van Gogh's PaintingsDocumento6 pagineREVIGO 2017 Original Colours of Van Gogh's Paintingssdrtfg100% (1)

- COLOR INDEX Flint Group PigmentsDocumento6 pagineCOLOR INDEX Flint Group Pigmentsalfosoa5505Nessuna valutazione finora

- PV - Color Report Aw 24 25 enDocumento46 paginePV - Color Report Aw 24 25 endegtyartatiana333Nessuna valutazione finora

- Clariant Flyer Genapol ED 2015 ENDocumento2 pagineClariant Flyer Genapol ED 2015 ENDtotecnico MorterosNessuna valutazione finora

- Visual and Instrumental Assessments of Color Differences in Automotive CoatingsDocumento9 pagineVisual and Instrumental Assessments of Color Differences in Automotive CoatingsTallaNessuna valutazione finora

- Formulation Guidelines For Formulating Effect Pigments in Anhydrous Powder Products Update December 2011Documento7 pagineFormulation Guidelines For Formulating Effect Pigments in Anhydrous Powder Products Update December 2011Hanabi_MineNessuna valutazione finora

- Brochure - Printing - ScreenPrinting - ACHITEX MINERVADocumento12 pagineBrochure - Printing - ScreenPrinting - ACHITEX MINERVAeduardoaffreNessuna valutazione finora

- Project Report Sample - Cement PlantDocumento126 pagineProject Report Sample - Cement PlantArun Prasadh100% (2)

- PigmentsDocumento4 paginePigmentsRatih AriyaniNessuna valutazione finora

- Difference Between Dye & PigmentDocumento2 pagineDifference Between Dye & PigmentMehmood Ahmed100% (1)

- Haliza Katas Faculty of Pharmacy UKMDocumento31 pagineHaliza Katas Faculty of Pharmacy UKMunknownNessuna valutazione finora

- In Uence of Pigment On Biodeterioration of Acrylic Paint Lms in Southern BrazilDocumento10 pagineIn Uence of Pigment On Biodeterioration of Acrylic Paint Lms in Southern BrazilAecio De Miranda BreitbachNessuna valutazione finora

- Clay and Iron Oxide Pigments in The History of Painting PDFDocumento14 pagineClay and Iron Oxide Pigments in The History of Painting PDFNatasa IlicNessuna valutazione finora

- Luminall: PaintDocumento1 paginaLuminall: PaintreacharunkNessuna valutazione finora

- ASTMDocumento10 pagineASTMtenNessuna valutazione finora

- ASTM C 979 LanxessDocumento2 pagineASTM C 979 LanxessJuan Camilo Silva100% (1)

- Coatings Word August 2016Documento68 pagineCoatings Word August 2016sami_sakr100% (2)

- CodeDocumento7 pagineCodesynojohnNessuna valutazione finora

- Astm D332Documento3 pagineAstm D332NizarHamrouniNessuna valutazione finora

- Vmzinc CatalogDocumento20 pagineVmzinc CatalogMachalyn ChuaNessuna valutazione finora

- Homeinteriorpaint FractionsdecimalsandpercentsDocumento4 pagineHomeinteriorpaint Fractionsdecimalsandpercentsapi-281743386Nessuna valutazione finora

- A Comprehensive Guide To Making Your Own Paint MediaDocumento167 pagineA Comprehensive Guide To Making Your Own Paint MediaABC100% (4)

- Biolime Brochure Nov 2010Documento16 pagineBiolime Brochure Nov 2010Ghufran SaeedNessuna valutazione finora

- Ip RRLDocumento4 pagineIp RRLysabellanicoleNessuna valutazione finora

- Is Carbon Black Pigment Organic or InorganicDocumento3 pagineIs Carbon Black Pigment Organic or Inorganicwiwat dussadinNessuna valutazione finora

- 7677 Version 7thDocumento2 pagine7677 Version 7thDuc NguyenNessuna valutazione finora