Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

AMS M 10.4083 Isolation and Lockout Procedure

Caricato da

gmorkly2916Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

AMS M 10.4083 Isolation and Lockout Procedure

Caricato da

gmorkly2916Copyright:

Formati disponibili

Page 1 of 2 Isolation and Lockout Procedure Document Number: AMS M 10.

4008

Procedure

Procedure for safely and correctly isolating and locking out machines.

CORRECT PPE MUST BE WORN AT ALL TIMES

Purpose:

The purpose of the Isolation and Lockout Procedure is to prevent Fatalities, Injuries and Damage to personnel who work within or near energy source equipments.

Benefit:

The benefit of the Isolation and Lockout Procedure is that it prevents accidents which may occur as a result of people working near energy sources. This procedure is applicable to all AMS sites or any site where AMS personnel are operating. 1. Always wear correct PPE. 2. Always minimize risk. 3. If you are unsure ask your supervisor. 4. Always tell someone where you are working. 5. Watch out for others and warn them of hazards. Standard PPE consists of; 1. Leather steel capped boots. 2. Clear or tinted safety glasses 3. High visibility shirt, coveralls or vest 4. Hard Hat

Scope: Remember

PPE

Procedure: 1. Identify Isolation Requirements by ensuring that you understand the task or job to be performed and make sure all the necessary people are notified that the equipment will be out of service. 2. Register the isolation by recording all required information in the lockout register i.e. the date, time, name of the person using the equipment, registration number of equipment and your signature. 3. Ensure that all relevant energy sources have been identified. 4. Isolate and Lockout all energy sources by ensuring that the isolation switches are in the off position. Check that all required isolation valves are fully closed,

LAST UPDATED 10/12/2005

Page 2 of 2 Isolation and Lockout Procedure Document Number: AMS M 10.4008

Procedure

upstream and downstream of the equipment. Open all drain valves (if applicable) to vent or release any pressure. Check all movable parts are blocked or secured to prevent movement. Fit an isolation lock and Personal Danger tag to each isolation point.

5. Prove the Isolation by ensuring that the authorised person presses the control panel start button or try the ignition switch to see if the equipment has started. Ensure they are fully closed and there is no sign of material flowing out of the drain valve to be sure that the equipment is isolated. 6. Carry out the Work by putting out of service tag on each isolation point and notify the supervisor that work is completed. 7. Re-energise the Equipment by ensuring that the authorised person check that repairs have been completed, guards have been correctly put back in place, tools have been removed, restraints such as pins, blocks and chains have been removed, pipes and hoses have been reconnected, secured, locked and tags have been removed. Related Documents AMS M 10.4001 - Danger Tag Procedure AMS M 10.4002 - Out Of Service Tag Procedure

Approved:

Dated:

LAST UPDATED 10/12/2005

Potrebbero piacerti anche

- Sika Grout 212 215 212hp - MsdsDocumento9 pagineSika Grout 212 215 212hp - MsdsPeralatan Divisi3Nessuna valutazione finora

- Barricade ProcedureDocumento4 pagineBarricade ProcedureSravan PulsarboyNessuna valutazione finora

- 10 5 2013-16-23 Grad HSE Job DescriptionDocumento3 pagine10 5 2013-16-23 Grad HSE Job Descriptionemeka2012Nessuna valutazione finora

- Isolation and Tag Out ProcedureDocumento4 pagineIsolation and Tag Out ProcedurePerwez21Nessuna valutazione finora

- 0104 Sigma Thinner 21-04Documento6 pagine0104 Sigma Thinner 21-04ibrahim_mohamed3361Nessuna valutazione finora

- PSU Energized Electrical Safety ProgramDocumento30 paginePSU Energized Electrical Safety ProgramLeo Boy Veloria CasugoNessuna valutazione finora

- Ract No. (If Applicable) :si Gnature: DateDocumento8 pagineRact No. (If Applicable) :si Gnature: DatetaldienahmadNessuna valutazione finora

- 17 New Slide To Translate VN - JGC Comm TrainingDocumento21 pagine17 New Slide To Translate VN - JGC Comm Trainingsooner123456Nessuna valutazione finora

- Vulcanic Sand MSDSDocumento1 paginaVulcanic Sand MSDSmanthoexNessuna valutazione finora

- PDB PTW 2019 Ra and WL Vol. 1 10-11 Nov 2020Documento255 paginePDB PTW 2019 Ra and WL Vol. 1 10-11 Nov 2020Syed AmzarNessuna valutazione finora

- a-EHS-P-012 Working in Confined Space, Rev. ADocumento7 paginea-EHS-P-012 Working in Confined Space, Rev. ATrio Budi SantosoNessuna valutazione finora

- Hot Work Program PDFDocumento49 pagineHot Work Program PDFAnonymous wtK1AZBiNessuna valutazione finora

- Hazardous Energy Control Procedure: Lockout/Tagout SheetDocumento3 pagineHazardous Energy Control Procedure: Lockout/Tagout SheetPaul HymanNessuna valutazione finora

- Electrical Safety Signs ExplainedDocumento38 pagineElectrical Safety Signs ExplainedNarfred EgarNessuna valutazione finora

- Safety Guidelines For Electrical High VoltageDocumento6 pagineSafety Guidelines For Electrical High VoltageJeck SabarNessuna valutazione finora

- Simplified LOTO ProcedureDocumento8 pagineSimplified LOTO ProcedureLuqman OsmanNessuna valutazione finora

- Task Analysis Form for Proposed Tonnering Facility at Silo 7Documento4 pagineTask Analysis Form for Proposed Tonnering Facility at Silo 7boyettNessuna valutazione finora

- Safety, Health & EnvironmentDocumento60 pagineSafety, Health & EnvironmentGopalakrishnanNessuna valutazione finora

- Requirement and Technical Standard For Non Convention CargoDocumento56 pagineRequirement and Technical Standard For Non Convention CargoAbdul Qudus Abdull RazakNessuna valutazione finora

- 04 Safety and Loss PreventionDocumento4 pagine04 Safety and Loss PreventionThali MagalhãesNessuna valutazione finora

- Hot Work Permit To WorkDocumento3 pagineHot Work Permit To WorkMorris M.Nessuna valutazione finora

- Hot Work PermitDocumento1 paginaHot Work PermitKlyneRamirezNessuna valutazione finora

- Safety ManagerDocumento1 paginaSafety Manageromda4wadyNessuna valutazione finora

- Compressed Gas Cylinders PowerPointDocumento20 pagineCompressed Gas Cylinders PowerPointInspire KharianNessuna valutazione finora

- Root Cause Analysis Example Near Miss Asphalt Drop FULLDocumento9 pagineRoot Cause Analysis Example Near Miss Asphalt Drop FULLnayakya100% (1)

- Can A Water Pump ExplodeDocumento1 paginaCan A Water Pump ExplodeHimanshu ChichraNessuna valutazione finora

- Learning from Incidents: Chronic Unease and Weak SignalsDocumento2 pagineLearning from Incidents: Chronic Unease and Weak SignalsJoel CummingsNessuna valutazione finora

- Golden Rules SafetyDocumento5 pagineGolden Rules SafetyWimboro Galasakti PrabowoNessuna valutazione finora

- Notification of Incident/Hazard: Incident Report Ref: MLE/HSE/IRF/-03Documento3 pagineNotification of Incident/Hazard: Incident Report Ref: MLE/HSE/IRF/-03Abdul-kadiri SulleyNessuna valutazione finora

- JSA PRE-TEST UploadDocumento2 pagineJSA PRE-TEST UploadDenny Kurniawan PrawiraNessuna valutazione finora

- Name: SignDocumento1 paginaName: SignAdel AlKhedawyNessuna valutazione finora

- JSA Formet New Structural Steel FabricationDocumento7 pagineJSA Formet New Structural Steel Fabricationsakthi venkatNessuna valutazione finora

- Fabrication, Installation & Testing of 420m Compressed Air SystemDocumento6 pagineFabrication, Installation & Testing of 420m Compressed Air Systemvishwas salunkheNessuna valutazione finora

- WSH Guidelines Safeguarding Against Falling ObjectsDocumento26 pagineWSH Guidelines Safeguarding Against Falling ObjectsYuki FongNessuna valutazione finora

- Toolbox Talks Personal Protective Equipment English PDFDocumento1 paginaToolbox Talks Personal Protective Equipment English PDFHosamMohamedNessuna valutazione finora

- Annex 3 - Training Needs Analysis ToolDocumento7 pagineAnnex 3 - Training Needs Analysis ToolRamil RaquitNessuna valutazione finora

- Fire Drill Observation SheetDocumento2 pagineFire Drill Observation SheetParashuram PatilNessuna valutazione finora

- 704 Area Vehicle Entry ProcedureDocumento11 pagine704 Area Vehicle Entry ProcedureObominuru Egwonor FestusNessuna valutazione finora

- HSE-F-NEOM-008 - Final Incident-Accident ReportDocumento4 pagineHSE-F-NEOM-008 - Final Incident-Accident ReportAhmed MohamedNessuna valutazione finora

- Jsa Nitrogen Purging PDFDocumento2 pagineJsa Nitrogen Purging PDFBISWA RANJAN SAHOONessuna valutazione finora

- HSE Alert PDFDocumento2 pagineHSE Alert PDFjavariam99Nessuna valutazione finora

- Control of Hazardous EnergiesDocumento15 pagineControl of Hazardous EnergiesMika PelagioNessuna valutazione finora

- Helium MSDSDocumento10 pagineHelium MSDSYaka Fitra PanduNessuna valutazione finora

- Hot Work Permit Presentation SummaryDocumento26 pagineHot Work Permit Presentation SummaryKushan MondalNessuna valutazione finora

- Energy Isolation ProcedureDocumento33 pagineEnergy Isolation Procedure최승원Nessuna valutazione finora

- Appendix E - Monthly Meeting, Kick Off and HSE WorkshopDocumento2 pagineAppendix E - Monthly Meeting, Kick Off and HSE WorkshopNaba majeadNessuna valutazione finora

- JSA - Bolt TensioningDocumento5 pagineJSA - Bolt TensioningRaju KhalifaNessuna valutazione finora

- Lockout Tagout Procedures For GeneratorsDocumento34 pagineLockout Tagout Procedures For GeneratorsMd Rodi Bidin67% (3)

- Fire Protection Equipment Impairment NoticeDocumento1 paginaFire Protection Equipment Impairment NoticeAnonymous wtK1AZBiNessuna valutazione finora

- SAFE520bP - Injury ReportDocumento1 paginaSAFE520bP - Injury ReportMiracle DavidNessuna valutazione finora

- CL #06 CPTW PDFDocumento11 pagineCL #06 CPTW PDFmoNessuna valutazione finora

- PPE TrainingDocumento15 paginePPE TrainingChristopher SkinnerNessuna valutazione finora

- C1729 Is A New ASTM Standard For Aluminum JacketingDocumento2 pagineC1729 Is A New ASTM Standard For Aluminum JacketingTushar Arekar100% (2)

- TBT Press - Test.Documento2 pagineTBT Press - Test.John Vem BansagNessuna valutazione finora

- YmcaDocumento39 pagineYmcaViraj DuaNessuna valutazione finora

- Risk Assessment Plant Room / Boiler House (Access and Carrying Out Maintenance Work - Staff & Contractors)Documento2 pagineRisk Assessment Plant Room / Boiler House (Access and Carrying Out Maintenance Work - Staff & Contractors)Naveenkumar KuppanNessuna valutazione finora

- Workplace Safety A Complete Guide - 2020 EditionDa EverandWorkplace Safety A Complete Guide - 2020 EditionNessuna valutazione finora

- Hazard And Risk Analysis A Complete Guide - 2020 EditionDa EverandHazard And Risk Analysis A Complete Guide - 2020 EditionNessuna valutazione finora

- 0001 Site Road Report Web PDFDocumento53 pagine0001 Site Road Report Web PDFAri CleciusNessuna valutazione finora

- Indian Standard: Mild Steel Wire For General Engineering PurposesDocumento7 pagineIndian Standard: Mild Steel Wire For General Engineering PurposesDevendrasinh PadhiyarNessuna valutazione finora

- Global Positioning System Steering (GPSS) Converter Pilot's Operating HandbookDocumento32 pagineGlobal Positioning System Steering (GPSS) Converter Pilot's Operating HandbookDanielLobatoBernardesNessuna valutazione finora

- ZTE ZXR10 5960&5900E V2.09.10 Ethernet Switch Version Upgrade Guide - R1.0 - 560843Documento42 pagineZTE ZXR10 5960&5900E V2.09.10 Ethernet Switch Version Upgrade Guide - R1.0 - 560843Juan VegaNessuna valutazione finora

- By: Alex Mak, P. Eng. - Senior Field Applications Engineer, Alcan CableDocumento6 pagineBy: Alex Mak, P. Eng. - Senior Field Applications Engineer, Alcan Cablecyrus188Nessuna valutazione finora

- International Journal of Soft Computing and Engineering (IJSCE)Documento1 paginaInternational Journal of Soft Computing and Engineering (IJSCE)DrShiv K SahuNessuna valutazione finora

- Siemens: Procidia™ Control Solutions Selecting Your I - Ware™ V3.0 UpgradeDocumento2 pagineSiemens: Procidia™ Control Solutions Selecting Your I - Ware™ V3.0 UpgradeÁgost VitaNessuna valutazione finora

- Jet EnginesDocumento32 pagineJet EnginesFelichi Dacumos Balajadia50% (2)

- Insulating Firebrick (IFB)Documento2 pagineInsulating Firebrick (IFB)rickidenesNessuna valutazione finora

- Meteorology For OowDocumento130 pagineMeteorology For OowChiazor KevinNessuna valutazione finora

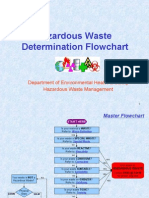

- HW FlowchartDocumento21 pagineHW Flowchartshilabuzz8194Nessuna valutazione finora

- Titan Mare Explorer (TiME) : The First Exploration of An Extra-Terrestrial SeaDocumento15 pagineTitan Mare Explorer (TiME) : The First Exploration of An Extra-Terrestrial SeaIan M MairNessuna valutazione finora

- Curriculum Vitae: Prakriti Kumar GhoshDocumento41 pagineCurriculum Vitae: Prakriti Kumar GhoshaNessuna valutazione finora

- Internal Loadings: External LoadsDocumento13 pagineInternal Loadings: External LoadsMuhammad Adeel AhsenNessuna valutazione finora

- Summative - Chemical ReactionDocumento2 pagineSummative - Chemical ReactionRosalie Tilos Orito67% (3)

- One, Two, Rotational Kinematics (Review)Documento3 pagineOne, Two, Rotational Kinematics (Review)Music LastNessuna valutazione finora

- VG7 Maintenance ManualDocumento18 pagineVG7 Maintenance ManualGustavo RodriguezNessuna valutazione finora

- Professor Course TimetableDocumento25 pagineProfessor Course TimetablesabitavabiNessuna valutazione finora

- Statistical Quality ControlDocumento6 pagineStatistical Quality ControlAtish JitekarNessuna valutazione finora

- NPT16 Transformer ControlDocumento16 pagineNPT16 Transformer ControlElver MesaNessuna valutazione finora

- Extec C12Specs PDFDocumento21 pagineExtec C12Specs PDFRached Douahchua100% (1)

- 3 Re 445 DSL SPC PDFDocumento58 pagine3 Re 445 DSL SPC PDFThomasBaby KavoorazhikathuNessuna valutazione finora

- Control System Components (ICE 3015): Zeroing SynchrosDocumento18 pagineControl System Components (ICE 3015): Zeroing SynchrosmeenasundarNessuna valutazione finora

- Presentation Digitaltwin Pneumatic System ADocumento8 paginePresentation Digitaltwin Pneumatic System ADibya joyNessuna valutazione finora

- QualityStage - Investigate Stage Intro - PR3 Systems BlogDocumento6 pagineQualityStage - Investigate Stage Intro - PR3 Systems BlogMuraliKrishnaNessuna valutazione finora

- WG FM Report Summarizes Key Discussions and DecisionsDocumento41 pagineWG FM Report Summarizes Key Discussions and DecisionsJeandelaSagesseNessuna valutazione finora

- Tutorial - Underfloor Air-ConditioningDocumento8 pagineTutorial - Underfloor Air-ConditioningJasper_HVACNessuna valutazione finora

- JAR 66 Module 1 Propeller Exam PracticeDocumento43 pagineJAR 66 Module 1 Propeller Exam Practicerobija1Nessuna valutazione finora

- DOZCO 1000A NC-PartbookDocumento7 pagineDOZCO 1000A NC-Partbookabu talibNessuna valutazione finora

- A 85 A 0 Module 2 UpDocumento39 pagineA 85 A 0 Module 2 UphimnnnNessuna valutazione finora