Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

BME Lecture 5 Shaper

Caricato da

Roop LalDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

BME Lecture 5 Shaper

Caricato da

Roop LalCopyright:

Formati disponibili

Lecture 4 Notes : shapers and planers Basic Mechanical Engineering ( Part B ) 1 Introduction: Both shapers and planers are

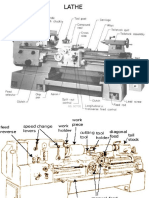

re machine tools which produce a flat surface. They are capable of machining a horizontal, vertical or inclined flat surface. They employ single-point cutting tools which are essentially similar to single-point cutting tools used on lathe. In both these machine tools, the cutting tool is subjected to interrupted cuts, the tools cuts in forward direction and is idle in the return direction. 2 SHAPING MACHINES OR SHAPER : Principle of Working Principal parts of a shaper are shown in Fig. 1.

Fig. 1 Principal parts of a shaper Shaper consists of a hollow machine bed made of cast iron which rests on the ground. Inside the hollow portion the machine drive mechanism is housed. This mechanism is called slotted lever quick return mechanism and it drives a horizontal ram which reciprocates in the guide ways provided on the top surface of the machine frame. In the front face of the ram, a tool post is fitted. This is a very special kind of tool post. It carries a slide which can be operated by a hand wheel and the entire tool post can be lowered or raised. Besides, the tool slide can be swiveled in a vertical plane and its inclination to the vertical (amount of swiveling) can be read off on a scale marked in degrees. The tool is inclined, when an inclined surface has to be machined. In the front portion of the base, a table is fitted. The table can be raised or lowered to vary its height. It can also be moved horizontally to left or right. A vice to hold the work piece

is provided on the table top. The tool does useful work i.e., cutting only in the forward stroke of the ram. It does not cut in return stroke i.e. it is idle during the return stroke of ram. In order that while returning, the tool may not rub and spoil the strip of the metal machined in the forward stroke, a special device called the clapper box is provided in the tool post. It lifts the tip of the tool during the return stroke. DRIVE Since useful work is done only during the forward stroke of ram, the mechanism driving the ram is so designed that the return stroke is completed in much less time than the forward stroke. The slotted lever quick return mechanism is illustrated in Figs. 2(a) and 2(b).

Fig. 2 Quick return mechanism Manufacturing Processes The crank AB (of adjustable length R) rotates with a uniform angular speed. The crank pin B is in the shape of a die block which is free to slide inside the slot in the slotted lever OBC. This slotted lever is pivoted at O and the other end C is connected to the ram by a short link arm as shown in Fig. 2 (a). When the crank AB rotates clockwise from position AB1 to AB2, the ram moves forward from left to right and when it rotates from position AB2 to AB1 the ram returns back to its original position. Clearly the time taken to complete forward stroke is proportional to angle (refer to Fig. 2 (b)) and the return stroke is completed in less time which is proportional to angle .

CUTTING TOOLS USED IN SHAPING The cutting tools for shapers are generally made of H.S.S., either solid or with brazed tips. Due to interrupted cuts, tungsten carbide tools are not preferred for shaping work. These tools are made sturdy with fairly generous size for shank and tip. Various types of tools useful for shaping are shown in Fig.3.

Fig. 3 Cutting tools used in shaping work OPERATIONS PERFORMED ON SHAPERS On a shaping machine, relatively small jobs can be machined. The size of a shaper is denoted by the maximum length of stroke of its ram and work pieces longer than the maximum stroke cannot be machined. The first step in machining a job is to mount the job on the shaper-table and clamp it tightly in the vice or on the table by means of T-bolts etc. The second step is to adjust the stroke of ram according to the length of work piece. The ram stroke is kept about 6070 mm longer than job. The stroke can be reduced or increased by altering the length of the crank AB (refer to Fig. 2). Now by changing the position of the location where short link arm is connected to the ram, the stroke is made to overlap the job, so that the stroke starts 3035 mm before the job and covers the whole length of work piece and ends 3035 mm beyond it. A tool is now selected and clamped in the tool post. The depth of cut is given by rotating the hand wheel and lowering the tool slide. Depth of cut is not given by raising the table height. Table height is adjusted only at the time of fixing the job according to the height of job. Feed is given by shifting the table laterally. The feed to the table can be given either manually or automatically. The feed is given during the return stroke of ram. Operations performed on a shaper can be easily understood from Fig. 4.

Fig. 4 Various operations performed on a shaping machine Contour cutting is a very skillful job as it calls for simultaneous operation of horizontal table

feed as well as vertical hand feed of the cutting tool. It can be performed only by a very skilled operator. PLANER OR PLANNING MACHINE Planer is used to machine flat surfaces on work pieces, which are too large and heavy to be accommodated on a shaping machine table. The fundamental difference between a planer and shaper is that in a planer, the cutting tool remains stationary and the planer table on which the work piece has been clamped moves past the cutting tool. The feed is given to the cutting tool and not to the table which reciprocates in the guide ways provided in the machine bed. A planer can handle much heavier cuts and more than one tool post is provided on one machine so that machining can be done quickly. Sometimes a horizontal surface and a vertical surface are machined simultaneously and the squareness of the surfaces is automatically ensured. PRINCIPLE OF WORKING A standard planer is shown in Fig. 5. The planer consists of a sturdy bed made of cast iron, on the upper surface of which Vee guide ways are machined all along the length the bed. The base of bed is grouted in the ground. Table is again made of cast iron having matching guide ways machined at its bottom so that it can slide longitudinally on the machine bed. The table has a long rack machined in the centre of its width which is used for giving reciprocating motion to the table. The table is provided with T-slots on its top surface, so that the work piece may be clamped securely on the table. Two vertical columns, one on each side of the bed and table are located as shown in the figure. A cross rail can slide up and down on the two vertical columns. Usually one or two tool posts (tool heads) are mounted on the cross rail and one side tool head is mounted on each column. Vertical tool heads can move laterally on the cross rail while side tool heads can move up and down on the vertical columns. There is arrangement for advancement or retraction of tools in the tool heads. A number of speeds and feeds are available for the tool heads.

Fig. 5 Schematic diagram of a planer

Even on a planer, the tools will cut material only in the forward stroke of the table, its return stroke is idle. To save idle time, the return stroke takes place at higher speed. This is achieved by a variable speed reversible motor drive and a system of limit switches fitted on the bed of the machine, which get actuated when the table reaches the end of its forward and reverse strokes. The length of the stroke can be adjusted to suit the length of the work piece by changing the position of the limit switches. Cutting tools used on planers: The planer tools are made of high speed steel, although tipped carbide tools are also used occasionally. These tools are, in general, similar to shaper tools, but are more robust and stronger. Specially shaped tools are used on planers for operations like Tslot cutting and dove tail slide cutting. In both shapers and planers, the tool or table starts from rest, picks up speed and then again slows down to zero speed during the forward or cutting stroke. It is customary to calculate cutting speed on the basis of average speed during the forward stroke. Feed and depth of cut are both expressed in mm. In case of feed, it is the lateral distance moved by the tool (on the cross-rail) per cutting stroke. Some examples of the diverse type of machining operations performed on a planer can be had by referring to Fig. 2.6. The surfaces shown shaded have been machined on planer.

Fig. 6 Components manufactured by planning/shaping processes

Potrebbero piacerti anche

- ShaperDocumento20 pagineShaperMilan SainiNessuna valutazione finora

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.Da EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.Nessuna valutazione finora

- Shaper Used As Surface GrinderDocumento1 paginaShaper Used As Surface Grinderradio-chaserNessuna valutazione finora

- Planer Quick Return MechanismDocumento21 paginePlaner Quick Return Mechanismlalagandu100% (1)

- Lecture 1 - Intro To Single Point Cutting Tool GeometryDocumento16 pagineLecture 1 - Intro To Single Point Cutting Tool GeometryMuhammad Umar IqtidarNessuna valutazione finora

- Capstan & Turret LatheDocumento27 pagineCapstan & Turret LatheMuraliNessuna valutazione finora

- Atlas Mill AccessoriesDocumento1 paginaAtlas Mill AccessoriesGary RepeshNessuna valutazione finora

- WErbsen CourseworkDocumento562 pagineWErbsen CourseworkRoberto Alexis Rodríguez TorresNessuna valutazione finora

- Ralph Patterson Tailstock Camlock 2Documento13 pagineRalph Patterson Tailstock Camlock 2supremesportsNessuna valutazione finora

- Lathes and Lathe Machining OperationsDocumento11 pagineLathes and Lathe Machining OperationsJunayed HasanNessuna valutazione finora

- Design of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureDocumento20 pagineDesign of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureVarthini RajaNessuna valutazione finora

- Shaper MachineDocumento81 pagineShaper Machinesam clastineNessuna valutazione finora

- Lathes and Lathe Machining OperationsDocumento18 pagineLathes and Lathe Machining Operationssarasrisam100% (1)

- Manual TornoDocumento60 pagineManual Tornojulie2420140% (1)

- Lathe DesignDocumento11 pagineLathe DesignShiyas Basheer0% (1)

- Unit-2 - 03 Aug 2015Documento98 pagineUnit-2 - 03 Aug 2015Prasad AurangabadkarNessuna valutazione finora

- Types of Angles in Drill BitsDocumento2 pagineTypes of Angles in Drill BitsAbdul AhadNessuna valutazione finora

- The Shape of The Cone of The Twist Drills Unit-2Documento5 pagineThe Shape of The Cone of The Twist Drills Unit-2Akesh KakarlaNessuna valutazione finora

- Lathe Part IDocumento151 pagineLathe Part Ishiva100% (2)

- Slotting MachineDocumento32 pagineSlotting Machinesanaashraf91% (11)

- Lathe-1Documento26 pagineLathe-1Meer Umar100% (2)

- Manufacturing of Spur Gear: Aim of The ExperimentDocumento5 pagineManufacturing of Spur Gear: Aim of The ExperimentParameshwara MeenaNessuna valutazione finora

- Gear and Gear TrainDocumento21 pagineGear and Gear Trainm_er100Nessuna valutazione finora

- Milling Machine (Group 7)Documento52 pagineMilling Machine (Group 7)Faisal Maqsood100% (1)

- 06-MeasuringAndMarkingMetals Text7Documento2 pagine06-MeasuringAndMarkingMetals Text7Instruktur MesinNessuna valutazione finora

- Non Chip FormingDocumento33 pagineNon Chip FormingNur AmirahNessuna valutazione finora

- Gear Cutting AttachmentDocumento40 pagineGear Cutting AttachmentGoutham Reddy100% (1)

- Study of Dividing HeadsDocumento10 pagineStudy of Dividing HeadsChandan SrivastavaNessuna valutazione finora

- 02 Dividing Head 1Documento22 pagine02 Dividing Head 1farid said errahmaniNessuna valutazione finora

- Grinding MachinesDocumento44 pagineGrinding MachinesPrashant Rao MeshramNessuna valutazione finora

- Lathe MachineDocumento22 pagineLathe MachineRaghavMaheshwariNessuna valutazione finora

- Machine Tools and Machining1Documento62 pagineMachine Tools and Machining1Faisal MaqsoodNessuna valutazione finora

- Drilling SRM UniviersityDocumento27 pagineDrilling SRM UniviersityBhavin Desai100% (2)

- Lathebeddesign00hornrich PDFDocumento56 pagineLathebeddesign00hornrich PDFLatika KashyapNessuna valutazione finora

- Jdsw51a Usb Mach3 (Blue) - 5aixsDocumento36 pagineJdsw51a Usb Mach3 (Blue) - 5aixsabelmil123Nessuna valutazione finora

- Lathe: GS, SctceDocumento48 pagineLathe: GS, SctceGouthamPrasad100% (2)

- Biax Electronic Scraper and AccessoriesDocumento16 pagineBiax Electronic Scraper and AccessoriesPaisaje Silencioso100% (1)

- 149-Workshop Hints & TipsDocumento1 pagina149-Workshop Hints & TipssyllavethyjimNessuna valutazione finora

- Tilting ViceDocumento35 pagineTilting ViceAakash DindigulNessuna valutazione finora

- Lathe AccessoriesDocumento4 pagineLathe AccessoriesBOT-X GAMING100% (1)

- Design of Milling Cutters1Documento67 pagineDesign of Milling Cutters1Ebrahim Abdullah HanashNessuna valutazione finora

- Chapter2 Locating Principles and DevicesDocumento57 pagineChapter2 Locating Principles and DevicesAbhishek KulhariNessuna valutazione finora

- Modification and Development of Work Holding Device - Steady-RestDocumento6 pagineModification and Development of Work Holding Device - Steady-RestInternational Journal of Innovative Science and Research Technology100% (1)

- Fresadora #12Documento15 pagineFresadora #12jmtortu100% (1)

- Drill Press Text BookDocumento138 pagineDrill Press Text BookEng_2014Nessuna valutazione finora

- Fordson Major ManualDocumento47 pagineFordson Major ManualHassan GDOURANessuna valutazione finora

- Production Technology (IV Sem)Documento24 pagineProduction Technology (IV Sem)Shubham AgrawalNessuna valutazione finora

- Machining Processes Used To Produce Various Shapes: MillingDocumento28 pagineMachining Processes Used To Produce Various Shapes: MillingSuleiman SaidNessuna valutazione finora

- Resharpening & Inspection Cutting Tools PDFDocumento10 pagineResharpening & Inspection Cutting Tools PDFHeineken Ya PraneetpongrungNessuna valutazione finora

- Metric - Threading Logan LatheDocumento2 pagineMetric - Threading Logan LatheShane RamnathNessuna valutazione finora

- Drilling Machine & ReamersDocumento42 pagineDrilling Machine & ReamersSomenath RahaNessuna valutazione finora

- Shaping MachineDocumento25 pagineShaping Machinekatakamharish100% (1)

- Name of The Experiment:: Study and Operation Bench Drilling MachineDocumento5 pagineName of The Experiment:: Study and Operation Bench Drilling MachinemadNessuna valutazione finora

- BORINGDocumento4 pagineBORINGPandi VelanNessuna valutazione finora

- Construction and Manufacture of AutomobilesDa EverandConstruction and Manufacture of AutomobilesValutazione: 5 su 5 stelle5/5 (1)

- Bme Lecture CNCDocumento18 pagineBme Lecture CNCRoop LalNessuna valutazione finora

- Assignment Unit IV BMEDocumento2 pagineAssignment Unit IV BMERoop LalNessuna valutazione finora

- Surface Mount TechnologyDocumento5 pagineSurface Mount TechnologyRoop Lal100% (1)

- Assignment Instrumentation V Sem EveningDocumento5 pagineAssignment Instrumentation V Sem EveningRAMAKANT RANANessuna valutazione finora

- BME Lecture Non Conventional MachiningDocumento16 pagineBME Lecture Non Conventional MachiningRoop Lal100% (1)

- Engg Graphics Sheet No. 4Documento4 pagineEngg Graphics Sheet No. 4Roop LalNessuna valutazione finora

- Welding by Roop Lal RanaDocumento21 pagineWelding by Roop Lal Ranaanmolmahajan1234Nessuna valutazione finora

- Sheet No. 3: Engg. GraphicsDocumento5 pagineSheet No. 3: Engg. GraphicsRoop LalNessuna valutazione finora

- Assignements - BMEDocumento4 pagineAssignements - BMERoop LalNessuna valutazione finora

- Lecture - 5 Notes: Milling Basic Mechanical Engineering (Part - B, Unit - I) 1Documento7 pagineLecture - 5 Notes: Milling Basic Mechanical Engineering (Part - B, Unit - I) 1Roop LalNessuna valutazione finora

- Sheet No. 3: Engg. GraphicsDocumento5 pagineSheet No. 3: Engg. GraphicsRoop LalNessuna valutazione finora

- DOM Syllabus B.tech Part-TimeDocumento1 paginaDOM Syllabus B.tech Part-TimeRoop LalNessuna valutazione finora

- Syllabus BMEDocumento2 pagineSyllabus BMERoop LalNessuna valutazione finora

- Lecture - 4 Notes: Drilling Basic Mechanical Engineering (Part - B) 1Documento5 pagineLecture - 4 Notes: Drilling Basic Mechanical Engineering (Part - B) 1Roop LalNessuna valutazione finora

- DOM Assignment - IIIDocumento1 paginaDOM Assignment - IIIRoop LalNessuna valutazione finora

- Syllabus Engineering GraphicsDocumento1 paginaSyllabus Engineering GraphicsRoop LalNessuna valutazione finora

- ED - Paper - May - Jun 2010Documento7 pagineED - Paper - May - Jun 2010Roop Lal100% (1)

- Syllabus Engineering GraphicsDocumento1 paginaSyllabus Engineering GraphicsRoop LalNessuna valutazione finora

- ED - I Paper Nov 2009.Documento3 pagineED - I Paper Nov 2009.Roop Lal100% (1)

- ED Paper - 10 Nov - DecDocumento14 pagineED Paper - 10 Nov - DecRoop Lal100% (1)

- Machine Design Syllabus Part-Time B.techDocumento1 paginaMachine Design Syllabus Part-Time B.techRoop LalNessuna valutazione finora

- DOM Assignment - IIIDocumento1 paginaDOM Assignment - IIIRoop LalNessuna valutazione finora

- Dom AssigimentDocumento2 pagineDom AssigimentRoop LalNessuna valutazione finora

- Machine Design - Assignment - IIDocumento1 paginaMachine Design - Assignment - IIRoop LalNessuna valutazione finora

- Rhetoric and Reality World Bank and CIDA Gender PoliciesDocumento24 pagineRhetoric and Reality World Bank and CIDA Gender PoliciesElaine BradleyNessuna valutazione finora

- Contract Lecturers Renewal GO06092017175117 - 999.Documento4 pagineContract Lecturers Renewal GO06092017175117 - 999.srinu MajjiNessuna valutazione finora

- Minimum Wage Wage Order National Wages and Productivity Commission Regional Tripartite Wages and Productivity BoardDocumento5 pagineMinimum Wage Wage Order National Wages and Productivity Commission Regional Tripartite Wages and Productivity BoardmcfalcantaraNessuna valutazione finora

- Labor Relations CasesDocumento477 pagineLabor Relations CasesrosebmendozaNessuna valutazione finora

- Return To Work Advisory ServicesDocumento45 pagineReturn To Work Advisory ServicesTogu MarpaungNessuna valutazione finora

- Frank Lorenzo - Case StudyDocumento2 pagineFrank Lorenzo - Case StudyRitik Rana0% (1)

- Mock 1 OBEDocumento2 pagineMock 1 OBEAbrar AbbasiNessuna valutazione finora

- 5-Minute Safety Talk #10 Takes Care of SafetyDocumento2 pagine5-Minute Safety Talk #10 Takes Care of SafetysaiNessuna valutazione finora

- Puducherry Municipalities Act, 1973Documento334 paginePuducherry Municipalities Act, 1973Latest Laws TeamNessuna valutazione finora

- The Great DepressionDocumento8 pagineThe Great Depressionapi-648772994Nessuna valutazione finora

- Springboard Hartlepool Matters Edition 9Documento4 pagineSpringboard Hartlepool Matters Edition 9Springboard HartlepoolNessuna valutazione finora

- BAGUIO WATER DISTRICT v. CRESENCIANO B. TRAJANO IN HIS OFFICIAL CAPACITY AS DIRECTOR OF BUREAU OF LABOR RELATIONS OF MINISTRY OF LABOR PDFDocumento3 pagineBAGUIO WATER DISTRICT v. CRESENCIANO B. TRAJANO IN HIS OFFICIAL CAPACITY AS DIRECTOR OF BUREAU OF LABOR RELATIONS OF MINISTRY OF LABOR PDFkhate alonzoNessuna valutazione finora

- Two Broad Strategies:: Segmentation of Rural MarketDocumento4 pagineTwo Broad Strategies:: Segmentation of Rural Marketkapooranukaran3493Nessuna valutazione finora

- SMC CompiledDocumento2 pagineSMC CompiledLovely De CastroNessuna valutazione finora

- MLCC 2014 The Hellenic CaseDocumento57 pagineMLCC 2014 The Hellenic CaseGoran JurisicNessuna valutazione finora

- Example Relating To PostingsDocumento5 pagineExample Relating To Postingsravibabu1620Nessuna valutazione finora

- Human Resource Management 1.1Documento12 pagineHuman Resource Management 1.1Sashwat AgarwalNessuna valutazione finora

- Trump National Golf Club Jupiter LcomplaintDocumento16 pagineTrump National Golf Club Jupiter LcomplaintLaw&CrimeNessuna valutazione finora

- Development of HRM ConceptDocumento30 pagineDevelopment of HRM Conceptmanisha_ms0% (1)

- Unfair Labor Practice in Collective Bargaining: Atty. Dominic Victor C. de AlbanDocumento17 pagineUnfair Labor Practice in Collective Bargaining: Atty. Dominic Victor C. de AlbanJica GulaNessuna valutazione finora

- Chapter - 2: Human Resource PlanningDocumento34 pagineChapter - 2: Human Resource Planningayuska pathakNessuna valutazione finora

- Chilso Mexican Bistro AnalysisDocumento13 pagineChilso Mexican Bistro Analysisapi-302035829Nessuna valutazione finora

- Oticon 2016Documento11 pagineOticon 2016The WritersNessuna valutazione finora

- Human Resources Powerpoint SlidesDocumento50 pagineHuman Resources Powerpoint Slidesabdul fahim najafiNessuna valutazione finora

- Modern Slavery Statement 2022Documento26 pagineModern Slavery Statement 2022Pedro VolkweisNessuna valutazione finora

- HRM - Chap4. Personnel Planning and RecruitingDocumento28 pagineHRM - Chap4. Personnel Planning and RecruitingHuyền MaiNessuna valutazione finora

- LABOR LAW Lecture 1Documento4 pagineLABOR LAW Lecture 1Jason LopezNessuna valutazione finora

- Square Pharmaceutical Report On Organizational BehaviorDocumento3 pagineSquare Pharmaceutical Report On Organizational BehaviorMuhammad MoinuddinNessuna valutazione finora

- Internship Report On Accorn Infrastructure Ltd.Documento49 pagineInternship Report On Accorn Infrastructure Ltd.Sagar SarkerNessuna valutazione finora

- 16 Callcenter Interview Questions and AnswersDocumento19 pagine16 Callcenter Interview Questions and AnswersTrish_Atienza_8433Nessuna valutazione finora