Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bioderived Lubricants

Caricato da

guiichDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Bioderived Lubricants

Caricato da

guiichCopyright:

Formati disponibili

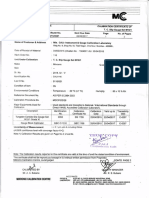

Idaho National Engineering and Environmental Laboratory

Bioderived Low-Emission Engine Lubricants

Thomas H. Ulrich, Ph.D.

Advisory Scientist

August 9, 2001

Idaho National Engineering and Environmental Laboratory

Multi-Lab Team

Argonne National Laboratory George Fenske - Tribology, Surface Science & Coatings Iowa State University Basil Nikolau - Biochemistry/Biophysics/Molecular Biology INEEL Tom Ulrich - Plant Science/ Biotechnology

Idaho National Engineering and Environmental Laboratory

Iowa State University

Center for Designer Crops

Director

Basil Nikolau

Idaho National Engineering and Environmental Laboratory

INEEL AGRICULTURE PROGRAM

Focus - Optimizing agriculture crop/biomass production systems

Supports the DOE-OIT Technology Roadmap for Plant/Crop-Based Renewable Resources 2020 and the INEEL BioEnergy Initiative:

Expanding basic computational sciences research Expanding our sensors and controls research Stepping up efforts in the plant sciences

Links basic science and engineering to solve industry needs

Idaho National Engineering and Environmental Laboratory

INEEL Capabilities

Science

Biotechnology

Microbiology Applied biotechnology With control of lignin biosynthesis, more carbon can be diverted to highervalue polysaccharides.

Plant Science

Genetics Agronomy Molecular Biology

Information

Artificial Intelligence GIS

Idaho National Engineering and Environmental Laboratory

BioDerived Lubricants Agenda

Objectives Issues The team Project Strategy Functional Genomics and in planta solutions Tribochemistry Paradigm Shift Review/Summary

Idaho National Engineering and Environmental Laboratory

Objective

Develop improved bioderived lubricant system for low-emission engines Improved bioderived lubricant that minimizes use of elements that poison aftertreatment devices, and Improved materials/surfaces that function with low-emission bioderived lubricants (e.g. S & P free lubes) Integrated project based on sound scientific principles in contrast to traditional Edisonian development of additives

Idaho National Engineering and Environmental Laboratory

Issues - Emissions, Emissions, Emissions (& Renewable Energy)

Aftertreatment devices poisoned by sulfur (P and others?) elements in fuels and lubricants Regulations proposed to limit sulfur from diesel fuels (10 ppm S) Will it also be necessary to limit levels of S, P and metals in engine lubricants? Many lubricant additives rely on S, P, and metal bearing compounds to protect engine Current bioderived engine lubes suffer from thermal stability (deposits) and wear is sacrificed for friction Can bioderived lubricant system (improved lubricant and surface materials) replace sulfur bearing compounds? Emission benefit + renewable/domestic oil product.

Idaho National Engineering and Environmental Laboratory

Bioderived Lubricant Issues

Engine applications represent a major challenge to bioderived lubricants

Renewable Lubricants and Agro Management Group field testing bioderived engine lubricants

Issues

Thermal stability - deposits in top ring (thermal effect catalytically assisted?)

Cu, Sb at levels of 1000 ppm effective individually, synergistic effect at 300 ppm - impact on Cu & Sb on aftertreatment device? Formation of acids - engine bearing degradation (Pb)

Idaho National Engineering and Environmental Laboratory

ANL/ Iowa State/INEEL Team With Industry

ANL - Tribology, Surface

Science & Coatings

Iowa State - Agricultural

Functional Genomics & Plant Molecular Genetics

INEEL - Plant

Science/Production & Biotechnology

Industrial Interest Plant Bioproduct Processing Additive Formulation Oil Blending Engine Testing

Idaho National Engineering and Environmental Laboratory

Project Strategy

Determine critical mechanisms by which boundary layer additives protect surfaces

Chemical bonding, composition, and structure Impact of substrate chemistry on mechanism

Identify bioderived compounds that possess critical attributes Modify bioderived compounds to produce optimum performance Genetically modify plants to optimize production of desired compounds

Based on first principles, can we identify the optimum compounds/attributes, and use functional genomics and biotechnology to modify appropriate plants to economically produce compounds with desired attributes?

Idaho National Engineering and Environmental Laboratory

Functional Genomics of Bioderived Lubricants

Identify genetic systems for producing novel biolubricant chemistries in plant seeds Overcome chemical and physical deficiencies in current seed oils (oxidative stability, alter melting point) Characterize the efficacy of bio-derived wax esters and branched chain fatty acids as biolubricants

Idaho National Engineering and Environmental Laboratory

Most plant oils are triacylglycerides acids R-groups = fatty

O = CH2-O-C-Rp O Rq-C-O-CH O = CH2-O-C-Rr =

Saturated fats

CH3-(CH2)n-COOH

n = 14 or 16

Unsaturated fats

CH3-(CH2)x-CH=CH-(CH2)y-COOH

x + y = 14

CH3-(CH2)x-CH=CH-CH2-CH=CH-(CH2)y-COOH CH3-(CH2)x-CH=CH-CH2-CH=CH-CH2-CH=CH-(CH2)y-COOH

x + y = 11

x+y =8

Idaho National Engineering and Environmental Laboratory

O O = CH2-O-C-Rp

CH3-OH/H +

BIOLUBRICANTS

O R-C-O-CH3

Rq-C-O-CH

O =

CH2-O-C-Rr

Plant oils are converted to methyl esters

Disadvantage: Cost of chemistry Oxidative instability - double bonds Solution: Hydrogenation Adds to cost Higher melting point

keep liquid in Duluth at winter

Idaho National Engineering and Environmental Laboratory

In planta solutions

Genetically modify plants to produce wax esters

eliminate cost of ester chemistry

Genetically modify plants to produce saturated, branched fatty acids

eliminate cost of hydrogenation chemistry eliminate oxidative instability lower melting point (i.e., stay liquid in Duluth)

Idaho National Engineering and Environmental Laboratory

Lubrication Regimes Understanding of Boundary Film Lubrication is Lacking

z Fluid

film lubrication well understood z Mixed and boundary lubrication regimes less understood z Complex surface chemistry associated with formation and behavior of protective surface films z Significant modification of subsurface regions

Ball Oil

z Proper

development of (bioderived) lubricant requires a more fundamental understanding of boundary film lubrication mechanisms

Flat

Idaho National Engineering and Environmental Laboratory

Tribochemistry

Lubricants contain critical compounds that provide low friction and prevent catastrophic failure/wear Most current additives (in particular boundary layer additive packages) rely on the presence of S, P, and metallic elements Boundary layer compounds react with surfaces to form protective films - surface chemistry/tribochemistry is critical Conventional BL compounds are developed for steel surfaces Additive packages often developed by trial & error Advanced tribological coatings/materials are often chemically different from steel - their performance with BL additives will differ Molecular Dynamic modeling of tribology is incomplete and limited to ideal situations Competing processes and additive interactions not considered - equivalent to modeling the basestock fluid How can we unravel and identify the complex tribochemistry mechanisms that occur at the surface to design and validate (bioderived) lubricant systems without extended Edisonian test protocols?

Idaho National Engineering and Environmental Laboratory

Paradigm Shift Required to Develop a Low-Emission Engine Lubricant

Typical lubricant development is segmented: Additive packages developed separately (by separate companies) and sold to oil companies that blend additives and basestocks into a formulated product The development of basestocks and additive packages are developed on a trial & error basis. Blends are prepared, and tested to determine performance - limited knowledge of what attributes are desired, and how they are affected by chemical (and tribochemical) properties Science (surface science & plant genetics) approach will be developed to identify key attributes, and to identify & direct the modification of bioderived compounds to achieve these attributes Team effort required to bring different disciplines together

Idaho National Engineering and Environmental Laboratory

Team Brings Together Necessary Disciplines to Develop Low-Emission Lubricant System

bioprocessing companies

Genetic Engineering of Vegetable Oils

desirable attributes

genes

Plant Production & Processing

Quantities for testing bioprocessing companies, & additive/oil companies

Small quantities for testing

Critical BLL Mechanism Tribology

Rig & Engine Validation

oil & additive companies OEMS, oil and additive companies

Idaho National Engineering and Environmental Laboratory

Summary

As a multi-lab/industrial team

Assess critical attribute requirements of lubricants Determine which bioderived products provide these requirements Develop the technologies to economically produce them

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Inspire Science Overview BrochureDocumento16 pagineInspire Science Overview BrochureJeffery Rafael Zeledon Tinoco0% (1)

- Design and Steel Fixing of SlabDocumento5 pagineDesign and Steel Fixing of SlabErastus Kagwe Tyson Jnr100% (2)

- 3 PilesDocumento37 pagine3 PilesAnonymous nwByj9LNessuna valutazione finora

- Road BOQDocumento129 pagineRoad BOQSunil Kumar GeraNessuna valutazione finora

- Determination of Maximum Span Between PipeDocumento7 pagineDetermination of Maximum Span Between PipeNabil Al-KhirdajiNessuna valutazione finora

- Design of Concrete Structures For The Storage of Liquids: New Zealand StandardDocumento12 pagineDesign of Concrete Structures For The Storage of Liquids: New Zealand Standardedisonmalahito0% (1)

- Process Industry Practices PipingDocumento6 pagineProcess Industry Practices Pipingraobabar21Nessuna valutazione finora

- From CP 114 To BS8110 EssayDocumento10 pagineFrom CP 114 To BS8110 EssayAlan CheungNessuna valutazione finora

- Abet Comm2 2015-2016 1Documento2 pagineAbet Comm2 2015-2016 1moneer1994Nessuna valutazione finora

- AME CET India PDFDocumento10 pagineAME CET India PDFAMECET 2020Nessuna valutazione finora

- Attachment 01-Project Standards & Specifications-PearlDocumento8 pagineAttachment 01-Project Standards & Specifications-Pearlum erNessuna valutazione finora

- Es 200 Easy - Pintu Geser OtomatisDocumento8 pagineEs 200 Easy - Pintu Geser OtomatisLivian TeddyNessuna valutazione finora

- Lab 3Documento8 pagineLab 3amraqstnaNessuna valutazione finora

- Design Development PlanDocumento1 paginaDesign Development PlanRajNessuna valutazione finora

- Vivek Rajendra Dusane: ObjectiveDocumento4 pagineVivek Rajendra Dusane: ObjectivebhavikaNessuna valutazione finora

- Hartip 3000Documento1 paginaHartip 3000Ricardo Andres RoseroNessuna valutazione finora

- A Review of Experimental Investigation On Coconut Shell As Replacement On Concrete As Course Aggregate in Their StrengthDocumento3 pagineA Review of Experimental Investigation On Coconut Shell As Replacement On Concrete As Course Aggregate in Their StrengthJohn Miranda DimaculanganNessuna valutazione finora

- CV FinalDocumento1 paginaCV Finalapi-417066611Nessuna valutazione finora

- Implementing A Maintenance Strategic Plan Using TPM MethodologyDocumento13 pagineImplementing A Maintenance Strategic Plan Using TPM MethodologyAlvaro SanchezNessuna valutazione finora

- Design of UPS With Customer Load Management Function Ko, Jae HunDocumento82 pagineDesign of UPS With Customer Load Management Function Ko, Jae HunArmandinho CaveroNessuna valutazione finora

- Evening Course Offerings Fall 2014Documento4 pagineEvening Course Offerings Fall 2014madithakNessuna valutazione finora

- DK ResumeDocumento5 pagineDK ResumeMandar NaikNessuna valutazione finora

- JR YamunaExpressway enDocumento8 pagineJR YamunaExpressway enShikhin GargNessuna valutazione finora

- Midterm EV407 May 2017Documento4 pagineMidterm EV407 May 2017khalil AlwastiNessuna valutazione finora

- BD Ps12eDocumento1 paginaBD Ps12eLiran AnabyNessuna valutazione finora

- Slip Gauge Pg-1 PDFDocumento1 paginaSlip Gauge Pg-1 PDFaliNessuna valutazione finora

- PosterDocumento1 paginaPosterPravin KenNessuna valutazione finora

- Structure 1Documento34 pagineStructure 1Yoon Myat BoNessuna valutazione finora

- Listado de PapersDocumento81 pagineListado de Paperssanrodrigo2Nessuna valutazione finora

- Azipod XO PresentationDocumento19 pagineAzipod XO PresentationButrosGali88Nessuna valutazione finora