Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

(Hydrocarbonprocessing) - Proper Relief-Valve Sizing Equation

Caricato da

mrf_neoDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

(Hydrocarbonprocessing) - Proper Relief-Valve Sizing Equation

Caricato da

mrf_neoCopyright:

Formati disponibili

Proper relief-valve sizing requires equation mastery | Hydrocarbon Processing | December 2011

Page 1 of 11

COPYING AND DISTRIBUTING ARE PROHIBITED WITHOUT PERMISSION OF THE PUBLISHER

Proper relief-valve sizing requires equation mastery

12.01.2011 |Kim, J. S., Bayer Technology Services, Baytown, Texas;Dunsheath, H. J. , BayerTechnologyServices,Baytown,Texas;Singh, N. R., Bayer CropScience,Institute,WestVirginia These simple and rigorous critical-flow equations will help stem the tide of potential catastrophic failures Keywords: Pressure-relief valves are reliable and effective pressure-relief devices that protect personnel from the dangers of over-pressurizing equipment, prevent damage to equipment, and minimize release of hazardous materials. Sizing relief valves involves determination of the rate of material release through the relief valve during the identified worst-case contingency. Relief valves are designed to relieve liquids, vapors or two phases from protected pressure vessels before excessive pressures are developed. A mistake in the relief-valve sizing can result in catastrophic failures because relief valves are usually the last defense to the process equipment against instrument failures, process upsets and operator errors. This article focuses on sizing the pressure-relief valves for critical flow of gases or vapors. Two-phase sizing methods1,2 are not well established, but it is generally understood that sizing methods for vapor or gas are well established and the results are relatively accurate. Relief-system designers favor simple sizing equations, and use the conventional vapor-sizing equation in American Petroleum Institute (API) Standard 520, using the ideal gas specific heat ratio.3 Although rigorous calculations using isentropic flash calculations give the most accurate results, the simple API relief-valve sizing equation is still preferred because of its simplicity. However, sometimes the real gas specific heat ratio is more readily available from a process simulator than the ideal gas specific heat ratio. Thus, a simple sizing equation using the real gas specific heat ratio was developed. Emerging from that development is an improved sizing equation using the real gas specific heat ratio. The results are compared with the conventional API sizing equation. Furthermore, a rigorous critical-flow equation with the isentropic flash is introduced as a recommended estimation tool for gas or vapor critical flow when the gas or vapor is known to deviate significantly from ideal conditions. Conventional API flow equation. Eq. 1 is the conventional API relief-valve sizing equation for critical vapor flow. The conventional API sizing equation requires five fluid property data: absolute pressure, P; kPa, absolute temperature, T; K, molecular weight, M, compressibility factor, Z, and ideal gas specific heat ratio, k*, at inlet conditions. The equation provides

http://www.hydrocarbonprocessing.com/Article/2942457/Proper-relief-valve-sizing-requires-equation-mastery.html?Print=true

10/04/2012

Proper relief-valve sizing requires equation mastery | Hydrocarbon Processing | December 2011

Page 2 of 11

satisfactory sizing results over a wide range of process conditions. However, the sizing equation is only valid for 0.8 < Z < 1.1.3 This means that the sizing results may not be satisfactory for very high pressure conditions or critical-point regions.

where:(1)

(2) where: A = Relief valve orifice area, mm2 W = Mass flow rate, kg/h Ck* = A function of the ratio of ideal gas specific heat at inlet conditions Kd = The coefficient of discharge Kb = The capacity correction factor due to backpressure Kc = The combination correction factor for installation with a rupture disk upstream Subscripts 1 = Fluid conditions at the inlet of the relief valve, where velocity is equal to zero

choke

= Choked (critical) conditions.

http://www.hydrocarbonprocessing.com/Article/2942457/Proper-relief-valve-sizing-requires-equation-mastery.html?Print=true

10/04/2012

Proper relief-valve sizing requires equation mastery | Hydrocarbon Processing | December 2011

Page 3 of 11

Real gas specific heat ratio. The new equation uses the real gas specific heat ratio in the sizing equation instead of the ideal gas specific heat ratio. In order to figure out what assumptions are needed to use the gas specific heat ratio as an isentropic expansion coefficient, it is required to check with Eq. 3. This equation is one of the widely used methods for calculating the isentropic expansion coefficient where rigorous relief-valve sizing is deemed necessary. The equation is based on the assumption that the isentropic expansion coefficient is constant. Although the isentropic expansion coefficient is actually not constant during the expansion process, the sizing results with the isentropic expansion coefficient are relatively good. The derivatives in Eq. 3 for the Redlich-Kwong and Peng-Robinson equations are readily available in the literature.4,5 The Peng-Robinson equation of state appears to be the most favorable with the SRK equation. Eq. 4 shows the derivative of pressure with respect to specific volume, v; m3/kg, at constant temperature and constant compressibility factor. The gas specific heat ratio becomes the isentropic expansion coefficient (n) when the compressibility factor is constant. Of course, the real gas specific heat ratio, k, will be the ideal gas specific heat ratio, k*, if the compressibility factor is 1. In conclusion, it is required to assume the constant compressibility factor when developing a sizing equation with the real gas specific heat ratio. (3)

(4) where: Pv = ZRT where R is a universal gas constant, 8.314 kPa-m3/kg-mole-K. Eq. 5 is easily found in textbooks.6 When ideal gases are expanded, they follow Eq. 5. However, Eq. 6 is for real gases provided that the compressibility factor is constant. Eq. 6 explains why the inlet compressibility factor is not to be included in Eq. 7. The real gas specific heat ratio already accounts for the value of the compressibility factor and non-ideality at high pressure conditions. Therefore, when the real gas specific heat ratio is used in the sizing equation, the compressibility factor is not necessary. If one uses the real gas specific heat ratio in Eq. 1, the compressibility factor will be accounted for twice. This may result in inadequate relief valves, as addressed in API520.7 A statistical analysis shows that about 7% of the equipment in the oil, gas and chemical industries had pressure-relief devices undersized.8 Pvk* = constant(5) (6)

http://www.hydrocarbonprocessing.com/Article/2942457/Proper-relief-valve-sizing-requires-equation-mastery.html?Print=true

10/04/2012

Proper relief-valve sizing requires equation mastery | Hydrocarbon Processing | December 2011

Page 4 of 11

The authors developed Eq. 7 for relief-valve sizing for critical vapor flow with the real gas specific heat ratio. The simple equation follows fundamental thermodynamic rules.

where: (7)

(8)

where Ck is a function of the ratio of real gas specific heat at inlet conditions. Although Eq. 7 may be satisfactory for critical-flow relief-valve sizing, the critical pressure prediction is not sufficiently accurate. In order to predict the accurate critical pressure, Eq. 9 is derived based on Eq. 7 being equal to Eq. 10. Instead of solving Eq. 9 for the isentropic expansion coefficient with the real gas specific heat ratio and compressibility factor, Eq. 12 fits well the correlation among the compressibility factor, real gas specific heat ratio and isentropic expansion coefficient over the range of 0 < n < 2.5. (9)

Finally, Eq. 10 can be obtained as a critical-flow sizing equation with the compressibility factor and isentropic expansion coefficient. Eq. 7 and Eq. 10 are identical, and the two equations give the same sizing results. However, Eq. 11 predicts better choked pressures than Eq. 8.

http://www.hydrocarbonprocessing.com/Article/2942457/Proper-relief-valve-sizing-requires-equation-mastery.html?Print=true

10/04/2012

Proper relief-valve sizing requires equation mastery | Hydrocarbon Processing | December 2011

Page 5 of 11

where: (10)

(11)

(12)

(13)

a = 4.8422E-5 b = 1.98366 c = 1.73684 d = 0.174274 e = 1.48802 where Cn is a function of the isentropic expansion coefficient at inlet conditions. Isentropic flash. Eq. 14, which requires a few iterations in an isentropic flash routine, is the most accurate sizing equation. The rigorous method uses the best predictions of the actual fluid properties since the calculated isentropic expansion coefficient is constant between two data points. The first trial of isentropic flash can start with an initial estimate of choked pressure at 55% of the inlet pressure. The choked condition is usually attained when the downstream pressure is about 45% to 65% of the inlet pressure. Repeat the isentropic flash with the new estimate until it stops changing. In case of liquid formation during the isentropic flash, the overall specific volume of the fluid has to be used in Eq. 15. Otherwise, it is better to use the temperature and compressibility factor in Eq. 15 to indicate that there is no condensation during expansion. The calculation details will be illustrated in the example calculations section. However, the equivalent results can be obtained using numerical integration with numerous flash calculations. The intensive numerical integration method is presented in API Standard 520.

http://www.hydrocarbonprocessing.com/Article/2942457/Proper-relief-valve-sizing-requires-equation-mastery.html?Print=true

10/04/2012

Proper relief-valve sizing requires equation mastery | Hydrocarbon Processing | December 2011

Page 6 of 11

where: (14)

(15)

where Cr is a function of the rigorous isentropic expansion coefficient, and Subscript 2 refers to fluid conditions at the outlet of the relief valve (at the nozzle throat). Comparison. The predictions of the simple flow equations have been compared with the most accurate estimates for the following two cases at six different pressures. The two cases include high pressures and critical-point regions to evaluate the limitations of the new simple method. The Peng-Robinson equation of state was used for the estimation of necessary fluid properties. Case 1: Air at 250 K. The first case considers the discharge of air at 250 K that is relieving at six different pressure levels of the inlet reduced pressure from 0.5 to 8. The inlet compressibility factors are in the range of 0.9 < Z < 1.1. Fig. 1 shows the mass flux (W/A) deviations of Eqs. 1 and 7 from Eq. 14. Here, the compressibility factor decreases during expansion. Therefore, both of the simple sizing equations appear to oversize the relief valves. The difference between the compressibility factors increases with increasing the inlet reduced pressure. Fig. 1 shows that both simple equations give conservative estimates as expected. The results of both equations are satisfactory at low pressures. However, if the vapor or gas is at high pressure and low temperature, one should use them with caution. Generally, the vapor or gas tends to behave ideally at high temperatures.

http://www.hydrocarbonprocessing.com/Article/2942457/Proper-relief-valve-sizing-requires-equation-mastery.html?Print=true

10/04/2012

Proper relief-valve sizing requires equation mastery | Hydrocarbon Processing | December 2011

Page 7 of 11

Fig. 1.Calculationresultsforhigh-pressure air at250K(Case 1). Case 2. Saturated n-hexane vapor. The second case considers the discharge of a pure component-saturated vapor (n-hexane) that is relieving at six different pressure levels of the inlet reduced pressure from 0.15 to 0.9. The inlet compressibility factors are in the range of 0.4 < Z < 0.9. Here, the compressibility factor increases during expansion. The difference between the compressibility factors increases with increasing the inlet reduced pressure. Therefore, the simple sizing equations appear to undersize the relief valves. Fig. 2 shows that the conventional simple API equation gives profoundly unconservative estimates as expected. Unlike the conventional simple equation, the results of Eq. 7 or Eq. 10 are satisfactory up to the inlet reduced pressure of 0.75. However, if the inlet reduced pressure is greater than approximately 0.7, one should use it with caution.

http://www.hydrocarbonprocessing.com/Article/2942457/Proper-relief-valve-sizing-requires-equation-mastery.html?Print=true

10/04/2012

Proper relief-valve sizing requires equation mastery | Hydrocarbon Processing | December 2011

Page 8 of 11

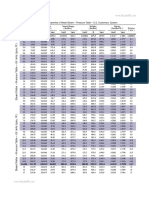

Fig. 2.Calculationresultsforsaturated n-hexane vapor under critical conditions (Case 2). Examples. A relief valve should release 10,000 kg/h of saturated n-hexane vapor (M = 86.18) at a relief pressure of 1,807.38 kPa (inlet reduced pressure of 0.6) and a relief temperature of 474 K. The compressibility factor at the conditions is 0.6279. Calculate the required actual orifice area based on Kd = 0.877, Kb = 1 and Kc = 1. The authors used a process simulator with a selection of the Peng-Robinson equation of state to obtain the necessary fluid properties. Calculations with Eq. 14. The results of isentropic flashes for Eq. 14 that were obtained from a process simulator are summarized in Table 1. Iterations were stopped after four trials, as the new choked pressure was close enough to the old one. The best estimate of required orifice area is 556 mm2.

http://www.hydrocarbonprocessing.com/Article/2942457/Proper-relief-valve-sizing-requires-equation-mastery.html?Print=true

10/04/2012

Proper relief-valve sizing requires equation mastery | Hydrocarbon Processing | December 2011

Page 9 of 11

Calculations with Eq. 1. Using the ideal gas specific heat ratio along with the inlet compressibility factor gives the required orifice area of 482 mm2, which is much smaller than the best estimate of 556 mm2. Calculations with Eq. 7. Using the real gas specific heat ratio gives the required orifice area of 567 mm2. Calculations with Eq. 10. Eq. 10 is technically identical to Eq. 7. This method will give a better estimate of the choked pressure than the Eq. 7 method.

All calculation results are summarized in Table 2 for comparison. The required orifice area estimated by the API sizing equation is not satisfactory as expected, and this may result in an under-sized relief valve. On the other hand, the new method by Eq. 7 or Eq. 10 produces satisfactory results. Recommended usage. Proper sizing of a relief valve requires not only using an accurate critical-flow equation, but also using accurate fluid properties. The simple sizing equation for critical vapor flow using the real gas specific heat ratio has been tested on two cases: air at higher pressures and n-hexane under critical conditions. Although in both cases the conventional API equation is difficult to properly size pressure relief devices, the new approach results in a significant improvement. It is also important to note that the compressibility factor should be removed in the simple sizing equation where the real gas specific heat ratio is used as an isentropic expansion coefficient. However, reliefsystem designers should be careful when sizing the pressure relief devices for vapor or gas at critical regions or high pressures where the gas or vapor deviates significantly from the ideal conditions.

http://www.hydrocarbonprocessing.com/Article/2942457/Proper-relief-valve-sizing-requires-equation-mastery.html?Print=true

10/04/2012

Proper relief-valve sizing requires equation mastery | Hydrocarbon Processing | December 2011

Page 10 of 11

Any simple equation involves assumptions that generally introduce errors. As demonstrated in the example calculations, the rigorous flow equation with isentropic flash is not so complicated and difficult to use. The rigorous flow equation with no assumptions uses the most accurate fluid properties. Therefore, using the rigorous flow equation with isentropic flash is recommended when the gas or vapor is known to behave significantly non-ideally. HP LITERATURE CITED

1 2

Darby, R., Evaluation of two-phase flow models for flashing flow in nozzles, Process Safety Progress, Vol. 19, No. 1, pp. 3239, 2000.

Diener, R. and J. Schmidt, Sizing of throttling device for gas/liquid two-phase flow, Part 1: Safety valves, Process Safety Progress, Vol. 23, No. 4, pp. 335344, 2004.

3 4 5

Sizing, selection and installation of pressure-relieving devices in refineries, API Standard 520, Part ISizing and selection, December 2008. Guidelines for pressure-relief and effluent-handling systems, Center for Chemical Process Safety (CCPS), AIChE, New York, 1998.

Pratt, R. M., Thermodynamic properties involving derivatives using the Peng-Robinson equation of state, Chemical Engineering Education, pp. 112115, Spring 2001.

6 7 8

Crowl, D. A. and J. F. Louvar, Chemical Process Safety: Fundamentals with Applications, Prentice-Hall, Englewood Cliffs, New Jersey, 1990. Shackelford, A., Using the ideal gas specific heat ratio for relief-valve sizing, Chemical Engineering, pp. 5459, November 2003.

Patrick, C., R. A. Kreder and W. Lee, Analysis identifies deficiencies in existing pressure-relief systems, Process Safety Progress, Vol. 19, No. 3, pp. 166172, 2000. The authors Jung Seob Kim is a principal process safety engineer at Bayer Technology Services, where he is responsible for designing emergency pressure relief systems and technical consultation. He has more than 25 years of experience in different roles with chemical process industry including with Samsung BP Chemicals Co. and Samsung Engineering Co. in Korea. He holds a BS degree in chemical engineering from the University of Seoul. Mr. Kim is a member of AIChE, and is a registered professional engineer in the state of Texas.

Heather Jean Dunsheath is a pressure safety specialist at Bayer Technology Services, where she is responsible for identifying potential overpressure scenarios and designing emergency pressure relief systems. She holds a BS degree in chemical engineering from Rice University and is a member of the Design Institute for Emergency Relief Systems.

http://www.hydrocarbonprocessing.com/Article/2942457/Proper-relief-valve-sizing-requires-equation-mastery.html?Print=true

10/04/2012

Proper relief-valve sizing requires equation mastery | Hydrocarbon Processing | December 2011

Page 11 of 11

Dr. Navneet R. Singh is a senior process engineer at Bayer CropScience LP, where he is responsible for process design, process modeling and emergency relief system design. He holds an MS degree and a Ph.D. from Purdue University, and a bachelors degree in chemical engineering from the Institute of Chemical Technology in Mumbai, India, is a senior member of AIChE and a certified functional safety professional.

PEDRO NEL PEREZ 12.28.2011 Very important explanations Pedro Nel Perez 12.28.2011 Very important this explanation

http://www.hydrocarbonprocessing.com/Article/2942457/Proper-relief-valve-sizing-requires-equation-mastery.html?Print=true

10/04/2012

Potrebbero piacerti anche

- Vapor PSV Sizing - Real Gas Specific Heat RatiosDocumento9 pagineVapor PSV Sizing - Real Gas Specific Heat RatiosChristopher Kenneth ChoaNessuna valutazione finora

- Fire Relief Rate Calculation-Part 2Documento4 pagineFire Relief Rate Calculation-Part 2zubair195Nessuna valutazione finora

- Improved Control Valve Sizing For Multiphase FlowDocumento10 pagineImproved Control Valve Sizing For Multiphase FlowThitikorn WassanarpheernphongNessuna valutazione finora

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationDa EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNessuna valutazione finora

- IVPL Control Valve Sizing ManualDocumento20 pagineIVPL Control Valve Sizing ManualGanesh YadavNessuna valutazione finora

- Diagnosing Instabilities in Distillation Column OverheadDocumento4 pagineDiagnosing Instabilities in Distillation Column OverheadRafaelNessuna valutazione finora

- How To Calculate Vessel Depressurization Time With QuickDocumento4 pagineHow To Calculate Vessel Depressurization Time With Quickhgandhi02Nessuna valutazione finora

- Relief and Blowdown System FlaringDocumento5 pagineRelief and Blowdown System FlaringRicardo NapitupuluNessuna valutazione finora

- DiersDocumento9 pagineDiers654525Nessuna valutazione finora

- Blowdown Calc FormulaeDocumento1 paginaBlowdown Calc FormulaeWayne MonneryNessuna valutazione finora

- Control Valve DPDocumento8 pagineControl Valve DPAmit SawantNessuna valutazione finora

- PSV For Distillation GuidelinesDocumento3 paginePSV For Distillation GuidelinesMubarik AliNessuna valutazione finora

- Tube Rupture (Two Phase - API App-D Method)Documento5 pagineTube Rupture (Two Phase - API App-D Method)Indra Kurniawan WijayaNessuna valutazione finora

- PSV Sizing - Two Phase (Two-Points)Documento2 paginePSV Sizing - Two Phase (Two-Points)Saeid Rahimi MofradNessuna valutazione finora

- DespresurizaciónDocumento3 pagineDespresurizaciónmatrix69Nessuna valutazione finora

- 11 8231 WP Safety Analysis Environment FINALDocumento21 pagine11 8231 WP Safety Analysis Environment FINALAlberto CorticelliNessuna valutazione finora

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentDa EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNessuna valutazione finora

- Restriction Orifice Flow Control GuideDocumento3 pagineRestriction Orifice Flow Control Guidemsr22Nessuna valutazione finora

- Estimation of Relief Load and Realistic Relieving Temperature For Heavy-End Fractionating ColumnsDocumento10 pagineEstimation of Relief Load and Realistic Relieving Temperature For Heavy-End Fractionating ColumnssdddNessuna valutazione finora

- Rigorously Size Relief Valves For Critical FluidsDocumento10 pagineRigorously Size Relief Valves For Critical Fluidsashirwad shetty100% (2)

- A Guideline For Design Pressure - Part 2Documento4 pagineA Guideline For Design Pressure - Part 2Said Ahmed SalemNessuna valutazione finora

- Gas-Liquid Separators Sizing Parameter - Campbell Tip of The MonthDocumento8 pagineGas-Liquid Separators Sizing Parameter - Campbell Tip of The MonthBalaji NaikNessuna valutazione finora

- Using DIERS Two Phase Equations To Estimate Tube Rupture FlowratesDocumento8 pagineUsing DIERS Two Phase Equations To Estimate Tube Rupture FlowratesNoirchevalNessuna valutazione finora

- Energy Optimization Using Pinch Analysis: Practical ConsiderationsDocumento10 pagineEnergy Optimization Using Pinch Analysis: Practical ConsiderationsconfyNessuna valutazione finora

- The Basis of API Corrolation For Fire Relief of Unwetted VesselsDocumento5 pagineThe Basis of API Corrolation For Fire Relief of Unwetted VesselscedwNessuna valutazione finora

- Blowdown of Vessels and Pipelines: S.M. Richardson & G. SavilleDocumento15 pagineBlowdown of Vessels and Pipelines: S.M. Richardson & G. SavillefaisalmuradNessuna valutazione finora

- Handbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28Da EverandHandbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28Nessuna valutazione finora

- Gas Blow-By From A Production Separator To Tank PDFDocumento7 pagineGas Blow-By From A Production Separator To Tank PDFebby1100% (1)

- Hydrate Formation in ValvesDocumento6 pagineHydrate Formation in ValvesChem.EnggNessuna valutazione finora

- Calculating Average Gas Release RatesDocumento5 pagineCalculating Average Gas Release RatesakashawalkerNessuna valutazione finora

- Using The Dynamic Depressuring Utility To Simulate High Pressure Blowdown ScenariosDocumento4 pagineUsing The Dynamic Depressuring Utility To Simulate High Pressure Blowdown Scenariosebby1Nessuna valutazione finora

- Dynamic simulation supports PSV over rupture disk for natural gas heater tube ruptureDocumento5 pagineDynamic simulation supports PSV over rupture disk for natural gas heater tube ruptureAbbasNessuna valutazione finora

- Calculate Saturated-Gas Loads For Vacuum SystemsDocumento3 pagineCalculate Saturated-Gas Loads For Vacuum SystemsFred FaberNessuna valutazione finora

- Reboiler HydraulicDocumento3 pagineReboiler Hydraulic54yreyeNessuna valutazione finora

- Calculating Settle-Out Pressure in Compressor Loops - Hydrocarbon Processing - November 2006Documento3 pagineCalculating Settle-Out Pressure in Compressor Loops - Hydrocarbon Processing - November 2006bogusiNessuna valutazione finora

- Heat-Exchanger Bypass Control: William L. LuybenDocumento9 pagineHeat-Exchanger Bypass Control: William L. LuybenYu Hui100% (1)

- Heat exchanger tube rupture case study: Addressing metal embrittlement risksDocumento6 pagineHeat exchanger tube rupture case study: Addressing metal embrittlement risksaegean227100% (1)

- Accurate Prediction of Tower ReliefDocumento5 pagineAccurate Prediction of Tower ReliefSheetal Solanki100% (1)

- Gas Sweetening-Part 1: Comparison of Amines - Campbell Tip of The MonthDocumento8 pagineGas Sweetening-Part 1: Comparison of Amines - Campbell Tip of The MonthAmit YadavNessuna valutazione finora

- Model A Refrigerated Gas Plant Workshop: ObjectiveDocumento25 pagineModel A Refrigerated Gas Plant Workshop: Objectivemiri-256Nessuna valutazione finora

- Reboiler Case StudyDocumento6 pagineReboiler Case StudyamlhrdsNessuna valutazione finora

- Blowdown ReportDocumento26 pagineBlowdown ReportPaul OhiorNessuna valutazione finora

- Special Focus: Reboiler Pinch: An Approach To Optimize Flare System Design During FEEDDocumento6 pagineSpecial Focus: Reboiler Pinch: An Approach To Optimize Flare System Design During FEEDGhasem Bashiri100% (1)

- Causes of Overpressurization: Understanding Common ScenariosDocumento1 paginaCauses of Overpressurization: Understanding Common ScenariosjargiaNessuna valutazione finora

- Latent Heat of Vaporization Via Hysys Flash Calculations - LinkedInDocumento5 pagineLatent Heat of Vaporization Via Hysys Flash Calculations - LinkedIngopinath87Nessuna valutazione finora

- AIChE Equipment Testing Procedure - Trayed and Packed Columns: A Guide to Performance EvaluationDa EverandAIChE Equipment Testing Procedure - Trayed and Packed Columns: A Guide to Performance EvaluationNessuna valutazione finora

- 08 ColumnPressureRelief PDFDocumento10 pagine08 ColumnPressureRelief PDFtaeebNessuna valutazione finora

- Optimizing Pressure Relief SystemsDocumento6 pagineOptimizing Pressure Relief SystemssgrsthNessuna valutazione finora

- Storage Tank Protection - Jump StartDocumento18 pagineStorage Tank Protection - Jump StartSushant SharmaNessuna valutazione finora

- For Exchanger Tube Rupture PDFDocumento3 pagineFor Exchanger Tube Rupture PDFNikhil DivateNessuna valutazione finora

- Natural Gas Processing from Midstream to DownstreamDa EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirNessuna valutazione finora

- Chemical Process Design and Simulation: Aspen Plus and Aspen Hysys ApplicationsDa EverandChemical Process Design and Simulation: Aspen Plus and Aspen Hysys ApplicationsValutazione: 2 su 5 stelle2/5 (1)

- Process Engineering: Facts, Fiction and FablesDa EverandProcess Engineering: Facts, Fiction and FablesValutazione: 3 su 5 stelle3/5 (2)

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Da EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Nessuna valutazione finora

- Understanding Distillation Using Column Profile MapsDa EverandUnderstanding Distillation Using Column Profile MapsNessuna valutazione finora

- Pressure Relief - Valve Sizing Mastery (HP)Documento4 paginePressure Relief - Valve Sizing Mastery (HP)Ricardo BecNessuna valutazione finora

- Article PSV Specific HeatDocumento6 pagineArticle PSV Specific Heatprq123Nessuna valutazione finora

- Safety Valve SizingDocumento33 pagineSafety Valve SizingAshok Kumar100% (1)

- Adiabatic Gas Law Apparatus ManualDocumento8 pagineAdiabatic Gas Law Apparatus ManualmarzinusNessuna valutazione finora

- Relief Valve Tutorial Spirax SarcoDocumento16 pagineRelief Valve Tutorial Spirax SarcoamokhtaNessuna valutazione finora

- Water Resources and Water PollutionDocumento50 pagineWater Resources and Water PollutionsairamvutukuriNessuna valutazione finora

- Clean Agents and Carbon DioxideDocumento2 pagineClean Agents and Carbon DioxideRemy PangkorNessuna valutazione finora

- GLO-T800-PRO-EVA-TEC-000-00001-00 H01 (GLO Fuel Gas System Study Report For Gendalo FPU)Documento100 pagineGLO-T800-PRO-EVA-TEC-000-00001-00 H01 (GLO Fuel Gas System Study Report For Gendalo FPU)Tifano Khristiyanto100% (3)

- Water-Steam Saturation Properties (By Pressure in US Units)Documento5 pagineWater-Steam Saturation Properties (By Pressure in US Units)Juan Carlos Ramirez DariasNessuna valutazione finora

- PARTS of SUN Detailed Lesson Plan 2021Documento7 paginePARTS of SUN Detailed Lesson Plan 2021Rhenalie Rose SalinasNessuna valutazione finora

- Put Rce072Documento1 paginaPut Rce072Ashish VermaNessuna valutazione finora

- 9A01503 Water Resources Engineering - IDocumento4 pagine9A01503 Water Resources Engineering - IsivabharathamurthyNessuna valutazione finora

- BTMAM Survey Compares Top AC Brands by Capacity, Power UsageDocumento9 pagineBTMAM Survey Compares Top AC Brands by Capacity, Power UsagePriya ManeNessuna valutazione finora

- Ice - Plant FrickDocumento4 pagineIce - Plant FrickFernandoReyesNessuna valutazione finora

- Pump and Gas Moving EquipmentDocumento13 paginePump and Gas Moving EquipmentM.Ghulam Al-AyubiNessuna valutazione finora

- Pipe Flow Expert Guide - System Calculation TolerancesDocumento13 paginePipe Flow Expert Guide - System Calculation TolerancesradiopascalgeNessuna valutazione finora

- PM SCHEDULE TITLEDocumento52 paginePM SCHEDULE TITLEsampath sarangaNessuna valutazione finora

- Salt Concentration: Fresh WaterDocumento31 pagineSalt Concentration: Fresh WaterAli Raza (Alee)Nessuna valutazione finora

- Pnaaw239 PDFDocumento165 paginePnaaw239 PDFSamErnesto007Nessuna valutazione finora

- Chemistry-States of Matter Part 1Documento3 pagineChemistry-States of Matter Part 1aditi kNessuna valutazione finora

- Hedco Water Division: Hampa Energy Engineering & Design CompanyDocumento7 pagineHedco Water Division: Hampa Energy Engineering & Design CompanyRaduNessuna valutazione finora

- EASEMENT-OF-AQUEDUCTS Notes PDFDocumento16 pagineEASEMENT-OF-AQUEDUCTS Notes PDFJustineNessuna valutazione finora

- CDB 4323 Assignment 2Documento7 pagineCDB 4323 Assignment 2Muhammad AnwarNessuna valutazione finora

- ME2134 Fluid Mechanics I Tutorial 1 SEO-Optimized TitleDocumento4 pagineME2134 Fluid Mechanics I Tutorial 1 SEO-Optimized TitleCl SkyeNessuna valutazione finora

- Calculation of Flow Through Nozzles and OrificesDocumento12 pagineCalculation of Flow Through Nozzles and OrificesrelaxmanNessuna valutazione finora

- 76BDocumento4 pagine76BJamie SchultzNessuna valutazione finora

- Compressible Flow Through Convergent and Laval NozzlesDocumento10 pagineCompressible Flow Through Convergent and Laval NozzlesIshwar SinghNessuna valutazione finora

- WaterDocumento25 pagineWaterabhishek tiwariNessuna valutazione finora

- Chapter 1 - Introduction: Sr. No. QuestionsDocumento15 pagineChapter 1 - Introduction: Sr. No. QuestionsAkashNessuna valutazione finora

- 1 - Gas Thermometer and Absolute ZeroDocumento6 pagine1 - Gas Thermometer and Absolute ZeroPeggie ZengNessuna valutazione finora

- Progress 4-Plan of Development Komretulesyen-19 Field (Nawasena Energy)Documento643 pagineProgress 4-Plan of Development Komretulesyen-19 Field (Nawasena Energy)Gh4n113 IdNessuna valutazione finora

- Australia Harvesting Rainwater For Environment, Conservation & Education: Some Australian Case Studies - University of TechnologyDocumento8 pagineAustralia Harvesting Rainwater For Environment, Conservation & Education: Some Australian Case Studies - University of TechnologyFree Rain Garden ManualsNessuna valutazione finora

- Lecture 1Documento26 pagineLecture 1Andrew ChikuselaNessuna valutazione finora

- Viscosity SensorDocumento14 pagineViscosity SensorerizaNessuna valutazione finora

- Measurement of Density, Specific Gravity and Viscosity of LiquidsDocumento10 pagineMeasurement of Density, Specific Gravity and Viscosity of LiquidsSaid Ahmed Ali100% (2)