Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Watermark Clarifier 2-Page Brochure

Caricato da

viksursDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Watermark Clarifier 2-Page Brochure

Caricato da

viksursCopyright:

Formati disponibili

M.W. WATERMARK, L.L.C.

4660 136th Avenue Holland, MI 49424

ph 616.399.8850 fax 616.399.8860 www.mwwatermark.com

M.W. WATERMARK SLANT PLATE CLARIFIER

The M.W. Watermark Slant Plate Clarifier is designed to provide low cost, efficient solids removal from a wide range of waste and process liquids. The inclined plate design allows the total gravity settling area to be as much as ten times more than the actual floor space occupied by the clarifier. Features

Utilized to separate suspended solids leaving effluent clear for discharge Compact size for limited space Internally designed flocculation/mixing tanks for increased efficiency Heavy duty 1 /4" steel construction Dye-Pen tested, sandblasted and two coats of epoxy applied to ensure full coverage and superior chemical resistance 1 /4" PVC removable settling plates Oversize dual sludge outlet flanges Large access hatch Sludge sampling ports

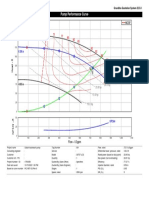

A reduction of the required floor space is acquired by diminishing the separation between the horizontal plates to a few inches and stacking the settling surfaces. Inclining the plates at 55 to provide self-flushing reduces the available horizontal projected area (effective settling area) by a factor equivalent to the cosine of the angle. The surface area diagram (below) graphically compares the floor space requirements of a slant plate clarifier with the equivalent horizontal projected settling area. Slant Plates Ideally Suited for:

Chemical processing Foundries Industrial wastewater solids Metal finishing operation Mining industry fines Power plants Steel & aluminum plants Water clarification

Horizontal Projected Area

Floor Space Requirement By a Horizontal Clarifier

M.W. WATERMARK, L.L.C. Resources For All of Your Water & Wastewater Needs Service Experience Expertise Savings

M.W. WATERMARK, L.L.C.

4660 136th Avenue Holland, MI 49424

ph 616.399.8850 fax 616.399.8860 www.mwwatermark.com

System Design Influent is fed into the clarifier downward through a feed channel between the laminar plate sections. As the velocity of the influent decreases near the bottom of the channel, larger particulate settles to the clarifier bottom. The influent enters the lower area of the laminar plate sections from the bottom of the influent channel. The liquid is then distributed across the entire width of the plates, and flows upward under laminar flow conditions. Particulates settle onto the plates and slide down to the clarifier bottom. The liquid exits the plate sections over weirs at the top that are designed to develop adequate pressure drop to maintain balanced flow through the plates. The liquid then flows into effluent channels, and out of the clarifier.

Principles of Slant Plate Clarifiers

A particle carried forward by the velocity of the liquid flow must settle at a rate that allows it to reach the bottom before passing through the clarifier. Thus, particles beginning at a point "A" must traverse some route lying between AB and AB' in order to avoid being carried over the outlet. If V is the horizontal velocity of the liquid, S the solids particle vertical settling velocity, L the length of the settling device, and D its depth, then particles entering at point A will settle to the bottom of the device only if V does not exceed: S(L/D) Since Vmax / S = L / D then, Vmax = S (L / D) Therefore, the velocity at which a horizontal clarifying device may be operated successfully is directly proportional to its length and inversely proportional to its depth.

Options

Mixers for Floc / Flash Tanks Coal-Tar Epoxy interior coating Feed Pumps Custom Design Sludge Removal Pumps

Contact us for more information. Your local Representative is:

M.W. WATERMARK, L.L.C. Resources For All of Your Water & Wastewater Needs Service Experience Expertise Savings

Potrebbero piacerti anche

- Sewage Disposal Works: Their Design and ConstructionDa EverandSewage Disposal Works: Their Design and ConstructionNessuna valutazione finora

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Da EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Valutazione: 5 su 5 stelle5/5 (2)

- Inclined Plate ClarifierDocumento2 pagineInclined Plate ClarifierKelvin SiewNessuna valutazione finora

- Sewer Appurtenances 075bar046sushmita AdhikariDocumento25 pagineSewer Appurtenances 075bar046sushmita AdhikariSushmita AdhikariNessuna valutazione finora

- Teoria Dec LamelarDocumento6 pagineTeoria Dec LamelarAlfonso José García LagunaNessuna valutazione finora

- Att Inox Drain Polonia - Rigola Mini - Cu Fanta - EngDocumento6 pagineAtt Inox Drain Polonia - Rigola Mini - Cu Fanta - EngIstvan MadacsyNessuna valutazione finora

- Design Sewer NetworkDocumento14 pagineDesign Sewer NetworkAhmad SanaNessuna valutazione finora

- Effluent ClarifierDocumento2 pagineEffluent ClarifierSutra IrawanNessuna valutazione finora

- Pollution prevention guide: Drainage moduleDocumento20 paginePollution prevention guide: Drainage moduleSaad ButtNessuna valutazione finora

- S1301 Lamella Brochure EN 1Documento8 pagineS1301 Lamella Brochure EN 1Yoto Gómez MosqueraNessuna valutazione finora

- Demister DistributerDocumento10 pagineDemister DistributercavnqnNessuna valutazione finora

- S1301 Lamella en Web - CompressedDocumento8 pagineS1301 Lamella en Web - CompressedAdam FendrychNessuna valutazione finora

- Wastewater Treatment / Sanitary EngineeringDocumento72 pagineWastewater Treatment / Sanitary EngineeringchintuNessuna valutazione finora

- Design of Sewerage SystemDocumento51 pagineDesign of Sewerage SystemRavi Shankar Mishra94% (18)

- Distillation Column DesignDocumento77 pagineDistillation Column Designsmeily100% (1)

- Combijet Catalogue (Issue 6) - 1Documento44 pagineCombijet Catalogue (Issue 6) - 1Максим Головко100% (1)

- Sewer Pipes and Flows in SewersDocumento28 pagineSewer Pipes and Flows in SewersBalanlan PenalesNessuna valutazione finora

- Chap 9 SedimentationDocumento31 pagineChap 9 SedimentationahhlNessuna valutazione finora

- Distillation: Introduction To Tray ColumnDocumento19 pagineDistillation: Introduction To Tray ColumnSusanth SunilNessuna valutazione finora

- Tray Column DesignDocumento17 pagineTray Column DesignLaras Wuri D.100% (3)

- Casing TypesDocumento13 pagineCasing Typeshardik khandelwal100% (3)

- Cone Type Flow MetersDocumento6 pagineCone Type Flow MetersHussam AhmedNessuna valutazione finora

- Clariflocculator TypesDocumento7 pagineClariflocculator TypesdexterNessuna valutazione finora

- Design Guide - TraysDocumento15 pagineDesign Guide - TraysMohamad FaifNessuna valutazione finora

- 11 - Highway DrainageDocumento41 pagine11 - Highway DrainageUsama EL AlaouiNessuna valutazione finora

- Vinayak AFMDocumento10 pagineVinayak AFMVipul VibhanshuNessuna valutazione finora

- Design of Sewerage SystemDocumento51 pagineDesign of Sewerage SystemZac Francis Daymond91% (11)

- Facts at Your Fingertips - Distillation PDFDocumento1 paginaFacts at Your Fingertips - Distillation PDFMarcelo PerettiNessuna valutazione finora

- Design of Sewerage Systems: by Prof. S.K. GuptaDocumento56 pagineDesign of Sewerage Systems: by Prof. S.K. GuptaKaran SinghNessuna valutazione finora

- DeltaStak BrochureDocumento8 pagineDeltaStak Brochurerichard gutierrezNessuna valutazione finora

- 5 Final CoagulationDocumento19 pagine5 Final CoagulationGroup-4 CommonNessuna valutazione finora

- Purification of Water SupplyDocumento82 paginePurification of Water SupplyUDAY BHUSHAN REHALIANessuna valutazione finora

- Save The Environment Save The LivesDocumento42 pagineSave The Environment Save The LivesPratik GhimireNessuna valutazione finora

- Cabletorq Thickeners/Clarifiers: Gl&V/Dorr-Oliver100Ft - Dia.Type"S"CabletorqthickenerDocumento4 pagineCabletorq Thickeners/Clarifiers: Gl&V/Dorr-Oliver100Ft - Dia.Type"S"Cabletorqthickenerdgomez686Nessuna valutazione finora

- Vortex Flow Inserts BrochureDocumento12 pagineVortex Flow Inserts BrochureKhanh ChiNessuna valutazione finora

- An Week4Documento24 pagineAn Week4Tania NoorNessuna valutazione finora

- Vane Separator (Brochure PEERLESSMFG)Documento6 pagineVane Separator (Brochure PEERLESSMFG)Julio OrtegaNessuna valutazione finora

- Microtunneling enDocumento7 pagineMicrotunneling enTauha Aziz ShahNessuna valutazione finora

- DewateringDocumento51 pagineDewateringShashikanta SahooNessuna valutazione finora

- Septic Tank HandoutDocumento8 pagineSeptic Tank HandoutDebkumar MukherjeeNessuna valutazione finora

- Sewage Sections-EeDocumento64 pagineSewage Sections-Eegautam dasNessuna valutazione finora

- RTR Points From All StandardDocumento23 pagineRTR Points From All Standardjana.alqimmaNessuna valutazione finora

- Casing Design Functions and ClassificationDocumento15 pagineCasing Design Functions and ClassificationNaser KhanNessuna valutazione finora

- Hydraulics Training Lesson 10Documento22 pagineHydraulics Training Lesson 10sponky05100% (1)

- Technical SpecificationsDocumento23 pagineTechnical SpecificationsZaid KhanNessuna valutazione finora

- Training Programme On Engineering Designs - Canal StructuresDocumento18 pagineTraining Programme On Engineering Designs - Canal Structuressudarsancivil100% (1)

- AqueductsDocumento34 pagineAqueductsMayyee Kumar0% (1)

- Importance of Cross Slope & Channel Drainage in Road ConstructionDocumento10 pagineImportance of Cross Slope & Channel Drainage in Road ConstructionshahzebkhattakNessuna valutazione finora

- SandHug BailerDocumento2 pagineSandHug BailerAhmedMohsenNessuna valutazione finora

- Well Completion PETRONASDocumento56 pagineWell Completion PETRONASAbdul Azis Zaenal Mustopa100% (4)

- Internals For Packed ColumnsDocumento20 pagineInternals For Packed Columnskingcobra008Nessuna valutazione finora

- katalogEN PDFDocumento8 paginekatalogEN PDFCarlos L. OyuelaNessuna valutazione finora

- Leopold ClariDAFDocumento17 pagineLeopold ClariDAFMichaelNessuna valutazione finora

- Waste Water Quantity Estimation:: Fluctuations in Dry Weather FlowDocumento18 pagineWaste Water Quantity Estimation:: Fluctuations in Dry Weather Flowwahaj_005Nessuna valutazione finora

- WB Floating Roof Drain Systems GuideDocumento11 pagineWB Floating Roof Drain Systems GuidevikramNessuna valutazione finora

- Packaged STPDocumento25 paginePackaged STPFarooqNessuna valutazione finora

- Benefits of high pressure jetting for cleaning tanks and vesselsDocumento9 pagineBenefits of high pressure jetting for cleaning tanks and vesselswoodywheelNessuna valutazione finora

- Needforwatertreatment 11Documento72 pagineNeedforwatertreatment 11Isuri UpasaraNessuna valutazione finora

- A Builder's Guide to Wells and Septic Systems, Second EditionDa EverandA Builder's Guide to Wells and Septic Systems, Second EditionNessuna valutazione finora

- Simple Plumbing Repairs for the Home and FarmsteadDa EverandSimple Plumbing Repairs for the Home and FarmsteadNessuna valutazione finora

- T15 Product LeafletDocumento3 pagineT15 Product LeafletCristian OrtizNessuna valutazione finora

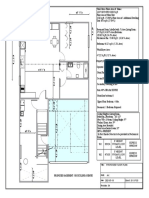

- Basement Floor Plan 1Documento1 paginaBasement Floor Plan 1viksursNessuna valutazione finora

- Grundfosliterature 6821622Documento2 pagineGrundfosliterature 6821622viksursNessuna valutazione finora

- Grundfosliterature 6821585Documento4 pagineGrundfosliterature 6821585viksursNessuna valutazione finora

- 508 New r4 01Documento1 pagina508 New r4 01viksursNessuna valutazione finora

- GLOBAL - BeLive Hotels - High Season - 2023Documento1 paginaGLOBAL - BeLive Hotels - High Season - 2023viksursNessuna valutazione finora

- Aluminum Ladder Flyer 03.30Documento1 paginaAluminum Ladder Flyer 03.30viksursNessuna valutazione finora

- Separate entrance basement suite planDocumento2 pagineSeparate entrance basement suite planviksursNessuna valutazione finora

- Standard Rupture Disc BrochureDocumento10 pagineStandard Rupture Disc BrochureviksursNessuna valutazione finora

- Existing Dwelling Secondary Suite ParkingDocumento25 pagineExisting Dwelling Secondary Suite ParkingviksursNessuna valutazione finora

- Grundfosliterature 5564592Documento77 pagineGrundfosliterature 5564592viksursNessuna valutazione finora

- Grundfosliterature 6014933Documento13 pagineGrundfosliterature 6014933viksursNessuna valutazione finora

- AM Evoline MiniBracketPlacementGuidanceDocumento5 pagineAM Evoline MiniBracketPlacementGuidanceviksursNessuna valutazione finora

- Keystone-Figure-221-222 - With Part Number-UnlockedDocumento2 pagineKeystone-Figure-221-222 - With Part Number-UnlockedviksursNessuna valutazione finora

- Supplemental Ds 2Documento1 paginaSupplemental Ds 2viksursNessuna valutazione finora

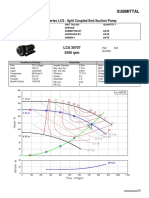

- Grundfos LCS pump submittalDocumento2 pagineGrundfos LCS pump submittalviksursNessuna valutazione finora

- True Weighted EfficiencyDocumento1 paginaTrue Weighted EfficiencyviksursNessuna valutazione finora

- PerformancedatasheetDocumento1 paginaPerformancedatasheetviksursNessuna valutazione finora

- SpecificationDocumento4 pagineSpecificationviksursNessuna valutazione finora

- LC, LCV, LF, LCS: End-Suction Centrifugal PumpsDocumento24 pagineLC, LCV, LF, LCS: End-Suction Centrifugal PumpsviksursNessuna valutazione finora

- Type-61 ElastomerSeatedButterflyValves 10 28 2022Documento10 pagineType-61 ElastomerSeatedButterflyValves 10 28 2022viksursNessuna valutazione finora

- BrochureDocumento2 pagineBrochureviksursNessuna valutazione finora

- Perforated Metal and Mesh - UnlockedDocumento1 paginaPerforated Metal and Mesh - UnlockedviksursNessuna valutazione finora

- CurvelandscapeDocumento1 paginaCurvelandscapeviksursNessuna valutazione finora

- Fixed Plant-Equipment Risk AssessmentDocumento7 pagineFixed Plant-Equipment Risk AssessmentMIL RABNessuna valutazione finora

- Inst - 1002 RLG ObDocumento10 pagineInst - 1002 RLG ObviksursNessuna valutazione finora

- AdditionalselectordataDocumento1 paginaAdditionalselectordataviksursNessuna valutazione finora

- New Text DocumentDocumento1 paginaNew Text DocumentviksursNessuna valutazione finora

- FSufZW700B-RMS ENDocumento3 pagineFSufZW700B-RMS ENviksursNessuna valutazione finora

- Ds-Oe-020 Data Sheet RlgobDocumento2 pagineDs-Oe-020 Data Sheet RlgobviksursNessuna valutazione finora

- th103 HydrDocumento2 pagineth103 Hydrvic13rNessuna valutazione finora

- Sizing Calculations RW CW HD ADDocumento27 pagineSizing Calculations RW CW HD ADBhavesh Panchal100% (1)

- Instructions For Installation, Operation, Care and MaintenanceDocumento10 pagineInstructions For Installation, Operation, Care and MaintenanceAdi HardiansyahNessuna valutazione finora

- Urban Stormwater Management Individual AssignmentDocumento3 pagineUrban Stormwater Management Individual AssignmentMastura Binti HaronNessuna valutazione finora

- 4 Headworks - Part 1Documento35 pagine4 Headworks - Part 1T.dushyankaNessuna valutazione finora

- Bombas 1Documento1 paginaBombas 1Gabriel LopezNessuna valutazione finora

- RBC Plant Design 300 m3 Day Sample ProjectDocumento3 pagineRBC Plant Design 300 m3 Day Sample Projectrq4you100% (1)

- AHP Important QuestionsDocumento22 pagineAHP Important QuestionsaadhithyarajasekaranNessuna valutazione finora

- Waste Pipe and Soil PipeDocumento4 pagineWaste Pipe and Soil PipeJeong Hannie100% (1)

- Chennai Disaster Management Plan With Zonal Ready ReckonersDocumento725 pagineChennai Disaster Management Plan With Zonal Ready ReckonersVaishnavi JayakumarNessuna valutazione finora

- West Seti & Karnali ChisapaniDocumento10 pagineWest Seti & Karnali ChisapaniBidur GautamNessuna valutazione finora

- WC Austral P: AUSTRAL Toilet and Tank Compact Elongated Trap Exposed, 1,0 GPF White ColorDocumento1 paginaWC Austral P: AUSTRAL Toilet and Tank Compact Elongated Trap Exposed, 1,0 GPF White Colorjimg05Nessuna valutazione finora

- 211000-FireSprinklerandStandpipeSystems 508Documento27 pagine211000-FireSprinklerandStandpipeSystems 508jkhgvdj mnhsnjkhgNessuna valutazione finora

- Shurflo Product Guide - 41429Documento23 pagineShurflo Product Guide - 41429senadbNessuna valutazione finora

- Assignment 1Documento6 pagineAssignment 1SayaliNessuna valutazione finora

- Orifice Catalogue EnglishDocumento11 pagineOrifice Catalogue Englishrahman ariwibowoNessuna valutazione finora

- Public Private Partnership Alandur SewerageDocumento12 paginePublic Private Partnership Alandur SewerageSubodh R Wasnick75% (4)

- Assessment of Non Revenue Water in District Meter Area DmaDocumento4 pagineAssessment of Non Revenue Water in District Meter Area DmaSekretariat SPSPNessuna valutazione finora

- Game plan to complete well and perforate intervals in Meleiha areasDocumento3 pagineGame plan to complete well and perforate intervals in Meleiha areasMohammed Ali YoussefNessuna valutazione finora

- Wastewater Treatment Plant General Design ChecklistDocumento4 pagineWastewater Treatment Plant General Design ChecklistJeffrey James100% (1)

- Dams in TelanganaDocumento39 pagineDams in TelanganaSamrat PvNessuna valutazione finora

- GREASE, SAND + OIL INTERCEPTORS Inspection Checklist V 1.0 - 201511041303368641Documento4 pagineGREASE, SAND + OIL INTERCEPTORS Inspection Checklist V 1.0 - 201511041303368641bradalbiNessuna valutazione finora

- Membrane Water Treatment Technologies for Clean Water ProductionDocumento22 pagineMembrane Water Treatment Technologies for Clean Water ProductionSnehal Dawkhar patilNessuna valutazione finora

- Process calculation for STP (Township and PlantDocumento30 pagineProcess calculation for STP (Township and PlantKamod RaiNessuna valutazione finora

- RR112 enDocumento8 pagineRR112 enqian heNessuna valutazione finora

- Trex 05106Documento10 pagineTrex 05106OSDocs2012Nessuna valutazione finora

- Main Hydraulic Pump..Documento8 pagineMain Hydraulic Pump..brahim82% (11)

- STP Calculation NS - 2200Documento42 pagineSTP Calculation NS - 2200Anandaraju Saminathan67% (3)

- Marina Square Fire Water TankDocumento1 paginaMarina Square Fire Water TankMalaka KumaraNessuna valutazione finora

- Environmental ProtectionDocumento29 pagineEnvironmental ProtectionMohammad usmanNessuna valutazione finora