Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cigre WG C4303 0

Caricato da

Saturnino42Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cigre WG C4303 0

Caricato da

Saturnino42Copyright:

Formati disponibili

10/03/2010

Cigr WG C4.303

Guide for the selection of insulators with respect to contamination conditions

Chris Engelbrecht: Convener WG C4.303

WG C4.303

Topics:

The selection of insulators with respect to polluted conditions

Present practise Vision of the future

Cigr guidelines Revised IEC 60815

WG C4.303

10/03/2010

Present practise I

Specification of Insulators

Mechanical

Guidance

Electrical

Testing

Ultimate failing load Cantilever load Etc.

IEC 60071 Ins. Co-ord. IEC 60815 Polluted ins.

LIWL (kV) SIWL (kV) Wet a.c. (kV) Creepage(mm)

IEC 60060 Test methods IEC 60507 Pollution tests

WG C4.303

Present practise II

1986 IEC 815 Published:

Much debate Mostly based on small posts Only porcelain and glass Guideline comprised

Simple site severity classification Simple table of creepage distance Correction for diameter Profile limitations

WG C4.303

10/03/2010

Site assessment by example descriptions

Very Light Example Description of Typical Environment > 50 km from any sea, desert, or open dry land > 10 km from man-made pollution sources or within a shorter distance, but: the prevailing wind is not directly from these pollution sources and/or subjected to regular monthly rain washing Light 10-50 km from the sea, a desert, or open dry land 5-10 km from man-made pollution sources or within a shorter distance, but: the prevailing wind is not directly from these pollution sources and/or subjected to regular monthly rain washing Medium 3-10 km from the sea, a desert, or open dry land 1-5 km from man-made pollution sources or within a shorter distance, but: the prevailing wind is not directly from these pollution sources and/or subjected to regular monthly rain washing or further away, but: a dense fog (or drizzle) often occurs after a long dry pollution accumulation season (several weeks or months) and/or heavy rains with a high conductivity occurs and/or there is a high NSDD level, typically between 5 and 10 times the ESDD level Heavy Within 3 km of the sea, a desert, or open dry land Within 1 km of man-made pollution sources or with a greater distance, but: a dense fog (or drizzle) often occurs after a long dry pollution accumulation season (several weeks or months) and/or there is a high NSDD level, typically between 5 and 10 times the ESDD Within the same distance of pollution sources as specified for Heavy areas and: directly subjected to sea-spray or dense saline fog or directly subjected to contaminants with high conductivity, or cement type dust with high density, and with frequent wetting by fog or drizzle Desert areas with fast accumulation of sand and salt, and regular condensation Areas with extreme levels of NSDD, more than 10 times the level of ESDD

Very heavy

WG C4.303

Creepage Distance

Shortest distance along the insulating surface [mm] Up to now

Specific creepage distance [mm/kV] Phase to phase voltage [Uh for equipment]

In future

Unified Specific creepage distance [mm/kV] Voltage across the insulator [norm. Uh /3]

Why this change

Not all insulators are phase to ground

Capacitor banks, phase to phase insulation etc

Direct comparison with Laboratory testing

WG C4.303

10/03/2010

Past IEC 60815 Recommendations

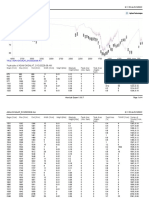

Category Salt Fog ESDD Layer Specific Creepage Unified Specific 2 conductivity [S] [g/l] [mm/kVpp] Creepage [mm/kVpg] [mg/cm ] Light 5 14 0.03 0.06 15 20 16 28 Medium 14 40 0.10 0.20 24 25 20 35 Heavy 40 112 0.30 0.60 > 36 25 43 Very Heavy > 112 > 0.60 31 54

1.4 1.2

Site classification Selection of creepage Correction for diameter

WG C4.303

Correction factor [Kd]

1 0.8 0.6 0.4 0.2 0 0 200 400 600 800 1000

Average Diameter [mm]

Whats wrong with this?

Let us look at past experience.

WG C4.303

10/03/2010

IEC 815 and Line insulators

Unified Specific Creepage Distance (USCD: mm/kV)

60 55 50 45 40 35 30

Generally works well However: Does not cover all insulator shapes Breaks down at high pollution levels

Commonly used Creepage distance requirement

25

Average curve

20

Range of experimental results

15

0.0065 0.01 0.02 0.04 0.065 0.1 0.2 0.4 0.65 1 2

Clean Fog Test (W ithstand SDD: mg/cm 2 )

0.7 1 2 3 5 7 10 20 30 50 70 100

3

200 300

Salt Fog Test (W ithstand Salinity: kg/m )

1.5 2 3 4 6 10 15 20 30 40 60 100 150

W et Contaminant Test (W ithstand Layer conductivity: S)

WG C4.303

IEC 815 and Equipment insulators

100 Unified Specific Creepage distance [mm/kV] 10 1 10 100 1000 Pollution severity [Salt-fog - g/l]

Not as good as for line insulators Important to correct for diameter

WG C4.303

10/03/2010

Why is this so?

You need to look at the flashover mechanism.

WG C4.303

Mechanism

Unit Gets Contaminated: - Dry Contamination non-conductive Unit becomes wet by condensation / absorption: -Wet Contamination conductive current flows - Corona Occurs due to E-field Redistribution Dry Bands Form due to Localized Heating -Where current density is high, e.g. close to pin - Dry Bands can be quenched by high wetting Arcs bridge Dry Bands - Dry bands grow due to heating at arc roots - Arcs extinguish if dry band too large - If wetting critical entire unit flashes

WG C4.303

I V

10/03/2010

SHAPE

Pollution

Type (Solubility)

DIMENSIONS

Voltage

Length Creepage Diameter

Flashover

Washing Wetting

WG C4.303

Form factor HC Wetting Intensity

Surface conductivity

Conclusion

The performance of an insulator is the result of a complex interaction between the insulator and its operating environment.

Every site is an exception: Consider fundamentals

WG C4.303

10/03/2010

Insulation coordination:

AC Systems

8

2.6 p.u 1.8 p.u

Insulation distance, m

7 6 5 4 3 2 1 300 500 700

Pollution Slow-front Lightning

900 1100 1300

Pollution Slow-front Lightning

Maximum system Voltage, kV Pollution based on glass or porcelain

WG C4.303

CIGR Guidelines:

Polluted insulators: A review of current knowledge Technical brochure 158, June 2000. Polluted insulators: Guidelines for selection and dimensioning

Part 1: General principles and the a.c. case Technical brochure 361 Part 2: The d.c. case Still being worked on

WG C4.303

10/03/2010

Cigr Review of current Knowledge

Technical brochure 158 (June 2000)

9 Chapters + Annexes: 185 Pages, 382 references

Introduction Pollution flashover process Insulator characteristics Environmental impact Pollution monitoring Testing procedures Insulator selection and dimensioning Palliatives and mitigation measures Thermal effects on metal oxide arresters

WG C4.303

Cigr AC Guidelines

Technical brochure 361 (June 2008)

General guidelines in Body

Outline of method Simplified statistical with correction factors

Detail technical information in Annex

Worked examples General descriptions of typical environments Site pollution severity assessment Insulator characteristics and correction factors Laboratory test method for polymeric insulators

WG C4.303

10/03/2010

Old insulators

WG C4.303

Observations: No Activity

Back

WG C4.303

Leakage current < 1 mA

10

10/03/2010

Observations: Corona

Back

WG C4.303

Leakage current < 10 mA

Observations: Pulsed scintillation

Back

WG C4.303

Leakage current 10-50 mA

11

10/03/2010

Observations: Continuous scintillation

Back

WG C4.303

Leakage current 40-70 mA

Observations: Pulsed dry-band arcs

Back

WG C4.303

Leakage current 60-100 mA

12

10/03/2010

Observations: Intense dry-band arcing

Back

WG C4.303

Leakage current > 100 mA

Pollution catch:

Function of the aerodynamic shape

weak vortices LowVelocity turbulence vortices weak vortex vortex wind direction wind direction LowVelocity turbulence

Back

WG C4.303

13

10/03/2010

Protected creepage

Protected areas

Back

WG C4.303

Classification of pollution

Active Pollution

(Form a conductive layer)

Inert Pollution

(Influence conductive layer)

Conductive pollution High solubility salts

NaCl, MgCl, NaSO4, etc

Hydrophilic pollution

Kaolin, clay

Hydrophobic Pollution

Silicone grease

Low solubility salts

Gypsum, Fly ash, Cement

Back

WG C4.303

14

10/03/2010

The Form Factor

ESDD Pollution density surface conductivity ( s ) Resistance is given by S 1 1 k dx Rins = s D( x) 0 or 1 Rins = K f

K f :Form factor

Back

WG C4.303

Hydrophobic properties

1 2 3

Back

WG C4.303

15

Potrebbero piacerti anche

- Alpha-Lipoic Acid and Diabetic NeuropathyDocumento7 pagineAlpha-Lipoic Acid and Diabetic NeuropathyPedro Rodriguez PicazoNessuna valutazione finora

- Measurement of Oil in Produced WaterDocumento38 pagineMeasurement of Oil in Produced WaterharlyakbarNessuna valutazione finora

- Cigre 029 Ultra-High-Voltage PDFDocumento88 pagineCigre 029 Ultra-High-Voltage PDFMarcosGodoyPereyraNessuna valutazione finora

- Cigre Publication 559Documento102 pagineCigre Publication 559Javier ChavezNessuna valutazione finora

- En 50216-6 2002Documento15 pagineEn 50216-6 2002Mahmoud ShaheenNessuna valutazione finora

- IMCORP TDR ProcedureDocumento9 pagineIMCORP TDR ProcedurelatifNessuna valutazione finora

- 700 - Web - Centro de Despacho Com AerogeradoresDocumento41 pagine700 - Web - Centro de Despacho Com AerogeradoresAndré SuzukiNessuna valutazione finora

- Final Plant DesignDocumento31 pagineFinal Plant DesignRishya Prava ChatterjeeNessuna valutazione finora

- 511 International Enquiry On Reliability of High Voltage Equipment Part 3 - Disconnectors and Earthing SwitchesDocumento148 pagine511 International Enquiry On Reliability of High Voltage Equipment Part 3 - Disconnectors and Earthing SwitchesepriNessuna valutazione finora

- IEEE Guide C5712200-2022Documento84 pagineIEEE Guide C5712200-2022Sontri ChiggumNessuna valutazione finora

- 513 International Enquiry On Reliability of High Voltage Equipment Part 5 - Gas Insulated Switchgear (GIS) Practices PDFDocumento172 pagine513 International Enquiry On Reliability of High Voltage Equipment Part 5 - Gas Insulated Switchgear (GIS) Practices PDFepri100% (1)

- Partial Discharge PDFDocumento11 paginePartial Discharge PDFMuhammad KashifNessuna valutazione finora

- Electra310-Juin2020 Low PDFDocumento116 pagineElectra310-Juin2020 Low PDFJose CasaisNessuna valutazione finora

- Diagnostic and Testing HV CableDocumento19 pagineDiagnostic and Testing HV CableSISWANTO0% (1)

- Real-Time Simulation Technology for Modern Power ElectronicsDa EverandReal-Time Simulation Technology for Modern Power ElectronicsNessuna valutazione finora

- Neplan Selectivity Analysis v42Documento43 pagineNeplan Selectivity Analysis v42alex100% (1)

- Shotcrete For Tunnel Final Linings Design and Construction ConsiderationsDocumento8 pagineShotcrete For Tunnel Final Linings Design and Construction ConsiderationsDaniel ZabalaNessuna valutazione finora

- 176 Ageing of The System. Impact On PlanningDocumento146 pagine176 Ageing of The System. Impact On Planningemailsepamku gorgomNessuna valutazione finora

- TB345 Alternating Current (Ac) Resistance of Helically Stranded ConductorsDocumento59 pagineTB345 Alternating Current (Ac) Resistance of Helically Stranded ConductorsDenisTarasNessuna valutazione finora

- Emerging Technologies and Material ChallengesDocumento70 pagineEmerging Technologies and Material ChallengesJohn HarlandNessuna valutazione finora

- New Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringDa EverandNew Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringNessuna valutazione finora

- Adverse Drug Reaction FormDocumento2 pagineAdverse Drug Reaction FormAre Pee Etc0% (1)

- Conference Proceedings 2014Documento456 pagineConference Proceedings 2014andersonkreischerNessuna valutazione finora

- Current Interruption Transients CalculationDa EverandCurrent Interruption Transients CalculationValutazione: 4 su 5 stelle4/5 (1)

- Siemens Power Cables Amp Their Applications PDFDocumento240 pagineSiemens Power Cables Amp Their Applications PDFEsteban De la CruzNessuna valutazione finora

- 767 - TBDocumento202 pagine767 - TBJavier A Maureira Calderón100% (1)

- 660Documento160 pagine660Chris ParkinsonNessuna valutazione finora

- Electra309 Avril2020 PDFDocumento146 pagineElectra309 Avril2020 PDFJose CasaisNessuna valutazione finora

- Arc Model PDFDocumento67 pagineArc Model PDFdankorankoNessuna valutazione finora

- Design of Plum Concrete Breast Wall Design Note No: SAI/TKD-219016/PKG-5/DN/STR/BW-04Documento9 pagineDesign of Plum Concrete Breast Wall Design Note No: SAI/TKD-219016/PKG-5/DN/STR/BW-04Rishikesh Majumdar100% (2)

- UHV Transmission TechnologyDa EverandUHV Transmission TechnologyChina Electric Power Research InstituteNessuna valutazione finora

- Ieee std43 2000 PDFDocumento27 pagineIeee std43 2000 PDFGheorghe BogdanNessuna valutazione finora

- Failure of The Collection Volume MethodDocumento10 pagineFailure of The Collection Volume MethodAnonymous V6y1QL6hnNessuna valutazione finora

- Voltage Dip Evaluation AND Prediction Tools: February 2009Documento104 pagineVoltage Dip Evaluation AND Prediction Tools: February 2009K DelverNessuna valutazione finora

- CIGREDocumento6 pagineCIGREGastón MassaferroNessuna valutazione finora

- Technical Report - Internal Arc - OrmazabalDocumento10 pagineTechnical Report - Internal Arc - OrmazabalAshish RanjanNessuna valutazione finora

- TOR-WG+B1 38+After+laying+tests+on+AC+and+DC+cable+systems+with+new+technologiesDocumento2 pagineTOR-WG+B1 38+After+laying+tests+on+AC+and+DC+cable+systems+with+new+technologiesWalter CataldoNessuna valutazione finora

- A2C4 39+Electrical+Transient+InteractionDocumento66 pagineA2C4 39+Electrical+Transient+InteractionicovinyNessuna valutazione finora

- Nexans 500 KV CableDocumento22 pagineNexans 500 KV CableFiras Atwan100% (1)

- Online PD Measurement Using Embedded VDS For 22kV GISDocumento51 pagineOnline PD Measurement Using Embedded VDS For 22kV GISzarchiwin05Nessuna valutazione finora

- Life Extension of Large Electric MotorsDocumento20 pagineLife Extension of Large Electric MotorsPradeep SinghNessuna valutazione finora

- Product Catalogue SomefluDocumento20 pagineProduct Catalogue SomefluIlkuNessuna valutazione finora

- Buhler 2003-Vademecum For Vitamin FormulationsDocumento144 pagineBuhler 2003-Vademecum For Vitamin FormulationsRok Kopinč100% (1)

- International Standard: High-Voltage Test Techniques - General Definitions and Test RequirementsDocumento8 pagineInternational Standard: High-Voltage Test Techniques - General Definitions and Test RequirementssknNessuna valutazione finora

- BS en 50180-1-2015Documento44 pagineBS en 50180-1-2015Rylai CrestfallNessuna valutazione finora

- 321635.CIGRE WG A306 Rio 2008Documento22 pagine321635.CIGRE WG A306 Rio 2008Sukant BhattacharyaNessuna valutazione finora

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsDa EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsNessuna valutazione finora

- CIGRE Green Books: Series Editor Cigre International Council On Large Electric Systems (CIGRE) Paris, FranceDocumento45 pagineCIGRE Green Books: Series Editor Cigre International Council On Large Electric Systems (CIGRE) Paris, FranceEsel DimapilisNessuna valutazione finora

- HV DC PrysmianDocumento32 pagineHV DC PrysmianFiras AtwanNessuna valutazione finora

- International Standard: IEC 62539 IEEE 930Documento9 pagineInternational Standard: IEC 62539 IEEE 930Brisner Acosta ValenciaNessuna valutazione finora

- Extruded Cables For HVDC Power TransmissionDocumento8 pagineExtruded Cables For HVDC Power TransmissionnicesreekanthNessuna valutazione finora

- 110KV BUS BAR SchemeDocumento35 pagine110KV BUS BAR Schememaxwell parassiNessuna valutazione finora

- Seminario de TransformadoresDocumento42 pagineSeminario de TransformadoresMiguelNessuna valutazione finora

- Iec60404 8 7 (Ed3.0) BDocumento42 pagineIec60404 8 7 (Ed3.0) BMor GreenbergNessuna valutazione finora

- Insulation Strength Characteristics: Topics To Be Covered in The FollowingDocumento52 pagineInsulation Strength Characteristics: Topics To Be Covered in The FollowingananizisikimNessuna valutazione finora

- 263 Controlled Closing of HVAC Circuit BreakerDocumento56 pagine263 Controlled Closing of HVAC Circuit BreakerepriNessuna valutazione finora

- Cast Resin Transformer - TrihalDocumento4 pagineCast Resin Transformer - Trihalscribd99190Nessuna valutazione finora

- A 3Documento51 pagineA 3janpol_uniNessuna valutazione finora

- Pfisterer Overhead Line Insulators Silicone InsulatorsDocumento20 paginePfisterer Overhead Line Insulators Silicone InsulatorsthangbinhbkNessuna valutazione finora

- Boosting The Reliability of Power System Models: Dong-Hyeon (DH) KimDocumento4 pagineBoosting The Reliability of Power System Models: Dong-Hyeon (DH) Kimleorese100% (1)

- 2016 CIGRE SC ScopeofWorkDocumento36 pagine2016 CIGRE SC ScopeofWorkaleksandarlaskovNessuna valutazione finora

- Cigre 015Documento23 pagineCigre 015emilioaraNessuna valutazione finora

- Epri Study On Bushing FailureDocumento54 pagineEpri Study On Bushing FailureChandran Muthuswamy100% (1)

- Practical Application of Tan Delta Diagnostic Testing in CablesDocumento7 paginePractical Application of Tan Delta Diagnostic Testing in CablesNouman AsgharNessuna valutazione finora

- CIGRE WG C4.23 - Guide To Procedures For Estimating The Lightning Performance of Transmission LinesDocumento2 pagineCIGRE WG C4.23 - Guide To Procedures For Estimating The Lightning Performance of Transmission Linesqais652002Nessuna valutazione finora

- Electromagnetic Transient Analysis On 500kV and 230kV Ecuador Transmission ProjectDocumento59 pagineElectromagnetic Transient Analysis On 500kV and 230kV Ecuador Transmission ProjectYANDRI PINARGOTE MENENENDEZ100% (2)

- AE Guide PC57.127-D10.0 12-29-06Documento50 pagineAE Guide PC57.127-D10.0 12-29-06Lindbergh キラ MarquezNessuna valutazione finora

- IntelliRupter PulseCloserDocumento24 pagineIntelliRupter PulseCloserThai TranNessuna valutazione finora

- 6RS2 400a TSNDocumento15 pagine6RS2 400a TSNSaad PathanNessuna valutazione finora

- HT14-IM2655 - Lecture 1 PDFDocumento33 pagineHT14-IM2655 - Lecture 1 PDFDiego Manuel Hernández AcostaNessuna valutazione finora

- Accurate Rapid Analysis of Alkali Contents in Portland CementDocumento4 pagineAccurate Rapid Analysis of Alkali Contents in Portland CementyinglvNessuna valutazione finora

- AICE-OQ - Unit-1Documento35 pagineAICE-OQ - Unit-1ramji_kkpNessuna valutazione finora

- A Study On Physico-Chemical Properties of Ground Water Quality of Various Locations of Kanpur CityDocumento3 pagineA Study On Physico-Chemical Properties of Ground Water Quality of Various Locations of Kanpur CityNeerja ShuklaNessuna valutazione finora

- Design of A Pulse Oximeter For Use in MiceDocumento27 pagineDesign of A Pulse Oximeter For Use in MiceIvoan VorchalasNessuna valutazione finora

- Anti Fouling SystemsDocumento3 pagineAnti Fouling SystemsSunny RaghavNessuna valutazione finora

- James B. Anderson - Quantum Chemistry by Random Walk: Higher Accuracy For H +-3Documento5 pagineJames B. Anderson - Quantum Chemistry by Random Walk: Higher Accuracy For H +-3Electro_LiteNessuna valutazione finora

- Papathanassiou - Stephanus of Alexandria Pharmaceutical Notions and Cosmology in His Alchemical WorkDocumento13 paginePapathanassiou - Stephanus of Alexandria Pharmaceutical Notions and Cosmology in His Alchemical WorkJames L. KelleyNessuna valutazione finora

- Off-Centre Anchoring of AZ Sheet Pile WallsDocumento18 pagineOff-Centre Anchoring of AZ Sheet Pile WallsjmmNessuna valutazione finora

- 06 - Measurement of Calcium in Soil Hi-Res PDFDocumento2 pagine06 - Measurement of Calcium in Soil Hi-Res PDFmac neroNessuna valutazione finora

- In Uence of Pre-Gelatinised Maize Starch On The Rheology, Microstructure and Processing of Imitation CheeseDocumento8 pagineIn Uence of Pre-Gelatinised Maize Starch On The Rheology, Microstructure and Processing of Imitation CheeseLina1929Nessuna valutazione finora

- Crumb Rubber Data - October 2021 - AFPADocumento14 pagineCrumb Rubber Data - October 2021 - AFPAAlexandru LetNessuna valutazione finora

- What To Expect When You're Expecting FEA - A Guide To Good PracticeDocumento15 pagineWhat To Expect When You're Expecting FEA - A Guide To Good PracticeSHANMUGAM VNessuna valutazione finora

- Type of Business VentureDocumento3 pagineType of Business VentureSasheen Dela CruzNessuna valutazione finora

- Development of A Standardized Procedure For CleaniDocumento5 pagineDevelopment of A Standardized Procedure For CleanimeiNessuna valutazione finora

- Effective Magnetic MomentDocumento1 paginaEffective Magnetic MomenttfurrowsNessuna valutazione finora

- Metallurgy of Iron and SteelmakingDocumento13 pagineMetallurgy of Iron and SteelmakingAgustine SetiawanNessuna valutazione finora

- Stabilization of Soil by Using Polypropylene FibersDocumento7 pagineStabilization of Soil by Using Polypropylene FibersIJRASETPublicationsNessuna valutazione finora

- Nerve Muscle PhysioDocumento30 pagineNerve Muscle Physiopatel_hanisha06Nessuna valutazione finora

- Asam Oksalat PDFDocumento4 pagineAsam Oksalat PDFfadhilNessuna valutazione finora