Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Unit 5 Induction Motor: Structure

Caricato da

Sivasubramani ShanmugaveluDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Unit 5 Induction Motor: Structure

Caricato da

Sivasubramani ShanmugaveluCopyright:

Formati disponibili

119

Induction Motor

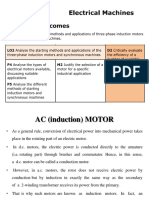

UNIT 5 INDUCTION MOTOR

Structure

5.1 Introduction

Objectives

5.2 Construction of Induction Motor

5.2.1 Stator Parts

5.2.2 Rotor Parts

5.2.3 Other Parts

5.3 Working of 3-Phase Induction Motor

5.3.1 Slip and Effect of Slip on Rotor Parameters

5.3.2 Torque and Torque-slip Characteristic

5.3.3 Power Flow

5.3.4 Equivalent Circuit of Inductor Motor

5.4 Starting and Speed Control

5.4.1 Starters for Poly Phase Induction Motors

5.4.2 Speed Control of 3-phase Induction Motor

5.5 Measurement of Slip

5.6 Summary

5.7 Answers to SAQs

5.1 INTRODUCTION

The most commonly encountered electric motors in industry are induction motors. In this

unit, we are introducing the construction features of induction motors to explain slip ring

induction motors and squirrel cage induction motors. Next, you will study various

relations between rotor emf, rotor current and torque developed in rotor. The choice of

selection of induction motor based on torque slip characteristics has been discussed. After

that, we will discuss equivalent circuit, no-load and blocked rotor tests of induction motor.

At the end of the unit, we will study speed control of induction motor which is very useful

in industrial drives.

Objectives

After studying this unit, you should be able to

give elementary description of various parts and types of induction motor,

explain the principle of working of induction motor and various stator and

rotor current relations,

describe torque-speed relations and condition for maximum torque,

describe power stages and efficiency of motor,

explain starting and speed control of induction motor, and

know effect of crawling and cogging of induction motor.

120

Electrical Technology

5.2 CONSTRUCTION OF INDUCTION MOTOR

The three-phase induction motor differs constructionally from the DC machine on certain

factors: its short air-gap, absence of a commutator, simple windings (particularly the cage)

and laminated stator. It is not possible, as in the DC machine, to make the frame as a part

of the magnetic circuit. The stator core must be carried in a shell or housing which

provides a means for protecting the stator and carrying the end-covers, bearings and

terminal box.

The following parts normally constitute an induction motor (the typical constructional

variation of slip-ring type is dealt under rotor construction).

5.2.1 Stator Parts

Let us discuss, in detail, each of them separately.

Frame

The frame of an induction motor may be cast or fabricated, depending upon the size

of the motor. For miniature and small motors, the frame has a single piece of short,

hollow cylinder cast-iron casting. It is cheaper to use cast iron where losses and

efficiency is of a lesser consideration than economy and where new designs and

modifications are not to be done on the machine.

However, for medium-sized and (in particular) large induction motors, fabricated

frame structure is exclusively used. Four or more arc-shaped rolled steel pieces are

joined together to form a cylindrical shape. The outer surface may be provided with

cooling fins so as to increase the heat dissipating area without increasing the overall

diameter. The chief advantage of fabricated construction is in its application to new

designs and modifications, which can be made without reference to existing

patterns. The principal constructional difficulty is the avoidance of distortion when

the parts are welded together.

The frame gives complete support and protection to the other parts (ruggedness) and

an eye-bolt on its top is useful for transit purposes.

Stator Core

The stator core provides the space for housing for the three-phase stator windings

and also forms the path for the rotating magnetic field. They are built up of thin

sheets of thickness (called stampings or laminations) of

0.35 mm to 0.65 mm with of a special core of steel, insulated one from the other by

means of paper. The gap facing inner circumference of the plates have suitable slots

punched out, either open, semi-closed or completely closed. Normally, the stator

core has semi-closed slots where the number of slots, S, is an integral multiple of 3

times the number of poles, p for which the induction motor is designed and

constructed [S = n. (3 p)], where n = 1, 2, 3 etc.

Every part of the stator core is subject to alternate changes in polarity of the

magnetic field (due to its rotating nature) so hysteresis losses and eddy-current

losses take place. To reduce the former, about 3-5% of silicon is added to high

grade steel and to reduce the latter, a large number of thin laminations are stacked

together.

5.2.2 Rotor Parts

Rotor Core

The construction of the rotor core should be separately discussed for (a) squirrel

cage motors, and (b) slip-ring motors. Certain common features are as follows :

(a) Both types have rotors constructed to thin sheets of special core steel,

but here the thickness is larger than that of stator stampings because no

appreciable iron loss is incurred in the rotor.

121

Induction Motor

(b) In small motors, the rotor core is mounted directly on the shaft, to

which it is keyed, and clamped between end-plates on the shaft and a

shrink-ring.

(c) For large motors, the rotor is built up on a fabricated spider, the cross-

section of which is shown below :

Terminal Box

Eye Bolt

Rib

Stator core

Stator slot

Stator coil

Air-gap

Longitudinal vent-slot

Shaft bore with key-way

Semi-closed slot for rotor

Frame

Stand

Figure 5.1(a) : Induction Motor Construction

(d) The rotor core surface have to be ground to obtain an accurate

air-gap.

(e) For dynamic balancing of rotor, after the winding of cage has been

done, there should be a provision in the rotor core, all along the

periphery, for small amount of weights to be attached, which finally

forms an integral part of the rotor.

Rotor Core for Squirrel Cage Induction Motor

Closed slots of either circular or rectangular shapes are provided in the

stamping. After the rotor core is stacked by the required number of

laminations, the rotor shaft is inserted through the space available at the

centre and firmly fitted by the key-way. For machines of small and medium

capacity, this assembly is then placed in a moulding machine, which forces

molten aluminium under pressure through the slots to form rotor bars, end

rings and cooling fan arrangement as an extension of end rings. This type

of die-cast rotor is simple and rugged in construction as shown in

Figure 5.1(b).

Figure 5.1(b) : Fabricated Rotor Spider for Induction Motor

122

Electrical Technology

For machines of larger capacity, copper or brass bars are driven through the

slots manually and the ends on both sides are then welded or silver-soldered

together to form end rings. The rotor bars are slightly inclined to the shaft

axis due to the skew provided while stacking the rotor stampings. Skewing

is done because:

(a) It helps the motor to run quietly by reducing magnetic hum.

(b) It reduces the locking tendency of the rotor.

Rotor Core for Slip Ring Induction Motor

Semi-closed slots for three-phase winding are provided in the stamping. In

cage-rotors, closed slots were used. This is the primary difference in the

stamping. Secondly, the molten aluminium or copper bars are not used.

Windings will be dealt separately.

Stator Winding

Three-phase stator winding is done on the stator core. One starting end and one

finishing end for each of the phase windings is brought out for inter-connection in Y

or fashion.

Single layer mesh windings are used for machines of smaller capacity and medium-

sized machines have double-layer lap windings. Large capacity motors employ

single layer concentric winding.

All the winding coils are placed in the slots, the slots are closed with wooden wedges

or paper insulator, which keeps the coil sides intact. The whole stator winding may

be impregnated with a thermosetting varnish and baked.

Rotor Cage or Rotor Winding

There is no rotor winding in squirrel cage motors where the short circuited

aluminium, copper and brass bars form the rotor bars. In slip ring motors, there is a

rotor winding on the rotor cage and hence are called the wound rotor motors.

The rotor is wound for the same number of poles as that of stator. The winding is

normally connected in star and the resultant three terminals are connected to three

slip-rings provided on one end of the shaft as shown below :

R

Wound Rotor

Slip Rings

Y B

Figure 5.2(a) : Slip Ring Induction Motor

When running normally, the slip-rings are short-circuited, but for starting purposes,

they are connected to a three-phase star-connected starting resistance, as shown in

Figure 5.2(b) alongside.

Rheostat

Figure 5.2(b) : Starting Resistance

123

Induction Motor

In slip-ring rotors of large size, a bar winding can be used because the choice of voltage is

usually free. For smaller machines, wire-wound rotors can be used, with coil arrangements

similar to those of the stator.

5.2.3 Other Parts

Shaft and Bearing

The shaft of an induction motor is short and stiff, in order to keep as small an air-

gap as is mechanically possible. This helps in removing any significant deflection in

the rotor. Even a small deflection in the shaft, and hence rotor, would create large

irregularities in the air-gap length which would lead to production of unbalanced

magnetic pull. For small and medium capacity motors, a roller bearing may be used

at the driving end and a ball bearing at the non-driving end.

Terminal Box and End Covers

The terminal boxes have been shown in the diagram Figure 5.3 with the connection

diagram for Y or connected stator. In squirrel cage motors, the rotor bars are

short-circuited in the construction itself, so rotor terminals are not available. But in

slip ring motors, it is essential to bring out the rotor terminals as it gives possibility

of inserting an additional resistance in the rotor circuit. In the terminal box shown,

only D, E, F constitute the rotor terminals, assuming that the other ends of it have

already been connected inside the machine. Sometimes, it is desirable to bring out

ends of each of the phases of the rotor. Then, together we have (6+6), i.e. 12

terminals on the terminal box.

A

1

B

1

C

1

C

2

A

2

B

2

D E F

Stator

terminals

Rotor

terminals

(in case of

slip-ring motors)

A

1

A

2

C

2

B

2

B

1 C

1

B

2

A

1

B

1

C

1

C

2

A

2

B

2

Star connected stator

Delta connected stator

B

1

A

2 C

1

C

2

A

1

A

1

C

2

B

1

A

2

C

1

B

2

Figure 5.3 : Parts of Induction Motor

Two end covers with suitable bearings provide support for the rotor assembly.

Brush Lifting and Short-Circuiting Gear

Brushes sliding on the slip rings are used for making connection of rotor windings

with the external circuit. Brush lifting and short-circuiting gear it used for operating

the brushes. This is fitted with one of the end-covers which is nearer to the slip-ring

side. Slip-rings are normally of brass or phosphor-bronze shrunk onto a cast-iron

sleeve with moulded mica insulation. The assembly is pressed onto the rotor shaft

and located either between the rotor core and the bearing, or onto the shaft

extension. This part is exclusively in slip-ring motors and not in the common type

squirrel cage motors.

5.3 WORKING OF 3-PHASE INDUCTION MOTOR

When three phase supply is connected across stator windings then a rotating flux is

produced in stator which rotates clockwise at synchronous speed giving

120

s

f

N

P

= .

124

Electrical Technology

When the rotor of 3-phase motor is placed in air gap of stator, a emf is induced in rotor

conductors. For squirrel cage rotor, conductors are shorted together and the four terminal

wound rotor conductors are connected with additional resistance between slip rings. The

induced emf causes a current to flow in these shorted conductors which produces a flux.

Due to reaction of this flux with stator flux a torque is produced and rotor rotates in same

direction of rotating flux with a speed less than synchronous speed.

5.3.1 Slip and Effect of Slip on Rotor Parameters

The rotating field revolves with the speed of synchronism, and if the rotor conductors were

to revolve at the same speed there would not be any torque. Hence, there is a difference

between rotor and rotating field speeds. The rotor speed is less than the rotating field speed

and the difference in speed is known as the slip of motor. Generally, slip lies between zero

to five percent.

Slip(s)

s r

s

N N

N

=

where N

s

is synchronous speed of rotating field in stator and N

r

is speed of rotor

(motor speed)

Percent slip 100

s r

s

N N

N

=

or Rotor speed (1 )

s

N s N =

Three phase induction motor is a particular form of transformer which has secondary

winding rotating. In transformer, the frequencies of primary and secondary windings are

same but in induction motor the frequency of emf induced in rotor (secondary winding)

depends on slip.

Rotor emf frequency = s frequency of applied voltage to stator = sf

The induced emf in rotor also depends on slip. When rotor is stationary the emf induced in

rotor is

2 1

2 1

1

Rotor emf ( )

n E

E E

n n

= = ,

where n = turns ration = n

1

/n

2

.

where n

2

and n

1

are number of turns in rotor and stator windings and E

1

is applied voltage

in stator. Now for moving rotor, rotor emf becomes sE

2

. Important thing to remember here

is that both E

1

and E

2

remain fixed by above relation even at different slip or load values.

The rotor resistance (R

2

) is constant with change in slip unless external resistance is added

or there is a change in temperature.

Rotor reactance at slip one (standstill) is X

2

or X

2

= 2 f L

2

where f is frequency of rotor emf at standfill and L

2

is inductance of rotor winding.

Now moving rotor frequency becomes sf, so

Rotor reactance = 2 sf L

2

= s X

2

So, rotor impedance at motion

2 2 2

2 2 2

Z R s X = +

The rotor current,

2 2

2

2 2 2

2

2 2

sE sE

I

Z

R s X

= =

+

125

Induction Motor

and rotor power factor

2 2

2

2 2 2

2

2 2

cos

R R

Z

R s X

= =

+

5.3.2 Torque and Torque-slip Characteristic

Torque

The torque developed by the rotor is proportional to the product of rotor current and

fundamental magnetic flux cutting the rotor. The total torque

T = K I

2

cos

2

where is the useful fundamental flux per pole and is proportional to rotor emf

(max.)

So T = K E

2

I

2

cos

2

We know

2

2

2 2 2

2 2

sE

I

R s X

=

+

and cos

2

=

2

2 2 2

2 2

R

R s X +

so

2

2

2 2 2

2 2

z

K s E R

T

R s X

=

+

For small value of slip (s X

2

)

2

is negligible compared to

2

2

R . So torque is

proportional to the slip when slip approaches unity or large values of slip, sX

2

is

large compared to R

2

so (R

2

)

2

is negligible compared to (sX

2

)

2

. Now torque is

approximately inversely proportional to the slip as shown by rectangular hyperbola.

For slip, s = 1, i.e. standsfill the torque

2

2 2

2 2

2 2

K R E

T

R X

=

+

is constant and is known as

starting torque. The approximate torque slip curve is shown in

Figure 5.4. The region where 0

dT

ds

> , is called stable region of operation where the

motor normally operates.

Slip

Speed

Torque Torque

Max. Torque

s = 0 s = 1

Starting Torque

Figure 5.4 : Torque Slip Characteristics

Maximum Torque

By inspection of torque slip curve, we see that the maximum torque developed at

particular slip, which is derived by differentiating T with respect to slip and by

putting 0 =

ds

dT

.

Here

2

2 2

2 2 2

2 2

K s E R

T

R s X

=

+

After putting 0 =

ds

dT

, we get

2 2

R s X = or

2

mat

2

R

s

X

=

126

Electrical Technology

The maximum torque is obtained when slip is equal to ratio of rotor resistance to

rotor reactance :

2

2

max

2

2

K E

T

X

=

and rotor power factor is .

2

1

The rotor reactance should be kept as low as possible otherwise torque developed is

reduced. The maximum torque is independent of rotor resistance, but the value of

slip at which maximum torque occurs is directly proportional to rotor resistance. If

we increase the rotor resistance the value of slip, at which maximum torque occurs,

approaches to one as shown in Figure 5.5.

Slip

Speed

Torque

s = 0 s = 1

Large R

2

Small R

2

Medium R

2

Max. Torque

R

2

is very large

Figure 5.5 : T-S Characteristic for Different Rotor Resistances

Starting Torque

We know that

Torque,

2

2 2

2 2

2 2

( )

K s E R

T

R s X

=

+

At the time of starting, s = 1 and E

2

is constant then

1 2

2 2

2 2

st

K R

T

R X

=

+

Maximum torque occurs when rotor resistance is equal to rotor reactance and the

relation between starting torque and rotor resistance becomes

1

2

2

st

K

T

R

=

T

st

R

2

Figure 5.6

127

Induction Motor

Starting Torque in Slip Ring Motor

Three resistors are used to start a slip-ring induction motor as shown in Figure 5.8.

These resistors are variable and are varied by three armed handle which makes a

star point. At the time of starting, all resistances are in the circuit and give high

starting torque. When starting resistance is all cut out, except that in the leads, and

the switch contacts remain closed, then this is comparable with the resistance of the

rotor itself. It is necessary to short circuit the rotor with the slip rings.

Stator

3-supply

Rotor

Slip rings

Starting

Variable

resistance

Figure 5.7 : Illustration for Starting Torque in Slip Ring Induction Motor

5.3.3 Power Flow

Normally, out of the power supplied to stator, a portion is wasted in stator copper loss and

another portion in stator iron loss. The remainder is supplied to rotor. Due to copper loss,

there is some voltage drop and just voltage transfer from stator to rotor. Let I

1

, E

1

and cos

are phase values of current, voltage and power factor on stator side. Then power

supplied to rotor is 3 I

1

E

1

cos. If n is turn ratio of stator to rotor turns then emf induced

in rotor is

n

E

1

at standstill. When rotor rotates at slip s then induced voltage is

n

E s

1

and

rotor current becomes n I

1

.

so rotor power losses = 3E

2

I

2

cos = 3s E

1

I

1

cos = s. Rotor input (i/p = input and

o/p = output)

Rotor copper loss

Rotor /

s

i p

=

then rotor output

= 3 E

1

I

1

cos 3 E

1

I

1

cos . s

= 3 E

1

I

1

cos (1 s) = Rotor input (1 s)

so

Rotor o/p

1

Rotor i/p

s =

and since

Rotor copper loss

Rotor i/p

s =

so

s

s

=

1 o/p Rotor

loss copper Rotor

Thus, Rotor i/p : rotor copper loss : rotor o/p = 1 : s : (1 s).

We know

Rotor o/p actual speed

1

Rotor i/p synchronous speed

r

s

N

s

N

= = =

so Rotor o/p = rotor i/p

speed s synchronou

speed actual

128

Electrical Technology

But Rotor o/p =

2

60

r

N

T w T

= 2 Torque Actual speed

so

60 Rotor o/p

Torque

2 actual speed

=

60 Rotor i/p

2 synchronous speed

=

Its unit is Newton-meter.

The synchronous watt is another unit of torque which is the torque that will develop one

watt at synchronous speed.

Example 5.1

An induction motor is rated as 5 KW at 1440 r.p.m., 50 Hz, 400 V line to line. The

rotational losses due to friction and windage are 279 watts. If the maximum torque

is found at 900 rpm, determine the maximum torque developed.

Solution

Synchronous speed for 50 Hz supply nearest to 1440 r.p.m is 1500 r.p.m.

Slip at full load

1500 1440 60

0.04

1500 1500

s

= = =

Rotor output at full load = 5000 W

Gross rotor output = 5000 + 279 = 5279 watts

96 . 0

04 . 0

04 . 0 1

04 . 0

s - 1

s

output gross Rotor

loss copper Rotor

=

= =

Rotor copper loss 5279

96 . 0

04 . 0

=

Rotor input

96 . 0

5279

5279

96 . 0

04 . 0

5279 = + =

Torque at full load

Rotor input at full load

60

2

s

N

=

5279 60

N-m

0.96 2 1500

=

= 0.5834 60 = 35.004 N-m

2

2 2

2 2 2

2 2

2

max

2

2

Torque at full load

Maximum Torque

2

fl

K S E R

T

R S X

T

K E

X

+

= =

2 2

2 2 2

2 2

R X S

R S X

=

+

2

2

2 2 2

2 2

2

2

2

R

S

X

as

a S

R

S

X

| |

|

\

= =

+

| |

+

|

\

129

Induction Motor

where

2

2

X

R

a = and S is the slip at full load

Slip at maximum torque

max

1500 900

0.4

1500

T

s

= = =

At maximum torque

2

max

2

0.4

T

R

s

X

= = or a = 0.4

Maximum torque

aS

S a

2

2 2

+

= full load torque

2 2

(0.4) (0.04)

0.5834 60

2 0.4 0.04

+

=

= 2.94617 60 N-m = 17.666 N-m

5.3.4 Equivalent Circuit of Induction Motor

The rotor current is given by

Impedance Rotor

emf Rotor

2

= I

2

2

2 2

2

2

2

X s R

E s

I

+

=

If n is stator to rotor turns ratio then stator current

n

I

I

2

1

=

or

2

2

2 2

2

2

1

X s R n

E s

I

+

=

to produce I

1

current in stator there is a requirement of voltage i.e. E

1

= n E

2

so that the

rotor impedance referred in stator winding

2 2 2

2 2 1 1

2

2 1 2

n R s X E E

nE

I I s E

n

+

= = =

2

2

2 2

2

2

X s R

s

n

+ =

( )

2

2

2

2

2

2

X n

s

R n

+

|

|

\

|

=

The rotor resistance

s

R n

2

2

can be divided as series combination of two resistance n

2

R

2

and . 1

1

2

2

|

\

|

s

R n The n

2

R

2

part remains constant and represents the physical rotor

resistance referred to stator side, i.e.

2

R . But |

\

|

1

1

2

2

s

R n varies from zero to infinite as

s changes from unity to zero and represents the rotor output in the form of power in this

resistance. The equivalent circuit referred to stator winding is shown in Figure 5.8.

130

Electrical Technology

1

0

m

X

0

R

0 =

2

n

X

1

R

1

n = X

2

2

N = R

2

2 2

R

R

2

n

2

2

R 1

1

s

1

1

s

Figure 5.8

The three phase induction motor may be compared with a transformer because it involves

changing flux linkages with respect to the stator and rotor winding.

The equivalent circuit parameters can be determined by no-load test and block rotor test

which are similar to OC and SC test on transformers. This topic is not covered here.

Example 5.2

A 3-phase, 500 volt, 6 pole, 50 Hz induction motor develops 30 b.h.p. at

990 r.p.m. at a power factor of 0.86 lagging. Calculate (i) the rotor copper loss, and

(ii) the total power and the number of cycles per minute of the rotor e.m.f.

The stator losses are equal at 2000 watts. Neglect mechanical and iron losses of the

rotor.

Solution

Given N

r

= 990 r.p.m., P = 6 and f = 50 Hz

Synchronous speed r.p.m. 1000

6

50 120 120

=

= =

P

f

N

s

Slip

1000 990

0.01

1000

s r

s

N N

s

N

= = =

Rotor output = 30 h.p. = 30 735.5 = 22065 watts

Rotor copper loss

Rotor output 1

s

s

=

(i) Rotor copper loss watts 88 . 222 22065

01 . 0 1

01 . 0

=

=

Stator output = Rotor input

= Rotor output + Rotor copper loss

= 22065 + 222.88

= 22287.88 watts

Stator input = Stator output + stator losses

= 22287.88 + 2000

= 24287.88 watts

(ii) Input power = 24.28788 kW

Rotor frequency = s f = 0.01 50

= 0.5 Hz = 0.5 cycles/sec

= 0.5 60 cycles/minutes = 30 cycles/min

131

Induction Motor

SAQ 1

A 3-phase, 400 volt, 4 pole, 50 Hz induction motor has a star connected stator and

rotor. The rotor resistance and standstill reactance are 0.2 ohm and 1.0 ohm,

respectively. The ratio of stator to rotor turns is 1.29. The full load slip is 4%.

Calculate the torque and power developed at full load. Find also the maximum

torque and speed at which it occurs.

5.4 STARTING AND SPEED CONTROL

5.4.1 Starters for Poly Phase Induction Motors

If motor is started with full voltage, the starting torque is good but very large currents, of

the order of 5-7 times the full-load current flow which causes objectionable voltage drop in

the power supply lines and hence undesirable dip in the supply line voltage. Consequently,

the operation of other equipment connected to the same supply line is affected

considerably.

If the motor is started with reduced voltage, there is no problem of high currents but it

produces an objectionable reduction in the starting torque, on account of the fact that

motor torque is proportional to the square of the applied voltage.

Methods of Starting Squirrel Cage I.M

There are basic four methods of starting the squirrel cage induction motor using

(a) Direct online starters

(b) Stator Resistor (or reactor) Starters

(c) Auto-transformer Starters

(d) Star-Delta Starters

Stop

Start

b

0

b

1 A

e

3

UVRC

e

2

O

1

O

2

O

3

M

1

M

2

M

3

e

1

A

1

C

2

C

1

A

2

B

1

B

2

S

1

R

Y

B

-connected stator

M

Rotor

Figure 5.9 : Direct Online Starter

132

Electrical Technology

Methods of Starting Slip-Ring (Wound Rotor) I.M.

Though all the above methods, except D.O.L. where the high currents may damage

the rotor windings, can also be employed for starting slip-ring motors, but it is

usually not done because the advantages of such motors cant be fully realized. So,

the method of adding resistance to the rotor circuit is the most common method for

rotor wound I.M. starting.

D.O.L. Starters

The above Figure 5.9 shows a contactor type D.O.L. starter connected to a

motor. As soon as the push-button S

1

is pressed, the contactor coil is

energized closing its contacts M

1

, M

2

and M

3

. Then, the motor windings get

full supply through back-up fuses e

1

, e

2

, e

1

and bimetallic relays O

1

, O

2

and

O

3

and the motor starts running. An auxiliary contact A in C

1

retains the

contactor in closed position after the release of start switch S

1

. An overload

tripping device e

1

, working in conjunction with bimetallic relays, is placed in

series with the contactor coil, so that during sustained overload, this opens

and the motor stops automatically. For stopping the motor any time, a stop

button is provided in series with the contactor coil.

Primary Resistor Starter and Reactor Starter

This method consists of connecting the motor to the line voltage through a

series resistance in each phase. The resistors are short-circuited when the

motor accelerates to the desired speed. Sequence of operation of switches

shown in Figure 5.10 is :

(a) Initially all switches are open.

(b) Switches 1, 2 and 3 are closed simultaneously and motor starts

running with full resistances in series.

(c) Switches 4, 5 and 6 are closed when motor speed picks up and

current becomes constant. Finally switches 7, 7, and 9 are

closed to cut all resistances and motors attains final steady state

speed.

Advantages : (i) It provides closed transition starting, resulting in smooth

starting without any transition high current.

(ii) A higher p.f. than auto-transformer starters.

1

R

Y

B

2

3

M

4 7

5 8

6 9

Figure 5.10 : Series Resistance Starting

Sometimes as an alternative to resistor starting, reactor starting is used. This

method is mainly used for large motors.

Auto-Transformer in the First Step Starters

In this type of starter, (A. T.) it attains the reduced voltage by means of an

auto transformer at the start. After a definite time interval (about 15 sec.),

and after the motor accelerates, it is transferred from the reduced voltage to

133

Induction Motor

the full voltage in the second step. A. T. are generally provided with voltage

drops to give 40%, 60%, 75% and 100% line voltage. The starting current

and starting torque depends on the tapping selected. In the third step, the

change-over switch may be hand operated or automatic through time relay

which connects the motor finally to the line by changing over from position A

to B.

R

A

B

B

Y

3ph

Bus Bar

Auto-Transformer

V

1

Stator

Rotor of sq. cage I.M.

Figure 5.11 : Simple Diagram of Auto-transformer Starter

Advantages of A.T. Starters

(i) Greater efficiency.

(ii) Taps on the transformer allow adjustment of starting torque to meet the

particular requirement.

Disadvantages of A. T. Starters

(i) It opens the circuit before the motor is connected directly to the line, thus

producing transient current and stresses.

(ii) It reduces the p.f. of the circuit.

(iii) The torque remains constant for the second step, resulting in acceleration

which is not smooth.

These disadvantages of open transition in A. T. may be overcome by the use of

Korndorfer connection, which introduces another step in starting. On the second

step, part of the A. T. remains in series with the stator windings. The third step

involves the transfer of the full-voltage without open transition.

Star-Delta Starter

It is cheaper as compared to A. T. starter. This method of starting is used for

motors designed to operate normally in delta. The six terminals from the three

phases of the stator must be available :

a, A : Terminals of phase A

b, B : Terminals of phase B

134

Electrical Technology

c, C : Terminals of phase C

Commercially, the terminals are marked A

1

, A

2

; B

1

, B

2

and C

1

, C

2

respectively. The motor is started with TPDT switch in position 1 and

subsequently switched to position 2.

Position 1 : Starting-windings connected in Y

Position 2 : Running-windings get connected in

R

Y

B

1

a

b

c

B

C

A

2

C

A

a

b

c

B

B

C

A

Start Run

Y

Triple Pole Double Throw (TPDT) Switch

Figure 5.12 : Star-Delta Starter

Let V

L

= Line Voltage

I

SP., Y

= Per phase motor current during start (in Y-connection)

I

L, y

= I

SP, Y

=

1

3 Z

V

L

. . .

(5.1)

[Since rotor circuit behaves almost as short circuit on starting as

2

1

1 0 R

s

| |

=

|

\

].

If stator winding is -connected, then, with direct switching the per-phase

motor current at start would be given by

I

SP.,

=

1

Z

V

L

. . .

(5.2)

Starting line current

, .,

1

3

3

L

L SP

V

I I

Z

= = . . .

(5.3)

It is shown from Eq. (5.1) to (5.2) that

135

Induction Motor

.,

1

,

1

1

Starting line current with star-delta starter 1 3

Starting line current with direct switching in delta 3

3

L

SL Y

L L

V

I

Z

V I

Z

= = =

and

2

2

L

Starting torque with star-delta starter 1 3

.

Starting torque with direct switching in delta 3

V

L

V | |

|

\

= =

Example 5.3

Determine approximately the ratio of starting torque to full load torque of a three

phase induction motor with

(a) star-delta starter, and

(b) an auto-transformer starter with 50% tapping used. The short circuit current

of the motor at normal voltage is 5 times the full load current and the full load

slip is 5%.

Solution

(a) Star-delta starter: In star-delta starter the voltage applied to each phase at

the time of starting is 3 1 times the normal phase voltage.

Starting current per phase

sc st

I I

3

1

= =

where I

sc

is the short circuit current per phase, i.e. starting current per phase

without Y- starter.

Since

2

2 2 2

2

R I

T I

s s

,

Starting Torque

2

st

st

st

I

T

S

where S

st

= slip at starting = 1

2

st st

T I or

2

3

sc

st

I

T . . .

(5.4)

Also, full load torque

2

st

fl

fl

I

T

S

. . .

(5.5)

where I

fl

and S

fl

are full load current and full load slip, respectively.

Dividing Eq. (5.1) by Eq. (5.2) we get

fl

fl

sc

fl

st

S

I

I

T

T

2

3

1

|

|

\

|

=

It is given that 5 =

fl

sc

I

I

and S

fl

= 0.05

( ) 417 . 0

3

25 . 1

05 . 0 5

3

1

2

= = =

fl

st

T

T

136

Electrical Technology

(b) Auto-transformer starter: Let the auto-transformer tapping ratio be K. Then

the phase voltage across the motor is K times the normal voltage.

Starting current

sc st

KI I = = .

At starting slip being unity, the starting torque

2

st st

T I or

2

( )

st sc

T KI

or

2 2

( )

st sc

T K I = . . .

(5.6)

Dividing Eq. (5.3) by Eq. (5.2), we get

2

2

| |

= |

|

\

st sc

fl

fl fl

T I

K S

T I

It is given that 5 . 0 and 05 . 0 , 5 = = = K S

I

I

fl

fl

sc

( ) ( )

2 2

0.5 5 0.05 0.3125 = =

st

fl

T

T

Example 5.4

A 6 pole, 50 Hz, three phase induction motor running on full load develops a useful

torque of 163 Newton-metres and the rotor electromotive force makes

90 complete cycles per minute. If BHP if the mechanical torque lost in friction be 14

Newton-metres, find the copper loss in the rotor windings, the input to the motor

and the efficiency. Stator losses total 750 watts.

Solution

Frequency of rotor emf

90

rps 1.5 rps

60

= =

But rotor emf frequency = slip stator emf frequency

Slip 03 . 0

50

5 . 1

= =

Synchronous speed

120 120 50

1000 rpm

6

s

f

N

P

= = = =

But

s r

s

N N

S

N

= or

1000

0.03

1000

r

N

=

Actual speed of motor N = 970 rpm.

BHP

970

2 163

2

60

22.195 BHP

746 60 746

r

N T

= = =

Gross torque produced = Useful torque + torque lost in friction

or Gross torque = 163 + 14 = 177 Newton metres

Mechanical power developed

2

60

r g

N T

=

177

60

970

2 =

137

Induction Motor

= 17979.33 watts

S

S

=

1 output gross Rotor

loss copper Rotor

or

Rotor copper loss 33 . 17979

03 . 0 1

03 . 0

=

= 556.06 watts

Rotor input = Rotor output + Rotor copper loss

= 17979.33 + 556.06 = 18535.39 watts

Motor input = Rotor input + Stator losses

= 18535.39 + 750

= 19285.39 watts

Efficiency of the motor 100

39 . 19285

163

60

970

2

Input

Output

= =

= 85.85%

5.4.2 Speed Control of 3-Phase Induction Motor

The stable operation of 3-phase induction motor is restricted within a small range of slips

and because of this restriction its application is limited to substantially constant speed

drives. We know that

120

s

f

N

P

=

Thus, we have the following methods of speed control:

(a) Frequency Variation

(b) Variation of Number of Poles

(i) using multiple windings

(ii) using consequent pole technique

(iii) pole-amplitude modulation

(c) Supply Voltage Variation

(i) Variation in Motor Parameters

(ii) Variation of rotor resistance or stator reactance

(iii) Variation of rotor reactance or both stator and rotor reactances

(d) Control of Rotor Slip Power

Frequency Variation

This method can be used for both squirrel cage and wound rotor type motors. This

method provides smooth control of speed. In frequency variation method the

variable frequency supply voltage is used. This voltage can be obtained from

(a) variable frequency alternator,

(b) rotating frequency converter,

(c) static converters and cyclo-converters.

Variation of Number of Poles

This method is generally recommended for squirrel cage induction motors and for

steady torque production where the stator and rotor poles should be equal. The

138

Electrical Technology

change in the number of stator poles must be accompanied with a change in the

number of rotor poles so the pole changing can be effected by the following methods

:

(a) Using multiple windings in stator for two different speeds, one for

higher speed and another for lower speed. Change over from one speed

to another is made by a switch.

(b) Pole changing with a single stator winding also can be achieved by

using consequent pole technique. In this technique the total stator

winding coils are connected in different manner according to constant

torque, constant power and variable torque and power applications.

Supply Voltage Variation

This method is used for both squirrel cage and wound rotor motors. In this method,

there are some disadvantages like torque is reduced with the reduction in supply

voltage. This method gives smooth stepless control, but the efficiency is

comparatively lower.

Variation in Motor Parameters

The speed control can be achieved by changing motor parameters. For wound motor

we can change rotor resistance, rotor reactance and stator reactance and for squirrel

cage motors only stator reactance can be changed. By rotor resistance variation

smooth speed control can be obtained. The drawback is that large copper losses

occurs at lower speeds.

Stator reactance method is not effective at lower slips with normal rotor resistance.

Better performance can be achieved by using high resistance rotors.

Control of Rotor Slip Power

The wound rotor induction motor can be operated at lower speeds by inserting

suitable resistance in the rotor circuit. In this method slip power is dissipated in the

rotor circuit. Control or recovery of slip powers as a means of speed control of

wound motor is based on the economic use of slip power and uses a slip power

converter for this purpose. By this method, a motor can also be run at super

synchronous speeds by feeding slip power into rotor.

SAQ 2

(a) The power input to a 500 volts, 50 Hz, 6 pole, three phase induction motor

running at 975 r.p.m is 40 kW. The stator losses are 1 kW. Calculate

(i) slip (ii) rotor copper loss (iii) B.H.P., and (iv) efficiency.

(b) A 4 pole, 200 V, 50 Hz, star-connected, 3-phase induction motor has primary

leakage impedance of 0.08 + j 2 , and an equivalent secondary leakage

impedance at standstill of 1.2 + j 1.0 per phase. The magnetizing current

may be assumed to be negligible. Find the maximum torque in synchronous

watts the motor can develop and the slip at which it occurs.

5.5 MEASUREMENT OF SLIP

There are three main methods of measuring the slip viz:

(a) by measuring the synchronous and actual speeds,

(b) by measuring the rotor frequency, and

(c) by the stroboscopic method.

139

Induction Motor

The first method, depends upon the difference of two relatively large and nearly equal

quantities.

The measurement of the rotor frequency can be effected by inserting a moving-coil

ammeter, preferably when rotor frequency is very low often not exceeding one or two

cycles per second. The frequency can be determined by counting the oscillations of the

pointer. If a central zero instrument is used, the number is a complete to and fro swings

which must be counted, but in the ordinary type the pointer is pressing against the zero

stop. The percentage slip is given by

100

frequency Stator

frequency Rotor

This method must be modified for cage type rotors, since there are no slip rings. There is

usually a small portion of the magnetic flux going right through the centre of the rotor and

cutting the shaft, which has a small e.m.f. induced in it. This can be detected by pressing a

lead against each end of the shaft. The other ends being connected to a sensitive moving-

coil millivoltmeter. The measurement is then made in the same way as with the wound

rotor.

In the stroboscopic method a disk, with alternate black and white sectors painted on it, is

attached to the end of the motor shaft. This disk is illuminated by means of a neon lamp

operated from the same supply. If the disk is normally in a poor light, an incandescent

lamp is sufficient. Alternatively, the stroboscopic disk may be viewed through a slot cut in

another disk driven by a small synchronous motor from the same supply. Assuming the

number of black sectors to be equal to the number of poles on the motor, one sector moves

forward a pole pitch in half a cycle if there is no slip at all. Then next black sector

occupies the original position of the first. But the disk is illuminated once every half-cycle,

so that the disk appears to be stationary. Since a certain amount of slip occurs, however,

the second black sector does not quite reach the initial position of the first in half a cycle,

with the result that the disk appears to rotate slowly in a direction opposite to that of the

motor. A complete apparent revolution of the disk thus corresponds to a slip of as many

cycles as there are pairs of poles on the motor. If the apparent revolutions of the disk per

minute are counted, the frequency of slip is obtained from

Apparent rpm

Rotor frequency = pairs of poles

60

The percentage slip is then calculated as before. For testing motors with different number

of poles, a series of disks is required having different number of sectors painted on them.

Example 5.5

The power input to a 415 V, 3-phase, 6-pole, 50 Hz induction motor is 50 kW when

running at 970 r.p.m. The total stator losses are 2.0 kW and the mechanical losses

are 1.5 kW. Determine (i) the rotor copper loss (ii) the gross torque in Newton-

meters, and (iii) the rotor resistance per phase if the rotor phase current

is 110 A.

Solution

Rotor input = Stator output

= Stator input Stator loss = 50 2 = 48 kW

Motor slip

970

s r s

s s

N N N

N N

= =

The synchronous speed r.p.m. 1000

6

50 120 120

=

= =

P

f

N

s

140

Electrical Technology

Motor slip

1000 970

0.03

1000

s

= =

Slip

input Rotor

loss copper Rotor

=

or Rotor copper loss = Slip Rotor input

= 0.03 48 kW = 1.44 kW

Gross rotor output = Rotor input Rotor copper loss

= 48 1.44 = 46.56 kW

Gross rotor torque

Gross rotor output

2

60

r

N

=

3

46.56 10

458.366 N-m

2 970

60

= =

Rotor copper loss =

2

2 2

3I R

= 1.44 10

3

watts

2

2

1440

3 (110)

R =

= 0.0397 per phase.

SAQ 3

(a) A efficiency of a 6 pole, 3-phase, 45 kW, 50 Hz induction motor is

92 percent. The stator losses equal 102 kW. Determine (i) the slip,

(ii) the rotor copper loss, (iii) the input, and (iv) the friction and windage

losses. The motor runs at 975 r.p.m.

(b) A squirrel-cage induction motor has a ratio of rotor stand still reactance to

resistance of 4 to 1 and maximum torque is 2.25 times the normal full load

torque. Calculate (i) the full load slip, and (ii) the ratio of starting torque to

normal torque with direct-on line starting.

5.6 SUMMARY

In Section 5.2 after a brief consideration of the constructional features of induction

motors, you learnt how a revolving magnetic field is produced. Next the rotor current and

torque-speed relations were derived and we also found the condition for maximum torque.

You learnt how to calculate performance characteristics of induction motor, power stages

and efficiency. Finally, you were introduced to various starters and speed control methods.

5.7 ANSWERS TO SAQs

SAQ 1

141

Induction Motor

Phase voltage Volts.

3

400

=

29 . 1

1

ns stator tur

s rotor turn

= = K

Standstill induced emf in the rotor per phase

2

400 1

179 Volts

1.29

3

E = =

Rotor impedance at full load ( ) ( )

2

2

2

2 2

SX R Z + = =

or ( ) ( ) = = + = 204 . 0 0416 . 0 1 04 . 0 2 . 0

2 2

2

Z

2

2

2

179 0.04

35.1 amp.

0.204

SE

I

Z

= = =

Total copper losses

2

2

2

3 R I =

2

3 (35.1) 0.2 =

= 739.2 watts

We know,

S

S

=

1 output gross Rotor

loss copper Rotor

Rotor gross output

( ) 739.2 1 0.04

0.04

=

= 17740 watts

= 17.74 KW

Rotor speed = (1 0.04) 1500

= 1440 r.p.m.

Gross torque developed

rotor output

2

60

r

T

N

=

17740 60

117.6 N-m

2 1440

= =

For maximum torque, R

2

= S X

2

2

2

0.2

0.2

1

R

S

X

= = =

Rotor e.m.f. per phase

2

179 0.2 35.8 Volts

r

E S E = = =

2 2 2 2

2 2 2

( ) (0.2) (0.2 1) Z R s X = + = +

= 0.283

2

2

35.8

126.5 amp

0.283

r

E

I

Z

= = =

142

Electrical Technology

Copper losses (Total) = 3 (126.5)

2

0.2 = 9601 W

Rotor gross output

1 S

S

=

Rotor copper loss

1 0.2

9601 38404 Watts

0.2

= =

Speed N

r

at maximum torque = (1 S) N

s

= 0.8 1500

= 1200 r.p.m.

Maximum torque T

max

Rotor output

2

60

r

N

=

38402

2 1200

60

=

= 305.61 N-m

SAQ 2

(a) Input to the stator = 40 kW

Stator losses = 1 kW

Stator output = Rotor input = 40 1 = 39 kW

Synchronous speed corresponding to 6 poles

r.p.m. 1000

6

50 120 120

=

= =

P

f

N

s

(i) Slip % 5 . 2 025 . 0

1000

25

1000

975 1000

= = =

=

s

s

N

N N

S

(ii) Rotor copper loss = slip rotor input

= 0.025 39 kW = 0.975 kW

Rotor output = Rotor input Rotor copper loss

= 39 0.975 = 38.025 kW

(iii) B.H.P. 972 . 50

746 . 0

025 . 38

= = BHP

(iv) % 06 . 95

40

100 025 . 38

Input

Output

Efficiency =

= =

(b) The equivalent per phase circuit of motor is given below :

E

1

0.8 j2 j1

1.2

s

143

Induction Motor

volts

3

200

1

= E

s j j

E

I

/ 2 . 1 1 2 8 . 0

1

1

+ + +

=

or

3 ) / 2 . 1 8 . 0 (

3 200

1

j s

I

+ +

=

( )

2 2

2

2

1

) 3 ( ) / 2 . 1 8 . 0 (

3 200

+ +

=

s

I

The input power to the rotor circuit is given by watts / 2 . 1

2

1

s I which is also a

measure of the torque developed in synchronous watts.

Hence, torque developed per phase

2

2

2

200 1.2

3

0.8 1.2

(3)

s

T

s

| |

|

\

=

+ | |

+

|

\

The maximum value of the toque is obtained at a slip which makes :

0

dT

ds

=

2 2 2

2 2

2

2

2

2

1.2 200 1.2 1.2 1.2

0.8 3 (0.8 3

3

1.2

1.8 (3)

d

s s ds s

s

dT

ds

s

(

| | | | | |

( + + + +

` ` | | |

\ ) ( \ \

)

=

(

| |

+ + (

|

\ (

2 2

2

2 2

2

2

2

1.2 200 1.2 1.2 1.2 1.2

0.8 3 2 0.8

3

1.2

1.8 (3)

s s s

s s

s

(

| | | | | | | | | |

( + + + +

` | | | | |

\ \ ( \ \ \

)

=

(

| |

+ + (

|

\ (

2

2

2

2

2

2

200 1.2 1.2 1.2 1.2

0.8 3 2 0.8

3

1.2

1.8 (3)

s s s

s

s

| | | | | | | |

+ + +

` | | | |

\ \ \ ) \

=

(

| |

+ + (

|

\ (

This is zero when

s s s

2 . 1 2 . 1

8 . 0 2 9

2 . 1

8 . 0

2

)

`

+ = +

)

`

+

i.e.,

2 2

88 . 2 92 . 1

9

44 . 1 92 . 1

64 . 0

s

s

s

s

+ = + + +

144

Electrical Technology

or

2

1.44

9.64

s

=

or

2

1.44

9.64

s =

or

max

1.44

9.64

T

s s = =

giving s

max T

= 0.387.

Therefore maximum torque will occur at a slip of 0.387.

Substituting s

max T

= 0.387 in the torque expression, we get

Maximum torque per phase

( )

( )

1707

9 387 . 0 2 . 1 8 . 0

387 . 0 / 2 . 1 3 200

2

2

=

+ +

=

The maximum torque the motor can develop is

1707 3 = 5121 synchronous watts.

SAQ 3

(a) (i) Motor speed N = 975 r.p.m.

Synchronous speed r.p.m. 1000

6

50 120 120

=

= =

P

f

N

s

Slip 025 . 0

1000

975 1000

=

=

s

s

N

N N

s = 2.5 percent

(ii) Motor output = 45 kW

Efficiency = 92%

Motor input

Output 45

kW 48.913 kW

Efficiency 0.92

= = =

(iii) Rotor input = Stator output = Motor input Stator losses

= 48.913 1.2 = 47.713 kW

Rotor copper loss = slip rotor input

= 0.025 47.713 kW

= 1.1928 kW

(iv) Rotor output = Rotor input Rotor copper loss

= 47.713 1.1928 = 46.5202 kW

Friction and windage losses = Rotor output Net output

= 46.5202 45

= 1.5202 kW

(b)

1

4

resistance Rotor

standstill at reactance Rotor

2

2

= =

R

X

145

Induction Motor

25 . 0

4

1

2

2

= = =

X

R

a

2 2

2

torque Maximum

torque load Full

S a

aS

T

T

m

f

+

= =

But (given) 25 . 2 =

f

m

T

T

2 2

) 25 . 0 (

25 . 0 2

25 . 2

1

S

S

+

= . . .

(1)

or S

2

1.125 S + 0.0625 = 0

2

) 0625 . 0 ( 4 ) 125 . 1 ( 125 . 1

2

= S

2

008 . 1 125 . 1

= S

= 0.0585, 1.0665

Here value greater than 1 is inadmissible

Full load slip = 0.0585 or 5.85 percent

2 2

) 25 . 0 ( 1

25 . 0 2

1

2

torque Maximum

torque Starting

+

=

+

= =

a

a

T

T

m

s

or

0625 . 1

5 . 0

=

m

s

T

T

. . .

(2)

Multiplying Eq. (1) by Eq. (2), we have

0625 . 1

5 . 0

25 . 2 =

m

s

f

m

T

T

T

T

or 059 . 1 =

f

s

T

T

Ratio of starting torque to normal torque = 1.059.

Potrebbero piacerti anche

- Three Phase Induction Motor Construction and WorkingDocumento63 pagineThree Phase Induction Motor Construction and WorkingMce RegNessuna valutazione finora

- Three Phase Induction Motor GuideDocumento63 pagineThree Phase Induction Motor GuideTuhin techNessuna valutazione finora

- 3-Phase INDUCTION MOTORDocumento6 pagine3-Phase INDUCTION MOTORrgegNessuna valutazione finora

- Construction of Three Phase Induction MotorDocumento6 pagineConstruction of Three Phase Induction MotorMuhammadZaydArattKhanNessuna valutazione finora

- Induction MotorsDocumento23 pagineInduction MotorsOsama SalemNessuna valutazione finora

- Three Phase Induction Motor ADocumento2 pagineThree Phase Induction Motor AKantharaj ChinnappaNessuna valutazione finora

- Chapter ThreeDocumento67 pagineChapter Threeetayhailu80% (5)

- EM-II Unit 2Documento21 pagineEM-II Unit 2Naresh GollapalliNessuna valutazione finora

- 3-Phase IM Construction and WorkingDocumento15 pagine3-Phase IM Construction and Working19M647 - SRIRAM ANessuna valutazione finora

- Induction Motor Operation, Torque & Speed ControlDocumento23 pagineInduction Motor Operation, Torque & Speed ControlmijouNessuna valutazione finora

- CH3 EditDocumento46 pagineCH3 EditLetk ZelalemNessuna valutazione finora

- DcmotornoteDocumento8 pagineDcmotornotesohag97Nessuna valutazione finora

- Introduction to Electrical Machines Chapter on Induction MachinesDocumento64 pagineIntroduction to Electrical Machines Chapter on Induction MachinesTheødřøš ÄbNessuna valutazione finora

- 1.what Are The Main Parts of Three-Phase Induction Motor?Documento7 pagine1.what Are The Main Parts of Three-Phase Induction Motor?Saiteja ReddyNessuna valutazione finora

- Machine Design PPT FinalDocumento25 pagineMachine Design PPT FinalRahul Pandey100% (2)

- Construction of Three Phase Induction MotorDocumento13 pagineConstruction of Three Phase Induction MotorAttaUrRahmanNessuna valutazione finora

- Em 2 Chapter 3Documento51 pagineEm 2 Chapter 3Sudhanshu SinghNessuna valutazione finora

- ASYNCHRONOUS MOTOR GUIDEDocumento124 pagineASYNCHRONOUS MOTOR GUIDEADDIS JOHNNessuna valutazione finora

- The Electric Motor ConstructionDocumento13 pagineThe Electric Motor ConstructionraffyNessuna valutazione finora

- Motor Manufacturing Process FlowDocumento8 pagineMotor Manufacturing Process FlowcmashtamoorthyNessuna valutazione finora

- BEE-lab, Experiment 4Documento10 pagineBEE-lab, Experiment 4DHRUV JAINNessuna valutazione finora

- Induction Motor Construction and OperationDocumento36 pagineInduction Motor Construction and Operationkyaw winNessuna valutazione finora

- Assignments No. 2 All Equipments Used To Manufacture The Alternator and MotorsDocumento22 pagineAssignments No. 2 All Equipments Used To Manufacture The Alternator and MotorsTE45 Aniket DusaneNessuna valutazione finora

- Engineering College: Assosa UniversityDocumento98 pagineEngineering College: Assosa UniversityKedir AddisuNessuna valutazione finora

- Design of SM PDFDocumento23 pagineDesign of SM PDFpraveenNessuna valutazione finora

- Three Phase Induction MotorDocumento3 pagineThree Phase Induction MotorRaghu Jgfyc100% (2)

- Design of A. C. MachineDocumento11 pagineDesign of A. C. MachineMahesh PatelNessuna valutazione finora

- Induction Machines: Operating Principle and ConstructionDocumento100 pagineInduction Machines: Operating Principle and ConstructionFaiselNessuna valutazione finora

- Induction MotorDocumento46 pagineInduction MotorSyed Muhammad Munavvar Hussain100% (5)

- Practical-4 Aim: To study basic principle and construction of 3-ϕ induction motorDocumento14 paginePractical-4 Aim: To study basic principle and construction of 3-ϕ induction motorJay SathvaraNessuna valutazione finora

- Induction Motor and FaultsDocumento23 pagineInduction Motor and FaultsSurendra BairwaNessuna valutazione finora

- Three Phase IM in A Nut ShellDocumento8 pagineThree Phase IM in A Nut ShellKrishnamoorthy AyyasamiNessuna valutazione finora

- GRP No.1 El-P-MachineryDocumento12 pagineGRP No.1 El-P-MachineryYasin OmaryNessuna valutazione finora

- Improving Efficiency of Squirrel Cage Induction MotorsDocumento31 pagineImproving Efficiency of Squirrel Cage Induction MotorsDular PatelNessuna valutazione finora

- Three Phase Induction Motor: Presented BY: Ms. R.SindhujaDocumento33 pagineThree Phase Induction Motor: Presented BY: Ms. R.SindhujaKayalvizhi SelvamNessuna valutazione finora

- CH 3 MachineDocumento22 pagineCH 3 MachineTeshale AlemieNessuna valutazione finora

- Electrical Machines2Documento11 pagineElectrical Machines2ARVINDNessuna valutazione finora

- Practical-3 Aim: To study basic principle and construction of 3-ϕ induction motorDocumento14 paginePractical-3 Aim: To study basic principle and construction of 3-ϕ induction motorJay SathvaraNessuna valutazione finora

- Eliminating Rotor ProblemsDocumento6 pagineEliminating Rotor Problemssuzette TabladaNessuna valutazione finora

- Chapter Three Induction Machines: Electromechanical ConversionDocumento67 pagineChapter Three Induction Machines: Electromechanical ConversiontsegayNessuna valutazione finora

- Induction Motors ExplainedDocumento165 pagineInduction Motors ExplainedMillion GebretsadikNessuna valutazione finora

- Induction MotorDocumento43 pagineInduction MotorAshvani ShuklaNessuna valutazione finora

- Lecture1424353332 PDFDocumento101 pagineLecture1424353332 PDFamulya00428Nessuna valutazione finora

- 3 Phase Induction Motor Construction (Autosaved)Documento17 pagine3 Phase Induction Motor Construction (Autosaved)ZUBAIRNessuna valutazione finora

- Induction Motor: by Ashvani Shukla Manager (C&I) BGR EnergyDocumento15 pagineInduction Motor: by Ashvani Shukla Manager (C&I) BGR Energywondi BETNessuna valutazione finora

- UNIT -IVDocumento24 pagineUNIT -IVdurairajgeetha318Nessuna valutazione finora

- Three Phase Induction MotorDocumento11 pagineThree Phase Induction MotorMohamed Ashraf Abd Elaazem Ali ٢٠١٥٠١٣٨٣Nessuna valutazione finora

- Exp 1 Em-Ii PDFDocumento4 pagineExp 1 Em-Ii PDFabhay sharmaNessuna valutazione finora

- Induction Machines: Ee462: Advanced Electric Machines and DrivesDocumento5 pagineInduction Machines: Ee462: Advanced Electric Machines and DrivesTerry rickyNessuna valutazione finora

- Basic Parts of a Three Phase (3-Փ) Squirrel Cage Induction MotorDocumento2 pagineBasic Parts of a Three Phase (3-Փ) Squirrel Cage Induction Motoravandetq15Nessuna valutazione finora

- Machine LabDocumento9 pagineMachine Labvikashyadavsy9Nessuna valutazione finora

- 3-Phase Induction Motor GuideDocumento101 pagine3-Phase Induction Motor Guidekelemyas ayalewNessuna valutazione finora

- 3-Phase Induction Motor BasicsDocumento34 pagine3-Phase Induction Motor BasicsMizanur RahmanNessuna valutazione finora

- Brushed DC Motors GuideDocumento32 pagineBrushed DC Motors GuideEvren SoydanNessuna valutazione finora

- Electrical Skills (Eepw2241) : DC MotorsDocumento6 pagineElectrical Skills (Eepw2241) : DC MotorsVenkata Rajkumar ChNessuna valutazione finora

- Induction Motor ReportDocumento13 pagineInduction Motor ReportShivani SinghNessuna valutazione finora

- Chapter 7 Induction Machines-EEE301Documento96 pagineChapter 7 Induction Machines-EEE301DilekNessuna valutazione finora

- AC Motors, Starter, DG SetDocumento16 pagineAC Motors, Starter, DG SetAnupKapadiaNessuna valutazione finora

- (JPP-1) - (Indefinite Integration) - 11th SepDocumento52 pagine(JPP-1) - (Indefinite Integration) - 11th Sepfunnyvideos. comNessuna valutazione finora

- Cat Em58 Em58s Emc58 eDocumento3 pagineCat Em58 Em58s Emc58 eAdolfo SantoyaNessuna valutazione finora

- LA303-003 Discovery 3-LR3 - Method Change - Diesel Engine Removal Procedure 07-12-2005Documento2 pagineLA303-003 Discovery 3-LR3 - Method Change - Diesel Engine Removal Procedure 07-12-2005fadholiNessuna valutazione finora

- PBL62 1 30M3Documento1 paginaPBL62 1 30M3Hai Tran HongNessuna valutazione finora

- OOADDocumento21 pagineOOADNamelessNessuna valutazione finora

- Cat DP150 Forklift Service Manual 2 PDFDocumento291 pagineCat DP150 Forklift Service Manual 2 PDFdiegoNessuna valutazione finora

- Musical Instruments Speech The Chinese Philosopher Confucius Said Long Ago ThatDocumento2 pagineMusical Instruments Speech The Chinese Philosopher Confucius Said Long Ago ThatKhánh Linh NguyễnNessuna valutazione finora

- Bootstrap CorewarDocumento4 pagineBootstrap CorewarloutrargentNessuna valutazione finora

- Thin - Cambered - Reflexed Airfoil Development For Micro-Air VehiclesDocumento185 pagineThin - Cambered - Reflexed Airfoil Development For Micro-Air VehiclesSaherAbdElMalakNessuna valutazione finora

- Classroom Management PlanDocumento6 pagineClassroom Management Planapi-607580556Nessuna valutazione finora

- Cambridge International Examinations: Additional Mathematics 4037/12 May/June 2017Documento11 pagineCambridge International Examinations: Additional Mathematics 4037/12 May/June 2017Ms jennyNessuna valutazione finora

- The UX Jobs Handbook v1.01Documento58 pagineThe UX Jobs Handbook v1.01Jeff ConstansNessuna valutazione finora

- Scenario Pack 3048-3050 - Operational Turning Points - REVIVAL TrialsDocumento41 pagineScenario Pack 3048-3050 - Operational Turning Points - REVIVAL TrialsSly MantisNessuna valutazione finora

- 2019 Orientation PresentationDocumento45 pagine2019 Orientation Presentationaee2 gm2100% (1)

- College of Architecture: Why Does It Matter?Documento6 pagineCollege of Architecture: Why Does It Matter?Emma SwanNessuna valutazione finora

- Webpage Evaluation GuideDocumento1 paginaWebpage Evaluation Guideankit boxerNessuna valutazione finora

- DEA462F - EntelliGuard G Circuit Breakers - Lo-ResDocumento8 pagineDEA462F - EntelliGuard G Circuit Breakers - Lo-Resyasser foudaNessuna valutazione finora

- Creep Behavior of GPDocumento310 pagineCreep Behavior of GPYoukhanna ZayiaNessuna valutazione finora

- Study of the Courier Industry at BookMyPacketDocumento34 pagineStudy of the Courier Industry at BookMyPacketPiyush MittalNessuna valutazione finora

- Milgrams Experiment On Obedience To AuthorityDocumento2 pagineMilgrams Experiment On Obedience To Authorityapi-233605868Nessuna valutazione finora

- Engine Coolant Temperature Sensor PM3516 3516B Power Module NBR00001-UPDocumento2 pagineEngine Coolant Temperature Sensor PM3516 3516B Power Module NBR00001-UPFaresNessuna valutazione finora

- Advanced View of Projects Raspberry Pi List - Raspberry PI ProjectsDocumento186 pagineAdvanced View of Projects Raspberry Pi List - Raspberry PI ProjectsBilal AfzalNessuna valutazione finora

- CH 1 Limits & ContinuityDocumento35 pagineCH 1 Limits & ContinuityDzulFadhly100% (3)

- Convention of Film Blocking Day 2Documento6 pagineConvention of Film Blocking Day 2GENELYN GAWARANNessuna valutazione finora

- Chapter - 4 Ob Perception ReDocumento23 pagineChapter - 4 Ob Perception Rep bbNessuna valutazione finora

- Altamirov DishniDocumento95 pagineAltamirov DishniEmersonJParedes100% (1)

- MGEC61 - LEC 01 & LEC 02 International Economics: Finance Summer 2021Documento8 pagineMGEC61 - LEC 01 & LEC 02 International Economics: Finance Summer 2021Yutong WangNessuna valutazione finora

- Rule 4 - Types of Construction (Book Format)Documento2 pagineRule 4 - Types of Construction (Book Format)Thea AbelardoNessuna valutazione finora

- Hpe Msa 1060/2060/2062 Storage ArraysDocumento22 pagineHpe Msa 1060/2060/2062 Storage ArraysCostin RaducanuNessuna valutazione finora