Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

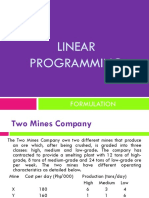

MA3908 Linear Programming Formulation Examples

Caricato da

mashi_jumpDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MA3908 Linear Programming Formulation Examples

Caricato da

mashi_jumpCopyright:

Formati disponibili

MA3908 Linear programming formulation - questions Question A company manufactures two products (A and B) and the profit per

unit sold is 3 and 5 respectively. Each product has to be assembled on a particular machine, each unit of product A taking 12 minutes of assembly time and each unit of product B 25 minutes of assembly time. The company estimates that the machine used for assembly has an effective working week of only 30 hours (due to maintenance/breakdown). Technological constraints mean that, for every five units of product A produced, at least two units of product B must be produced. Formulate the problem of how much of each product to produce as a linear program. Question A food is manufactured by refining raw oils and blending them together. The raw oils come in two categories: Vegetable oil: VEG1 VEG2 Non-vegetable oil: OIL1 OIL2 OIL3 The prices for buying each oil are given below (in /tonne) VEG1 VEG2 OIL1 OIL2 OIL3 115 128 132 109 114 The final product sells at 180 per tonne. Vegetable oils and non-vegetable oils require different production lines for refining. It is not possible to refine more than 210 tonnes of vegetable oils and more than 260 tonnes of non-vegetable oils. There is no loss of weight in the refining process and the cost of refining may be ignored. There is a technical restriction relating to the hardness of the final product. In the units in which hardness is measured this must lie between 3.5 and 6.2. It is assumed that hardness blends linearly and that the hardness of the raw oils is: VEG1 VEG2 OIL1 OIL2 OIL3 8.8 6.2 1.9 4.3 5.1

It is required to determine what to buy and how to blend the raw oils so that the company maximises its profit. Formulate the above problem as a linear program. What assumptions do you make in formulating this problem by linear programming?

MA3908 Linear programming formulation - answers Answer Let xA = number of units of A produced xB = number of units of B produced then the constraints are: 12xA + 25xB 30(60) (assembly time) xB 2(xA/5) (technological) i.e. xB - 0.4xA 0 i.e. 5xB >= 2xA where xA, xB 0 and the objective is maximise 3xA + 5xB Answer Variables We need to decide how much of each oil to use so let xi be the number of tonnes of oil of type i used (i=1,...,5) where i=1 corresponds to VEG1, i=2 corresponds to VEG2, i=3 corresponds to OIL1, i=4 corresponds to OIL2 and i=5 corresponds to OIL3 and where xi 0 i=1,...,5 Constraints cannot refine more than a certain amount of oil x1 + x2 210 x3 + x4 + x5 260 hardness of the final product must lie between 3.5 and 6.2 (8.8x1 + 6.2x2 + 1.9x3 + 4.3x4 + 5.1x5)/(x1 + x2 + x3 + x4 + x5) 3.5 (8.8x1 + 6.2x2 + 1.9x3 + 4.3x4 + 5.1x5)/(x1 + x2 + x3 + x4 + x5) 6.2 As written above the hardness constraints are non-linear but can be transformed to the two linear constraints: (8.8x1 + 6.2x2 + 1.9x3 + 4.3x4 + 5.1x5) 3.5(x1 + x2 + x3 + x4 + x5) (8.8x1 + 6.2x2 + 1.9x3 + 4.3x4 + 5.1x5) 6.2(x1 + x2 + x3 + x4 + x5) i.e. 3.5(x1+x2+x3+x4+x5) (8.8x1+6.2x2+1.9x3+4.3x4+5.1x5) 6.2(x1+x2+x3+x4+x5)

Objective The objective is to maximise total profit, i.e. maximise 180(x1 + x2 + x3 + x4 + x5) - 115x1 - 128x2 - 132x3 - 109x4 - 114x5 The assumptions we make in solving this problem by linear programming are: o all data/numbers are accurate o hardness does indeed blend linearly o no loss of weight in refining o can sell all we produce

Potrebbero piacerti anche

- Ot (Unit I)Documento19 pagineOt (Unit I)Dharani C KNessuna valutazione finora

- Project Management 3 Problems Assignment 2015Documento7 pagineProject Management 3 Problems Assignment 2015DoreenNessuna valutazione finora

- LP Model 2022Documento13 pagineLP Model 2022Hamza MasoodNessuna valutazione finora

- Blending or Mixing Problem:: Raw Materials Final ProductsDocumento2 pagineBlending or Mixing Problem:: Raw Materials Final Productsumair talashNessuna valutazione finora

- Ex 03Documento3 pagineEx 03Tushar GuptaNessuna valutazione finora

- MAN305 Fixed Charge ProblemDocumento2 pagineMAN305 Fixed Charge ProblemTunahan AydınNessuna valutazione finora

- Imp2 PreDocumento21 pagineImp2 PreHamza MasoodNessuna valutazione finora

- Note1 Model FormulationDocumento17 pagineNote1 Model Formulationアユ ギタ100% (1)

- Formulation of LPP: Unit VDocumento53 pagineFormulation of LPP: Unit VHareesh Kumar JainNessuna valutazione finora

- Quantitative Method For MGT DecisionDocumento9 pagineQuantitative Method For MGT DecisionAgat0% (1)

- Zambian Open University: Bba 313 - Operations ResearchDocumento6 pagineZambian Open University: Bba 313 - Operations ResearchMASMO SHIYALANessuna valutazione finora

- Sensitivity Analysis in Simplex Method - GJSDocumento24 pagineSensitivity Analysis in Simplex Method - GJSAkshat Gandhi0% (1)

- ESM503 Fall2010 HW2Documento3 pagineESM503 Fall2010 HW2Ahmed ZidanNessuna valutazione finora

- Question Bank On Operations Research UniDocumento39 pagineQuestion Bank On Operations Research UniManiranjan KumarNessuna valutazione finora

- University of Engineering and Technology PeshawarDocumento4 pagineUniversity of Engineering and Technology PeshawarZaka UllahNessuna valutazione finora

- Operations Research: Multi Objective Decision ProblemDocumento8 pagineOperations Research: Multi Objective Decision ProblemAnkit Kumar SinghNessuna valutazione finora

- HW 01Documento7 pagineHW 01TibelchNessuna valutazione finora

- QAMD Tena QuestionsDocumento21 pagineQAMD Tena QuestionsCheru TerefeNessuna valutazione finora

- UntitledDocumento29 pagineUntitledumapanneerselvamNessuna valutazione finora

- Or Examples SolutionsDocumento14 pagineOr Examples Solutionsmohamadalfar111100% (1)

- Question Bank On Operations ResearchDocumento11 pagineQuestion Bank On Operations ResearchManiranjan KumarNessuna valutazione finora

- Integer - Programming - PPT (Compatibility Mode)Documento20 pagineInteger - Programming - PPT (Compatibility Mode)Harsh BhardwajNessuna valutazione finora

- C&O 370 Deterministic OR ModelsDocumento13 pagineC&O 370 Deterministic OR ModelsLanxi WangNessuna valutazione finora

- HW F92Documento64 pagineHW F92Eduar Fernando Aguirre GonzalezNessuna valutazione finora

- Linear Programming: I Sem LPP Quant-IDocumento27 pagineLinear Programming: I Sem LPP Quant-IBabitha RaghuNessuna valutazione finora

- Act3 LFVPDocumento11 pagineAct3 LFVPluis vazquezNessuna valutazione finora

- Quantitative Methods LPDocumento41 pagineQuantitative Methods LPRyan BekinfieldNessuna valutazione finora

- Lecture 3 - Linear ProgrammingDocumento14 pagineLecture 3 - Linear ProgrammingSakshi Khatri100% (1)

- University of Engineering and Technology PeshawarDocumento4 pagineUniversity of Engineering and Technology PeshawarZaka UllahNessuna valutazione finora

- QAMD - Work Sheet (SC)Documento19 pagineQAMD - Work Sheet (SC)Tesfu100% (1)

- Linear ProgrammingDocumento21 pagineLinear ProgrammingemmaNessuna valutazione finora

- Optimization Problems 1Documento12 pagineOptimization Problems 1AnjanNessuna valutazione finora

- Linear - Prog Q 3 4Documento12 pagineLinear - Prog Q 3 4Aatif_Saif_80Nessuna valutazione finora

- IPandBIPDocumento30 pagineIPandBIPMritunjay HansdaNessuna valutazione finora

- R7410301 Operations ResearchDocumento2 pagineR7410301 Operations ResearchsivabharathamurthyNessuna valutazione finora

- QA Assignment 02-15A - 14BDocumento3 pagineQA Assignment 02-15A - 14BZinegnaw MekonnenNessuna valutazione finora

- Linear Programming PDFDocumento17 pagineLinear Programming PDFmann20Nessuna valutazione finora

- Gleitlager enDocumento32 pagineGleitlager enMarcelo Topon100% (1)

- LINEAR PROGRAMMING Formulation ExampleDocumento40 pagineLINEAR PROGRAMMING Formulation ExampleAlyssa Audrey JamonNessuna valutazione finora

- Linear Programming: Mathematical Models (Part II) : Instructors: Dr. Safaa Amin Dr. Doaa EzzatDocumento16 pagineLinear Programming: Mathematical Models (Part II) : Instructors: Dr. Safaa Amin Dr. Doaa EzzatAbdi Mucee TubeNessuna valutazione finora

- Semere Tesfaye MBAO-8977-14BDocumento8 pagineSemere Tesfaye MBAO-8977-14Bamirhaile71Nessuna valutazione finora

- Section 3 Section 3: Routine MaintenanceDocumento2 pagineSection 3 Section 3: Routine MaintenanceСергій БоженкоNessuna valutazione finora

- Group Assignment Optimisation 10.4.21-V1Documento9 pagineGroup Assignment Optimisation 10.4.21-V1anuNessuna valutazione finora

- Formulating IpsDocumento26 pagineFormulating IpsEkin MedyaNessuna valutazione finora

- Study Unit 3 - Integer Linear Programming - ILPDocumento21 pagineStudy Unit 3 - Integer Linear Programming - ILPMarthinus MaraisNessuna valutazione finora

- Or ObjectivesDocumento22 pagineOr ObjectivesKAYNessuna valutazione finora

- 7 LP Sensitivity AnalysisDocumento9 pagine7 LP Sensitivity AnalysiszuluagagaNessuna valutazione finora

- Industrial LubricantsDocumento10 pagineIndustrial LubricantsPrasath GovindarajNessuna valutazione finora

- Linear ProDocumento25 pagineLinear ProApoorv SaxenaNessuna valutazione finora

- Practice Problems in Professional Industrial EngineeringDocumento15 paginePractice Problems in Professional Industrial EngineeringBlair0% (1)

- CHE F422 - Compre - PRT PDFDocumento4 pagineCHE F422 - Compre - PRT PDFTarun MandalamNessuna valutazione finora

- Pgdorm Sem 2 2017-18Documento5 paginePgdorm Sem 2 2017-18ZirohNessuna valutazione finora

- Sunco Oil WRDDocumento4 pagineSunco Oil WRDPaula CardenasNessuna valutazione finora

- Service Bulletin - (TB00!99!2090) - Lubrication Oils For Medium Speed EnginesDocumento8 pagineService Bulletin - (TB00!99!2090) - Lubrication Oils For Medium Speed Enginesps_visjehotmailcomNessuna valutazione finora

- ExamplesDocumento14 pagineExamplesYeeXuan TenNessuna valutazione finora

- Ilp and MilpDocumento53 pagineIlp and MilpabhishekNessuna valutazione finora

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Da EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Valutazione: 5 su 5 stelle5/5 (1)

- Troubleshooting and Repair of Diesel EnginesDa EverandTroubleshooting and Repair of Diesel EnginesValutazione: 1.5 su 5 stelle1.5/5 (2)

- IA1 - Mock AssessmentDocumento3 pagineIA1 - Mock AssessmentMohammad Mokhtarul HaqueNessuna valutazione finora

- Calculate PostageDocumento4 pagineCalculate PostageShivam ThakurNessuna valutazione finora

- Hippa and ISO MappingDocumento13 pagineHippa and ISO Mappingnidelel214Nessuna valutazione finora

- Direct Marketing CRM and Interactive MarketingDocumento37 pagineDirect Marketing CRM and Interactive MarketingSanjana KalanniNessuna valutazione finora

- CV - Nguyen Quang HuyDocumento5 pagineCV - Nguyen Quang HuyĐoan DoãnNessuna valutazione finora

- 2012 Brochure Keltan Final en PDFDocumento20 pagine2012 Brochure Keltan Final en PDFJorge Zegarra100% (1)

- G6Documento14 pagineG6Arinah RdhNessuna valutazione finora

- List of TCP and UDP Port NumbersDocumento44 pagineList of TCP and UDP Port NumbersElvis JavierNessuna valutazione finora

- ELEN 325 Lab 1 PrelabDocumento8 pagineELEN 325 Lab 1 PrelabAndrew ZellerNessuna valutazione finora

- How To Start A Fish Ball Vending Business - Pinoy Bisnes IdeasDocumento10 pagineHow To Start A Fish Ball Vending Business - Pinoy Bisnes IdeasNowellyn IncisoNessuna valutazione finora

- Final ME Paper I IES 2010Documento18 pagineFinal ME Paper I IES 2010pajadhavNessuna valutazione finora

- Intel L515 - User - GuLidarDocumento20 pagineIntel L515 - User - GuLidarRich ManNessuna valutazione finora

- Questionnaire Exercise: Deals Desk Analyst Please Answer Below Questions and Email Your Responses Before First Technical Round of InterviewDocumento2 pagineQuestionnaire Exercise: Deals Desk Analyst Please Answer Below Questions and Email Your Responses Before First Technical Round of InterviewAbhinav SahaniNessuna valutazione finora

- Chapin Dance Syllabus 23-24Documento3 pagineChapin Dance Syllabus 23-24api-231581209Nessuna valutazione finora

- Managing Apps in Windows 10Documento29 pagineManaging Apps in Windows 10CourageMarumeNessuna valutazione finora

- Self-Study Guidance - Basic Accounting. 15 Problems With Detailed Solutions.Documento176 pagineSelf-Study Guidance - Basic Accounting. 15 Problems With Detailed Solutions.Martin Teguh WibowoNessuna valutazione finora

- Openness and The Market Friendly ApproachDocumento27 pagineOpenness and The Market Friendly Approachmirzatouseefahmed100% (2)

- Today Mass Coloration in The Lndustri-Al Environment: Lenzinger BerichteDocumento5 pagineToday Mass Coloration in The Lndustri-Al Environment: Lenzinger BerichteAditya ShrivastavaNessuna valutazione finora

- ManagementLetter - Possible PointsDocumento103 pagineManagementLetter - Possible Pointsaian joseph100% (3)

- Presentation On Plant LayoutDocumento20 paginePresentation On Plant LayoutSahil NayyarNessuna valutazione finora

- Hetron CR 197Documento3 pagineHetron CR 197Faidhi SobriNessuna valutazione finora

- OTP Protocol PharmacistsDocumento14 pagineOTP Protocol PharmacistsericNessuna valutazione finora

- Pipenet: A Wireless Sensor Network For Pipeline MonitoringDocumento11 paginePipenet: A Wireless Sensor Network For Pipeline MonitoringMykola YarynovskyiNessuna valutazione finora

- OTDRDocumento57 pagineOTDRarijeetdguy3051100% (1)

- Faculty Performance Appraisal Report (Draft1)Documento3 pagineFaculty Performance Appraisal Report (Draft1)mina dote100% (1)

- Choosing Your PHD TopicDocumento9 pagineChoosing Your PHD TopicvilaiwanNessuna valutazione finora

- LINDE Spare Parts ListDocumento2 pagineLINDE Spare Parts Listsharafudheen_s100% (2)

- Oliva - A Maturity Model For Enterprise Risk ManagementDocumento14 pagineOliva - A Maturity Model For Enterprise Risk ManagementErika FerreiraNessuna valutazione finora

- Fss Operators: Benchmarks & Performance ReviewDocumento7 pagineFss Operators: Benchmarks & Performance ReviewhasanmuskaanNessuna valutazione finora

- VTP Renault 6.14.1 Web Version - Pdf.pagespeed - Ce.c T5zGltXA PDFDocumento176 pagineVTP Renault 6.14.1 Web Version - Pdf.pagespeed - Ce.c T5zGltXA PDFIbrahim AwadNessuna valutazione finora