Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

C 1 GC 15293 A

Caricato da

szbaloghDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

C 1 GC 15293 A

Caricato da

szbaloghCopyright:

Formati disponibili

Green Chemistry

Cite this: DOI: 10.1039/c1gc15293a www.rsc.org/greenchem

Dynamic Article Links

View Online

COMMUNICATION

Replacing dichloroethane as a solvent for rhodium-catalysed intermolecular alkyne hydroacylation reactions: the utility of propylene carbonate

Philip Lenden,a Paul M. Ylioja,a Carlos Gonz lez-Rodrguez,a David A. Entwistleb and Michael C. Willis*a a

Downloaded by INP Toulouse on 04 July 2011 Published on 22 June 2011 on http://pubs.rsc.org | doi:10.1039/C1GC15293A

Received 17th March 2011, Accepted 17th May 2011 DOI: 10.1039/c1gc15293a

Propylene carbonate is an excellent solvent for rhodiumcatalysed intermolecular alkyne hydroacylation reactions, allowing a variety of b-S-aldehydes and alkynes to be combined in high yields, to deliver enone products. The effective use of propylene carbonate removes the need to employ dichloroethane as solvent.

Introduction

The transition-metal catalysed intermolecular hydroacylation of alkenes and alkynes is a highly atom-efcient transformation which allows the construction of synthetically useful ketones via the addition of an acyl group and a hydrogen atom across an unsaturated CC bond.1 Intermolecular hydroacylation has yet to be extended to a general process due to the propensity of the acyl-metal intermediate to undergo decarbonylation as an unproductive side reaction. Our group has previously disclosed a chelation-controlled intermolecular hydroacylation process, which utilises a thioether (or dithiane) chelate2 in the aldehyde component to stabilise the key acyl-rhodium intermediate and thus suppress decarbonylation3,4 (Scheme 1). The resulting methodology permits the atom efcient synthesis of a range of 1,4-dicarbonyl compounds (with alkene substrates) and enones (with alkyne substrates), and is tolerant of a wide variety of

Scheme 1 b-S-Chelating aldehydes in rhodium-catalysed intermolecular alkene and alkyne hydroacylation reactions.

a Department of Chemistry, University of Oxford, Chemistry Research Laboratory, Manseld Road, Oxford, UK, OX1 3TA. E-mail: michael.willis@chem.ox.ac.uk; Fax: +44 1865 285002; Tel: +44 1865 285126 b Research API, Pzer Global Research and Development, Sandwich, Kent, UK, CT13 9NJ Electronic supplementary information (ESI) available: Experimental details and spectroscopic data for all new compounds. See DOI: 10.1039/c1gc15293a

functional groups, including free hydroxyl groups, halogens, and silyl ethers. Currently, the preferred solvents for this process are acetone and 1,2-dichloroethane (DCE); however, neither are without their drawbacks. The limitation conferred by acetone is its low boiling point of 56 C (760 mmHg), which can increase reaction times or reduce yields in the case of more challenging reaction systems. DCE, while higher boiling, has signicant toxicity issues and like other halogenated solvents is undesirable for use on scale due to the environmental hazards associated with its use and disposal. Propylene carbonate, on the other hand, is gaining prominence as a useful solvent in organic synthesis due to its many desirable properties. Organic carbonates are used in a variety of industrial applications, such as degreasing, paint stripping, and as electrolytes in lithium ion batteries.5 Propylene carbonate itself is a polar aprotic solvent which is non-toxic (to the extent that it has been used as a carrier solvent in cosmetics and topically applied medicines6 ), noncorrosive and biodegradable.7 In addition to excellent solvency of metal ions8 and organic compounds, its physical properties are also desirable: it has low viscosity, low vapour pressure and is miscible with water. A recent paper in this journal by Jessop9 urged scientists to assess the green-ness of solvents for a given application based on the environmental effects of solvents, including their synthesis, use and disposal. Propylene carbonate can be synthesised in an atom-efcient manner from propylene oxide and carbon dioxide,1012 resulting in a short synthesis tree with none of the downsides which would prevent it from being considered as a green solvent. More importantly, the use of propylene carbonate as a direct replacement solvent for DCE avoids the production of any chlorinated waste. These factors show propylene carbonate as being clearly advantageous to DCE in a like-for-like comparison.13 Despite the existing commercial uses, propylene carbonate has not seen extensive use as a solvent for transition metal catalysis. Several examples of its use are known: Borner and coworkers have published a number of accounts of the use of propylene carbonate as a solvent for catalytic asymmetric hydrogenations with rhodium and iridium catalysts;8,14 Behr and coworkers have described examples of catalysis with propylene carbonate as a solvent,1519 including platinum-catalysed hydrosilylation and rhodium-catalysed hydroformylation reactions; and Reetz and coworkers described its use in stabilising palladium clusters and Green Chem.

This journal is The Royal Society of Chemistry 2011

View Online

their use in catalysing Heck reactions.20 A review on the use of organic carbonates as solvents and in catalysis has recently been published,21 and contains further examples of catalysis which use propylene carbonate as a solvent. Herein we describe the use of propylene carbonate as a solvent for the chelationassisted rhodium-catalysed intermolecular hydroacylation of Schelating aldehydes with a variety of alkynes. This reaction represents a synthetically useful and operationally simple protocol for intermolecular hydroacylation as a method for the construction of enones.

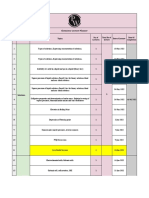

Table 1 (Contd.)

Entry Aldehyde 4 1a

Alkyne (R2 ) Product C2 H4 Ph

Yield (%)b 83

Results and discussion

Downloaded by INP Toulouse on 04 July 2011 Published on 22 June 2011 on http://pubs.rsc.org | doi:10.1039/C1GC15293A

Ph

86

The viability of using propylene carbonate as a solvent for our intermolecular hydroacylation methodology was investigated by carrying out reactions between representative aldehydes and alkynes selected from classes which had previously been described using either DCE or acetone as the reaction solvent. For comparrison, a representative transformation performed in both acetone and DCE, is shown in Scheme 2.

1b

Hex

95

1b

C2 H4 Ph

87

1b

cyclopropyl

90

Ph

84

10 Scheme 2 Representative alkyne hydroacylation reactions performed in acetone and DCE.

1c

Hex

86

It was found that these reactions could be carried out in propylene carbonate with a catalyst system comprising commercially available rhodium complex [Rh(nbd)2 ]BF4 in combination with dppe as the ligand. The catalysts did not require preactivation by hydrogenation. Table 1 summarises the results, which are grouped by aldehyde class: b-methylthiopropanal

Table 1 Propylene carbonate as solvent in intermolecular rhodiumcatalysed alkyne hydroacylation reactionsa

11

1c

C3 H6 Cl

74

12

1c

C2 H4 Ph

94

13d

Ph

73

14d Entry 1 Aldehyde Alkyne (R2 ) Ph Product Yield (%)b 90 15d

1d

Bu

73

1d

Hex

83

1a

Bu

91c

16d

1d

C2 H4 Ph

75

1a

Hex

91

Aldehyde (1.5 mmol), alkyne (1.65 mmol), catalyst (5 mol.%), propylene carbonate, 70 C, 1 h. b Isolated yields. c A reaction performed using 1 mol.% catalyst delivered a 91% yield. d Alkyne (2.25 mmol) and DPEphos ligand employed, 16 h.

Green Chem.

This journal is The Royal Society of Chemistry 2011

View Online

Downloaded by INP Toulouse on 04 July 2011 Published on 22 June 2011 on http://pubs.rsc.org | doi:10.1039/C1GC15293A

(1a) is the simplest aldehyde that fulls the requirement of a chelating b-S-substituent, and this was combined with four alkynes, in all cases delivering the expected hydroacylation adducts in excellent yields (entries 14). Although the reactions were routinely performed using a 5 mol.% catalyst loading it was also possible to reduce this loading and retain good activity. For example, performing the reaction shown in entry 2, but employing a 1 mol.% catalyst loading, the enone product was still obtained in 91% yield. Entries 58 document the successful use of a more hindered alkyl aldehyde (1b) with four representative alkynes (entries 69). The aromatic aldehyde, 2-(methylthio)benzaldehyde (1c), was also employed without issue (entries 1013). The nal group of reactions all employ b-dithiane-aldehyde 1d. This sterically demanding aldehyde proved to be a more challenging substrate for the catalyst system described in this paper, and several modications were required to drive these reactions to completion: a larger excess of alkyne (1.5 equivalents, compared to 1.1 equivalents in the previously described examples), a prolonged reaction time, and changing the ligand from dppe to the second generation DPEphos catalyst system.2d These modications enabled the desired hydroacylation products to be synthesised in good yields.

Conclusion

In conclusion, we have demonstrated that propylene carbonate is a viable solvent for our previously described intermolecular hydroacylation methodology. The reactions described employ commercially available pre-catalysts and ligands, require no activation of the pre-catalyst by hydrogenation and use a solvent which is environmentally benign, non-ammable, non-toxic, and more attractive for use on scale than the previously used 1,2dichloroethane.

5 6 7 8

Acknowledgements

We thank the EPSRC, Pzer, Xunta de Galicia PGIDIT INCITE and FSE (Angeles Alvarino contract and Estadas grants: 2008/178, 2009/188 and 2010/163 to CGR) for funding, and Mr Angus Logan for technical assistance.

9 10 11 12 13 14 15 16 17 18 19 20 21

Representative experimental procedure: exemplied by the preparation of (E)-5-(methylthio)-1-phenylpent-1-en-3-one. [Rh(nbd)2 ]BF4 (14 mg, 0.0375 mmol) and dppe (15 mg, 0.0375 mmol) were dissolved in propylene carbonate (2.5 mL) and stirred at room temperature for 10 min. 3(methylthio)propionaldehyde (75 mL, 0.75 mmol) then phenylacetylene (90 mL, 0.83 mmol) were added and the reaction heated at 70 C for 1 h. The reaction mixture was loaded directly onto silica and eluted with 30% Et2 O/petrol to furnish the pure product as a yellow oil (139 mg, 90%). 1 (a) M. C. Willis, Chem. Rev., 2010, 110, 725748; (b) C.-H. Jun, E.-A. Jo and J.-W. Park, Eur. J. Org. Chem., 2007, 18691881. 2 (a) M. C. Willis, S. J. McNally and P. J. Beswick, Angew. Chem., Int. Ed., 2004, 43, 340343; (b) M. C. Willis, H. E. Randell-Sly,

R. L. Woodward and G. S. Currie, Org. Lett., 2005, 7, 22492251; (c) M. C. Willis, H. E. Randell-Sly, R. L. Woodward, S. J. McNally and G. S. Currie, J. Org. Chem., 2006, 71, 52915297; (d) G. L. Moxham, H. E. Randell-Sly, S. K. Brayshaw, R. L. Woodward, A. S. Weller and M. C. Willis, Angew. Chem., Int. Ed., 2006, 45, 7618 7622; (e) G. L. Moxham, H. E. Randell-Sly, S. K. Brayshaw, A. S. Weller and M. C. Willis, Chem.Eur. J., 2008, 14, 83838389; (f) J. D. Osborne and M. C. Willis, Chem. Commun., 2008, 50255027; (g) J. D. Osborne, H. E Randell-Sly, G. S. Currie, A. R. Cowley and M. C. Willis, J. Am. Chem. Soc., 2008, 130, 1723217233; (h) H. E. Randell-Sly, J. D. Osborne, R. L. Woodward, G. S. Currie and M. C. Willis, Tetrahedron, 2009, 65, 51105117; (i) R. J. Pawley, G. L. Moxham, R. Dallanegra, A. B. Chaplin, S. K. Brayshaw, A. S. Weller and M. C. Willis, Organometallics, 2010, 29, 17171728; (j) C. Gonz lez-Rodrguez, S. R. Parsons, A. L. Thompson and M. C. a Willis, Chem.Eur. J., 2010, 16, 1095010954. For alternative chelation-controlled intermolecular hydroacylation reactions, see: (a) C.-H. Jun, H. Lee, J.-B. Hong and B.-I. Kwon, Angew. Chem., Int. Ed., 2002, 41, 21462147; (b) M. Imai, M. Tanaka, K. Tanaka, Y. Yamamoto, N. Imai-Ogata, M. Shimowatari, S. Nagumo, N. Kawahara and H. Suemune, J. Org. Chem., 2004, 69, 11441145; (c) T. Tanaka, M. Tanaka and H. Suemune, Tetrahedron Lett., 2005, 46, 60536056; (d) K. Tanaka, Y. Shibata, T. Suda, Y. Hagiwara and M. Hirano, Org. Lett., 2007, 9, 12151218; (e) R. T. Stemmler and C. Bolm, Adv. Synth. Catal., 2007, 349, 11851198; (f) Y. Shibata and K. Tanaka, J. Am. Chem. Soc., 2009, 131, 12552 12553; (g) M. C. Coulter, K. G. M. Kou, B. Galligan and V. M. Dong, J. Am. Chem. Soc., 2010, 132, 1633016333; (h) D. T. H. Phan, K. G. M. Kou and V. M. Dong, J. Am. Chem. Soc., 2010, 132, 16354 16355. For non-chelating examples, see: (a) Y.-T. Hong, A. Barchuk and M. J. Krische, Angew. Chem., Int. Ed., 2006, 45, 68856888; (b) A. H. Roy, C. P. Lenges and M. Brookhart, J. Am. Chem. Soc., 2007, 129, 20822093; (c) S. Omura, T. Fukuyama, J. Horiguchi, Y. Murakami and I. Ryu, J. Am. Chem. Soc., 2008, 130, 1409414095; (d) F. Shibahara, J. F. Bower and M. J. Krische, J. Am. Chem. Soc., 2008, 130, 1412014122; (e) V. M. Williams, J. C. Leung, R. L. Patman and M. J. Krische, Tetrahedron, 2009, 65, 50245029. K. Xu, Chem. Rev., 2004, 104, 43034418. US Patent, 5 993 787, 1999. K. Beyer, W. Bergfeld, W. Berndt, W. Carlton, D. Hoffmann, A. Schroeter and R. Shank, J. Am. Coll. Toxicol., 1987, 6, 2351. J. Bayardon, J. Holz, B. Sch ffner, V. Andrushko, S. Verevkin, A. a Preetz and A. Borner, Angew. Chem., Int. Ed., 2007, 46, 5971 5974. P. G. Jessop, Green Chem., 2011, DOI: 10.1039/C0GC00797H. Jpn. Pat., JP7267944, 1995. M. North, R. Pasquale and C. Young, Green Chem., 2010, 12, 1514 1539. J. E. Dengler, M. W. Lehenmeier, S. Klaus, C. E. Anderson, E. Herdtweck and B. Rieger, Eur. J. Inorg. Chem., 2011, 336343. R. K. Henderson, C. Jim nez-Gonz lez, D, J. C. Constable, S. R. e a Alston, G. G. A. Inglis, G. Fisher, J. Sherwood, S. P. Binks and A. D. Curzons, Green Chem., 2011, 13, 854862. B. Sch ffner, V. Andrushko, J. Bayardon, J. Holz and A. Borner, a Chirality, 2009, 21, 857861. A. Behr and N. Toslu, Chem. Eng. Technol., 2000, 23, 122125. A. Behr, F. Naendrup and D. Obst, Adv. Synth. Catal., 2002, 344, 11421145. A. Behr, F. Naendrup and D. Obst, Eur. J. Lipid Sci. Technol., 2002, 104, 161166. A. Behr and C. F ngewisch, J. Mol. Catal. A: Chem., 2003, 197, a 115126. A. Behr, D. Obst and B. Turkowski, J. Mol. Catal. A: Chem., 2005, 226, 215219. M. T. Reetz and G. Lohmer, Chem. Commun., 1996, 19211922. B. Sch ffner, F. Sch ffner, S. P. Verevkin and A. Borner, Chem. Rev., a a 2010, 110, 45544581.

This journal is The Royal Society of Chemistry 2011

Green Chem.

Potrebbero piacerti anche

- 1 s2.0 S1631074809000708 MainDocumento12 pagine1 s2.0 S1631074809000708 MainszbaloghNessuna valutazione finora

- Tetrahedron A 2012 BINAP Derivetives Hidrogénezés És HidroformilezésDocumento7 pagineTetrahedron A 2012 BINAP Derivetives Hidrogénezés És HidroformilezésszbaloghNessuna valutazione finora

- Szilános HeterogenizálásDocumento8 pagineSzilános HeterogenizálásszbaloghNessuna valutazione finora

- Om 200070 ADocumento6 pagineOm 200070 AszbaloghNessuna valutazione finora

- OrganoMetSolv PDFDocumento4 pagineOrganoMetSolv PDFHung Quoc DangNessuna valutazione finora

- H0binap Vs H8binap ChanDocumento6 pagineH0binap Vs H8binap ChanszbaloghNessuna valutazione finora

- BINAP-Ru and - RH Catalysts Covalently Immobilised On Silica and TheirDocumento9 pagineBINAP-Ru and - RH Catalysts Covalently Immobilised On Silica and Theirsanke222Nessuna valutazione finora

- Eur. J, 2010, 16, 6509-6517 Reek Anti-Halpern SupportingDocumento13 pagineEur. J, 2010, 16, 6509-6517 Reek Anti-Halpern SupportingszbaloghNessuna valutazione finora

- 1 s2.0 S1631074809000708 MainDocumento12 pagine1 s2.0 S1631074809000708 MainszbaloghNessuna valutazione finora

- Green Chem, 2008,10,1,59Documento8 pagineGreen Chem, 2008,10,1,59szbaloghNessuna valutazione finora

- Eur. J, 2010, 16, 6509-6517 Reek Anti-HalpernDocumento9 pagineEur. J, 2010, 16, 6509-6517 Reek Anti-HalpernszbaloghNessuna valutazione finora

- Binepines, ChemSocRew2011 Gladiali ReviewDocumento20 pagineBinepines, ChemSocRew2011 Gladiali ReviewszbaloghNessuna valutazione finora

- CH-Pi KölcsönhatásDocumento4 pagineCH-Pi KölcsönhatásBalogh SzabolcsNessuna valutazione finora

- Applied Surface Science: Ping Xue, Fang Xu, Lidong XuDocumento6 pagineApplied Surface Science: Ping Xue, Fang Xu, Lidong XuszbaloghNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Haroon 1Documento119 pagineHaroon 1Hasnain HasnainNessuna valutazione finora

- A Supramolecular Chemistry Basis For Molecular Logic and ComputationDocumento10 pagineA Supramolecular Chemistry Basis For Molecular Logic and ComputationPathrodo MediaNessuna valutazione finora

- Unit 5. Food Processing and Preservation TechniquesDocumento30 pagineUnit 5. Food Processing and Preservation Techniquesfeyisa100% (1)

- Class XII Chemistry Worksheet - P Block (17th & 18th Group) PDFDocumento1 paginaClass XII Chemistry Worksheet - P Block (17th & 18th Group) PDFDevil KingNessuna valutazione finora

- Preparación de Nitroso Metil Urea PDFDocumento4 paginePreparación de Nitroso Metil Urea PDFJuanManuelAmaroLuisNessuna valutazione finora

- Organic Chemistry 11th Edition Ebook PDFDocumento41 pagineOrganic Chemistry 11th Edition Ebook PDFlouise.merrill249100% (36)

- Chemistry Lecture Planner: Sno Chapter Name Topics No. of Lectures Total No of Date of Lecture Date of CompletionDocumento7 pagineChemistry Lecture Planner: Sno Chapter Name Topics No. of Lectures Total No of Date of Lecture Date of CompletionLØST๛ PAINNessuna valutazione finora

- Activity Worksheet #4 Module 4: Cell TransportDocumento3 pagineActivity Worksheet #4 Module 4: Cell TransportSenpai ChibiNessuna valutazione finora

- Chapter 18: Ethers and Epoxides Thiols and Sulfides: AlcoholsDocumento10 pagineChapter 18: Ethers and Epoxides Thiols and Sulfides: AlcoholsivanNessuna valutazione finora

- Butter Phulwara PDFDocumento1 paginaButter Phulwara PDFHari Chandra Poudyal0% (1)

- Selected Total Syntheses (Furstner) PDFDocumento280 pagineSelected Total Syntheses (Furstner) PDFludoNessuna valutazione finora

- Carbon Based Materials: A Promising Approach For Water Depollution by Electrochemical Advanced Oxidation ProcessesDocumento36 pagineCarbon Based Materials: A Promising Approach For Water Depollution by Electrochemical Advanced Oxidation ProcessesmektanNessuna valutazione finora

- C581 PDFDocumento568 pagineC581 PDFAkash YadavNessuna valutazione finora

- Susu Evaporasi-Veg FatDocumento4 pagineSusu Evaporasi-Veg FatIndah NurvitasariNessuna valutazione finora

- Pre Treatment For Fabrics Before DyeingDocumento16 paginePre Treatment For Fabrics Before DyeingNayomi Rathnaweera0% (1)

- Chemical Engineering Journal: Tam Do Minh, Jianzhi Song, Anjan Deb, Ligen Cha, Varsha Srivastava, Mika Sillanpää TDocumento25 pagineChemical Engineering Journal: Tam Do Minh, Jianzhi Song, Anjan Deb, Ligen Cha, Varsha Srivastava, Mika Sillanpää TShabnam MurshidNessuna valutazione finora

- Monk Fruit (Siraitia Grosvenorii) - Health Aspects and Food ApplicationsDocumento8 pagineMonk Fruit (Siraitia Grosvenorii) - Health Aspects and Food ApplicationsANGIE MARCELA CASTELLANOS GOMEZNessuna valutazione finora

- Carbohydrates: By: Sir Rodel C. Espino Mcnp-Isap Biochemistry InstructorDocumento68 pagineCarbohydrates: By: Sir Rodel C. Espino Mcnp-Isap Biochemistry InstructorAlthea Aubrey AgbayaniNessuna valutazione finora

- Alcohols+,+Phenols+,+Ether+ +Best+PYQDocumento128 pagineAlcohols+,+Phenols+,+Ether+ +Best+PYQArpit ShirbhateNessuna valutazione finora

- Degradation of Cytokinins by Cytokinin Oxidases in PlantsDocumento13 pagineDegradation of Cytokinins by Cytokinin Oxidases in PlantsRoikka HazarikaNessuna valutazione finora

- Food Label Lesson PlanDocumento11 pagineFood Label Lesson Planapi-353012963Nessuna valutazione finora

- KASP Genotyping Quick Start Guide: 2. AssayDocumento15 pagineKASP Genotyping Quick Start Guide: 2. AssayYanyan LiuNessuna valutazione finora

- MS Ijbpas 2018 44801Documento9 pagineMS Ijbpas 2018 44801Charlene Mae AlcaideNessuna valutazione finora

- Cardiac GlycosidesDocumento22 pagineCardiac GlycosidesMai Chi100% (1)

- Increasing Sustainability of Industrial Coatings With Imerys Functional MineralsDocumento28 pagineIncreasing Sustainability of Industrial Coatings With Imerys Functional Mineralss0n1907Nessuna valutazione finora

- Study of Esterification and Transesterification in Biodiesel Production From Used Frying Oils in A Closed SystemDocumento7 pagineStudy of Esterification and Transesterification in Biodiesel Production From Used Frying Oils in A Closed SystemMariuxiNessuna valutazione finora

- BASF Glyoxal BrochureDocumento8 pagineBASF Glyoxal BrochureMukund KsNessuna valutazione finora

- Discovery Studio Visualizer PDFDocumento3 pagineDiscovery Studio Visualizer PDFShin KaojuNessuna valutazione finora

- Agro EmulsifiersDocumento3 pagineAgro EmulsifiersFarizal HammiNessuna valutazione finora

- Applied Sciences: (Elaeocarpus Ganitrus Roxb.) (Propionibacterium Acne)Documento8 pagineApplied Sciences: (Elaeocarpus Ganitrus Roxb.) (Propionibacterium Acne)Wahidin HidayatNessuna valutazione finora