Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)

Caricato da

kamalakarsastry1353Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)

Caricato da

kamalakarsastry1353Copyright:

Formati disponibili

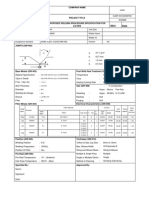

WPS NO.: DATE : PQR NO.

: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 6 6 5.1 E 6013 1 2

ESAB/ADVANI/D&H

SKETCH / DETAIL : 1 (A) : : : : SQ BUTT NO NA SMAW TYPE : MANUAL FIG 1 (A)

To To To To

IS 2062 / EQ. GR.B 1 1

mm mm Filler Size Electrode Flux Type Backing / Storage Consumable Insert : : : : 3.15 mm As per Manuf. Std. None

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

3G UPHILL NA NA NA NA NA NA DC 18 to 30 STRAIGHT 80 TO 140 NA NA NA NA

Position of Fillet

NA

POST WELD HEAT TREATMENT (QW 407) Temperature : NA Time : NA Other : NA Flowrate Gas Backing Purging TECHNIQUE (QW 410) String or weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. Amps Range Volts Range : : : : : : : : : : : : : NA NA NA String / Weaving NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

WELDING PROCEDURE Pass No. Welding Process Filler Material Class E6013 E6013 E6013 Dia 3.15 3.15 3.15 Travel Speed mm / min 85 to 100 90 to 125 90 ot 125

ROOT

SUB. PASS AFTER BACK CHIP

FINAL APPROVAL NAME : SIGNATURE : DATE :

SMAW SMAW SMAW

STRAIGHT 80 to 120 20 to 24 STRAIGHT 90 to 130 24 to 28 STRAIGHT 90 to 130 24 to 28 HINDUSTAN PETROLUEM CORP. LTD

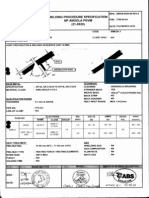

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 6 6 to 8 5.1 E 6013 1 2

ESAB/ADVANI/D&H

SKETCH / DETAIL : 1 (B) : : : : SQ BUTT NO NA SMAW TYPE : MANUAL FIG 1 (B)

To To To To

IS 2062 / EQ. GR.B 1 1

mm mm Filler Size Electrode Flux Type Backing / Storage Consumable Insert : : : : 3.15 / 4 mm As per Manuf. Std. None

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

2G NA NA NA NA NA NA DC 20 to 28 REVERSE 80 TO 140 NA NA NA NA

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. Amps Range Volts Range

NA

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String / Weaving NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

WELDING PROCEDURE Pass No. Welding Process Filler Material Class E6013 E6013 E6013 E6013 Dia 3.15 4 4 4 Travel Speed mm / min 80 to 100 100 to 150 100 ot 150 100 ot 150

ROOT

SUB. PASS AFTER BACK CHIP SUB. PASS

FINAL APPROVAL NAME : SIGNATURE : DATE :

SMAW SMAW SMAW SMAW

STRAIGHT 80 to 115 20 to 24 STRAIGHT 120 to 190 24 to 28 STRAIGHT 120 to 180 24 to 28 120 to 180 24 to 28 STRAIGHT HINDUSTAN PETROLUEM CORP. LTD

Heat Input

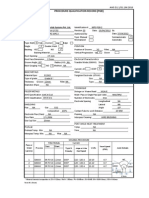

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 10 6 to 20 5.1 E 6013 1 2

ESAB/ADVANI/D&H

SKETCH / DETAIL : 1 (B) : : : : SINGLE "V" NO NA SMAW TYPE : MANUAL FIG 1 (B)

To To To To

IS 2062 / EQ. GR.B 1 1

mm mm Filler Size Electrode Flux Type Backing / Storage Consumable Insert : : : : 3.15 / 4 mm As per Manuf. Std. None

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

3G NA NA NA NA NA NA DC 20 to 28 STRAIGHT 80 TO 140 NA NA NA NA

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. Amps Range Volts Range

NA

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String / Weaving NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

WELDING PROCEDURE Pass No. Welding Process Filler Material Class E6013 E6013 E6013 E6013 Dia 3.15 4 4 4 Travel Speed mm / min 80 to 100 100 to 150 100 ot 150 100 ot 150

ROOT

SUB. PASS AFTER BACK CHIP SUB. PASS

FINAL APPROVAL NAME : SIGNATURE : DATE :

SMAW SMAW SMAW SMAW

STRAIGHT 80 to 115 20 to 24 STRAIGHT 120 to 190 24 to 28 STRAIGHT 120 to 180 24 to 28 STRAIGHT 120 to 180 24 to 28 HINDUSTAN PETROLUEM CORP. LTD

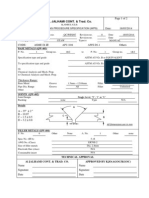

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited MAHUL TERMINAL

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 5 5 5.1 E 6013 1 2

ESAB/ADVANI/D&H

SKETCH / DETAIL : 2 (A) : : : : SQ BUTT NO NA SMAW TYPE : MANUAL FIG 2 (A)

To To To To

IS 2062 / EQ. GR.B 1 1

mm mm Filler Size Electrode Flux Type Backing / Storage Consumable Insert : : : : 3.15 mm As per Manuf. Std. None

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

3G UPHILL NA NA NA NA NA NA DC 18 to 30 STRAIGHT 80 TO 140 NA NA NA NA

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. Amps Range Volts Range

NA

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String / Weaving NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

WELDING PROCEDURE Pass No. Welding Process Filler Material Class E6013 E6013 E6013 Dia 3.15 3.15 3.15 Travel Speed mm / min 85 to 100 90 to 125 90 ot 125

ROOT

SUB. PASS AFTER BACK CHIP

FINAL APPROVAL NAME : SIGNATURE : DATE :

SMAW SMAW SMAW

STRAIGHT 80 to 120 20 to 24 STRAIGHT 90 to 130 24 to 28 STRAIGHT 90 to 130 24 to 28 HINDUSTAN PETROLUEM CORP. LTD

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade : : : SQ BUTT NO NA SMAW IS 2062 / EQ. GR.B 1 1 5 mm 5 mm 5.1 E 6013 1 2

ESAB/ADVANI/D&H

SKETCH / DETAIL : 2(B)

FIG 2 (B)

WELDING PROCESS : BASE METALS (QW 403) Material Specification : Type / Grade No. : P. No. : Group No. : Thick of Coupon : Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

TYPE : MANUAL To To To To IS 2062 / EQ. GR.B 1 1

Filler Size Electrode Flux Type Backing / Storage Consumable Insert

: : : :

3.15 / 4 mm As per Manuf. Std. None

2G NA NA NA NA NA NA DC 20 to 28 STRAIGHT 80 TO 140 NA NA NA NA

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. Amps Range Volts Range

NA

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String / Weaving NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

WELDING PROCEDURE Pass No. Welding Process Filler Material Class E6013 E6013 E6013 E6013 Dia 3.15 4 4 4 Travel Speed mm / min 80 to 100 100 to 150 100 ot 150 100 ot 150

ROOT

SUB. PASS AFTER BACK CHIP SUB. PASS

FINAL APPROVAL NAME : SIGNATURE : DATE :

SMAW SMAW SMAW SMAW

STRAIGHT 80 to 115 20 to 24 STRAIGHT 120 to 180 24 to 28 STRAIGHT 120 to 180 24 to 28 STRAIGHT 120 to 180 24 to 28 HINDUSTAN PETROLUEM CORP. LTD

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 5 5 5.1 E 7018 1 2

ESAB/ADVANI/D&H

SKETCH / DETAIL : 3 : : : : T FILLET NO NA SMAW TYPE : MANUAL FIG 3

To To To To

IS 2062 / EQ. GR.B 1 1

mm mm Filler Size Electrode Flux Type Backing / Storage Consumable Insert : : : : 3.15 / 4 mm As per Manuf. Std. None

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

NA NA NA NA NA NA DC 20 to 28 STRAIGHT 80 TO 180 NA NA NA NA

Position of Fillet

2F

POST WELD HEAT TREATMENT (QW 407) Temperature : NA Time : NA Other : NA Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Amps Range 100 to 135 120 to 190 : : : : : : : : : : : : : NA NA NA String / Weaving NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

WELDING PROCEDURE Pass No. Welding Process Filler Material Class Dia E7018 E7018 3.15 4 Type & Pol. REVERSE REVERSE Volts Range 20 to 24 24 to 28 Travel Speed mm / min 80 to 120 90 to 150

ROOT

SUB. PASS

SMAW SMAW

APPROVAL NAME : SIGNATURE : DATE :

HINDUSTAN PETROLUEM CORP. LTD

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon Thickness Range FILLER MATERIAL (QW 404) Spec. No. (SFA) AWS No. (CLASS) A. No.: F. No.: Make POSITION (QW 405) Position of Groove AWS No. (CLASS) PREHEAT (QW 406) Preheat Temp. (Min) Interpass Temp. (Max) Preheat Maint GAS (QW 408) Shielding Gas Percentage Comp. Trailing ELECTRICAL CHARACTERISTICS (QW Current Mode Volts Electrical Polarity Amperage Tungsten Electrode Size & Type Mode of Metal Transfer (GMAW) Elect. Wire - Feed,Speed,Range Other : : : : : : : : : : : : : : : : : : : 409) : : : : : : : : IS 2062 / EQ. GR.B 1 1 5 5 5.1 E 7018 1 2

ESAB/ADVANI/D&H

SKETCH / DETAIL : 3A : : : : T FILLET NO NA SMAW TYPE : MANUAL FIG 3

To To To To

IS 2062 / EQ. GR.B 1 1

mm mm Filler Size Electrode Flux Type Backing / Storage Consumable Insert : : : : 3.15 / 4 mm As per Manuf. Std. None

NA NA NA NA NA NA DC 20 to 28 STRAIGHT 80 TO 180 NA NA NA NA

Position of Fillet

2F

POST WELD HEAT TREATMENT (QW 407) Temperature : NA Time : NA Other : NA Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Amps Range 100 to 135 120 to 190 120 to 190 120 to 190 : : : : : : : : : : : : : NA NA NA String / Weaving NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

WELDING PROCEDURE Pass No. Welding Process Filler Material Class Dia E7018 E7018 E7018 E7018 3.15 4 4 4 Type & Pol. REVERSE REVERSE REVERSE REVERSE Volts Range 20 to 24 24 to 28 24 to 28 24 to 28 Travel Speed mm / min 80 to 120 90 to 150 90 to 150 90 to 150

ROOT

SUB. PASS ROOT 2 SUB. PASS ROOT 3 SUB. PASS 4 TO 5

SMAW SMAW SMAW SMAW

APPROVAL NAME : SIGNATURE :

HINDUSTAN PETROLUEM CORP. LTD

DATE :

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. : : : : IS 2062 / EQ. GR.B 1 1 8 8 5.1 E 7018 1 2

ESAB/ADVANI/D&H

SKETCH / DETAIL : 4 : : : : T FILLET NO NA SMAW TYPE : MANUAL FIG 4

To To To To

IS 2062 / EQ. GR.B 1 1

Thick of Coupon : Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

mm mm Filler Size Electrode Flux Type Backing / Storage Consumable Insert : : : : 3.15 / 4 mm As per Manuf. Std. None

NA NA NA NA NA NA DC 20 to 28 STRAIGHT 80 TO 180 NA NA NA NA

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. REVERSE REVERSE REVERSE REVERSE REVERSE REVERSE Amps Range 100 to 135 120 to 190 120 to 190 100 to 135 120 to 190 120 to 190 Volts Range 20 to 24 24 to 28 24 to 28 20 to 24 24 to 28 24 to 28

2F

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String / Weaving NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

WELDING PROCEDURE Pass No. INSIDE ROOT

SUB. PASS (2) SUB. PASS (3)

Welding Process

Filler Material Class E7018 E7018 E7018 E7018 E7018 E7018 Dia 3.15 4 4 3.15 4 4

Travel Speed mm / min 80 to 120 90 to 150 90 to 150 90 to 120 100 to 150 100 to 150

SMAW SMAW SMAW SMAW SMAW SMAW

OUTSIDE 1ST PASS

SUB. PASS (2) FINAL (3)

APPROVAL NAME : SIGNATURE :

HINDUSTAN PETROLUEM CORP. LTD

DATE :

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. : : : : IS 2062 / EQ. GR.B 1 1 12 mm 12 to 24 mm 5.1 E 7018 1 2

ESAB/ADVANI/D&H

SKETCH / DETAIL : 4 : : : : DOUBLE "V" NO NA SMAW TYPE : MANUAL FIG 4

To To To To

IS 2062 / EQ. GR.B 1 1

Thick of Coupon : Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

Filler Size Electrode Flux Type Backing / Storage Consumable Insert

: : : :

3.15 / 4 mm As per Manuf. Std. None

3G NA NA NA NA NA NA DC 20 to 28 REVERSE 80 TO 180 NA NA NA NA

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. REVERSE REVERSE REVERSE REVERSE REVERSE REVERSE Amps Range 100 to 135 120 to 190 120 to 190 100 to 135 120 to 190 120 to 190 Volts Range 20 to 24 24 to 28 24 to 28 20 to 24 24 to 28 24 to 28

2F

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String / Weaving NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

WELDING PROCEDURE Pass No. INSIDE ROOT

SUB. PASS (2) SUB. PASS (3)

Welding Process

Filler Material Class E7018 E7018 E7018 E7018 E7018 E7018 Dia 3.15 4 4 3.15 4 4

Travel Speed mm / min 80 to 120 90 to 150 90 to 150 90 to 120 100 to 150 100 to 150

SMAW SMAW SMAW SMAW SMAW SMAW

BACK SIDE 1ST PASS

SUB. PASS (2) FINAL (3)

APPROVAL NAME : SIGNATURE :

VISHAL STRUCTURALS PVT. LTD.

HINDUSTAN PETROLUEM CORP. LTD

DATE :

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade : : : SQUARE BUTT WITH BACKING STRIP & FILLET YES NA SMAW IS 2062 / EQ. GR.B 1 1 12 mm 12 to 16 mm 5.1 E 7018 1 4

ESAB/ADVANI/D&H

SKETCH / DETAIL : 5

FIG

WELDING PROCESS : BASE METALS (QW 403) Material Specification : Type / Grade No. : P. No. : Group No. : Thick of Coupon : Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

TYPE : MANUAL To To To To IS 2062 / EQ. GR.B 1 1

Filler Size Electrode Flux Type Backing / Storage Consumable Insert

: : : :

3.15 / 4 mm As per Manuf. Std. None

1G NA NA NA NA NA NA DC 20 to 28 REVERSE 90 TO 190 NA NA NA NA

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. Amps Range Volts Range

2F

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

WELDING PROCEDURE Pass No. Welding Process Filler Material Class E7018 E7018 E7018 E7018 Dia 3.15 4 4 3.15 Travel Speed mm / min 90 to 120 100 to 150 100 to 150 90 ot 120

ROOT (1,2)

SUB. PASS (3) SUB. PASS (4)

FINAL (5,6) APPROVAL NAME : SIGNATURE : DATE :

SMAW SMAW SMAW SMAW

100 to 135 20 to 24 REVERSE REVERSE 120 to 190 24 to 28 REVERSE 120 to 190 24 to 28 REVERSE 100 to 135 20 to 24 HINDUSTAN PETROLUEM CORP. LTD

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade : : : LAP FILLET NO NA SMAW IS 2062 / EQ. GR.B 1 1 10 mm 10 to 16 mm 5.1 E 6013 1 2

ESAB/ADVANI/D&H

SKETCH / DETAIL : 6

FIG

WELDING PROCESS : BASE METALS (QW 403) Material Specification : Type / Grade No. : P. No. : Group No. : Thick of Coupon : Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

TYPE : MANUAL To To To To IS 2062 / EQ. GR.B 1 1

Filler Size Electrode Flux Type Backing / Storage Consumable Insert

: : : :

3.15 / 4 mm As per Manuf. Std. None

NA NA NA NA NA NA DC 20 to 28

Electrode-Straight

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. Amps Range Volts Range

2F

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

90 TO 190 NA NA NA NA

WELDING PROCEDURE Pass No. Welding Process Filler Material Class E6013 E6013 E6013 Dia 3.15 4 4 Travel Speed mm / min 80 to 120 90 to 150 90 ot 150

ROOT

SUB. PASS

FINAL APPROVAL NAME : SIGNATURE : DATE :

SMAW SMAW SMAW

STRAIGHT 80 to 120 20 to 24 STRAIGHT 90 to 190 24 to 28 STRAIGHT 90 to 190 24 to 28 HINDUSTAN PETROLUEM CORP. LTD

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited MAHUL TERMINAL

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 12 mm To To To To IS 2062 / EQ. GR.B 1 1 : : : : LAP FILLET NO NA SMAW TYPE : MANUAL

SKETCH / DETAIL : 7

FIG

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

12 to 16 mm 5.1 E 7018 1 4

ESAB/ADVANI/D&H

Filler Size Electrode Flux Type Backing / Storage Consumable Insert

: : : :

3.15 / 4 mm As per Manuf. Std. None

NA NA NA NA NA NA DC 20 to 28

Electrode-Straight

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. Amps Range Volts Range

2F

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

90 TO 190 NA NA NA NA

WELDING PROCEDURE Pass No. Welding Process Filler Material Class E7018 E7018 E7018 Dia 3.15 4 4 Travel Speed mm / min 80 to 120 90 to 150 90 ot 150

ROOT (1)

SUB. PASS (2)

FINAL (3,4) APPROVAL NAME : SIGNATURE : DATE :

SMAW SMAW SMAW

REVERSE 80 to 120 20 to 24 REVERSE 90 to 190 24 to 28 REVERSE 90 to 190 24 to 28 HINDUSTAN PETROLUEM CORP. LTD

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 6 6 5.1 E 7018 1 2

ESAB/ADVANI/D&H

SKETCH / DETAIL : 8 : : : : T FILLET NO NA SMAW TYPE : MANUAL FIG 8

To To To To

IS 2062 / EQ. GR.B 1 1

mm mm Filler Size Electrode Flux Type Backing / Storage Consumable Insert : : : : 3.15 / 4 mm As per Manuf. Std. None

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

NA NA NA NA NA NA DC 20 to 28

Electrode-Straight

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. REVERSE REVERSE Amps Range 100 to 135 90 to 190 Volts Range 20 to 24 24 to 28

2F

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

80 TO 180 NA NA NA NA

WELDING PROCEDURE Pass No. Welding Process Filler Material Class E7018 E7018 Dia 3.15 4 Travel Speed mm / min 80 to 120 90 to 150

ROOT

SUB. PASS

SMAW SMAW

APPROVAL NAME : SIGNATURE : DATE :

HINDUSTAN PETROLUEM CORP. LTD

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited MAHUL TERMINAL

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 6 6 5.1 E 6013 1 2

ESAB/ADVANI/D&H

SKETCH / DETAIL : 9 : : : : T FILLET NO NA SMAW TYPE : MANUAL FIG 9

To To To To

IS 2062 / EQ. GR.B 1 1

mm mm Filler Size Electrode Flux Type Backing / Storage Consumable Insert : : : : 3.15 / 4 mm As per Manuf. Std. None

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

NA NA NA NA NA NA DC 20 to 28

Straight

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. STRAIGHT STRAIGHT STRAIGHT STRAIGHT Amps Range 80 to 120 90 to 190 80 to 120 90 to 190 Volts Range 20 to 24 24 to 28 20 to 24 24 to 28

2F

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

80 TO 180 NA NA NA NA

WELDING PROCEDURE Pass No. ONE SIDE CONT. ROOT (1) Welding Process Filler Material Class E6013 E6013 E6013 E6013 Dia 3.15 4 3.15 4 Travel Speed mm / min 80 to 120 90 to 150 80 to 120 90 to 150

SMAW SMAW 2nd STITCH FILLET 100 (100) 100 ROOT (1) SMAW SUB. PASS (2) SMAW

SUB. PASS (2)

APPROVAL NAME : SIGNATURE : DATE :

HINDUSTAN PETROLUEM CORP. LTD

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 5 5 5.1 E 6013 1 2

ESAB/ADVANI/D&H

SKETCH / DETAIL : 10 (A) : : : : LAP FILLET NO NA SMAW TYPE : MANUAL FIG 10 (A)

To To To To

IS 2062 / EQ. GR.B 1 1

mm mm Filler Size Electrode Flux Type Backing / Storage Consumable Insert : : : : 3.15 / 4 mm As per Manuf. Std. None

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

NA NA NA NA NA NA DC 20 to 28

Straight

Position of Fillet

2F

POST WELD HEAT TREATMENT (QW 407) Temperature : Time : Other : Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. STRAIGHT STRAIGHT Amps Range 80 to 120 90 to 190 Volts Range 20 to 24 24 to 28 : : : : : : : : : : : : :

NA NA NA NA NA NA String NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

80 TO 180 NA NA NA NA

WELDING PROCEDURE Pass No. Welding Process Filler Material Class E6013 E6013 Dia 3.15 4 Travel Speed mm / min 80 to 120 90 to 150

ROOT (1)

SUB. PASS (2)

SMAW SMAW

APPROVAL NAME : SIGNATURE : DATE :

HINDUSTAN PETROLUEM CORP. LTD

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 6 6 5.1 E 6013 1 2

ESAB/ADVANI/D&H

SKETCH / DETAIL : 10 (B) : : : : LAP FILLET NO NA SMAW TYPE : MANUAL FIG 10 (B)

To To To To

IS 2062 / EQ. GR.B 1 1

mm mm Filler Size Electrode Flux Type Backing / Storage Consumable Insert : : : : 3.15 / 4 mm As per Manuf. Std. None

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

NA NA NA NA NA NA DC 20 to 28

Straight

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. STRAIGHT STRAIGHT Amps Range 80 to 120 90 to 190 Volts Range 20 to 24 24 to 28

2F

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

80 TO 180 NA NA NA NA

WELDING PROCEDURE Pass No. Welding Process Filler Material Class E6013 E6013 Dia 3.15 4 Travel Speed mm / min 80 to 120 90 to 150

ROOT (1)

SUB. PASS (2)

SMAW SMAW

APPROVAL NAME : SIGNATURE : DATE :

HINDUSTAN PETROLUEM CORP. LTD

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 5 5 5.1 E 6013 1 2

ESAB/ADVANI/D&H

SKETCH / DETAIL : 11 : : : : T FILLET NO NA SMAW TYPE : MANUAL FIG 11

To To To To

IS 2062 / EQ. GR.B 1 1

mm mm Filler Size Electrode Flux Type Backing / Storage Consumable Insert : : : : 3.15 / 4 mm As per Manuf. Std. None

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

NA NA NA NA NA NA DC 20 to 28

Straight

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. STRAIGHT STRAIGHT STRAIGHT STRAIGHT Amps Range 80 to 120 90 to 190 80 to 120 90 to 190 Volts Range 20 to 24 24 to 28 20 to 24 24 to 28

3F

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

80 TO 180 NA NA NA NA

WELDING PROCEDURE Pass No. ONE SIDE CONT. ROOT (1) Welding Process Filler Material Class E6013 E6013 E6013 E6013 Dia 3.15 3.15 3.15 3.15 Travel Speed mm / min 80 to 120 90 to 150 80 to 120 90 to 150

SMAW SMAW 2nd SITCH FILLET 100 (100) 100 ROOT (1) SMAW SUB. PASS (2) SMAW

SUB. PASS (2)

APPROVAL NAME : SIGNATURE : DATE :

VISHAL STRUCTURALS PVT. LTD.

HINDUSTAN PETROLUEM CORP. LTD

Note : 1) For 5mm to 16mm joint separate WPS has to be made using E7018 Rod 2) Inner joint bulk head shall have doublers plate

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 16 5 to 16 5.1 E 7018 1 4

ESAB/ADVANI/D&H

SKETCH / DETAIL : 7 : : : : LAP FILLET NO NA SMAW TYPE : MANUAL FIG 7

To To To To

IS 2062 / EQ. GR.B 1 1

mm mm Filler Size Electrode Flux Type Backing / Storage Consumable Insert : : : : 3.15 / 4 mm As per Manuf. Std. None

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

NA NA NA NA NA NA DC 20 to 28

Electrode-Straight

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. Amps Range Volts Range

2F

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

90 TO 190 NA NA NA NA

WELDING PROCEDURE Pass No. Welding Process Filler Material Class Dia Travel Speed mm / min

SMAW SMAW 2nd SITCH FILLET 100 (100) 100 ROOT (1) SMAW SUB. PASS (2) SMAW

SUB. PASS (2)

ONE SIDE CONT. ROOT (1)

E6013 E6013 E6013 E6013

3.15 3.15 3.15 3.15

STRAIGHT STRAIGHT STRAIGHT STRAIGHT

80 to 120 90 to 190 80 to 120 90 to 190

20 to 24 24 to 28 20 to 24 24 to 28

80 to 120 90 to 150 80 to 120 90 to 150

APPROVAL NAME :

VISHAL STRUCTURALS PVT. LTD.

HINDUSTAN PETROLUEM CORP. LTD

SIGNATURE : DATE :

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 5 5 5.1 E 6013 1 2

ESAB/ADVANI/D&H

SKETCH / DETAIL : 12 : : : : T FILLET NO NA SMAW TYPE : MANUAL FIG 12

To To To To

IS 2062 / EQ. GR.B 1 1

mm mm Filler Size Electrode Flux Type Backing / Storage Consumable Insert : : : : 3.15 / 4 mm As per Manuf. Std. None

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

NA NA NA NA NA NA DC 20 to 28

Straight

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. STRAIGHT STRAIGHT Amps Range 80 to 120 90 to 190 Volts Range 20 to 24 24 to 28

2F

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

80 TO 180 NA NA NA NA

WELDING PROCEDURE Pass No. Welding Process Filler Material Class E6013 E6013 Dia 3.15 4 Travel Speed mm / min 80 to 120 90 to 150

ROOT (1)

SUB. PASS (2)

SMAW SMAW

APPROVAL NAME :

VISHAL STRUCTURALS PVT. LTD.

HINDUSTAN PETROLUEM CORP. LTD

SIGNATURE : DATE :

Note : Submit separate WPS for Bulkhead to Pontoon top / Deck top welding

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited MAHUL TERMINAL

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 6 6 5.1 E 7018 1 4

ESAB/ADVANI/D&H

SKETCH / DETAIL : 13 : : : : T FILLET NO NA SMAW TYPE : MANUAL FIG 13

To To To To

IS 2062 / EQ. GR.B 1 1

mm mm Filler Size Electrode Flux Type Backing / Storage Consumable Insert : : : : 3.15 / 4 mm As per Manuf. Std. None

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

NA NA NA NA NA NA DC 20 to 28

Straight

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. REVERSE REVERSE REVERSE REVERSE Amps Range 100 to 135 130 to 190 100 to 135 130 to 190 Volts Range 20 to 24 24 to 28 20 to 24 24 to 28

2F

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

80 TO 180 NA NA NA NA

WELDING PROCEDURE Pass No. INSIDE ROOT (1)

SUB. PASS (2)

Welding Process

Filler Material Class E7018 E7018 E7018 E7018 Dia 3.15 4 3.15 4

Travel Speed mm / min 80 to 120 90 to 150 80 to 120 90 to 150

SMAW SMAW SMAW SMAW

OUTSIDE ROOT (1)

SUB. PASS (2)

APPROVAL NAME : SIGNATURE :

HINDUSTAN PETROLUEM CORP. LTD

DATE :

Note : Joint at the point where Outer rim & Lap of Bottom Deck plate meet shall be like a) Bottom deck has to be made Sq Butt joint for 100 mm length WPS Pg (a) should be submitted separately Hence Joggly not needed

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 6 6 5.1 E 6013 1 2

ESAB/ADVANI/D&H

SKETCH / DETAIL : 14 : : : `` T FILLET NO NA SMAW TYPE : MANUAL FIG 14

To To To To

IS 2062 / EQ. GR.B 1 1

mm mm Filler Size Electrode Flux Type Backing / Storage Consumable Insert : : : : 3.15 / 4 mm As per Manuf. Std. None

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

NA NA NA NA NA NA DC 20 to 28

Straight

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. STRAIGHT STRAIGHT STRAIGHT STRAIGHT Amps Range 80 to 120 90 to 190 80 to 120 90 to 190 Volts Range 20 to 24 24 to 28 20 to 24 24 to 28

2F

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

80 TO 180 NA NA NA NA

WELDING PROCEDURE Pass No. ONE SIDE CONT. ROOT (1) Welding Process Filler Material Class E6013 E6013 E6013 E6013 Dia 3.15 4 3.15 4 Travel Speed mm / min 80 to 120 90 to 150 80 to 120 90 to 150

SMAW SMAW 2nd STITCH FILLET 100 (100) 100 ROOT (1) SMAW SUB. PASS (2) SMAW

SUB. PASS (2)

APPROVAL NAME :

HINDUSTAN PETROLUEM CORP. LTD

SIGNATURE :

DATE :

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 16 16 5.1 E 7018 1 4

ESAB/ADVANI/D&H

SKETCH / DETAIL : 15 : : : : DOUBLE V BUTT NO NA SMAW TYPE : MANUAL FIG 15

To To To To

IS 2062 / EQ. GR.B 1 1

mm mm Filler Size Electrode Flux Type Backing / Storage Consumable Insert : : : : 3.15 mm As per Manuf. Std. None

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

3G UPHILL NA NA NA NA NA NA DC 20 to 28

Straight

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. REVERSE REVERSE REVERSE REVERSE REVERSE Amps Range 80 to 120 90 to 130 90 to 130 90 to 130 90 to 130 Volts Range 20 to 24 24 to 28 24 to 28 24 to 28 24 to 28

NA

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String / Weaving NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

80 TO 130 NA NA NA NA

WELDING PROCEDURE Pass No. Welding Process Filler Material Class E7018 E7018 E7018 E7018 E7018 Dia 3.15 3.15 3.15 3.15 3.15 Travel Speed mm / min 80 to 100 90 to 125 90 to 125 90 to 125 90 to 125

ROOT (1)

SUB. PASS (2) SUB. PASS (3,4)

SMAW SMAW SMAW SMAW SMAW

AFTER BACK CHIP 1ST PASS

FINAL

APPROVAL NAME : SIGNATURE :

VISHAL STRUCTURALS PVT. LTD.

HINDUSTAN PETROLUEM CORP. LTD

DATE :

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited MAHUL TERMINAL

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 5 5 5.1 E 6013 1 2

ESAB/ADVANI/D&H

SKETCH / DETAIL : 16 : : : `` LAP FILLET NO NA SMAW TYPE : MANUAL FIG 16

To To To To

IS 2062 / EQ. GR.B 1 1

mm mm Filler Size Electrode Flux Type Backing / Storage Consumable Insert : : : : 3.15 / 4 mm As per Manuf. Std. None

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

NA NA NA NA NA NA DC 20 to 28

Electrode-Straight

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. STRAIGHT STRAIGHT Amps Range 80 to 120 90 to 190 Volts Range 20 to 24 24 to 28

2F

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

80 TO 180 NA NA NA NA

WELDING PROCEDURE Pass No. Welding Process Filler Material Class E6013 E6013 Dia 3.15 4 Travel Speed mm / min 80 to 120 90 to 150

ROOT (1)

SUB. PASS (2)

SMAW SMAW

APPROVAL NAME : SIGNATURE : DATE :

HINDUSTAN PETROLUEM CORP. LTD

Note : L 75 X 75 X 8 only has to be used

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 5 5 5.1 E 7018 1 4

ESAB/ADVANI/D&H

SKETCH / DETAIL : 17 : : : : T FILLET NO NA SMAW TYPE : MANUAL FIG 17

To To To To

IS 2062 / EQ. GR.B 1 1

mm mm Filler Size Electrode Flux Type Backing / Storage Consumable Insert : : : : 3.15 mm As per Manuf. Std. None

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

NA NA NA NA NA NA DC 20 to 28

Straight

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. REVERSE REVERSE REVERSE REVERSE Amps Range 80 to 120 90 to 190 80 to 120 90 to 190 Volts Range 20 to 24 24 to 28 20 to 24 24 to 28

3F

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String / Weaving NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

80 TO 180 NA NA NA NA

WELDING PROCEDURE Pass No. ONE SIDE CONT. ROOT (1) Welding Process Filler Material Class Dia 3.15 3.15 3.15 3.15 Travel Speed mm / min 80 to 120 90 to 150 80 to 120 90 to 150

SMAW E7018 SMAW E7018 2ND SIDE STITCH FILLET 100 (100) 100 ROOT (1) SMAW E7018 SUB. PASS (2) SMAW E7018

SUB. PASS (2)

APPROVAL NAME : SIGNATURE : DATE :

HINDUSTAN PETROLUEM CORP. LTD

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 10 mm To To To To IS 2062 / EQ. GR.B 1 1 : : : : Single V Full Pen Butt Joint NO Chip Back to Sound metal & reweld SMAW TYPE : MANUAL

SKETCH / DETAIL : 18

FIG 18

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

1.76 to 20 mm

5.1 E 6013 1 2

ESAB/ADVANI/D&H

Filler Size Electrode Flux Type Backing / Storage Consumable Insert

: : : :

3.15 mm As per Manuf. Std. None

3G UPHILL NA NA NA NA NA NA DC 18 to 20

Electrode - Negative

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. STRAIGHT STRAIGHT STRAIGHT STRAIGHT STRAIGHT STRAIGHT Amps Range 90 to 95 90 to 95 100 to 120 90 to 95 90 to 95 100 to 120 Volts Range 22 to 24 18 to 20 18 to 20 22 to 24 18 to 20 22 to 24

NA

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String / Weaving NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm 0.275 0.238 0.238 0.275 0.238 0.275

100 TO 120 NA NA NA NA

WELDING PROCEDURE Pass No. Welding Process Filler Material Class E6013 E6013 E6013 E6013 E6013 E6013 Dia 3.15 3.15 4 3.15 3.15 4 Travel Speed mm / min 65 to 90 85 to 90 85 to 90 65 to 90 85 to 90 65 to 90

ROOT

HOT PASS FILLING CAPPING

SMAW SMAW SMAW SMAW SMAW SMAW

AFTER BACK CHIP SUB PASS

FINAL

APPROVAL NAME : SIGNATURE : DATE :

HINDUSTAN PETROLUEM CORP. LTD

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 5 5 5.1 E 6013 1 2

ESAB/ADVANI/D&H

SKETCH / DETAIL : 19 : : : `` T FILLET NO NA SMAW TYPE : MANUAL FIG 19

To To To To

IS 2062 / EQ. GR.B 1 1

mm mm Filler Size Electrode Flux Type Backing / Storage Consumable Insert : : : : 3.15 / 4 mm As per Manuf. Std. None

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

NA NA NA NA NA NA DC 20 to 28

Straight

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. STRAIGHT STRAIGHT Amps Range 80 to 120 90 to 190 Volts Range 20 to 24 24 to 28

2F

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

80 TO 180 NA NA NA NA

WELDING PROCEDURE Pass No. Welding Process Filler Material Class E6013 E6013 Dia 3.15 4 Travel Speed mm / min 80 to 120 90 to 150

ROOT (1)

SUB. PASS (2)

SMAW SMAW

APPROVAL NAME : SIGNATURE : DATE :

HINDUSTAN PETROLUEM CORP. LTD

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 12 mm To To To To IS 2062 / EQ. GR.B 1 1 : : : : SQUARE BUTT WITH BACKING STRIP YES NA SMAW TYPE : MANUAL

SKETCH / DETAIL : 20

FIG

20

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

12 to 16 mm 5.1 E 7018 1 4

ESAB/ADVANI/D&H

Filler Size Electrode Flux Type Backing / Storage Consumable Insert

: : : :

3.15 / 4 mm As per Manuf. Std. None

NA NA NA NA NA NA DC 20 to 28 REVERSE 90 TO 190 NA NA NA NA

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. Amps Range Volts Range

2F

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

WELDING PROCEDURE Pass No. Welding Process Filler Material Class E7018 E7018 E7018 E7018 Dia 3.15 4 4 3.15 Travel Speed mm / min 90 to 120 100 to 150 100 to 150 90 ot 120

ROOT (1,2)

SUB. PASS (3) SUB. PASS (4)

FINAL (5,6) APPROVAL NAME : SIGNATURE : DATE :

SMAW SMAW SMAW SMAW

REVERSE 100 to 135 20 to 24 REVERSE 120 to 190 24 to 28 REVERSE 120 to 190 24 to 28 REVERSE 100 to 135 20 to 24 HINDUSTAN PETROLUEM CORP. LTD

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade : : : SQUARE BUTT W/BACKING PLT. FOR COD YES NA SMAW IS 2062 / EQ. GR.B 1 1 12 mm 12 to 16 mm 5.1 E 7018 1 4

ESAB/ADVANI/D&H

SKETCH / DETAIL : 21

FIG

21

WELDING PROCESS : BASE METALS (QW 403) Material Specification : Type / Grade No. : P. No. : Group No. : Thick of Coupon : Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

TYPE : MANUAL To To To To IS 2062 / EQ. GR.B 1 1

Filler Size Electrode Flux Type Backing / Storage Consumable Insert

: : : :

3.15 / 4 mm As per Manuf. Std. None

1G NA NA NA NA NA NA DC 20 to 28 REVERSE 90 TO 190 NA NA NA NA

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. Amps Range Volts Range

: 407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA

String NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

WELDING PROCEDURE Pass No. Welding Process Filler Material Class E7018 E7018 E7018 E7018 Dia 3.15 4 4 3.15 Travel Speed mm / min 90 to 120 100 to 150 100 to 150 90 ot 120

ROOT (1,2)

SUB. PASS (3) SUB. PASS (4)

FINAL (5 TO 10) APPROVAL

SMAW SMAW SMAW SMAW

REVERSE 100 to 135 20 to 24 REVERSE 120 to 190 24 to 28 REVERSE 120 to 190 24 to 28 REVERSE 100 to 135 20 to 24 HINDUSTAN PETROLUEM CORP. LTD

NAME :

SIGNATURE : DATE :

Note : WPS for 10mm to insert plate joint should be submitted separately

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade : : : SQUARE BUTT W/BACKING PLT. FOR COD YES NA SMAW IS 2062 / EQ. GR.B 1 1 12 mm 12 to 16 mm 5.1 E 7018 1 4

ESAB/ADVANI/D&H

SKETCH / DETAIL : 22

WELDING PROCESS : BASE METALS (QW 403) Material Specification : Type / Grade No. : P. No. : Group No. : Thick of Coupon : Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

TYPE : MANUAL To To To To IS 2062 / EQ. GR.B 1 1

ANNULAR TO CLEAN OUT BOTTOM JOINT

Filler Size Electrode Flux Type Backing / Storage Consumable Insert

: : : :

3.15 / 4 mm As per Manuf. Std. None

1G NA NA NA NA NA NA DC 20 to 28 REVERSE 90 TO 190 NA NA NA NA

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. Amps Range Volts Range

: 407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA

String NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

WELDING PROCEDURE Pass No. Welding Process Filler Material Class E7018 E7018 E7018 Dia 3.15 4 3.15 Travel Speed mm / min 90 to 120 100 to 150 90 ot 120

ROOT (1)

SUB. PASS (2)

FINAL (3 TO 4) APPROVAL

SMAW SMAW SMAW

100 to 135 20 to 24 REVERSE REVERSE 120 to 190 24 to 28 REVERSE 100 to 135 20 to 24 HINDUSTAN PETROLUEM CORP. LTD

NAME :

SIGNATURE : DATE :

Note : WPS for 10mm to insert plate joint should be submitted separately

WPS NO.: DATE : PQR NO.: CLIENT : LOCATION : Hindustan Petroleum Corporation Limited MAHUL TERMINAL

WPS-VSPL-026- REV 0

11.11.2009

PQR-VSPL- REV 0

QW-482 - WELDING PROCEDURE SPECIFICATION

(REF. SPECIFICATION : ASME SECTION IX)

JOINT DESIGN (QW 402) Type Backing Backing Material Type / Grade WELDING PROCESS BASE METALS (QW 403) Material Specification Type / Grade No. P. No. Group No. Thick of Coupon : : : : : IS 2062 / EQ. GR.B 1 1 6 6 5.1 E 6013 1 2

ESAB/ADVANI/D&H

SKETCH / DETAIL : 23 : : : : T FILLET NO NA SMAW TYPE : MANUAL FIG 9

To To To To

IS 2062 / EQ. GR.B 1 1

mm mm OUTER RIM TO BOTTOM DECK LAP JOINT Filler Size Electrode Flux Type Backing / Storage Consumable Insert : : : : 3.15 / 4 mm As per Manuf. Std. None

Thickness Range : FILLER MATERIAL (QW 404) Spec. No. (SFA) : AWS No. (CLASS) : A. No.: : F. No.: : Make : POSITION (QW 405) Position of Groove : AWS No. (CLASS) : PREHEAT (QW 406) Preheat Temp. (Min) : Interpass Temp. (Max) : Preheat Maint : GAS (QW 408) Shielding Gas : Percentage Comp. : Trailing : ELECTRICAL CHARACTERISTICS (QW 409) Current Mode : Volts : Electrical Polarity : Amperage : Tungsten Electrode Size & Type : Mode of Metal Transfer (GMAW) : Elect. Wire - Feed,Speed,Range : Other :

NA NA NA NA NA NA DC 20 to 28

Straight

Position of Fillet POST WELD HEAT TREATMENT (QW Temperature Time Other Flowrate Gas Backing Purging TECHNIQUE (QW 410) String of weave Bead Orifice or Gas Cup Size Initial / Interpass Cleaning Method of back gauging Oscillation Contact Tube to work distance Multiple of Single Pass (/ side) Multiple of Single Electrode Travel Speed Range Peening Current & Voltage Type & Pol. STRAIGHT STRAIGHT STRAIGHT STRAIGHT Amps Range 80 to 120 90 to 190 80 to 120 90 to 190 Volts Range 20 to 24 24 to 28 20 to 24 24 to 28

2F

407) : NA : NA : NA : : : : : : : : : : : : : NA NA NA String NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kJ / mm

80 TO 180 NA NA NA NA

WELDING PROCEDURE Pass No. ONE SIDE CONT. ROOT (1) Welding Process Filler Material Class E6013 E6013 E6013 E6013 Dia 3.15 4 3.15 4 Travel Speed mm / min 80 to 120 90 to 150 80 to 120 90 to 150

SMAW SMAW 2nd STITCH FILLET 100 (100) 100 ROOT (1) SMAW SUB. PASS (2) SMAW

SUB. PASS (2)

APPROVAL NAME : SIGNATURE : DATE :

VISHAL STRUCTURALS PVT. LTD.

HINDUSTAN PETROLUEM CORP. LTD

WPS NO.: DATE WPS NO.: CLIENT LOCATION : : HINDUSTAN PETROLEUM CORPORATION LTD. QW-482 - WELDING PROCEDURE SPECIFICATION (REF. SPECIFICATION : ASME SECTION IX) SKETCH / DETAIL: SQ. BUTT NO FIG 1 (A) NA SWAM TYPE MANUAL To To To To IS 2062 / EQ. GR.B 1 1

JOINT DESIGN (QW-402) Type Backing Backing material Type / Grade WELDINHG PROCESS BASE METALS (QW 403) IS 2062 / EQ. Material Specification GR.B Type / Grade No. 1 P. No. 1 Group No. 6 mm Thick of Coupon 6 mm Thickness Range FILLER MATERIAL (QW 404) 5.1 Spec. No. (SFA) E 6013 AWS No. (CLASS) 1 A. No. : 2 F. No. : Make ESAB/ADVANI/D&H POSITION (QW 405) 3G Position of Groove UPHILL Weld Progression PREHEAT (QW 406) NA Preheat Temp.(Min) NA Interpass Temp.(Max) Preheat Maint GAS (QW 408) NA Shielding Gas NA Percentage Comp. NA Trailing ELECTRICAL CHARACTERISTICS (QW 409) DC Current Mode 18 to 30 Volts STRAIGHT Electrical Polarit 80 TO 140 Amperage NA Tungsten Electrode Size & Type NA Mode of Metal Transfer (GMAW) NA Elect. Wire - Feed,Speed,Range NA Other WELDING PROCEDURE Welding Process Material Filler Pass No. Class Dia AFTER BACK CHIP E6013

Filler Size Electrode Flux Type Backing / Storage Consumable Insert

: : : :

Position of Fillet

POST WELD HEAT TREATMENT (QW 407) Temperature : Time : Others : Flowrate : Gas Backing : Purging : TECHNIQUE (QW 410) String or weave Bead : Orifice or Gas Cup Size : Initial / Interpass Cleaning : Method of back gauging : Oscillation : Contact Tube to work distance : Multiple or Single Pass ( / Side) : Multiple or Single Electrode : Travel Speed Electrode : Peening

Type & Pol.

Amps Range

Volts Range

mm / min

3.15 / 4 mm As per Manuf. Std. Non

NA

NA NA NA NA NA NA String / Weaving NA Wire Brushing Grinding NA NA Multiple Single SEE TABLE NA Heat Input kj / mm

Potrebbero piacerti anche

- Wps 316L SMAW+GTAW R00Documento2 pagineWps 316L SMAW+GTAW R00Richard Periyanayagam86% (14)

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Documento5 pagineWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocumento4 pagineWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNessuna valutazione finora

- PQR FormatDocumento2 paginePQR Formatravi0009880% (5)

- WPS For Structure Mild Steel Fillet WeldDocumento2 pagineWPS For Structure Mild Steel Fillet WeldHarkesh Rajput76% (17)

- WPS 316 LDocumento4 pagineWPS 316 Llaz_k100% (2)

- WPS (AsmeDocumento8 pagineWPS (AsmeMohammad Elhedaby100% (6)

- WPS GTAW Stainless SteelDocumento4 pagineWPS GTAW Stainless SteelAnand NarayananNessuna valutazione finora

- Sample Wps-Carbon Steel GTAW+SMAWDocumento2 pagineSample Wps-Carbon Steel GTAW+SMAWchetan85100% (7)

- WPS FormatDocumento1 paginaWPS FormatAbdullah AnsariNessuna valutazione finora

- Wps 316L Gtaw R00Documento3 pagineWps 316L Gtaw R00Richard Periyanayagam100% (3)

- WPSDocumento3 pagineWPSKhurram Burjees100% (1)

- Wqt-Visual-Mag - BS 2Documento24 pagineWqt-Visual-Mag - BS 2KyNessuna valutazione finora

- WPS PQR A36.20Documento5 pagineWPS PQR A36.20gchaves504100% (2)

- WPS For Different Materail by BhelDocumento176 pagineWPS For Different Materail by Bhelsaisssms911691% (46)

- Procedure For WPSDocumento7 pagineProcedure For WPSSatish KeskarNessuna valutazione finora

- WPS & PQRDocumento46 pagineWPS & PQRJohn Candidate CIns88% (8)

- 6GR WPS PQRDocumento15 pagine6GR WPS PQRKiukStaks100% (6)

- According To ASME IX: Welding Procedure Specification (W.P.S)Documento4 pagineAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNessuna valutazione finora

- Specification Type or Grade AWS Group No. Thickness Size (NPS) Schedule DiameterDocumento3 pagineSpecification Type or Grade AWS Group No. Thickness Size (NPS) Schedule Diametercentaury2013Nessuna valutazione finora

- TopCorbelco - WPS FCAW Sa 516 GR 70Documento6 pagineTopCorbelco - WPS FCAW Sa 516 GR 70miltonangulomorrisNessuna valutazione finora

- For Fillet Weld Joint Project:Production ManifoldDocumento1 paginaFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- WPS PQR-03Documento12 pagineWPS PQR-03Ranjan KumarNessuna valutazione finora

- A 36 WPSDocumento2 pagineA 36 WPSNaqqash Sajid100% (1)

- Procedure Qualification Record (PQR)Documento3 pagineProcedure Qualification Record (PQR)Senthil KumaranNessuna valutazione finora

- WQTDocumento1 paginaWQTRamkunwar YadavNessuna valutazione finora

- Fcaw 16 THKDocumento5 pagineFcaw 16 THKparesh2387Nessuna valutazione finora

- Gtaw Smaw 6 Inch 6G CSDocumento1 paginaGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- Asme PQRDocumento4 pagineAsme PQRHong Dae Yoon100% (2)

- WPS-46 - Gtaw & Smaw Tig + SmawDocumento8 pagineWPS-46 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaNessuna valutazione finora

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Documento20 pagineWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- WPS MigDocumento3 pagineWPS MigAJOJOY00960% (5)

- WPS Format For ASME IX - PQR-AllDocumento3 pagineWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- Reports - QAQC - R0Documento10 pagineReports - QAQC - R0talupurumNessuna valutazione finora

- Welding Traceability Record 1Documento1 paginaWelding Traceability Record 1Alfian Imaduddin100% (1)

- Approved Welding Procedures List RegioDocumento2 pagineApproved Welding Procedures List Regiogabriel__regio100% (1)

- Alum 6xxx PwpsDocumento1 paginaAlum 6xxx PwpsAbu Zahid100% (1)

- WPS Sa 335 P91 PipeDocumento3 pagineWPS Sa 335 P91 Pipecsankarananth50% (2)

- Iqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlDocumento1 paginaIqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlAjayNessuna valutazione finora

- Ilcs-Smaw-D1.3-Deck (G) WPSDocumento3 pagineIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- PQR Gmaw3gDocumento4 paginePQR Gmaw3gdevendrasingh2021100% (3)

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocumento1 paginaWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNessuna valutazione finora

- Weld Map SampleDocumento2 pagineWeld Map SampleKhushal TripathiNessuna valutazione finora

- Welding Table WPS & PQR Check List (Sheet, 2 Pages)Documento2 pagineWelding Table WPS & PQR Check List (Sheet, 2 Pages)abomanar100486375% (4)

- WPS PQRDocumento51 pagineWPS PQRLuis Muñoz100% (1)

- Welding Procedure Specification: Technip KT India LimitedDocumento5 pagineWelding Procedure Specification: Technip KT India LimitedDeepak100% (1)

- Wps A53 Gtaw R00Documento2 pagineWps A53 Gtaw R00Richard PeriyanayagamNessuna valutazione finora

- Wps p91 - BhelDocumento2 pagineWps p91 - BhelAshish Gupta100% (4)

- Procedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingDocumento6 pagineProcedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingNovita Dwi IsnaeniNessuna valutazione finora

- Welding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002Documento2 pagineWelding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002shervinyNessuna valutazione finora

- WPSDocumento2 pagineWPSJuli Agus50% (2)

- Wps For Ss Welding in Pump Room: Phase-3A Development at Indira Gandhi International AirportDocumento5 pagineWps For Ss Welding in Pump Room: Phase-3A Development at Indira Gandhi International Airportamit rajputNessuna valutazione finora

- Sa 516 GR 70 WPSDocumento5 pagineSa 516 GR 70 WPSRajesh Owaiyar71% (7)

- P 91 - Welding WPSDocumento2 pagineP 91 - Welding WPSSuhailshah123475% (4)

- Wps Gtaw Monel b127 b164Documento2 pagineWps Gtaw Monel b127 b164Srinivasan Muruganantham67% (3)

- WPS FormatDocumento2 pagineWPS FormatAmit SarkarNessuna valutazione finora

- WPS002 312Documento2 pagineWPS002 312proxywarNessuna valutazione finora

- Qw-482 Welding Procedure Specification (WPS)Documento4 pagineQw-482 Welding Procedure Specification (WPS)Aldeline SungahidNessuna valutazione finora

- WPS Resrvoire Sous Pression Smaw SawDocumento6 pagineWPS Resrvoire Sous Pression Smaw SawDanem HalasNessuna valutazione finora

- 1035 03Documento2 pagine1035 03Anuj ShahiNessuna valutazione finora