Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

RC820 (2E RELAY) Instruction Manual: Toshiba

Caricato da

iam_sutat5147Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

RC820 (2E RELAY) Instruction Manual: Toshiba

Caricato da

iam_sutat5147Copyright:

Formati disponibili

TOSHIBA

6F9E0092

RC820 (2E RELAY) INSTRUCTION MANUAL

RELAY MODELS RC820-HP-YRC820-AP-Y

AUXILIARY MODULES RC-81A (GROUND FAULT) RC-81 B (PHASE REVERSAL) RC-81C (GROUND FAULT/PHASE REVERSAL)

TOSHIBA CORPORATION

TOSHIBA

6F9E0092

C 0 M T E N T S Page OUTJ,INI: ____---_--_________--------------------------_--------------_----------__-_________________--------------------------------------------------------_-----2 2 2 3 7 I. 0 13 16 17 19 20 22 24

INITIAL IMSPECTION APPLICATIONS

RATINGS AND PERFORXAPJCZS PRECAUTIONS IN APPLICATIONS INSTALLATION

---_---_-_____-______________________ ----------_---_--_--________

CIRCUIT CONSTRUCTIONS IIOM TO SET SELIKTION

---------_-----_-_-_------------------AND ADJUSTEIENTS -_-_----_-______________ -----------------------

INSPECTION AND MAINTEI4ANCE TROUBLE-SHOOTING

-______________-_________________ ------------------------------------------------

INSTALLATION TEST PROCEDURE GROIJND FAULT TEST FORM

-l-

TOSHIEA

6F9E0092

OUTLINE

The 2E Relay (static relay for three-phase induction motors) is widely used in various industrial fields to protect induction motors against overloads and other abnormal conditions (i.e., single phase, unbalanced phases). Optional plug-in type modules can be installed which include the RCRlA ground fault module, RCRlB phase reversal module, and RCRlC ground fault/phase reversal module.

INITIAL INSPECTION

(1)

Check that the 2E Relay and/or additional module is per ordering specifications.

(2)

Check

the 21: Relay and/or additional module for damage

incurred during shipment (breakage, loose parts).

APPLICATIONS

The 2'3 Relay and/or additional module is used to protect three phase induction motors and other three-phase loads, not only from ovcrloa~ds and single phase conditions phase reversal an83 ground fault. but also from

TI T: $

a i!

- 2

T O S H I B A

6F9E 0092

RATINGS Table :. Table 1 \

AND

PERFORMANCES

ists the ratings and performance of the 21? Relay. Ratings al nc 1 Performances of the 2E Relay ..___.. RI, 82?-- ._. --;gl* 1 ;FE;12 1 Kzi12m

-.-~--_

...u,. T y p e - F o r m

Items

-'\

Applicable ckcuit

-.

Wee-phase circuits rated up to 600V AC, 50/60 HZ - Direct (Also, applicable to high-voltage circuit: by cc&in&q with high-voltage CTS) Dual functions (2E relay) ---- Over load acd Single phase protection. 7AT mmG;-

Protective functions

Rat&l ampere-

Rated current -

turns Setting range Ultimate operating current Operating time setting range Operating time accuracy

%~150% of rated at-[75+(5+1(l+20+40)%1 105*125% of current setting 3s40 Sec. for starting characteristics at 600% of current setting [3+(2+5+10+20) sec.1 +20% of tine setting 85% of current setting under one-phase ccmpletely loss state (When measured on either remaining phase.) -- See Fig. 1 --___--.-Less than

Gverload operating characteristics

Single-phase protection 3perating zharacteristics Iontrol voltage

Minimum operating current operating time Rating Tolerance

4 sec.

10@~12OV/200+240 V AC, lrd , SO/60 HZ 85% s 110%

<z ?

- 3 -

TOSHIBA

6F9E0092

RC 8 2 0 -

L.. \ Type -Form

Itemi Control pzw H P 1Y HPlY12 APlY

T HP~Y HPZY12 AP2Y 2

VA

Power consmlption

circuit __Detecting circuit

0.3 VA/phase at rateJ current

contact Output arrangement ___contact Contxt specifications : capacity NEMA B300

1x0 - NC 12OV AC-5.OA 12OV AC-3.OA 125V IX!-0.2A 250V DC-O.lA LED

(SPDT/FOIIII C)

(Resistive load) (Inductive load, pf=0.40) (iJR=7ms) (IdR=7ms)

Fault in&cation Reset r,ode

RCP?O --H PElY --. Mdnunl R&et T y p e RCH20-HP! ,Y12 Man~algRemote Reset Jr;82G--A~!~~<.~: A u t o Reset..T&_e _...___

Application conditions

Ambient temp:rature Relative hwnidity

- 1 0 ?I +GOOC

4 5 Q, 8 5 % a t 2 0 C

_I s: ! - 4 -

jl i

T O S H I B A

6F9E009'2

The a'dditional modules are connected to the 2E relay with gold plated pins and their principal ratings are the same as that of 2E Relay. range and parformances. Table 2 Ratings and Performances of optional modules RC8lA \ K81l3 RC81C In Table 2 is listed its ratings

l-._ _ T&e-Form

Items Operating Phase current reversal Operating zharacteristics time

90% of 2K relay 90% of 2E relay current setting current set&y

Less than 0.58 Less than 0.5s

Grouncl fault 411 s l?A current zcr setting Primary Maximum fault current tiround fault time settitq htput signal -~~~ rrip indication -______-.

o.ls~l.os

l\ ~~ \

o.ls~l.os

output contacts of basic relay

__._~ -.-.. LED (manual reset) __12ik4cnA 12ii:4omA Connected connected Impedance : Imwance : zoosl 3oos3

<CT

-5-

TOSHIEA

6F9E0092

Overload operating characteristics Ultimate operating current --- 105-125 of current setting Single phase protection operating characteristics min. operating current --- 85% of current setting

., .I~./,

..,-.

+...

.,.+~

.___

,l,nl---C~Ilii~.-Overload operatingL-./,-characteristics-

'?I-Single

NUT,TIPLCS

OF LOAD CURRENT

MULTIPLES OF LOAD CURRENT RUNNING CliARAC'TEHISTIC

STARTING CIIARACTCRISTIC

Fi.g .

3.

Operating

characteristic

curve

-. 0 ?i 6 6 -

TOSHIBA

6F9E0092

PR E C A U T I O N S

IN

A PP L I C A T I O N S

When planning to use Toshiba Static 2E Relays, be sure to give full consideration to the following precautions: (1) (Control power source supply The power circuit must be arranged so that control Ipower is always supplied to the 2E Relay before the main circuit is switched ON. (2) Limit the secondary burden when combining with external cT's. When the relay is used in a medium an excessive CT secondary

or high voltage circuit,

burden may cause secondary current waveform distortion. !;ince large waveform distortion may be detected as unbalanced current, limit the external CT secondary burden according to the overcurrent constant while referring to Table 3. Table 3

Limit of external CT secondary burden Recommended Secondary Burden Not greater than 50% of rating Not greater than 85% of rating

l(l or above

Up to rated burden

-7

TOSHIBA

6F9E0092

(3) Application on DC systems See Fig. 2. In DC control systems main current does not flow sinusoidaly even though the power system (voltage) may be AC, so the 2E Relay, and/or modules, are not applicable. additional

Three-phase AC power supply

2E CT 2E Relay

-

Thyristor

23

DCM

?-

DC Motor

Fig. 2 Example of misapplication of the 2E Relay

TOSHIBA

6F9E0092

(4) The 2E Relay has phase unbalance detecting characteristics. Figure 4 shows how the current's unbal-

anced trip point depends upon the relay's current setting and the unbalanced current rate.

Current setting value:iOo%

Current Setting value:125%

Current setting value:150%

50

I max.:

Max.

phase cUrrent

0 0 :100

200 300 400 500 600 700 800

-Max. phase current (percent of current setting)

Fig. 3 Phase unbalance detecting characteristics

- 9

TOSI-IIRA

6FPE0092

INSTALLATION 1. Surface Mounting -

The 2E relay will be shipped with mounting feet loose. Before installation, attach the mounting feet to the The below shown mounting feet relay as shown Fig. 4. and hardware will be shipped together with the relay as standard accessory. Do not use a screw-locking agent when tightening.

Mounting

Feet

AcceSSOry

5CO.20)

Dia-4

Mounting

M3.5

ScrfwS \

setting Switches Time Setting

Trip Indication

Fig. 4 Surface mount type 2E Relay

- 10 -

TOSHIBA

6F9E0092

2.'

Flush Mountins For is flush mounting, flush mounting kit (order separately)

required. installation, attach the flush mounting fee to the instead of surface mounting feet as shown Fig.5.

Before relay

Flush Parts

Mounting

Kit

I

Feet Nylatch I

Quantity 2 1 4 I

Flush Flush M4 M4

Mounting Cover

with

Screws Spring Washers

Mountiny

Panel Terminal

8(0.32)Dia

-2 Mounting EaO(2.36)

Holes Conductor

kp-4

Nylatch

j 170(2'.75)_jj,' .47+0.2) .66+0.2) -

5(0.2)Dia

1 . 6 M i n L 3 . 2 M a x ( 0 . 0 6 m i n 2, 0 . 1 2 5 max)

-4 Mounting Holes

Fig. 5 Flush mount type 2E

Relay

- 11 -

TOSHIBA

6F9EO092

3.

Optional Install module) For:

Module module as

Installation with two knurl after screws the (accessory of

shown

Fig. 6

relay

installation

and wiring to the relay are completed. module to installation, peel off the side label on open the holes for connection pins.

the relay

4.8(0.1?) Dia-2 Kounting Holes -

Fin Contacts ,

Indicator

+--11.1 -.

z

Fig. 6A

-+--

Mounting -

i6OC2.36) P.20 i

1 lsl cl:Y8, 1 (0.59)

Additional

m'2dul.e

Fig. 68

z 5

- 12 -

Combination of 2l? relay and additional module

TOSHIBA

6F9E0092

CIRCUIT When Fig. 1) 2) 3) wiring primary

CONSTRUCTIONS wires through the CT windows, see

9, take care of the following: Primary Primary Primary wires must wires wires must must go go through through the the in same correct the same CT windows.

direction. turns through

have

number of

the CT windows. Before low voltage applying induction the the 2E Relay and/or additional Fig. 8, module which for

motor

protection,

see

illustrates

typical

wiring

connections. low voltage

Applying the 2E Relay for high voltage,or large

-

capacity the CT

systems,

see

Fig.

9.

It is necessary to is,

CT

balance length.

secondary

load,

that

secondary

wire

Built-in CT window

l pqqgJ-e Nwnker of turns 1

Vumber

of turns2

3 passes

-:= -.T e

2 PCs5

Number of turns 3 wires

Fig.

Installation built-in

of

passing

through

the

CT's

z ! 13 -

TOSHIBA

6F9E0092

Low-voltage pows!r supply 200V 21 240V AC

In case of low-voltage circuits (rated at 600V or less) Applied circuit wire is directly passed through the built-in CT window. CAUTION: * Connections of control power source AC 100-120V --- Terminals l-2 AC 200-240V --- Terminals l-3 ** Connections of output contacts NC-contact (opened when the 2E Relay operated) --- Terminals 8-9 NO-contact (closed when the 2E Relay operated) --- Terminals 9-10 *** Connections of Remote reset switch Remote reset --- Terminals 4-5 /P ,'Special spec.: RC820- tl P CIY I 2\\

/ Viiriny lenqth,from 2F tn r e s e t SwitLh \ mu>t he 1w.s than :m. i

Tow-voltage induction motor

i.jy.

~~~~~~~~~

~pplicatloll

i.r low-vnlrdg~ - 1 4 -

i n d u c t i o n motor circuit

TOSHIEA

6F9E0092

Kigh-voltage power supp1;, 2.3KV % 13.8KV nc

PT Or Control transformer (2.3KV/12OV or 13.8KV,'120V)

I r ___-

stop

iigh-voltage :ontactor

A

+.;i

-

contaqm owatl~ co11

~--1

Jt-start

M

+

High voltage CT

High-voltage induction :ootor

High-voltage CT secondary circuit wires pass through the windows of the built-in CT's.

Fig. 9 Typical application to high-voltage induction motor circuit with ground fault protection

- 15-

TOSHIBA

6F9E0092

IIOW TO SET

The 213

relay is offered in three models, Ampere-Turn 7AT 55AT 1lOAT Rating

Model RC820-F:PlY RCDi.O-iiP2Y RC820-;.:P3Y

with each having ?.n adjustable (Ampere-Turn) range of 75%150%. Each model has direct wiring capability through the three current transformer's ). windows. This is limited to 165 amperes

(X820-r!P3Y \ ..

For larger currents, or voltages above 6OOV,

the use of extern;J current transformers is required. Selection of the suitable model may require some preliminary calculations. See "Current Setting Adjustments" to -.

determine if the calculated "% Dial Setting" can be obtained with the selected model given the motor's full load current (FLA).

limiting

Model Selection can also be influenced by wire

Size

the number of turns that can be passed through the

CT windows (0.75 in. by 0.75 in.).

16 -

TOSHIBA

6F9E0092

SELECTION

AND

ADJUSTMENTS

(1) Current Setting Adjustment N(T)=2E Amp-Turn -~iotor-F~~ -.--. ~- Ratio* Rating x External CT

N(T)

: Number of turns through the 2E's built-in CT's, rounded off to nearest integer (CT wraps are additive).

Current Setting % .Z Motor FLA x N(T) ~100% 2E Amp-Turn RAz-xE<ternai CT Ratio* CT Ratio: Ex. 500A/5A CT's = 1OO:l

Exts!rnal

If no external CT's are used, substitute with "1.0". ** For 1.15 Service Factor Motors. If the motor has a 1.0 S.

F., multiply the calculated Current Setting %" by 0.93.

-

NOTE :

Select the external CT'S ratio so that the current setting 8 is as close to 100% as possible.

Example Ul:

5OHP, 4GOV 65A Full Load, 1.15 S.F. Across-the-line start. Since the full load falls within the range of the 55 AT (75 - 150%) 2E Relay's CT's, and no external CT's are required, The 8 Dial Setting _ 65~1~100% = 118% = 115% or 120% 55

Example X2:

2OOHP, 46OV, 240A Full Load, 1.15 S.F. Across-the-line start. 240 Amps exceeds the highest rated 2E Relay, therefore, external CT's must be used, and the HPlY , 7 AT rated 2E, will be chosen as the standard model when the current exceeds the HP3Y 's rating. If 300/5 CT's are used,

2 8 - 17 -

TOSHIBA

6F9E0092

the Current Setting 8 = 240 x N(T) x 100% 7 x (300) 5 = N(T) x 57.14%. And if 2 turns through the 2E Relay's CT windows (from the external CT'S) are used, the 8 Dial Setting = 2 x 57.14 = 114% = 110% or 115% (2) Time setting Determine the protection curve from 2E Relay operating curves shown in Fig. 1, and read the operating time at 'Adjust the time setting dip

GOO% of setting current.

switch to the nearest setting above the operating time. When using the RC81A or RC81C with the 2E Relay, determine the settings with the same manner mentioned above. (3) Fault Indication and Reset The LED on the 2E relay is illuminated by any trip condition. The optional module's have individual indicators (LED's). When the 2E Relay detects an overload, single phase or phase unbalance condition, and the LED indicator lights, When the

throw the reset toggle switch to reset the relay.

2E relay equiped with an optional module detects a phase reversal or ground fault n>f!t- the t.G,Jqle swi !( /I of the 2E relay and optional module to turn off both LED'S.

$ :! - 18 -

TOSHIBA

6F9E0092

INSPECTION

AND

MAINTENANCE

Before inspection and maintenance, read the following items to determine the maintenance period.

Intervals

of

inspection

(1) When the 2E Relay and/or additional module in an ordinary electric control room is operated under relatively good environmental conditions . . . . . Approx. annually (2) When the 2E Relay and/or additional module is operated under adverse environmental conditions . . . . . Approx. semi-annually Items to be inspected (1) Dust accumulation . . . . . When dust accumulation or contami-

nation is observed near the current-conducting components, wipe them clean with a soft, dry cloth. gasol.ine, (2) Loose Do NOT use

bengine, or other organic solvents.

stress

(3) Presel: points of the current-setting and time-setting switches (4) Operation of the test switch, if necessary (5) Operating characteristics, if necessary

(6)

Damage or other defects

- 19 -

TOSHIBA

6F9E0092

TROUBLE-SHOOTING 1n case of trouble, determine the cause of the trouble in accordance with the sequence shown in Fig. 10 or Fig. 11. After clarifying the cause, chart to correct the problem.

2~

take the actions shown in the

nelay fails to operate I

Iil~~~i~~~~~F:..:I.;.;...I.. 4

Check the sequence of primary wires Incorrect Correct it 1

set

current

normally

Operates

Fig. 10 Trouble-shooting table ('#hen 2E Relay fails to operate)

i - ;o-

TOSHIEA

6F9E0092

2E Relay trips during motor start-up and operation

Check the phase sequence Check the motor and load to eliminate

Abnormal Ch

Operates normally (See Fig. 1)

current

value

Fig. 11 Trouble-shooting table

n 9

(When 2E Relay operates during motor start-up and operating)

3 -21 -

TOSHIBA

6F9E0092

-1:NSTALLATION TEST PROCEDURE

It is not necessary to schedule periodic maintenance and testing of the ground fault protection. However, if tests

are desired to confirm the proper operation of the system, one of the following procedures can be used.

Iri--

1. Mounted in corltrol panel Power _~---__-------------------r--------

~;~~~lc~-~--:l,:;ll,+ Y L ___________ --------------_------------ -------- Fig. 12 Test circuit Note. The above figure shows the relay reset. (not tripped). The resistor in the test unit is for currtnt llr~:~?in~j. 1. 2. 3. 4. 5. 6. 7.

--j

When testing the ground fault module, keep the main circuit de-energized. Set the ground current knob at a proper value of IGS. (ground fault trip point) Connect the test wire through the ZCT window as show in Fig. 12. Apply control power to the 2E and interrupting device. Apply 1.25xIGS with the test circuit and interrupt the current when the relay operates. Check the operation of the relay with test switch on the 2E and check that the LED indicator lights. If the relay does not operate at the set time, interrupt the test current., cheek the current setting and the repeat test.

-

22 -

TOSHIBA

6F9EOo92

2.

Bc?nch

Test

r-------------------I

, - - - -----------t---t

I I I

M

GROUND CURRENT- DELAY DETECT

OUTPUT

;RCDlA or RCBlC L-_----------------------------J

I I II W820 L.

2-l i-u

Pl I+ I

I

POk TER PLY t

P2 s"p

Fig.

13

Test

circuit

Note. The above figure The resistor in 1. 2. 3. 4. 5.

shows the relay reset.(not tripped). the test unit is for current limiting.

Connect the sensor and relay as shown in FIG. 13. Set the ground current knob at a proper value of IGS (ground fault trip point). Apply 1.25xIGS with the test circuit and interrupt the current when the relay operates. Check the operation of the relay with the test switch on the 2E and check that the LED indicator lights. If relay does not operate at the settilm,interrul>t ,hc: es-l: current, check the culrbnt sett.iny nt\~ repeat ihe th<(;.

- 23-

TOSHIBA

6F9E0097

- Gl'?-;-

P..UL:

--.- ---.. T:...: F...:..

vo. --

Date

Setting -

Test current

Result

Not .e

- 24 -

Potrebbero piacerti anche

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- 110 Waveform Generator Projects for the Home ConstructorDa Everand110 Waveform Generator Projects for the Home ConstructorValutazione: 4 su 5 stelle4/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Valutazione: 2.5 su 5 stelle2.5/5 (3)

- Volvo Ignition PartsDocumento6 pagineVolvo Ignition PartswguenonNessuna valutazione finora

- Alternator Voltage Regulator With Droop CT Connections: DescriptionDocumento4 pagineAlternator Voltage Regulator With Droop CT Connections: Descriptionمصطفئ العراقي AlfailyNessuna valutazione finora

- Confidential Manual for Rainbow 150 Welder RepairDocumento54 pagineConfidential Manual for Rainbow 150 Welder RepairJaroslaw Brzozowski100% (2)

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionNessuna valutazione finora

- Calibrate 175-4998 Signal ConverterDocumento5 pagineCalibrate 175-4998 Signal ConverterImad Hmd75% (4)

- Norkontrol Dgu-8800Documento198 pagineNorkontrol Dgu-8800Павел100% (1)

- GXT2-10000T230 Service ManualDocumento33 pagineGXT2-10000T230 Service ManualMilton Mejia80% (10)

- Ignition System BasicsDocumento27 pagineIgnition System BasicsRajesh KumarNessuna valutazione finora

- ICM21Documento8 pagineICM21pldalpianNessuna valutazione finora

- 3 Axis TB6600 CNC Driver Board Users ManualDocumento10 pagine3 Axis TB6600 CNC Driver Board Users Manualalvarnal100% (2)

- Engineering Document: 757-4002-097 CAD #D8478Documento29 pagineEngineering Document: 757-4002-097 CAD #D8478Vasi ValiNessuna valutazione finora

- MHAWK LHD Manual Electrico PDFDocumento52 pagineMHAWK LHD Manual Electrico PDFAlex BravoNessuna valutazione finora

- Variable Speed AC Drives with Inverter Output FiltersDa EverandVariable Speed AC Drives with Inverter Output FiltersNessuna valutazione finora

- Transformer Driver For Isolated Power Supplies: Features ApplicationsDocumento29 pagineTransformer Driver For Isolated Power Supplies: Features Applicationsngongpro27Nessuna valutazione finora

- Diagrama Electrico Retroexcavadora 420F2 Serie NSBDocumento36 pagineDiagrama Electrico Retroexcavadora 420F2 Serie NSBCristian Proyecting PeruNessuna valutazione finora

- Manual Sr1a201bdDocumento112 pagineManual Sr1a201bdphilcogabi100% (1)

- 3 Axis TB6560 CNC Driver Board Users ManualDocumento13 pagine3 Axis TB6560 CNC Driver Board Users ManualJoão Luis Paiva JuniorNessuna valutazione finora

- v65d v6 0 Instruction ManualDocumento57 paginev65d v6 0 Instruction ManualMr.K ch100% (1)

- MA7200 Installation ManualDocumento169 pagineMA7200 Installation ManualWilmer AlegriaNessuna valutazione finora

- Tc-2060 Instruction Manual v0.09Documento93 pagineTc-2060 Instruction Manual v0.09Herry SusiloNessuna valutazione finora

- KT60KM06Documento2 pagineKT60KM06Luciano DiasNessuna valutazione finora

- At 30 IcDocumento9 pagineAt 30 IcCristina AntohiNessuna valutazione finora

- STK681-210-E: Forward/Reverse Motor DriverDocumento0 pagineSTK681-210-E: Forward/Reverse Motor Driverfredy51Nessuna valutazione finora

- Soft Starter Carlo Gavazzi Bse 4012bDocumento4 pagineSoft Starter Carlo Gavazzi Bse 4012bBranko MedanNessuna valutazione finora

- Sla7024m PDFDocumento12 pagineSla7024m PDFEJASMANYNessuna valutazione finora

- DS13 Series SSRDocumento4 pagineDS13 Series SSRdanieltorniNessuna valutazione finora

- Sla7024m (Motor Driver)Documento13 pagineSla7024m (Motor Driver)Franklin Miranda RoblesNessuna valutazione finora

- 3A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesDocumento12 pagine3A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesGiovanni Carrillo VillegasNessuna valutazione finora

- Datasheet - HK rt8110 7327105 PDFDocumento14 pagineDatasheet - HK rt8110 7327105 PDFLuis CarlosNessuna valutazione finora

- MAX1858 Evaluation Kit: General Description FeaturesDocumento7 pagineMAX1858 Evaluation Kit: General Description Features9183290782Nessuna valutazione finora

- Coduri de Eroare La VFD-ELDocumento82 pagineCoduri de Eroare La VFD-ELr_corneliu1710Nessuna valutazione finora

- Fda5000c Eng v2.3 - 2Documento109 pagineFda5000c Eng v2.3 - 2JUAN RODRIGUEZNessuna valutazione finora

- Vfd150c43a ManualDocumento458 pagineVfd150c43a Manualhau100% (2)

- Imprimir Datasheet 1Documento14 pagineImprimir Datasheet 1Randy Siancas VelezNessuna valutazione finora

- An 1599Documento20 pagineAn 1599nisha770Nessuna valutazione finora

- I. V. R Operation Manual PDFDocumento20 pagineI. V. R Operation Manual PDFR Jay FranNessuna valutazione finora

- TB6560 - T4 - V4 4 Axis CNC Dirver Manual and TB6560-T4-V3 4 Axis CNC Dirver Manual 20110510Documento16 pagineTB6560 - T4 - V4 4 Axis CNC Dirver Manual and TB6560-T4-V3 4 Axis CNC Dirver Manual 20110510Ersin CelebiNessuna valutazione finora

- LM319 Dual ComparatorDocumento8 pagineLM319 Dual ComparatorDurbha RaviNessuna valutazione finora

- Advanced Motion Controls S16a8Documento8 pagineAdvanced Motion Controls S16a8ElectromateNessuna valutazione finora

- LM555 Timer: Literature Number: SNAS548BDocumento14 pagineLM555 Timer: Literature Number: SNAS548BKenly WallNessuna valutazione finora

- ICL8069 - Low Voltage Reference - Intersil CorporationDocumento6 pagineICL8069 - Low Voltage Reference - Intersil Corporationwlen2012Nessuna valutazione finora

- Lm555 555c TimerDocumento12 pagineLm555 555c TimerAlexis Orellana VediaNessuna valutazione finora

- LCM Module: Industrial Co., LTDDocumento18 pagineLCM Module: Industrial Co., LTDelectropicNessuna valutazione finora

- Description Power Range: Analog Servo DriveDocumento9 pagineDescription Power Range: Analog Servo DriveElectromateNessuna valutazione finora

- FAN8082 (KA3082N) : Bi-Directional DC Motor DriverDocumento13 pagineFAN8082 (KA3082N) : Bi-Directional DC Motor DriverFrancisco Hernandez MartinezNessuna valutazione finora

- Lock Out Relay PDFDocumento10 pagineLock Out Relay PDFshaikhsajid242Nessuna valutazione finora

- Panasonic SA UX100PPDocumento21 paginePanasonic SA UX100PPboroda2410100% (3)

- 5-CH BTL DRIVER FOR DVD PLAYER WITH DISC BIDIRECTIONAL DRIVER AND TWO VARIABLE REGULATORSDocumento8 pagine5-CH BTL DRIVER FOR DVD PLAYER WITH DISC BIDIRECTIONAL DRIVER AND TWO VARIABLE REGULATORSalbinicue1Nessuna valutazione finora

- 5101 Motor DriverDocumento11 pagine5101 Motor DriverMoise CristinaNessuna valutazione finora

- VFDL Frekvenciavalto ENGDocumento16 pagineVFDL Frekvenciavalto ENGreghieNessuna valutazione finora

- Hat530n en ManualDocumento19 pagineHat530n en Manualdario sanchezNessuna valutazione finora

- 5-10542 Viper 100 DatasheetDocumento9 pagine5-10542 Viper 100 DatasheetMahmoud NaguibNessuna valutazione finora

- HIGH POWER FREQUENCY-STABILIZED 300mW DIODE LASER FOR RAMAN SPECTROSDocumento17 pagineHIGH POWER FREQUENCY-STABILIZED 300mW DIODE LASER FOR RAMAN SPECTROSRussell Decotis100% (1)

- FAN7602 - Green Current Mode PWM Controller - Fairchild SemiconductorDocumento17 pagineFAN7602 - Green Current Mode PWM Controller - Fairchild SemiconductorVijay MistryNessuna valutazione finora

- Sla7024 26 29mDocumento12 pagineSla7024 26 29mbashtavNessuna valutazione finora

- Samsung Sv5000W-1 PDFDocumento103 pagineSamsung Sv5000W-1 PDFsigi_204Nessuna valutazione finora

- Advanced Motion Controls S100a20Documento8 pagineAdvanced Motion Controls S100a20ElectromateNessuna valutazione finora

- LM555 Timer: General Description FeaturesDocumento12 pagineLM555 Timer: General Description FeaturesMark J A. OkyoNessuna valutazione finora

- Atmel 24C02Documento26 pagineAtmel 24C02kukinjosNessuna valutazione finora

- Analog Servo Drive: Description Power RangeDocumento9 pagineAnalog Servo Drive: Description Power RangeElectromateNessuna valutazione finora

- Canon EF-S 17-55 F-2.8 Is USM ManualDocumento13 pagineCanon EF-S 17-55 F-2.8 Is USM Manualiam_sutat5147Nessuna valutazione finora

- Chapter Electric MotorsDocumento24 pagineChapter Electric MotorsDenstar Ricardo SilalahiNessuna valutazione finora

- Teoria Variadores de FrecuencuiaDocumento12 pagineTeoria Variadores de FrecuencuiaasotozuazuaNessuna valutazione finora

- Woltex Water MeterDocumento2 pagineWoltex Water Meteriam_sutat5147Nessuna valutazione finora

- Presentation Thornton Presentation Conductivity MeasurementDocumento43 paginePresentation Thornton Presentation Conductivity Measurementiam_sutat5147Nessuna valutazione finora

- Philips - General LightingDocumento15 paginePhilips - General Lightingrumahsketch0% (1)

- Catalogo Contactores en Vacio MitsubichiDocumento16 pagineCatalogo Contactores en Vacio MitsubichiWalter CataldoNessuna valutazione finora

- NC941 One Zone Call Controller C/W PSU: General InstallationDocumento2 pagineNC941 One Zone Call Controller C/W PSU: General InstallationjaguardiamejiasNessuna valutazione finora

- Arc Fault Protection System REA 10 - : Product GuideDocumento32 pagineArc Fault Protection System REA 10 - : Product GuideAlbertoNessuna valutazione finora

- C-Arm HF 49R Instt - ServiceDocumento55 pagineC-Arm HF 49R Instt - ServiceAHMED AWAD ALI100% (1)

- 7SecIX IX.2.04 PlasteringDocumento4 pagine7SecIX IX.2.04 PlasteringAnonymous 7ZYHilDNessuna valutazione finora

- Estimate List 1Documento7 pagineEstimate List 1parecproNessuna valutazione finora

- FGB220K Datasheet FDocumento2 pagineFGB220K Datasheet FWagner AngenendtNessuna valutazione finora

- Service Manual: Mode MP1200 DVPDocumento13 pagineService Manual: Mode MP1200 DVPSilverio SogorbNessuna valutazione finora

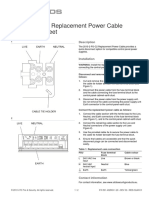

- 501-402803-1-20 (EN) R02 2010-2-PS-C2 Replacement Power Cable Installation SheetDocumento2 pagine501-402803-1-20 (EN) R02 2010-2-PS-C2 Replacement Power Cable Installation SheetDanNessuna valutazione finora

- Mercedes-Benz Viano PF Dubei Daniel OvidiuDocumento5 pagineMercedes-Benz Viano PF Dubei Daniel OvidiudansempaiNessuna valutazione finora

- 2001 - AR423 - BCT04 - 21 - Glass Construction PDFDocumento67 pagine2001 - AR423 - BCT04 - 21 - Glass Construction PDFrcxy98Nessuna valutazione finora

- SI Fuel Injection SystemDocumento15 pagineSI Fuel Injection Systemashvini gautamNessuna valutazione finora

- VCTDS 0036 EN Web PDFDocumento8 pagineVCTDS 0036 EN Web PDFAbdul RahimNessuna valutazione finora

- Data Sheet Eu2Documento7 pagineData Sheet Eu2admin peoNessuna valutazione finora

- C13960MCDC08Documento3 pagineC13960MCDC08xuanloc214Nessuna valutazione finora

- Disassembly and Reassembly Guide for Main System and LCD AssemblyDocumento9 pagineDisassembly and Reassembly Guide for Main System and LCD AssemblyСергей СалтыковNessuna valutazione finora

- PTC MZ73B-30RMDocumento5 paginePTC MZ73B-30RMJimmys959Nessuna valutazione finora

- CCTV 3+1 Premium Cable for Reliable SurveillanceDocumento2 pagineCCTV 3+1 Premium Cable for Reliable SurveillanceShashank SaxenaNessuna valutazione finora

- Price Revision NOV - 2021Documento68 paginePrice Revision NOV - 2021Mihir MehraNessuna valutazione finora

- SATIP-P-104-04 Rev 7 FinalDocumento4 pagineSATIP-P-104-04 Rev 7 FinalHatemS.MashaGbehNessuna valutazione finora

- Bill Materiales Cat6 Cat6ADocumento28 pagineBill Materiales Cat6 Cat6AVivianaNessuna valutazione finora

- Heavy Duty Standby Switch Installation for Billm Blues Junior AmplifierDocumento9 pagineHeavy Duty Standby Switch Installation for Billm Blues Junior AmplifierAndrea CeciniNessuna valutazione finora

- StonemasonryDocumento46 pagineStonemasonryWawaChumelNessuna valutazione finora

- Unit Test I Illumination 17-18Documento8 pagineUnit Test I Illumination 17-18Madhura TuljapurkarNessuna valutazione finora