Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ups Series 100

Caricato da

palotito_eDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ups Series 100

Caricato da

palotito_eCopyright:

Formati disponibili

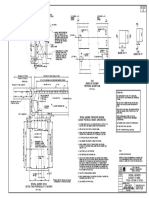

GRUNDFOS DATA BOOKLET

Series 100

Circulator pumps 50/60 Hz

Contents

General data

Performance range Product range, 1 x 230 V, 50 Hz Type keys Applications Heating systems Domestic hot-water systems Cooling and air-conditioning systems Construction Material specification Installation Motor Pumped liquids Ambient and liquid temperatures Maximum system pressure Inlet pressure Energy labelling Curve conditions 3 5 6 7 7 7 7 8 8 8 8 9 9 9 9 9 9

Technical data

Circulator pumps for heating systems ALPHA Pro 15-40, 25-40, 32-40 ALPHA Pro 15-60, 25-60, 32-60 Air separator pump Circulator pumps for domestic hot water Special versions Product range, special versions 10 10 11 20 24 31 31

Accessories

Pipe connections Grundfos controls Union and valve kits Insulation kits Service kit for ALPHA+ Timer and thermostat for COMFORT Fittings for COMFORT 37 38 40 40 40 40 41

Further product documentation

WinCAPS WebCAPS 42 43

General data

Series 100

Performance range

p [kPa]

60

H [m]

6

GRUNDFOS ALPHA Pro

50

40

30

20

2

ALP HA P

AL PH A

Pro XX -60

10

ro X

X-4 0

TM03 1347 1805 TM01 9186 2505

0 0.0 0.4 0.8 1.2 1.6 2.0 2.4 2.8

Q [m/h]

p [kPa]

50

H [m]

GRUNDFOS ALPHA+

40

30

20

AL

10 1

ALP HA +X X -4

PH A+

XX -60

0 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

Q [m/h]

1.0

0.0

0.2

0.4

0.6

0.8

Q [l/s]

General data

Series 100

p [kPa] 100 80 60 40

H [m] 10.0 8.0 6.0 4.0

UP

UPS 25-1

S2

5-1

UPS

25

20

UPS

UPS 25 -60 UPS 2 5-50 UPS 25 -40

UPS 2 5-30

25-8

UP

UP

UP S3

UP

S3

32

20

2.0

S3

0

2-6

UP

-8

2-5

40

(F

-5

UP S 40

0F

10 8 6 4

UPS

UP

2-4

-8 0

1.0 0.8 0.6 0.4

25-20

UP S3

32

-3

2-2

0.2 0.3 0.4 0.6 0.8 1.0 0.2 0.4 2.0 0.6 4.0 0.8 1.0 6.0 8.0Q [m/h] 2.0 Q [l/s]

TM00 9602 3701 TM00 9603 0503

p [kPa]

40

H [m]

6.0 4.0

COMFORT, UP-N, UP(S)-B

UPS 2 5-60 B UP 20-4 5N UPS 25-40 B

UP 25 -80 B

S3 UP

UP

20

S4 0-

0B 2-8

2.0

UP 20 -

50 F

30 N

(FB )

10 8 6 4

1.0 0.8 0.6 0.4

UP

UP

1 5 -1 4B

2014 B X

UP 2

0-15 N

UP 2

2 0.2

0-07 N

0.1 0 0.2 0.4 0.6 0.8 1 2 4 6 8 10

Q [m/h]

0.2 0.4 0.6 0.8 1.0 2.0

Q [l/s]

General data

Series 100

Product range, 1 x 230 V, 50 Hz

Pump material Liquid temperature Cast iron +2C to +95C

TM02 7023 2303

Cast iron +2C to +110C

TM02 7023 2303

Cast iron 25C to +110C

TM02 7024 2303

Cast iron 25C to +95C

TM02 7024 2303

Stainless steel/bronze +2C to +110C

TM02 7023 2303

Stainless steel/bronze 25C to+110C

TM02 7024 2303

Bronze 25 to +95C

TM02 7024 2303

Brass +2C to +95C

TM02 7022 2303

Terminal box position

Pump type ALPHA Pro 15-40 ALPHA Pro 25-40 ALPHA Pro 32-40 ALPHA Pro 15-60 ALPHA Pro 25-60 ALPHA Pro 32-60 ALPHA+ 15-40 ALPHA+ 25-40 ALPHA+ 32-40 ALPHA+ 15-60 ALPHA+ 25-60 ALPHA+ 32-60 UPS 25-20 UPS 32-20 UPS 25-30 UPS 32-30 UPS 25-40 UPS 32-40 UPS 25-50 UPS 32-50 UPS 25-60 UPS 32-60 UPS 25-80 UPS 32-80 UPS 25-120 UPS 25-125 UPS 40-50 F UPS 32-80 F UPS 40-80 F UP 15-14 UP 20-14 UP 20-07 N UP 20-15 N UP 20-30 N UP 20-45 N UPS 25-40 B UPS 25-60 B UP 25-80 B UPS 32-80 B UPS 32-50 FB UPS 40-50 FB On request: Pump housing with air separator, type A. Special range of twin-head pumps and 60 Hz pumps, page 31.

General data

Series 100

Type keys

GRUNDFOS ALPHA Pro

Example Type range Nominal diameter (DN) of suction and discharge ports [mm] Maximum head [dm] Maximum head [dm] Pump housing with air separator Brass pump housing Bronze pump housing Integrated isolating and non-return valves Port-to-port length [mm] 24-hour timer ALPHA Pro 25 - 40 (A) (B) 180

GRUNDFOS COMFORT

Example Circulator pump Type range: 15 = Rp , length 80 mm 20 = G 1, length 110 mm UP 20 -14 B X U T

GRUNDFOS ALPHA+

Example Type range Nominal diameter (DN) of suction and discharge ports [mm] Maximum head [dm] Pump housing with air separator Bronze pump housing Port-to-port length [mm] ALPHA+ 25 - 40 (A) (B) 180

Thermostat

UP, UPS

Example Circulator pump S = Electric UP S D 40 -40 F

Twin-head pump Nominal diameter (DN) of suction and discharge ports Maximum head [dm] Pipe connection = Pipe thread (no letter = pipe thread) F = Flange Pump housing = Cast iron (no letter = cast iron) N = Stainless steel B = Bronze A = Pump housing with air separator, upward water flow K = Cold water version KU = Cold water version (filled terminal box)

General data

Series 100

Applications

The Grundfos circulator pumps, Series 100, are specifically designed for heating systems. The pumps are also suitable for circulation of domestic hot water and for circulation of liquid in cooling and air-conditioning systems.

One-pipe heating system

Heating systems

For central and district heating systems, use pump types ALPHA Pro, ALPHA+ or UPS. The GRUNDFOS ALPHA Pro and ALPHA+ automatically control the differential pressure by adjustment of pump performance to the actual heating demand, without the use of external components.

Two-pipe heating system

The pumps are used primarily for one- and two-pipe heating systems, but are also suitable, e.g. for mixing loops in large systems. For underfloor heating systems, it is advisable to use the bronze versions, types ALPHA Pro B, ALPHA+ B and UP(S) B, as the pumped liquid may often become aerated, causing an ordinary cast-iron pump housing to corrode.

Underfloor heating system

For circulation of domestic hot water, use type COMFORT or type UP-N with stainless-steel pump housing or type UP(S)-B with brass/bronze pump housing. The UP-N and UP(S)-B can be connected to an on/off time switch to save energy. The on/off time switch can switch the pump on/off to limit pump operation to periods when hot water is usually required.

Domestic hot-water system

It is recommended to keep the operating temperature lower than 65C to avoid precipitation of calcium.

Cooling and air-conditioning systems

For cooling and air-conditioning systems, use standard pumps, type UPS, or special versions, type UPS-K, depending on type/size. (See product range.) Temperature range: 25C to +95C 25C to +110C

Cooling and air-conditioning system

M M

These pumps are thus suitable for circulation of both cold and hot water.

TM01 0167 0697

TM01 0166 0697

COMFORT is available with integrated timer and thermostat.

TM01 0165 0697

Domestic hot-water systems

TM01 0164 0697

UPS can be operated at three speeds.

TM01 0163 0697

General data

Series 100

Construction

The ALPHA Pro, ALPHA+ and UP, UPS pumps are of the canned rotor type, i.e. pump and motor form an integral unit without shaft seal and with only two gaskets for sealing. The bearings are lubricated by the pumped liquid. The pumps are characterised by: ceramic shaft and radial bearing carbon thrust bearing stainless-steel rotor can and bearing plate impeller in corrosion-resistant material pump housing of cast iron, bronze or stainless steel.

Installation

The pump must always be installed with horizontal motor shaft. At start-up the rotor can is to be vented by removing the plug in the top of the motor. Within a short time, the rotor forces the remaining air out into the system via the shaft.

TM00 0361 5196

Material specification

Pos. Component 1 2 3 4 5 6 Pump housing Impeller Shaft Bearing Bearing plate Thrust bearing retainer Gaskets Material Cast iron EN-GJL-150/200 Bronze Stainless steel Composite / PES or PP Ceramics Ceramics/carbon Stainless steel Stainless steel/ EPDM rubber EPDM rubber 1.4301 1.4301 DIN W.-Nr. EN-JL 1020/1030 2.1176.01 1.4301

Motor

GRUNDFOS ALPHA Pro

The motor is a 2-pole, synchronous permanent-magnet motor. The pump controller is incorporated in the control box which is fitted to the stator housing with two screws and connected to the stator via a terminal plug. Incorporating the controller, the control box has a display and two selector switches. The display is lit when the electrical supply is switched on and shows the actual power consumption. The purpose of the switches are: Selection of control curve and Activation or deactivation of automatic night-time duty. The controller complies with EN 61 000-6-1 and EN 61 000-6-3. The motor of GRUNDFOS ALPHA Pro is protected by the electronics in the control box and requires no external motor protection.

UPS N-version

3 2

TM00 9672 5196

GRUNDFOS ALPHA+

The motor is a 2-pole, asynchronous squirrel-cage motor with radio noise filter to VDE 0875. The terminal box and motor-pump unit have been tested in accordance with VDE 0700. The motor of GRUNDFOS ALPHA+ is impedanceprotected and therefore requires no external motor protection. Incorporating the controller, the terminal box has a selector switch and an indicator light for supply voltage indication. The controller meets the requirements of EN 61 800-3. The terminal box is fitted to the stator housing by means of screws and connected to the stator by means of a terminal plug.

5 1 4 6

General data

Series 100

UP, UPS pumps

The motor is a 2- or 4-pole, asynchronous squirrel-cage motor in conformity with the EMC directive. Standards used: EN 61 000-6-2 and EN 61 000-6-3. The terminal box and the motor-pump unit have been wet-tested to EN 60 335-1: 1994 and EN 60 335-2-51: 1997. Single-phase pumps are available in versions with one, two or three speeds. Three-phase pumps are available in versions with one or two speeds. The terminal box is easily accessible and has functional cable connecting terminals. The cable entry is tight and has a built-in cable relief. The cable entry of singlephase motors can be pushed out of its guide to facilitate the correct fitting of the cable. Insulation class: Cable connection: F/H Pg 11 for 5.6 - 10 mm cable

Inlet pressure

To avoid cavitation noise and damage to the pump bearings, the following minimum pressures are required at the pump suction port:

Liquid temperature Inlet pressure 85C 0.5 m head 0.049 bar 90C 2.8 m head 0.27 bar 110C 11.0 m head 1.08 bar

Energy labelling

Grundfos circulator pumps except GRUNDFOS COMFORT, UP-N and twin-head pumps are provided with the energy label. The energy label indicates the energy-saving level of the pump. The energy classification system has seven levels, i.e. from A to G. Level A is the best. The energy label can be used to compare pumps of the same type and size.

The motor incorporates thermal overload or impedance protection. Therefore, no external motor protection is required.

Curve conditions

The guidelines below apply to the performance curves on the following pages: The bold parts of the curves show the recommended performance range. Test liquid: Airless water. The GRUNDFOS ALPHA Pro and ALPHA+ curves apply to a density of = 983.2 kg/m3 and a liquid temperature of 60C. The measurements for UP and UPS have been made at a water temperature of 80C for pumps for Great Britain (1 x 230/240 V) and 20C for other voltages. All curves show average values and should not be used as guarantee curves. If a specific minimum performance is required, individual measurements must be made. The GRUNDFOS ALPHA Pro and ALPHA+ curves apply to a kinematic viscosity of = 0.474 mm2/s (0.474 cSt). The UP, UPS and UPE curves apply to a kinematic viscosity of = 1 mm2/s (1 cSt). The conversion between head H [m] and pressure p [kPa] has been made for water with a density of = 1000 kg/m3. For liquids with other densities, e.g. hot water, the discharge pressure is proportional to the density.

Pumped liquids

Depending on type, Grundfos circulator pumps are designed for the following liquids: thin, clean, non-aggressive and non-explosive liquids without solid particles or fibres cooling liquids, not containing mineral oil domestic hot water softened water. The kinematic viscosity of water is = 1 mm2/s (1 cSt) at 20C. If the circulator pump is used for a liquid with a higher viscosity, the hydraulic performance of the pump will be reduced. Example: 50% glycol at 20C means a viscosity of approx. 10 mm2/s (10 cSt) and a reduction of pump performance by approx. 15%. When selecting a pump, the viscosity of the pumped liquid must be taken into consideration.

Ambient and liquid temperatures

Liquid temperatures, see table on page 5. The ambient temperature for standard pumps with a permissible liquid temperature from +2C to +110C should always be lower than the liquid temperature, as otherwise condensation may form in the stator housing.

Maximum system pressure

Pump with unions (PN 10): 1.0 MPa (10 bar) Flanged pump (PN 6/10): 0.6/1.0 MPa (6/10 bar) Pump with Grundfos flanges: 1.0 MPa (10 bar)

Technical data

Circulator pumps for heating systems

ALPHA Pro 15-40, 25-40, 32-40

TM03 1591 2405ALPHA Pro 15-40, 25-40, 32-40

1 x 230 V, 50 Hz

H [m] 4 3 2 1 0 0.0 0

Speed Min. Max. I II III

0.4 10

0.8

1.2 20

1.6 30

2.0

Q [m/h] Q [l/min]

In [A] 0.06 0.23 0.09 0.17 0.23

P 1 [W] 6 25 8 18 25

Connections: System pressure: Liquid temperature: Energy class: Also available with:

See "Union and valve kits" on page 12 Max. 10 bar +2C to +110C (TF 110) A Bronze pump housing, type B (only ALPHA Pro 25-40 B 180)

The pump incorporates overload protection. Pump type ALPHA Pro 15-40 ALPHA Pro 25-40 ALPHA Pro 25-40 ALPHA Pro 32-40 Dimensions [mm] L1 130 130 180 180 H1 28 28 28 30 H2 116 116 116 116 H3 57 57 57 57 B1 97 97 97 97 B2 48 48 48 48 B3 77 77 77 77 E 122 122 122 122 G 1 1 1 2 Weights [kg] Net 2.4 2.4 2.5 2.8 Gross 2.6 2.6 2.7 3.0 Ship. vol. [m3] 0.00516 0.00516 0.00516 0.00516

Weights of bronze versions are approx. 10% higher.

10

TM03 0907 0705

Technical data

Circulator pumps for heating systems

ALPHA Pro 15-60, 25-60, 32-60

6 5 4 3 2 1 0 0.0 0

Speed Min. Max. I II III

TM03 1592 2405ALPHA Pro 15-60, 25-60, 32-60

1 x 230 V, 50 Hz

H [m]

0.4 10

0.8

1.2 20

1.6 30

P 1 [W] 6 50 8 31 50

2.0

2.4 40

Q [m/h] Q [l/min]

In [A] 0.06 0.45 0.09 0.28 0.45

Connections: System pressure: Liquid temperature: Energy class: Also available with:

See "Union and valve kits" on page 12 Max. 10 bar +2C to +110C (TF 110) A Bronze pump housing, type B (only ALPHA Pro 25-60 B 180)

The pump incorporates overload protection. Dimensions [mm] L1 130 130 180 180 H1 28 28 28 30 H2 116 116 116 116 H3 57 57 57 57 B1 97 97 97 97 B2 48 48 48 48 B3 77 77 77 77 E 122 122 122 122 G 1 1 1 2 Weights [kg] Net 2.4 2.4 2.5 2.8 Gross 2.6 2.6 2.7 3.0

Pump type ALPHA Pro 15-60 ALPHA Pro 25-60 ALPHA Pro 25-60 ALPHA Pro 32-60

Ship. vol. [m3] 0.00516 0.00516 0.00516 0.00516

Weights of bronze versions are approx. 10% higher.

TM03 0907 0705

11

Technical data

Circulator pumps for heating systems

ALPHA+ 15-40, 25-40, 32-40

H [m] 4 3 2 1

TM03 1344 1705

1 x 230 V, 50 Hz

B3 G H3

0 0.0 0

Speed Min. Max. I II III

0.4 10

0.8

1.2 20

1.6 30

P1 [W] 20 45 35 35 45

2.0

2.4 40

Q [m/h] Q [l/min]

In [A] 0.09 0.22 0.10 0.16 0.22

B1

B2

H1

H2

Connections: System pressure: Liquid temperature: Energy class: Also available with:

See "Union and valve kits" page 40 Max. 10 bar +2C to +110C (TF 110) B Bronze housing, type B (only ALPHA+ 25-40 B 180)

The motor incorporates thermal overload protection. Pump type ALPHA+ 15-40 ALPHA+ 25-40 ALPHA+ 25-40 ALPHA+ 32-40 Dimensions [mm] L 130 130 180 180 H1 28 32 32 39 H2 103 103 103 103 H3 57 57 57 57 B1 92 92 92 92 B2 48 48 48 48 B3 77 77 77 77 G 1 1 1 2 Weights [kg]* Net 2.4 2.4 2.6 2.7 Gross 2.6 2.6 3.0 3.1 Ship. vol. [m3] 0.00432 0.00432 0.00432 0.00432

* Weights of bronze versions are approx. 10% higher.

12

TM03 1632 2505

Technical data

Circulator pumps for heating systems

ALPHA+ 15-60, 25-60, 32-60

H [m] 6 5 4

L G B3 H3

1 x 230 V, 50 Hz

3 2

TM03 1345 1705

0 0.0 0.4 0.8 1.2 1.6 2.0 2.4 2.8 3.2 Q [m/h] 0 10

Speed Min. Max. I II III

B1

B2

H1

H2

20

30

P1 [W] 35 80 40 55 80

40

50

Q [l/min]

In [A] 0.14 0.34 0.17 0.23 0.34

Connections: System pressure: Liquid temperature: Energy class: Also available with:

See "Union and valve kits" page 40 Max. 10 bar +2C to +110C (TF 110) B Bronze housing, type B (only ALPHA+ 25-60 B 180)

The motor incorporates thermal overload protection. Pump type ALPHA+ 15-60 ALPHA+ 25-60 ALPHA+ 25-60 ALPHA+ 32-60 Dimensions [mm] L 130 130 180 180 H1 28 32 32 39 H2 103 103 103 103 H3 57 57 57 57 B1 92 92 92 92 B2 48 48 48 48 B3 77 77 77 77 G 1 1 1 2 Weights [kg]* Net 2.4 2.4 2.6 2.7 Gross 2.6 2.6 3.0 3.1 Ship. vol. [m3] 0.00432 0.00432 0.00432 0.00432

* Weights of bronze versions are approx. 10% higher.

UPS 25-20 / UPS 32-20

p [kPa] 20 H [m] 2.0

3

180

1 x 230 V, 50 Hz

15

1.5

10

1.0

0.5

TM00 9756 2405

0.0 0.0 0.4 0.8 1.2 1.6 2.0 Q [m/h]

0.0

0.1

0.2

0.3

0.4

0.5

Q [l/s]

Speed 3 2 1

P1 [W] 65 40 25

In [A] 0.26 0.18 0.11

Connections: System pressure: Liquid temperature: Energy class:

" or 1" unions and valves Max. 10 bar +2C to +110C (TF 110) F

Pump type UPS 25-20 UPS 32-20

Dimensions [mm] L 180 180 H1 32 39 H2 102 102 B1 75 75 B2 51 51 G 1 2 Net 2.6 2.6

Weights [kg] Gross 2.8 2.8

Ship. vol. [m3] 0.004 0.004

TM00 9386 2105

TM03 1632 2505

13

Technical data

Circulator pumps for heating systems

UPS 25-30 / UPS 32-30

p [kPa] 25 20 15 10 5 0 H [m]

3

180

1 x 230 V, 50 Hz

2.5 2.0 1.5 1.0 0.5

TM00 9748 0397

0.0 0.0 0.5 1.0 1.5 2.0 2.5 Q [m/h]

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

Q [l/s]

Speed 3 2 1

P1 [W] 55 40 25

In [A] 0.24 0.16 0.10

Connections: System pressure: Liquid temperature: Energy class:

" or 1" unions and valves Max. 10 bar +2C to +110C (TF 110) D

Pump type UPS 25-30 UPS 32-30

Dimensions [mm] L 180 180 H1 32 39 H2 102 102 B1 75 75 B2 51 51 G 1 2 Net 2.6 2.6

Weights [kg] Gross 2.8 2.8

Ship. vol. [m3] 0.004 0.004

UPS 25-40 / UPS 32-40

p [kPa] 40 H [m] 4

3 2

180

1 x 230 V, 50 Hz

30

3

1

20

10

TM00 9749 2405

0 0.0 0.5 1.0 1.5 2.0 2.5 Q [m/h]

0.0

0.2

0.4

0.6

0.8

Q [l/s]

Speed 3 2 1

P1 [W] 45 35 25

In [A] 0.20 0.16 0.12

Connections: System pressure: Liquid temperature: Energy class: Cold-water version:

", 1" or 1" unions and valves Max. 10 bar +2C to +110C (TF 110) B K for 25C to +95C (TF 95) Weights [kg] Ship. vol. [m3] 0.004 0.004

Pump type UPS 25-40 UPS 32-40

Dimensions [mm] L 180 180 H1 32 39 H2 102 102 B1 75 75 B2 51 51 G 1 2

Net 2.6 2.6

Gross 2.8 2.8

14

TM00 9386 2105

TM00 9386 2105

Technical data

Circulator pumps for heating systems

UPS 25-50 / UPS 32-50

p [kPa] 40 H [m] 4

3 2

180

1 x 230 V, 50 Hz

30

20

10

TM00 97503 2105

0 0.0 0.5 1.0 1.5 2.0 2.5 3.0 Q [m/h]

0.0

0.2

0.4

0.6

0.8

Q [l/s]

Speed 3 2 1

P1 [W] 50 45 35

In [A] 0.23 0.20 0.16

Connections: System pressure: Liquid temperature: Energy class: Cold-water version:

", 1" or 1" unions and valves Max. 10 bar +2C to +110C (TF 110) B K for 25C to +95C (TF 95) Weights [kg] Ship. vol. [m3] 0.004 0.004

Pump type UPS 25-50 UPS 32-50

Dimensions [mm] L 180 180 H1 32 39 H2 102 102 B1 75 75 B2 51 51 G 1 2

Net 2.6 2.6

Gross 2.8 2.8

UPS 25-60 / UPS 32-60

p [kPa] 50 40 30 20 10 0 H [m]

3

180

1 x 230 V, 50 Hz

5 4 3 2 1

TM00 9751 2405

0 0.0 0.5 1.0 1.5 2.0 2.5 3.0 Q [m/h]

0.0

0.2

0.4

0.6

0.8

Q [l/s]

Speed 3 2 1

P1 [W] 70 60 50

In [A] 0.30 0.27 0.22

Connections: System pressure: Liquid temperature: Energy class: Cold-water version:

", 1" or 1" unions and valves Max. 10 bar +2C to +110C (TF 110) C K for 25C to +95C (TF 95) Weights [kg] Ship. vol. [m3] 0.004 0.004

Pump type UPS 25-60 UPS 32-60

Dimensions [mm] L 180 180 H1 32 39 H2 102 102 B1 75 75 B2 51 51 G 1 2

Net 2.6 2.6

Gross 2.8 2.8

TM00 9386 2105

TM00 9386 2105

15

Technical data

Circulator pumps for heating systems

UPS 25-80

p [kPa] 80 70 60 50 40 30 20 10 0 H [m] 8 7 6 5 4 3 2

1 3 2

180

1 x 230 V, 50 Hz

TM00 9754 2405

0 0 1 2 3 4 5 6 7 8 Q [m/h]

0.0

0.5

1.0

1.5

2.0

Q [l/s]

Speed 3 2 1

P1 [W] 190 175 130

In [A] 0.83 0.78 0.60

Connections: System pressure: Liquid temperature: Energy class:

" or 1" unions and valves Max. 10 bar 25C to +110C (TF 110) D

Pump type UPS 25-80

Dimensions [mm] L 180 H1 32 H2 130 B1 82 B2 52 G 1

Weights [kg] Net 4.2 Gross 4.5

Ship. vol. [m3] 0.008

UPS 32-80

p [kPa] 80 H [m] 8 7 60 6 5 40 4 3 20 2 1 3 2

180

1 x 230 V, 50 Hz

TM00 9753 2405

0 0 1 2 3 4 5 6 7 8 9 10 Q [m/h]

0.0

0.5

1.0

1.5

2.0

2.5

3.0

Q [l/s]

Speed 3 2 1

P1 [W] 240 205 135

In [A] 1.05 0.91 0.62

Connections: System pressure: Liquid temperature: Energy class:

" or 1" unions and 1" valves Max. 10 bar 25C to +110C (TF 110) D

Pump type UPS 32-80

Dimensions [mm] L 180 H1 39 H2 130 B1 82 B2 60 G 2

Weights [kg] Net 4.8 Gross 5.1

Ship. vol. [m3] 0.0102

16

TM00 8945 2105

TM00 8945 2105

Technical data

Circulator pumps for heating systems

UPS 25-120

p [kPa] 120 100 80 60 40 20 0 H [m] 12 10 8

1 3 2

180

1 x 230 V, 50 Hz

6 4 2 0 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 Q [m/h]

TM02 2205 3901

0.0

0.2

0.4

0.6

0.8

1.0

Q [l/s]

Speed 3 2 1

P1 [W] 235 180 120

In [A] 1.02 0.78 0.53

Connections: System pressure: Liquid temperature: Energy class:

" unions and valves Max. 10 bar 25C to +95C (TF 110) F

Pump type UPS 25-120

Dimensions [mm] L 180 H1 32 H2 130 B1 82 B2 69 G 1

Weights [kg] Net 4.4 Gross 4.6

Ship. vol. [m3] 0.006

UPS 25-125

p [kPa] 120 100 80 60 40 20 0 H [m]

3

180

1 x 230 V, 50 Hz

12 10 8 6 4 2 0 0.0

TM02 2204 3901

0.5

1.0

1.5

2.0

2.5

3.0

3.5

Q [m/h]

0.0

0.2

0.4

0.6

0.8

1.0

Q [l/s]

Speed 3 2 1

P1 [W] 270 210 135

In [A] 1.18 0.93 0.61

Connections: System pressure: Liquid temperature: Energy class:

" unions and valves Max. 10 bar +2C to +95C (TF 95) E

Pump type UPS 25-125

Dimensions [mm] L 180 H1 32 H2 130 B1 82 B2 69 G 1

Weights [kg] Net 4.4 Gross 4.6

Ship. vol. [m3] 0.006

TM02 1329 2105

TM02 1329 2105

17

Technical data

Circulator pumps for heating systems

UPS 32-80 F

p [kPa] 80 H [m] 8 7 60 6 5 40 4 3 20 2 1 3 2

220

1 x 230 V, 50 Hz

TM00 9753 2405

0 0 1 2 3 4 5 6 7 8 9 10 Q [m/h]

0.0

0.5

1.0

1.5

2.0

2.5

3.0

Q [l/s]

Speed 3 2 1

P1 [W] 240 205 135

In [A] 1.05 0.91 0.62

Connections: System pressure: Liquid temperature: Energy class:

1" screwed flanges or 32 mm flanges for welding Max. 6/10 bar +2C to +110C (TF 110) D

Pump type UPS 32-80 F

Dimensions [mm] L 220 H1 60 H2 130 B1 85 B2 65 G

Weights [kg] Net 6.5 Gross 6.8

Ship. vol. [m3] 0.0112

UPS 40-50 F

p [kPa] 50 40 30 20 10 0 H [m] 5 4

1 3 2

250

1 x 230 V, 50 Hz

3 2 1

TM00 9755 2405

0 0 1 2 3 4 5 6 7 8 9 Q [m/h]

0.0

0.5

1.0

1.5

2.0

2.5

Q [l/s]

Speed 3 2 1

P1 [W] 115 110 85

In [A] 0.51 0.48 0.38

Connections: System pressure: Liquid temperature: Energy class:

1" screwed flanges or 40 mm flanges for welding Max. 6/10 bar 25C to +110C (TF 110) C

Pump type UPS 40-50 F

Dimensions [mm] L 250 H1 65 H2 130 B1 82 B2 65 G

Weights [kg] Net 8.1 Gross 8.5

Ship. vol. [m3] 0.0122

18

TM00 9393 2105

TM00 9393 2105

Technical data

Circulator pumps for heating systems

UPS 40-80 F

p [kPa] 80 H [m] 8 7 60 6 5 40 4 3 20 2 1 3 2

250

1 x 230 V, 50 Hz

TM00 9753 2405

0 0 1 2 3 4 5 6 7 8 9 10 Q [m/h]

0.0

0.5

1.0

1.5

2.0

2.5

3.0

Q [l/s]

Speed 3 2 1

P1 [W] 240 205 135

In [A] 1.05 0.91 0.62

Connections: System pressure: Liquid temperature: Energy class:

1" screwed flanges or 40 mm flanges for welding Max. 6/10 bar 25C to +110C (TF 110) D

Pump type UPS 40-80 F

Dimensions [mm] L 250 H1 65 H2 130 B1 82 B2 65 G

Weights [kg] Net 8.1 Gross 8.5

Ship. vol. [m3] 0.0122

TM00 9389 2105

19

Technical data

Circulator pumps for heating systems

Air separator pump

Grundfos Airlectric is a combined circulator pump and air separator. It removes air from the centre of the system and thus offers optimum operating conditions for any automatic air vent - without extra installation cost. The air-containing liquid is guided from the suction port to the nozzle of the air-separating chamber. In the nozzle, the liquid is caused to circulate considerably in the relatively large chamber, thus creating a low pressure in the top of the chamber. This low pressure combined with the now reduced low velocity of the liquid will cause a separation of air from the liquid. Due to its lower density, the air will escape through an automatic air vent fitted to the air-separating chamber. The air separator pump is available only for upward water flow. The pump housing has an Rp 3/8 thread for the air vent. The air vent is not supplied with the pump.

20

TM00 8966 4296

Technical data

Circulator pumps for heating systems

ALPHA+ 25-40 A

H [m] 4 3 2 1

180

Rp 3/8

1 x 230 V, 50 Hz

B3

H3

TM03 1344 1705

0 0.0 0

Speed Min. Max. I II III

0.4 10

0.8

1.2 20

1.6 30

P1 [W] 20 45 25 35 45

2.0

2.4 40

Q [m/h] Q [l/min]

In [A] 0.09 0.22 0.10 0.16 0.22

B1

B2

H1

H2

Connections: System pressure: Liquid temperature: Energy class:

See "Union and valve kits" page 40 Max. 10 bar +2C to +110C (TF 110) B

The motor incorporates thermal overload protection.

Pump type ALPHA+ 25-40 A

Dimensions [mm] L 180 H1 49 H2 113 H3 81 B1 92 B2 51 B3 78 G 1

Weights [kg] Net 3.6 Gross 4.0

Ship. vol. [m3] 0.00542

ALPHA+ 25-60 A

H [m] 6 5 4

180

Rp 3/8

1 x 230 V, 50 Hz

B3

H3

2

TM03 1345 1705 TM03 1631 2505

1 0 0.0 0.4 0.8 1.2 1.6 2.0 2.4 2.8 3.2 Q [m/h] 0 10

Speed Min. Max. I II III

B1

B2

H1

H2

20

30

40

50

Q [l/min]

In [A] 0.14 0.34 0.17 0.23 0.34

P1 [W] 35 80 40 55 80

Connections: System pressure: Liquid temperature: Energy class:

See "Union and valve kits" page 40 Max. 10 bar +2C to +110C (TF 110) B

The motor incorporates thermal overload protection.

Pump type ALPHA+ 25-60 A

Dimensions [mm] L 180 H1 49 H2 113 H3 81 B1 92 B2 51 B3 78 G 1

Weights [kg] Net 3.6 Gross 4.0

Ship. vol. [m3] 0.00542

TM03 1631 2505

21

Technical data

Circulator pumps for heating systems

UPS 25-20 A

p [kPa] 20 H [m] 2.0

3

180

1 x 230 V, 50 Hz

15

1.5

10

1.0

0.5

TM00 9756 24057

0.0 0.0 0.4 0.8 1.2 1.6 2.0 Q [m/h]

0.0

0.1

0.2

0.3

0.4

0.5

Q [l/s]

Speed 3 2 1

P1 [W] 65 40 25

In [A] 0.26 0.18 0.11

Connections: System pressure: Liquid temperature: Energy class:

" or 1" unions and valves Max. 10 bar +2C to +110C (TF 110) F

Pump type UPS 25-20 A

Dimensions [mm] L 180 L1 65 H1 49 H2 112 B1 61 B2 65 G 1

Weights [kg] Net 3.5 Gross 3.7

Ship. vol. [m3] 0.0053

UPS 25-30 A

p [kPa] 25 20 15 10 5 0 H [m]

3

180

1 x 230 V, 50 Hz

2.5 2.0 1.5 1.0 0.5

TM00 9748 0397

0.0 0.0 0.5 1.0 1.5 2.0 2.5 Q [m/h]

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

Q [l/s]

Speed 3 2 1

P1 [W] 55 40 25

In [A] 0.24 0.16 0.10

Connections: System pressure: Liquid temperature: Energy class:

" or 1" unions and valves Max. 10 bar +2C to +110C (TF 110) D

Pump type UPS 25-30 A

Dimensions [mm] L 180 L1 65 H1 49 H2 112 B1 61 B2 65 G 1

Weights [kg] Net 3.5 Gross 3.7

Ship. vol. [m3] 0.0053

22

TM00 8931 2105

TM00 8931 2105

Technical data

Circulator pumps for heating systems

UPS 25-40 A

p [kPa] 40 H [m] 4

3 2

180

1 x 230 V, 50 Hz

30

3

1

20

10

TM00 9749 2405

0 0.0 0.5 1.0 1.5 2.0 2.5 Q [m/h]

0.0

0.2

0.4

0.6

0.8

Q [l/s]

Speed 3 2 1

P1 [W] 45 35 25

In [A] 0.20 0.16 0.12

Connections: System pressure: Liquid temperature: Energy class:

" or 1" unions and valves Max. 10 bar +2C to +110C (TF 110) B

Pump type UPS 25-40 A

Dimensions [mm] L 180 L1 65 H1 49 H2 112 B1 61 B2 65 G 1

Weights [kg] Net 3.5 Gross 3.7

Ship. vol. [m3] 0.0053

UPS 25-60 A

p [kPa] 50 40 30 20 10 0 H [m]

3

180

1 x 230 V, 50 Hz

5 4 3 2 1

TM00 9751 2405

0 0.0 0.5 1.0 1.5 2.0 2.5 3.0 Q [m/h]

0.0

0.2

0.4

0.6

0.8

Q [l/s]

Speed 3 2 1

P1 [W] 70 60 50

In [A] 0.30 0.27 0.22

Connections: System pressure: Liquid temperature: Energy class:

" or 1" unions and valves Max. 10 bar +2C to +110C (TF 110) C

Pump type UPS 25-60 A

Dimensions [mm] L 180 L1 65 H1 49 H2 112 B1 61 B2 65 G 1

Weights [kg] Net 3.5 Gross 3.7

Ship. vol. [m3] 0.0053

TM00 8931 2105

TM00 8931 2105

23

Technical data

Circulator pumps for domestic hot water

GRUNDFOS COMFORT

The water-conduction part of the pump is hermetically separated from the stator with a stainless-steel spherical separator. The motor can be separated from the pump housing, enabling easy maintenance and replacement. GRUNDFOS COMFORT is supplied with isolating shells.

Applications

domestic hot-water systems in single- and two-family houses small heating systems cooling and air-conditioning systems.

Ambient and liquid temperatures

Liquid temperature: +2C to +95C

Pumped liquids

thin, clean, non-aggressive and non-explosive liquids without solid particles or fibres cooling liquids, not containing mineral oil domestic hot water softened water. The kinematic viscosity of water is = 1 mm2/s (1 cSt) at 20C. If the circulator pump is used for a liquid with a higher viscosity, the hydraulic performance of the pump will be reduced. Example: 50% glycol at 20C means a viscosity of approx. 10 mm2/s and a reduction of pump performance by approx. 15%. When selecting a pump, the viscosity of the pumped liquid must be taken into consideration.

It is recommended to keep the operating temperature as low as possible (e.g. 65C) to avoid lime precipitation. The ambient temperature should always be lower than the liquid temperature, as otherwise condensation may form in the stator housing.

Maximum system pressure

PN 10: 1.0 MPa (10 bar)

Inlet pressure

To avoid cavitation noise and damage to the pump bearing at high temperatures, the following minimum pressures are required at the pump suction port.

Liquid temperature Inlet pressure 85C 0.5 m head 0.049 bar 95C 2.8 m head 0.27 bar

Motor

Enclosure class: Insulation class: IP 42 F

24

TM01 9238 1500

Technical data

Circulator pumps for domestic hot water

UP 15-14

p [kPa] H [m] 1.2 1.0 8 0.8

80

1 x 230 V, 50 Hz

H4 G H3

0.4 0.2

TM01 9070 0503

0.0 0.00

0.1 0.04

0.2

0.3 0.08

0.4 0.12

Q [m/h] Q [l/s]

B1 B2

H2 H1

P1 [W] 25

In [A] 0.11

Connections: System pressure: Liquid temperature:

Various fittings, see page 41 Max. 10 bar +2C to +95C (TF 95)

Pump type UP 15-14 B UP 15-14 BU UP 15-14 BT UP 15-14 BUT

Dimensions [mm] L1 80 80 80 80 L2 90 90 H1 25 25 25 25 H2 13.5 13.5 13.5 13.5 H3 133 155 H4 205 205 B1 79.5 79.5 79.5 79.5 B2 84 84 84 84 G Rp Rp Rp Rp

Weights [kg] Net 1.00 1.15 1.05 1.16 Gross 1.12 1.31 1.24 1.32

Ship. vol. [m3] 0.0026 0.0034 0.0034 0.0034

UP 20-14

p [kPa] H [m] 1.2 1.0 8 0.8

110

1 x 230 V, 50 Hz

H4 G H3

0.4 0.2

TM01 9098 0503

0.0 0.00

0.1 0.04

0.2

0.3 0.08

0.4 0.12

Q [m/h] Q [l/s]

B1 B2

H2 H1

P1 [W] 25

In [A] 0.11

Connections: System pressure: Liquid temperature:

Various fittings, see page 41 Max. 10 bar +2C to +95C (TF 95)

Pump type UP 20-14 BX UP 20-14 BXU UP 20-14 BXT UP 20-14 BXUT

Dimensions [mm] L1 110 110 110 110 H1 25 25 25 25 H2 21 21 21 21 H3 133 155 H4 205 205 B1 79.5 79.5 79.5 79.5 B2 84 84 84 84 G G 1 G 1 G 1 G 1

Weights [kg] Net 1.20 1.35 1.25 1.36 Gross 1.35 1.51 1.44 1.52

Ship. vol. [m3] 0.0026 0.0034 0.0034 0.0034

TM01 8555 1602

0.0

L1

0.6

TM01 8554 1602

0.0

L2 L1

0.6

25

Technical data

Circulator pumps for domestic hot water

UP 20-07 N

p [kPa] H [m]

150

1 x 230 V, 50 Hz

6.0

0.6

4.5 0.4 3.0 0.2 1.5

TM00 9760 0397

0.0

0.0 0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 Q [m/h]

0.00 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45

Q [l/s]

Speed 1

P1 [W] 50

In [A] 0.24

Connections: System pressure: Liquid temperature:

" or 22 mm unions and valves Max. 10 bar +2C to +110C (TF 110)

Pump type UP 20-07 N

Dimensions [mm] L 150 H1 25 H2 100 B1 75 B2 43 G 1 Net 2.1

Weights [kg] Gross 2.3

Ship. vol. [m3] 0.004

UP 20-15 N

p [kPa] H [m]

150

1 x 230 V, 50 Hz

10

1.0

0.5

TM00 9765 0397

0.0 0.0 0.5 1.0 1.5 2.0 Q [m/h]

0.0

0.1

0.2

0.3

0.4

0.5

0.6 Q [l/s]

Speed 1

P1 [W] 65

In [A] 0.28

Connections: System pressure: Liquid temperature:

" or 22 mm unions and valves Max. 10 bar +2C to +110C (TF 110)

Pump type UP 25-15 N

Dimensions [mm] L 150 H1 28 H2 100 B1 75 B2 43 G 1 Net 2.1

Weights [kg] Gross 2.3

Ship. vol. [m3] 0.004

26

TM00 8932 2105

TM00 8932 2105

Technical data

Circulator pumps for domestic hot water

UP 20-30 N

p [kPa] H [m]

150

1 x 230 V, 50 Hz

30

3.0

20

2.0

10

1.0

TM00 9752 0397

0.0 0.0 0.5 1.0 1.5 2.0 2.5 Q [m/h]

0.0

0.2

0.4

0.6

0.8

Q [l/s]

Speed 1

P1 [W] 75

In [A] 0.31

Connections: System pressure: Liquid temperature:

" or 22 mm unions and valves Max. 10 bar +2C to +110C (TF 110)

Pump type UP 20-30 N

Dimensions [mm] L 150 H1 28 H2 100 B1 75 B2 43 G 1 Net 2.1

Weights [kg] Gross 2.3

Ship. vol. [m3] 0.004

UP 20-45 N

p [kPa] 40 H [m] 4

150

1 x 230 V, 50 Hz

30

20

10

TM00 9759 2405

0 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 Q [m/h]

0.0

0.2

0.4

0.6

0.8

1.0

Q [l/s]

Speed 1

P1 [W] 115

In [A] 0.50

Connections: System pressure: Liquid temperature:

" or 22 mm unions and valves Max. 10 bar 25C to +110C (TF 110)

Pump type UP 20-45 N

Dimensions [mm] L 150 H1 28 H2 123 B1 82 B2 51 G 1 Net 4.0

Weights [kg] Gross 4.3

Ship. vol. [m3] 0.004

TM00 9388 2105

TM00 8932 2105

27

Technical data

Circulator pumps for domestic hot water

UPS 25-40 B

p [kPa] 40 H [m] 4

3 2

180

1 x 230 V, 50 Hz

30

3

1

20

10

TM00 9749 2405

0 0.0 0.5 1.0 1.5 2.0 2.5 Q [m/h]

0.0

0.2

0.4

0.6

0.8

Q [l/s]

Speed 3 2 1

P1 [W] 45 35 25

In [A] 0.20 0.16 0.12

Connections: System pressure: Liquid temperature: Energy class:

", 1", 22 or 28 mm unions and valves Max. 10 bar +2C to +110C (TF 110) B

Pump type UPS 25-40 B

Dimensions [mm] L 180 H1 32 H2 102 B1 75 B2 51 G 1 Net 2.9

Weights [kg] Gross 3.1

Ship. vol. [m3] 0.004

UPS 25-60 B

p [kPa] 50 40 30 20 10 0 H [m]

3

180

1 x 230 V, 50 Hz

5 4 3 2 1

TM00 9751 2405

0 0.0 0.5 1.0 1.5 2.0 2.5 3.0 Q [m/h]

0.0

0.2

0.4

0.6

0.8

Q [l/s]

Speed 3 2 1

P1 [W] 70 60 50

In [A] 0.30 0.27 0.22

Connections: System pressure: Liquid temperature: Energy class: Cold-water version:

", 1", 22 or 28 mm unions and valves Max. 6/10 bar +2C to +110C (TF 110) C Type BK for 25C to +95C (TF 95) Weights [kg] Ship. vol. [m3] 0.004

Pump type UPS 25-60 B

Dimensions [mm] L 180 H1 32 H2 102 B1 75 B2 51 G 1 Net 2.9

Gross 3.1

28

TM00 9386 2105

TM00 9386 2105

Technical data

Circulator pumps for domestic hot water

UP 25-80 B

p [kPa] 80 70 60 50 40 30 20 10 0 H [m] 8 7 6 5 4 3 2

180

1 x 230 V, 50 Hz

TM00 9758 2405

0 0 1 2 3 4 5 6 7 8 Q [m/h]

0.0

0.5

1.0

1.5

2.0

Q [l/s]

Speed 1

P1 [W] 190

In [A] 0.83

Connections: System pressure: Liquid temperature: Energy class:

", 1", 22 or 28 mm unions and valves Max. 10 bar 25C to +110C (TF 110) D Weights [kg] Ship. vol. [m3] 0.008

Pump type UP 25-80 B

Dimensions [mm] L 180 H1 32 H2 130 B1 82 B2 52 G 1 Net 4.2

Gross 4.5

UPS 32-80 B

p [kPa] 80 H [m] 8 7 60 6 5 40 4 3 20 2 1 3 2

180

1 x 230 V, 50 Hz

TM00 9753 2405

0 0 1 2 3 4 5 6 7 8 9 10 Q [m/h]

0.0

0.5

1.0

1.5

2.0

2.5

3.0

Q [l/s]

Speed 3 2 1

P1 [W] 240 205 135

In [A] 1.05 0.91 0.62

Connections: System pressure: Liquid temperature: Energy class:

1", 28 or 42 mm unions and 1" valves Max. 10 bar 25C to +110C (TF 110) D

Pump type UPS 32-80 B

Dimensions [mm] L 180 H1 39 H2 130 B1 82 B2 60 G 2 Net 5.2

Weights [kg] Gross 5.5

Ship. vol. [m3] 0.0102

TM00 8945 2105

TM00 9387 2105

29

Technical data

Circulator pumps for domestic hot water

UPS 32-50 FB

p [kPa] 50 40 30 20 10 0 H [m] 5 4

1 3 2

220

1 x 230 V, 50 Hz

3 2 1

TM00 9755 2405

0 0 1 2 3 4 5 6 7 8 9 Q [m/h]

0.0

0.5

1.0

1.5

2.0

2.5

Q [l/s]

Speed 3 2 1

P1 [W] 115 110 85

In [A] 0.51 0.48 0.38 Dimensions [mm]

Connections: System pressure: Liquid temperature: Energy class:

1" screwed flanges or 40 mm flanges for welding Max. 6/10 bar 25C to +110C (TF 110) C Weights [kg] Ship. vol. [m3] 0.008

Pump type UPS 32-50 FB

L 220

H1 60

H2 130

B1 82

B2 65

Net 5.3

Gross 5.6

UPS 40-50 FB

p [kPa] 50 40 30 20 10 0 H [m] 5 4

1 3 2

250

1 x 230 V, 50 Hz

3 2 1

TM00 9755 2405

0 0 1 2 3 4 5 6 7 8 9 Q [m/h]

0.0

0.5

1.0

1.5

2.0

2.5

Q [l/s]

Speed 3 2 1

P1 [W] 115 110 85

In [A] 0.51 0.48 0.38 Dimensions [mm]

Connections: System pressure: Liquid temperature: Energy class:

1" screwed flanges or 40 mm flanges for welding Max. 6/10 bar 25C to +110C (TF 110) C Weights [kg] Ship. vol. [m3] 0.0122

Pump type UPS 40-50 FB

L 250

H1 75

H2 130

B1 82

B2 75

Net 9.3

Gross 9.7

30

TM00 9333 2105

TM00 9332 2105

Technical data

Special versions

Product range, special versions

Pump type UP 25-25 UP 32-25 UPS 25-20 UPS 32-20 UPS 25-40 UPS 32-40 UPS 25-50 UPS 32-50 UPS 25-60 UPS 32-60 UP 25-80 UP 32-80 UP 20-07 N UP 20-15 N UP 20-30 N UP 20-45 N UP 32-80 B UP 40-50 FB UP 20-30 NK UP 25-80 UP 32-80 UPSD 32-50 F UPSD 32-80 F UPSD 40-50 F UPSD 40-80 F UP 25-72 UP 40-72 UP 20-62 N UPS 25-42 UPS 25-62 UPS 20-32 N 50 Hz 1 x 230 V 50 Hz 3 x 400 V 50 Hz 3 x 220 V 60 Hz 3 x 440 V 60 Hz 1 x 220 V

31

Technical data

Special versions

UPSD 32-50 F

p [kPa] 50 40 30 20 10 0 H [m] 5 4 3 2 1

3 2

220

1 x 230 V, 50 Hz

TM00 9768 2405

0 0 1 2 3 4 5 Q [m/h]

0.0

0.4

0.8

1.2

1.6

Q [l/s]

Speed 3 2 1

P1 [W] 110 100 80

In [A] 0.47 0.46 0.37 Dimensions [mm]

Connections: System pressure: Liquid temperature:

1" screwed flanges or 32 mm flanges for welding Max. 6/10 bar 25C to +110C (TF 110)

Pump type UPSD 32-50 F

Weights [kg] B1 134 B2 119 B3 128 Net 12.6 Gross 13.0

L1 220

L2 125

L3 95

L4 82

H1 70

H2 130

Ship. vol. [m3] 0.0126

UPSD 32-80 F

p [kPa] 60 H [m] 6 5 45 4 30 3 2 15

1 3 2

220

1 x 230 V, 50 Hz

TM00 9769 0397

0 0 1 2 3 4 5 6 Q [m/h]

0.0

0.5

1.0

1.5

Q [l/s]

Speed 3 2 1

P1 [W] 245 210 140

In [A] 1.04 0.92 0.63 Dimensions [mm]

Connections: System pressure: Liquid temperature:

1" screwed flanges or 32 mm flanges for welding Max. 6/10 bar 25C to +110C (TF 110)

Pump type UPSD 32-80 F

Weights [kg] B1 134 B2 119 B3 128 Net 12.6 Gross 13.0

L1 220

L2 125

L3 95

L4 82

H1 70

H2 130

Ship. vol. [m3] 0.0126

32

TM00 9335 2105

TM00 9396 2105

Technical data

Special versions

UPSD 40-50 F

p [kPa] 45 4 30 3 2 15 1

1

250

1 x 230 V, 50 Hz

H [m] 5

3 2

TM00 9767 0397

0 0 2 4 6 8 10 Q [m/h]

0.0

0.5

1.0

1.5

2.0

2.5

Q [l/s]

Speed 3 2 1

P1 [W] 140 130 90

In [A] 0.60 0.57 0.40 Dimensions [mm]

Connections: System pressure: Liquid temperature:

1" screwed flanges or 40 mm flanges for welding Max. 6/10 bar 25C to +110C (TF 110)

Pump type UPSD 40-50 F

Weights [kg] B1 134 B2 119 B3 128 Net 14.1 Gross 14.5

L1 250

L2 150

L3 100

L4 82

H1 75

H2 130

Ship. vol. [m3] 0.0126

UPSD 40-80 F

p [kPa] 60 H [m] 6 5 45 4

1 3 2

250

1 x 230 V, 50 Hz

30

3 2

15

TM00 9766 0397

0 0 2 4 6 8 10 Q [m/h]

0.0

0.5

1.0

1.5

2.0

2.5

Q [l/s]

Speed 3 2 1

P1 [W] 240 205 135

In [A] 1.05 0.91 0.62 Dimensions [mm]

Connections: System pressure: Liquid temperature:

1" screwed flanges or 40 mm flanges for welding Max. 6/10 bar 25C to +110C (TF 110)

Pump type UPSD 40-80 F

Weights [kg] B1 134 B2 119 B3 128 Net 14.1 Gross 14.5

L1 250

L2 150

L3 100

L4 82

H1 75

H2 130

Ship. vol. [m3] 0.0126

TM00 8972 2105

TM00 9335 2105

33

Technical data

Special versions

UP 20-62 N

p [kPa] H [m] 7 60 6 5 45 4 30 3 2 15

150

3 x 440 V, 60 Hz

TM00 9764 0397

0 0 1 2 3 4 5 Q [m/h]

0.0

0.5

1.0

Q [l/s]

Speed 1

P1 [W] 180

In [A] 0.30

Connections: System pressure: Liquid temperature:

" or 22 mm unions and valves Max. 10 bar 25C to +110C (TF 110)

Pump type UP 20-62 N

Dimensions [mm] L 150 H1 26 H2 123 B1 80 B2 51 G 1

Weights [kg] Net 4.0 Gross 4.3

Ship. vol. [m3] 0.008

UP 25-72

p [kPa] H [m] 7 60 6 5 45 4 30 3 2 15

180

3 x 440 V, 60 Hz

TM00 9762 0397

0 0 1 2 3 4 5 6 7 Q [m/h]

0.0

0.5

1.0

1.5

2.0

Q [l/s]

Speed 1

P1 [W] 185

In [A] 0.31

Connections: System pressure: Liquid temperature:

" or 1" unions and valves Max. 10 bar 25C to +110C (TF 110)

Pump type UP 25-72

Dimensions [mm] L 180 H1 32 H2 130 B1 80 B2 52 G 1

Weights [kg] Net 4.3 Gross 4.6

Ship. vol. [m3] 0.008

34

TM00 8960 2105

TM00 8964 2105

Technical data

Special versions

UP 40-72 F

p [kPa] H [m] 7 60 6 5 45 4 30 3 2 15

250

3 x 440 V, 60 Hz

TM00 9763 0397

0 0 1 2 3 4 5 6 7 8 9 10 Q [m/h]

0.0

0.5

1.0

1.5

2.0

2.5

Q [l/s]

Speed 1

P1 [W] 230

In [A] 0.35

Connections: System pressure: Liquid temperature:

1" screwed flanges or 40 mm flange for welding Max. 10 bar 25C to +110C (TF 110)

Pump type UP 40-72 F

Dimensions [mm] L 250 H1 65 H2 130 B1 80 B2 65 G -

Weights [kg] Net 7.4 Gross 7.8

Ship. vol. [m3] 0.0122

UPS 25-42

p [kPa] 40 35 30 25 20 15 10 5 0 0.0 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 Q [m/h] 1.0

1

180

1 x 220 V, 60 Hz

H [m] 4.0

3.0

2

2.0

TM01 0152 0597

0.0

0.2

0.4

0.6

0.8

1.0

Q [l/s]

Speed 3 2 1

P1 [W] 85 50 30

In [A] 0.40 0.26 0.15 Dimensions [mm]

Connections: System pressure: Liquid temperature:

" or 22 mm unions and " or 22 mm valves Max. 10 bar +2C to +110C (TF 110)

Pump type UPS 25-42

Weights [kg] B2 51 G 1 Net 2.6 Gross 2.8

L 180

H1 32

H2 102

B1 75

Ship. vol. [m3] 0.004

TM00 9386 2105

TM00 8962 2105

35

Technical data

Special versions

UPS 25-62

p [kPa] 60 50 40 30 20 10 0 H [m] 6 5 4 3 2 1 0 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 Q [m/h]

2 3

180

1 x 220 V, 60 Hz

TM01 0153 0597

0.0

0.1

0.2 0.3

0.4

0.5 0.6

0.7

0.8 0.9

1.0

1.1 Q [l/s]

Speed 3 2 1

P1 [W] 115 65 35

In [A] 0.51 0.30 0.17

Connections: System pressure: Liquid temperature:

" or 1" unions and valves Max. 10 bar +2C to +110C (TF 110)

Pump type UPS 25-62

Dimensions [mm] L 180 H1 32 H2 102 B1 75 B2 51 G 1

Weights [kg] Net 2.6 Gross 2.8

Ship. vol. [m3] 0.004

UP 20-32 N

p [kPa] H [m]

150

1 x 220 V, 60 Hz

30

3.0

20

2.0

10

1.0

TM01 0154 0597

0.0 0.0 0.5 1.0 1.5 2.0 2.5 Q [m/h]

0.0

0.2

0.4

0.6

Q [l/s]

Speed 1

P1 [W] 95

In [A] 0.43

Connections: System pressure: Liquid temperature:

" or 22 mm unions and " or 22 mm valves Max. 10 bar +2C to +110C (TF 110)

Pump type UP 20-32 N

Dimensions [mm] L 150 H1 28 H2 100 B1 75 B2 43 G 1

Weights [kg] Net 2.1 Gross 2.3

Ship. vol. [m3] 0.004

36

TM00 8932 2105

TM00 9386 2105

Accessories

Series 100

Pipe connections

Unions

Rp

TM00 9678 5196 TM00 9679 5196

Rp

TM00 9681 2097

mm

TM00 9680 5196

mm

TM00 9677 2097

Pump connection

Pump type 20-xx 25-xx 32-xx N, B B B G 1 G 1 G2

"

"

1"

1"

1"

1"

"

1"

1"

22

28

10

12

15

18

22

28

42

Flanges

Rp

TM00 9682 5196 TM00 9683 5196

TM00 9684 2097

TM00 9685 5196

Pump connection

Pump type 21-xxF 36-xxF 32-xxF Oval Square PN 6 PN 10 PN 6 PN 10 PN 6 PN 10

"

1"

1" 1" "

"

1"

1"

22

28 " 1" 1" 1" 2" 32 40 50 1" 1" 32 40

40-xxF

B B

= Cast iron = Brass/bronze

TM00 9686 5196

Rp

mm

Rp (mm)

Rp (mm)

37

Accessories

Series 100

Grundfos controls

TS 3: On/off time switch

The on/off time switch is fitted directly to the wall. The time switch automatically switches the pump on/off at preset intervals. It is available with 24-hour or week dial.

Type TS 3/T TS 3/W Time switch 24-hour dial Week dial Product no. 1 x 220 V 96406992 96406993

I

TM01 0205 2602

12 9 3 6

ST 200: On/off time switch and timed speed control

The ST 200 control is designed to control all singlephase UP, UPS pumps. The control automatically changes over from one speed to another at preset intervals or only switches on/off (according to wiring).

Type ST 200 ST 200/TG ST 200/WG Time switch 24-hour dial 24-hour dial with battery back-up Week dial with battery back-up Product no. 1 x 220 V 60041110 60041210 60041310

TM00 5142 5094 TM00 5143 5094

SAT 200: On/off time switch and timed speed control

The SAT 200 control has the same functions as the above-mentioned ST 200 control, but in addition, the SAT 200 features a built-in fuse and shorter intervals.

Type SAT 200/TG SAT 200/WG Time switch 24-hour dial with battery back-up Week dial with battery back-up Product no. 1 x 220 V 60010210 60010310

38

Accessories

Series 100

Grundfos controls

GES 200: Timed changeover between pump heads

The GES 200 control is designed for control of all single-phase twin-head pumps. The control automatically changes over between the two pump heads at preset intervals. By selecting different speeds for the duty pump and the standby pump, a speed control facility can be obtained (e.g. left pump on speed 3, right pump on speed 2).

Type GES 200/WG Time switch Week dial with battery back-up Product no. 1 x 220 V 60020310

ET 2: Temperature switch

The ET 2 temperature switch can be used in conjunction with ST 200, SAT 200 and GES 200 controls. The ET 2 is a switch controlling according to the outdoor, room, flow-pipe or return-pipe temperature.

Control signal Type Temperature switch With housing and outdoor sensor Temperature (outdoor, room, flow pipe, return pipe) ET 2 With sensor for external pipe mounting With sensor for internal pipe mounting and bushing Product no. ID4383 ID4384 ID4385

Differential-pressure controls are also available.

Terminal block

The terminal block is fitted to the terminal box and used for the connection of external controls (e.g. for external changeover between two speeds).

Terminal block 605003

TM00 5144 5094

Type

Product no.

TM00 9103 4396

39

Accessories

Series 100

Union and valve kits

Pump type ALPHA+ 25-40, 25-40 A, 25-60, 25-60 A Description " unions 1" unions " valves 1" valves " unions ALPHA+ 25-40B, 25-60 B 1" unions " valves 1" valves ALPHA+ 32-40, 32-60 1" unions 1" unions Material Cast iron Cast iron MS MS MS MS MS MS Cast iron Cast iron Product number 529921 529922 519805 519806 529971 529972 519805 509921 509922 519806

Service kit for ALPHA+

Insulation kits

Series 100 can be fitted with two insulating shells. The insulating thickness of the insulating kit corresponds to the nominal diameter of the pump. The insulation kit, which is tailored to the individual pump type, encloses the entire pump housing. The two shells are easily fitted around the pump.

Description Plug - GRUNDFOS ALPHA+ Product number 595562

Timer and thermostat for COMFORT

According to the table below, the pump types B, BT, BX and BXT can be upgraded with a 24-hour timer. The timer for the pump types BT and BXT includes a thermostat for replacement.

Supplied with Shut-off valve and non-return valve Product numbers

24-hour timer

24-hour timer

TM01 9205 4902

UP 15-14 B UP 15-14 BU UP 15-14 BT UP 15-14 BUT UP 20-14 BX UP 20-14 BXU UP 20-14 BXT UP 20-14 BXUT

Thermostat

Pump type

96433891 96433892 96433891 96433892

Pump type ALPHA+ 15-40, 25-40, 32-40, 25-60, 32-60 ALPHA+ 25-40 A, 25-60 A UPS 25-20 UPS 32-20 UPS 25-30 UPS 32-30 UPS 25-40 UPS 32-40 UPS 25-60 UPS 32-60 UPS 25-80 UPS 32-80 UPS 25-20 A UPS 25-30 A UPS 25-40 A UPS 25-60 A UPS 40-50 F UPS 25-40 B UPS 25-60 B UP 25-80 B UPS 32-80 B UPS 40-50 FB

Insulation kit 505821 505822 505821 505821 505821 505821 505821 505821 505821 505821 525242 525242 505822 505822 505822 505822 525243 505821 505821 525242 525242 525243

40

24-hour timer + thermostat

TM01 9911 3400

Accessories

Series 100

Fittings for COMFORT

Pump type Fitting

TM01 8539 0300

Description

Connection

Material

Prod. no.

Extension set Length = 35 mm each

Rp / G 1

MS

96433911

TM01 8540 0300

Extension set Length = 25 mm each

Rp / G 1

MS

96433912

TM01 8541 0300

UP 15-XX

Extension set Length = 30 mm each

Rp / G 1

MS

96433913

TM01 8647 0300

Non-return valve

MS

96433904

TM01 8648 0300

Shut-off valve

MS

96433905

TM01 8542 0300

Extension set Length = 40 mm

G 1 / G 1

MS

96436559

TM01 8643 0300

Union set

G 1 x 15 mm int. / R ext.

MS

96433907

UP 20-XX

TM01 8644 0300

Union set

G 1 x Rp int.

MS

96433908

TM01 8645 0300

Union set

G 1 x Rp int. / R ext.

MS

96433909

TM01 8646 0300

Union set

G x 22 mm int.

MS

96433910

TM01 8560 0300

UP 15-XX UP 20-XX

Venting flange

Flange Union nut Hose

PP CuZn40Pb2 PE

96433906

41

Further product documentation

In addition to this printed data booklet, Grundfos offers the following sources of product documentation. WinCAPS WebCAPS.

WinCAPS

WinCAPS is a Windows-based Computer Aided Product Selection program containing information on more than 90,000 Grundfos products.

cd-wincaps

Available on CD-ROM in more than 15 languages, WinCAPS offers detailed technical information selection of the optimum pump solution dimensional drawings of each pump detailed service documentation installation and operating instructions wiring diagrams of each pump.

Fig. 1 WinCAPS CD-ROM

Click Catalogue and select a product from the extensive product catalogue.

Click Sizing and select the most suitable pump for your application.

Fig. 2 WinCAPS

42

WinCAPS

Further product documentation

WebCAPS

WebCAPS is a Web-based Compute Aided Product Selection program and a web-version of WinCAPS. WebCAPS is accessible on Grundfos homepage,

www.grundfos.com, and offers

detailed technical information dimensional drawings of each pump wiring diagrams of each pump.

Click Catalogue and select a product from the extensive product catalogue.

Click Literature to select and download Grundfos documentation by browsing the product ranges or performing a specific search. Literature includes: data booklets installation and operating instructions service, etc.

Click Service to find information on service kits and spare parts.

Click Replacement and select the right replacement pump based on the current installation. Click CAD drawings to select and download CAD drawings in: .stp .dxf .dwg

Click Search and select a product from the extensive product catalogue.

Being a registered user click Log in to: save your settings define and save your own units save personalised information. Click Settings and select your preferred options.

Click Sizing and select the most suitable pump for your application.

Fig. 3 WebCAPS

WebCAPS_English

43

Being responsible is our foundation Thinking ahead makes it possible Innovation is the essence

V7124413 1105

Repl. V7124413 0705

GB

Subject to alterations.

GRUNDFOS A/S . DK-8850 Bjerringbro . Denmark Telephone: +45 87 50 14 00 www.grundfos.com

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Tecnoflex TPCDocumento8 pagineTecnoflex TPCpalotito_eNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Model STR800 (DP, GP & AP) Remote SealsDocumento10 pagineModel STR800 (DP, GP & AP) Remote Sealspalotito_eNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- HE Mono-Block IIDocumento4 pagineHE Mono-Block IIpalotito_eNessuna valutazione finora

- Honeywell Production IntelligenceDocumento4 pagineHoneywell Production Intelligencepalotito_eNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- s200 RelayDocumento2 pagines200 Relaypalotito_eNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Inverter Ip-35155a Bn44-00124eDocumento2 pagineInverter Ip-35155a Bn44-00124eBazlur Rahman71% (7)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Scenic Pro d7Documento1 paginaScenic Pro d7palotito_eNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- TEK 1503C Manual TDRDocumento128 pagineTEK 1503C Manual TDRpalotito_eNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Guardian Newsletter January 2015 PDFDocumento11 pagineGuardian Newsletter January 2015 PDFpalotito_eNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Manual MR3420Documento121 pagineManual MR3420palotito_eNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Carburattor Set UpDocumento3 pagineCarburattor Set Uppalotito_eNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- How To Revive An Old Computer: Howard FosdickDocumento65 pagineHow To Revive An Old Computer: Howard Fosdickpalotito_eNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- ISA Fact SheetDocumento2 pagineISA Fact Sheetpalotito_eNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Bench HooksDocumento3 pagineBench Hookspalotito_e80% (5)

- Bearing Pad "A" Bearing Pad "B": Bd-Id1EDocumento11 pagineBearing Pad "A" Bearing Pad "B": Bd-Id1EJUAN RULFONessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Vertical Pump Ranges: Sulzer PumpsDocumento4 pagineVertical Pump Ranges: Sulzer Pumpsjhonny_restrepo001Nessuna valutazione finora

- Tablas de Esfuerzos PDFDocumento729 pagineTablas de Esfuerzos PDFSamuel PohezNessuna valutazione finora

- 149 - Ic-P&id-07 (Contact Tanks) - Ic-P&id-07Documento1 pagina149 - Ic-P&id-07 (Contact Tanks) - Ic-P&id-07Fun TonNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Seal Oil System 2Documento31 pagineSeal Oil System 2Raga Lasya100% (8)

- FRA MV Cable TerminationsDocumento1 paginaFRA MV Cable Terminationsmohamed1303Nessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- PO1541 - Ojas Infra GSF - MV Cable Marking and Drum Label v1.0Documento6 paginePO1541 - Ojas Infra GSF - MV Cable Marking and Drum Label v1.0Sanjay GadhaveNessuna valutazione finora

- Vitor Renan Vitor Gama - Dissertação (Ppgeq) 2021Documento65 pagineVitor Renan Vitor Gama - Dissertação (Ppgeq) 2021JatousNessuna valutazione finora

- Searay 330 Sundancer-ReportDocumento11 pagineSearay 330 Sundancer-ReportAshok KamathNessuna valutazione finora

- Civil Offer LetterDocumento4 pagineCivil Offer LetterArjit Singh80% (5)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Str. Design Calc of Boundary WallDocumento7 pagineStr. Design Calc of Boundary WallAnonymous NBGW6fj8Yl100% (2)

- KAT-A 1912 DUOJET Edition13 02-01-2017 ENDocumento6 pagineKAT-A 1912 DUOJET Edition13 02-01-2017 ENwinston11Nessuna valutazione finora

- Tds Mol Transol 220 GBDocumento2 pagineTds Mol Transol 220 GBMaDa GeoNessuna valutazione finora

- Toda Hut: Vernacular ArchitectureDocumento9 pagineToda Hut: Vernacular ArchitectureKrittikaNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Location: Capacity: Architect: Mr. Anil Yadav: Qutub Institutional Area 150 PatientsDocumento18 pagineLocation: Capacity: Architect: Mr. Anil Yadav: Qutub Institutional Area 150 PatientsManishaDhimanNessuna valutazione finora

- Revit 2014 Set BDocumento5 pagineRevit 2014 Set Bar2k5shikhaNessuna valutazione finora

- MSS SP 58 - 2002 Normas de FabricacionDocumento2 pagineMSS SP 58 - 2002 Normas de FabricacionJose Alberto Martinez Holguin100% (1)

- Pressostat Steer - GeearDocumento240 paginePressostat Steer - GeearПетр ШкильNessuna valutazione finora

- Innova M3 New: 3. InstallationDocumento8 pagineInnova M3 New: 3. InstallationAndreea DanielaNessuna valutazione finora

- Squatting WC Pan: Special FeaturesDocumento2 pagineSquatting WC Pan: Special FeaturesRushan LakdimuthuNessuna valutazione finora

- Dow ELITE 5220G Enhanced Polyethylene ResinDocumento2 pagineDow ELITE 5220G Enhanced Polyethylene Resinusman3549606Nessuna valutazione finora

- Gen TT Install InstructionsDocumento25 pagineGen TT Install Instructionsspsperformance1Nessuna valutazione finora

- Fire Wall DesignDocumento4 pagineFire Wall DesignIrshad KhanNessuna valutazione finora

- S 220 BobcatDocumento403 pagineS 220 BobcatGustavo100% (4)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Materials ReviewerDocumento9 pagineMaterials ReviewerKaizer DAnNessuna valutazione finora

- Oi/N Malaysia Final Examination: SessionDocumento10 pagineOi/N Malaysia Final Examination: Sessionsharif100% (1)

- ISO and CENDocumento3 pagineISO and CENhabeebrahNessuna valutazione finora

- Butterfly Valve CatalogueDocumento6 pagineButterfly Valve CatalogueromeshmoreyNessuna valutazione finora

- 026 StihlDocumento48 pagine026 StihlManuel PedrosaNessuna valutazione finora

- Metric Hex Bolt ChartsDocumento1 paginaMetric Hex Bolt ChartsPraburamNessuna valutazione finora