Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Restoring The Memory On An Excel CNC With Fanuc 0 Control

Caricato da

malexorozcoDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Restoring The Memory On An Excel CNC With Fanuc 0 Control

Caricato da

malexorozcoCopyright:

Formati disponibili

John Robbins Automation Consultants, Inc. 4491 Foskuhl Rd. Floyds Knobs, IN.

47119 812 923 3718 812 923 5396 (fax)

Restoring the Memory on an Excel CNC with Fanuc 0 Control

About once or twice a month I get a telephone call from a shop owner asking what a RAM parity alarm is. He explains that "The alarm just showed up when I turned the machine on. I powered down and back up several times but it won't go away." "Well", I explain, "Basically, it means that the memory area on the CNC is shot. All of the data is corrupted. You need to clear the memory and restart. Just like doing a format on a PC hard drive." This is always followed by the same question. "Can I save my programs?" "No", I explain, "The programs, along with all of the machine parameters, are already lost." It's at this point that the shop owner realizes that the hundreds of hours he has spent programming a multitude of parts has just vanished. Now there are two options at this point. The first option is for the owner to clear the memory area and reload all of the data from a backup. A typical machine can be brought back to original condition in less then one hour if there is a good backup. If there is no backup then he must use the second option. That is to reprogram all of his parts. This can only begin after the machine parameters have been reinstalled. Have you got a copy of these parameters handy? It's fairly obvious that option number one would be the easiest. For this to be able to happen it is critical that a good backup of the machine information be available. There are a large number of machine controls out there. Each has its own procedure to backup and restore data. Over the next few issues I'll provide you with the procedures to complete this task on as many controls as possible. I'm going to start with the Fanuc 0 control. This is the most widely used control manufactured by Fanuc. To begin you must have a PC connected to the RS232 port and able to transmit and receive programs. We'll start by backing up all of the data. After that I will show you how to reload everything. Please note that some machines may not have all of the options we discuss. It is also important to note that the Fanuc operating system has different functions depending upon the level of software. Think of this as the difference between the way Windows 3.1 and Windows 2000 differ. I'll try to cover as much as possible. If you have any additional questions or comments please contact me at my office.

4491 Foskuhl Rd. Floyds Knobs, IN. 47119 812-923-3718

John Robbins Automation Consultants, Inc. 4491 Foskuhl Rd. Floyds Knobs, IN. 47119 812 923 3718 812 923 5396 (fax)

Backing up the machine data 1. Connect the RS232 cable between the PC and the CNC. Start the communications package that you wish to use. Set the package up to receive the parameter file. Place the machine in EDIT mode with memory protect off. Press the PARM key to display the parameter screen. Verify that the top left corner of the screen reads parameter. While holding the # key in press the green OUTPT key. This will start the parameter file transmitting from the CNC. After the parameters are finished press the PARM key again to display the diagnostics page. Set the PC up to receive the diagnostic file. Hold the # key in and press the green OUTPT key. This will send all of the diagnostics out to the PC. Some early versions of the 0 control did not allow for the transmitting of the diagnostics. If your machine will not allow this, record the diagnostics manually. Start with diagnostic 300 and record every fifth value. (300, 305, 310, etc.) Do this up to 395. Record all of the 400 and 500 level diagnostics. 4. Set the PC up to receive the programs. We will output all of the programs as one large file. If you are using any 9000 macro programs you must set parameter 10 bit 4 = 0 in order to output these programs. Press the PRGM key until the program page is displayed. Type in O-9999 ( use the letter O not the number 0) and press the green OUTPT key. All of the programs in memory will be transmitted. The newer versions of Fanuc software make use of an I/O soft key. This key is located under the CRT on the machine tool. If your machine has it press the I/O soft key then type in O-9999. After this press the PUNCH soft key. This will transmit the programs. 5. If you wish, you can also output the tool offset data. To do so set the PC up to receive the file. Display the tool offset page and press the green OUTPT key. Note that the work offsets will be recorded with the parameters when they are output. There are several items that should be recorded manually. These include any macro variables in the 500 or above range. You should also record all of the 900 parameters. These will be needed when reinstalling the memory.

2.

3.

6.

Now you have all of the data backed up your safe. Well, maybe not. You may wish to look at the data using a standard text editor. Make sure that all of the information looks proper without any unusual characters in it. It can be a royal pain if you go to restore the data only to find out that it wasn't saved properly on the PC. Copy the files you saved to a disk for additional protection. You don't want a hard drive crash on your computer causing you to redo everything.

4491 Foskuhl Rd. Floyds Knobs, IN. 47119 812-923-3718

John Robbins Automation Consultants, Inc. 4491 Foskuhl Rd. Floyds Knobs, IN. 47119 812 923 3718 812 923 5396 (fax)

Restoring Memory on Fanuc 0

1.

Hold the RESET and DELETE key while powering up. This will erase all memory in the machine! The machine will power up with a number of alarms. Press the e-stop button in. Press the PARM key- go to parameter 900 and enter parameters 900 through 917. A "000" alarm appears after entering the first parameter. Just go back to parameters and enter the values for 901. After you enter parameter 901 a message will appear asking you to delete the memory area. Press the DELETE key. Enter the remainder of the 900 parameters. When finished verify all parameters were entered correctly. Power machine down for 10 seconds then power up Go to parameter page #1 in MDI mode and set ISO = 1 Page down to parameter #2 Enter 0000 0000 for one stop bit. Use 0000 0001 for two stop bits. Go to parameter # 552 set it to 10 for a baud rate of 4800. Set it to 11 for a baud rate of 9600. Place machine in edit mode with the memory protect key off. With the parameter screen displayed push the INPUT key. LSK should appear in the lower right corner of the CRT. From the PC transmit the parameter file to the CNC. The LSK flashing on the CRT should change to INPUT. After the file starts transmitting. It will take several minutes to read the file. Power the machine down and up again. Verify parameter 2 bit 0 and parameter 552. Go to the first page of the parameters and set the machine to the increment system you wish to use, inch or metric. Go to diagnostic page- Verify Diagnostics is displayed in the upper left corner of the CRT. Hold EOB in and push INPUT. Transfer the diagnostics file to the CNC. Verify that parameter 10 bit 4 = 0

2. 3.

4.

5. 6. 7. 8. 9.

10.

11. 12.

13. 14. 15.

4491 Foskuhl Rd. Floyds Knobs, IN. 47119 812-923-3718

John Robbins Automation Consultants, Inc. 4491 Foskuhl Rd. Floyds Knobs, IN. 47119 812 923 3718 812 923 5396 (fax)

16.

Go to Edit mode and push the PGRM key. Push the Input key and LSK should start flashing on the CRT. Transfer the program file to the CNC. If the screen has the I/O soft key push it then the READ key. LSK will appear. Transfer the program file. When finished go back to parameters and set parameter 10 bit 4 = 1. After this set PWE=0. Push reset to clear the alarm (must be in MDI mode) Verify the inch/metric setting on the first parameter page. Push the OFFSET key until tool offsets are displayed. Press input. LSK will appear Transfer the offset file. Verify all offsets. (This will only work if you have the G10 option setting.) Enter any extended work offsets P1-P8 by hand. Power down Power up holding the LQP and CANCLE key. Move away form home position several inches and zero out at 25% rapid. You should be ready to operate the machine. I know it sounds like a lot of steps but it sure beats programming all of those parts again.

17. 18.

19. 20.

21.

4491 Foskuhl Rd. Floyds Knobs, IN. 47119 812-923-3718

Potrebbero piacerti anche

- NC Mill SFTWR ManualDocumento100 pagineNC Mill SFTWR ManualPham LongNessuna valutazione finora

- Special Electric Motors: High-Speed Machining MotorsDocumento68 pagineSpecial Electric Motors: High-Speed Machining MotorsAbed samadsureyft7vewyrNessuna valutazione finora

- Manual SupplementDocumento4 pagineManual SupplementxnsxmannyNessuna valutazione finora

- 1999 Dodge CodesDocumento23 pagine1999 Dodge CodesNoel Spangenburg100% (1)

- Jumbo Lift 3200 NT PDFDocumento55 pagineJumbo Lift 3200 NT PDFAvishay TufikianNessuna valutazione finora

- 15 Minutes 1 Hour 1 Hour 30 Minutes 10: Cream Puffs IDocumento1 pagina15 Minutes 1 Hour 1 Hour 30 Minutes 10: Cream Puffs IThomas SjölingNessuna valutazione finora

- Hho Gasoline EngineDocumento19 pagineHho Gasoline EngineJaison KurianNessuna valutazione finora

- Jgaurora A5 User Guide 201801Documento21 pagineJgaurora A5 User Guide 201801Katsumoto SanNessuna valutazione finora

- Slingmount Instructions For The Remington Nylon 66 Series RiflesDocumento2 pagineSlingmount Instructions For The Remington Nylon 66 Series RiflesSteve JohnsonNessuna valutazione finora

- AWCY? Apple PieDocumento8 pagineAWCY? Apple PieCWONessuna valutazione finora

- Manual Fresadora X4 SyilDocumento78 pagineManual Fresadora X4 SyilCarlosNessuna valutazione finora

- PowerTIG 250EX 2016Documento32 paginePowerTIG 250EX 2016Bob john100% (1)

- BeoLab 1 PDFDocumento26 pagineBeoLab 1 PDFTom RuyleNessuna valutazione finora

- PREPARE Policy BriefingDocumento2 paginePREPARE Policy BriefingAndrew SingerNessuna valutazione finora

- AMP Engineering PS90 Trigger InstructionsDocumento2 pagineAMP Engineering PS90 Trigger InstructionsAaron PigeonNessuna valutazione finora

- HP c6280 Users ManualDocumento35 pagineHP c6280 Users Manualzyxwv6Nessuna valutazione finora

- 2018 Xometry Partner Reference GuideDocumento16 pagine2018 Xometry Partner Reference GuideSteven DNessuna valutazione finora

- Dell 2145cn Service Manual PDFDocumento208 pagineDell 2145cn Service Manual PDFMārtiņš DreijersNessuna valutazione finora

- Delta Model 31-080 1" Belt Sander ManualDocumento12 pagineDelta Model 31-080 1" Belt Sander ManualRobert Steven Ciaccio0% (1)

- Ar15 Lower Machining Instructions PDFDocumento5 pagineAr15 Lower Machining Instructions PDFAntonioNessuna valutazione finora

- Samsung HT-D350 PDFDocumento58 pagineSamsung HT-D350 PDFboroda2410100% (2)

- Construction Plans For Champion TLUD StoveDocumento18 pagineConstruction Plans For Champion TLUD StoveRaymond KatabaziNessuna valutazione finora

- How To Build A Potato CannonDocumento16 pagineHow To Build A Potato CannonFknw bdNessuna valutazione finora

- Automatic Transmission - Transaxle U241e (Rm840u)Documento150 pagineAutomatic Transmission - Transaxle U241e (Rm840u)BrylantNessuna valutazione finora

- Dbs22 enDocumento14 pagineDbs22 enmilivoj11Nessuna valutazione finora

- One Method of Removing Soils From The Top Secret BDocumento16 pagineOne Method of Removing Soils From The Top Secret BjumpupdnbdjNessuna valutazione finora

- How To Wire An Arduino Based 3 Axis CNC MachineDocumento11 pagineHow To Wire An Arduino Based 3 Axis CNC MachineSetyo WidodoNessuna valutazione finora

- Service Manual: Monitor With DVD ReceiverDocumento85 pagineService Manual: Monitor With DVD ReceiverDumur SaileshNessuna valutazione finora

- EztrakDocumento3 pagineEztrakceyberNessuna valutazione finora

- Hot Wire Manchine - User Manual-ENDocumento41 pagineHot Wire Manchine - User Manual-ENZoliNessuna valutazione finora

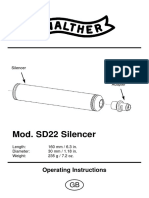

- Schalldaempfer SD22 Bed GBDocumento5 pagineSchalldaempfer SD22 Bed GBDjWagner007Nessuna valutazione finora

- Modifying .223 Magazines For The SAR-3Documento13 pagineModifying .223 Magazines For The SAR-3Arkane1988100% (1)

- Series 2 FAST ED MemoDocumento1 paginaSeries 2 FAST ED MemoNorth Country EMSNessuna valutazione finora

- Brooks PRI Automation ABM 407B 1 S CE S293 Manual 20163184612 PDFDocumento232 pagineBrooks PRI Automation ABM 407B 1 S CE S293 Manual 20163184612 PDFjack toddNessuna valutazione finora

- Being Prepared Before SHTF PDFDocumento2 pagineBeing Prepared Before SHTF PDFOhio Dodson Family EmergencyNessuna valutazione finora

- Wiring Carrier 38ckc-c3wDocumento2 pagineWiring Carrier 38ckc-c3wRay Ravel100% (1)

- A Projectile Is Projected From The Origin With A Velocity of 25Documento6 pagineA Projectile Is Projected From The Origin With A Velocity of 25AloneNessuna valutazione finora

- Commercial Cam PackagesDocumento29 pagineCommercial Cam PackagesShubham JainNessuna valutazione finora

- Belt Sander 0001Documento5 pagineBelt Sander 0001wienslaw5804Nessuna valutazione finora

- How I Made My Own Plasma Cutter From Junk (Corrected Version)Documento66 pagineHow I Made My Own Plasma Cutter From Junk (Corrected Version)Mike Klopfer100% (1)

- Cyberpunk 2020 - Net - Rules - Oceanpunk Neo-Cetaceans by MorninmanDocumento4 pagineCyberpunk 2020 - Net - Rules - Oceanpunk Neo-Cetaceans by MorninmanArixsonNessuna valutazione finora

- Hand Tools: An Educational Guide ForDocumento20 pagineHand Tools: An Educational Guide Forsaeedbhatti100% (2)

- Rockwell UniviseDocumento2 pagineRockwell UniviseRusty_Iron_WorksNessuna valutazione finora

- Cam SwitchDocumento33 pagineCam SwitchalstomNessuna valutazione finora

- Classic 300d LincolnDocumento32 pagineClassic 300d LincolnOswaldo Enrique SandreaNessuna valutazione finora

- Germansportguns Gsg5Documento34 pagineGermansportguns Gsg5Justin100% (1)

- Active Directory User ManualDocumento22 pagineActive Directory User ManualTim WilliamsNessuna valutazione finora

- EX380 Operator Maint Manual PDFDocumento35 pagineEX380 Operator Maint Manual PDFsimonNessuna valutazione finora

- How To Adjust HK Rifle SightsDocumento3 pagineHow To Adjust HK Rifle SightsBlackbenellieSBE1Nessuna valutazione finora

- Lincoln Welding SP 170t Im794Documento36 pagineLincoln Welding SP 170t Im794Anonymous hR3e8SsNessuna valutazione finora

- Orange PI ZeroDocumento19 pagineOrange PI Zerosondaya86Nessuna valutazione finora

- Ray Vickers Ar-15/M-16 BlueprintDocumento9 pagineRay Vickers Ar-15/M-16 BlueprintJoshua MunseyNessuna valutazione finora

- The Development of Armor-piercing Shells (With Suggestions for Their Improvement)Da EverandThe Development of Armor-piercing Shells (With Suggestions for Their Improvement)Nessuna valutazione finora

- Saiga 12 Shotgun Custom Order Form: About YOUDocumento3 pagineSaiga 12 Shotgun Custom Order Form: About YOURobert MonsonNessuna valutazione finora

- EASSON ES 8A DRO User Manual PDFDocumento114 pagineEASSON ES 8A DRO User Manual PDFJulio CezarNessuna valutazione finora

- Mobile RadiationDocumento52 pagineMobile RadiationNilesh GoswamiNessuna valutazione finora

- Buying First RifleDocumento5 pagineBuying First RiflesgrispoNessuna valutazione finora

- United - States - Army - TM - 9-1005-211-34 - 22 - June - 1964Documento48 pagineUnited - States - Army - TM - 9-1005-211-34 - 22 - June - 1964qcqapgh7748Nessuna valutazione finora

- MAZAK M PLUS T PLUS Memory Upgrade InstructionsDocumento10 pagineMAZAK M PLUS T PLUS Memory Upgrade InstructionsraviNessuna valutazione finora

- ISMR B-School BrochureDocumento28 pagineISMR B-School Brochurerahul kantNessuna valutazione finora

- FWD Week 47 Learning Material For Alaric YeoDocumento7 pagineFWD Week 47 Learning Material For Alaric YeoarielNessuna valutazione finora

- MP65557-1 Manual Técnico - 4900Documento371 pagineMP65557-1 Manual Técnico - 4900Tecnico IncoderNessuna valutazione finora

- Spring 2010 MidTerm OPKST CS101 Bc100200572Documento6 pagineSpring 2010 MidTerm OPKST CS101 Bc100200572cs619finalproject.comNessuna valutazione finora

- Etrade Bank-StatementDocumento5 pagineEtrade Bank-StatementMark Galanty100% (4)

- Checklist For Rebar and Concrete WorkDocumento4 pagineChecklist For Rebar and Concrete WorkDwinto RachmadNessuna valutazione finora

- BF V CatalogDocumento56 pagineBF V CatalogmaciasrobNessuna valutazione finora

- Robit Forepoling Catalogue ENG 03-2015Documento36 pagineRobit Forepoling Catalogue ENG 03-2015Purwadi Eko SaputroNessuna valutazione finora

- Lean ConstructionDocumento37 pagineLean ConstructionMohamed Talaat ElsheikhNessuna valutazione finora

- C-L-X® Type MC-HL (XHHW-2)Documento3 pagineC-L-X® Type MC-HL (XHHW-2)Xin LiNessuna valutazione finora

- A Comparison Study of Process Scheduling in Freebsd, Linux and Win2KDocumento12 pagineA Comparison Study of Process Scheduling in Freebsd, Linux and Win2Kbenito agusNessuna valutazione finora

- Mds SM13CRM 110 enDocumento5 pagineMds SM13CRM 110 enColinNessuna valutazione finora

- Design of Electrical Machines NotesDocumento24 pagineDesign of Electrical Machines Notesmadhes14Nessuna valutazione finora

- TGA Interpretation of Data, Sources of ErrorDocumento28 pagineTGA Interpretation of Data, Sources of ErrorUsman GhaniNessuna valutazione finora

- Aesa Vs PesaDocumento30 pagineAesa Vs Pesakab11512100% (1)

- Slot 22-23-24 Real Time CommunicationDocumento50 pagineSlot 22-23-24 Real Time CommunicationLinh BuiNessuna valutazione finora

- Omnifocus ShortcutsDocumento3 pagineOmnifocus ShortcutsLaGouloueNessuna valutazione finora

- Ai R16 - Unit-6Documento36 pagineAi R16 - Unit-6RakeshNessuna valutazione finora

- 3393 - Supervision of Concrete Construction Volume 2Documento271 pagine3393 - Supervision of Concrete Construction Volume 2Oum ChhayNoy100% (11)

- Geometallurgical Modelling of The Collahuasi Flotation CircuitDocumento6 pagineGeometallurgical Modelling of The Collahuasi Flotation CircuitFrancisco CampbellNessuna valutazione finora

- Zoom and Re-Zoom Team ActivityDocumento2 pagineZoom and Re-Zoom Team ActivityWalshie28050% (1)

- 747Documento12 pagine747GurdevBaines100% (3)

- Physics 16 - Thermal ProcessesDocumento19 paginePhysics 16 - Thermal ProcessesSuhaan HussainNessuna valutazione finora

- Eco-Friendly Fire Works CompositionDocumento4 pagineEco-Friendly Fire Works CompositionYog EshNessuna valutazione finora

- DAC AnalysisDocumento19 pagineDAC Analysisమురళీధర్ ఆది ఆంధ్రుడుNessuna valutazione finora

- Linux Overview (Commands)Documento9 pagineLinux Overview (Commands)fopataNessuna valutazione finora

- Prop Pro 32-4 FinalDocumento32 pagineProp Pro 32-4 FinalAhmed Ali KhanNessuna valutazione finora

- Development of Mmlps in India: Western DFC Eastern DFCDocumento2 pagineDevelopment of Mmlps in India: Western DFC Eastern DFCsdfg100% (2)

- Language Focus. Past Simple or Past ContinuousDocumento3 pagineLanguage Focus. Past Simple or Past ContinuoustotydnrNessuna valutazione finora

- Huawei FusionServer RH2288 V3 Data Sheet PDFDocumento2 pagineHuawei FusionServer RH2288 V3 Data Sheet PDFMartenMattisenNessuna valutazione finora