Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

A - General Index

Caricato da

zargeenaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

A - General Index

Caricato da

zargeenaCopyright:

Formati disponibili

1

A. GENERAL INDEX

1019198

Base Filler

WPS Metal Filler Metal Thickness Welding

tllL

Base M8talls! PN

os

Metals A&F Nos. Range in

f!lgn

emu

000 G_Welding Procedure

1 C8rbonSteel P-l, Group 1 E6010 A-1, F3 3116-0.864 SMAW

No

E7018 A-1, F-4

2 C8rbonSteel Pl, Group 1 ER7OS-2' A-1, F-6 1/16-0.436 GTAW

No

3 C8rbonSteel P-l, Group 1 E6010 A1, F-3 1/16-0.436 SMAW No

E7018 A-1, F-4

4 C8rbonSteer P-l, Group 1 ER7OS-2 A-1, F-6 3116-0.864 GTAW No

E7018 A-1. F-4 SMAW

Thisprocedure Is qualified lor cryogenic service to ,SOF.

5 C8rbonSleer Pl, Group 1 E6010 A-1, F3 3116-0.864 SMAW No

E7018 A-1, F-4

This procedure Is qualified for cryogenic service to -50F.

6 Carbon-ll2Mo Steel P-3, Group 1 E701o-A1 A-2, F3 3116-0.864 SMAW No

E7018Al A-2, F-4

7 1 1/4Cr-II2Mo Sleel P-4. Group 1 ER80S-B2 A-3, F-6 3116-0.864 GTAW Yes

E60XX-B2 A-3, F-4 SMAW

8 1 1/4Cr-II2Mo Steel P-4, Group 1 ER80S-B2 A-3, F-6 1/16-0.312 GTAW No

9 21/4Cr-1Mo Steel P-5. Group 1 ER90S-B3 A-4, F-6 3116-0.864 GTAW Yes

E90XXB3 A-4, F-4 SMAW

10 2 1/4Cr-l Mo Steel P-S. Group 1. ER90SB3 A-4, F-6 lIHHI2 GTAW No

11 Austenitic Stainless P-8, Group 1 E30S;XX A-8, F5 1/1&-518 SMAW No

12 Incoioy 800H P-45 Incon'.I72 1/16-0.474 GTAW No

13 Alloy P-21. : ERlloo F-21 1/1&-1/2 GTAW No

(3003)

-'14

Aluminum Alloy

"'-22

ER5052 F-22

. 1/1&-1/2 GTAW No

(5052)

15 5Cr-II2Mo Sleel . P-5, Group 2 E502'XX A-4, F-4 3116-1.124 SMAW Yes

16 5Cr-II2Mo Steel P5, Group 2 .' ER502 . A-4, F-6 3116-1.124 GTAW Yes

E502-XX A-4, F-4 SMAW

17 Ferritic Stainless P-7, Group 1 ENirFe-2 F-43 1116-314 SMAW No

',:

18 1 1I4Cr-112MoSteel P-4. Group 1 E8018B2L

A3, F-4 3116,2.00 SMAW Yes

19 1 1/4Cr-1i:!Mo Steel . P-4, Group 1 , ER80S-B2L

A-3, F-6 3116-2.00 GTAW Yes

E8018-B2L

A3, F-4 SMAW

20 1 1/4Cr-ll2Mo Steel to P-4. Grp. 1 to E80XX-B2

A-3. F-4 3116-0.864 SMAW Yes

21/4Cr-1Mo Steel P5, Grp. 1

.. ,

A-4. A6 1/16-0.430 GTAW Yes

21 2114Cr-1Mo Steel P5, Group 1 ER90S-B3

. 1

Basll

Fmer

WPS

Metal

FiUer

Metal

Thid<ness No. Base MetaUs)

Metals

A&E Nos.

Range in.

22 carton Steel to P1, Grp. tto

ENiCrFe-2

F-43

1/16-0.474 SMAW No

Hestelloy G-276 P-44

(Ince-Weld A)

23 Carbon Steel to P-1. Grp: 1 to

E701B

A-l. F-4

3I16-0.B64 SMAW

Ves

1 1/4Cr1I2Mo Steel P-4. Grp. 1

235 Certon Steel to P1. Grp. 1 to

E701B

Al. F-4

02BOmax.

SMAW

No

1 1/4Cr1I2Mo Steel P-4, Grp. 1

All Fillet

Welds

24 Martensitic Stainless P-6, Group 1

ENiCrFe-2

F-43

3116-1.124 SMAW

Ves

25 Aluminum Alloy P23

ER4043

F-23

1/16-112

GTAW

No

(6061)

26 Hastelloy B-2 P-44

ERNiMo-7

F-44

1/16-0.432 GTAW

No

27 Carton Steel P-1. Group 1

ER70S-2

A-I. F-6

1/16-318

Gw,W

No

2B Seal welding of All

SW,W

No

threaded pipe joints

t

29 Carbon Steel P.l, Group 1

ER70S-2

A-1. F-6

0.116-0.474 GTAW

No

E701B-l

A-l. F-4

SW,W

Th;sproceoure is qualifiedfor cryogenic service.to -500F.

!

30 Cartx>n Steel to P1, Grp. 1 to

ENiCu-7

F-42

1/16-3116

SW,W

No

Monel 400 P-42

(Monel 60)

31 Carbon Steel, P1. ,

ER70S-2

A-I. F-6

1/16-0.300

GW,W

No

32 5Crl!2t.1o Steel P-5. Group 2

ER502

A-4. F-6

1/16-0.B64 GW,W

Ves

E502-XX

A-4, F-4

Sw,W

33 , 1i4C, 1,'2Mo Steel P-4, Group 1

ERBOS-82

A-3. F6

3I16-0.B64

GMAW

Ves

.

EBOtB82

A-3. F-4

SMAW

34 Procedurelor plasma arc spray coating of chromium. oxide.

35 Carbon Steel to P1. Grp. 1 to

ENiCrFe-3

F-43

3116-1.00

SMAW

No

Austenitic Stamless P-B, Grp. 1

Itncooer 1B2)

36 lCr1I2Mo Steel to, P-4, G'p. 1 to

ENiCrFe-3

F-43

3116-9/16

SMAW

No

AusteOltlc Stainless PB. Grp. 1

(Inconel 1B2)

37 Carbon Steel to P-1. Grp. 1 10

E309XX

AB. F-5

3116-13116

SMAW

No

Martens,tlc Stainless P-6. Grp. 1

. ., 3B MartenSitic Stainlessto P6, Grp. 1 to

E309-XX

A-B. F-5

3116-13116

SMAW

No

AustenitiC Stainless PB. Grp. 1

39 Carbon Sleel to Pl, Grp. 1 10

EBOXX82

A3. F-4

3I16-0.B64

SMAW

ves

5Cr-112Mo Sleel P-5. Grp. 2

40 Carton Steel P-1. Group 1

E701B

A-I, F-4

3116-1.436

SMAW

No

4OS1 carton Steel P1, Group 1

E7018

A-I, F-4

3116-5.00

SMAW

Ves

carbon Steel P-1. Group,'

E7018

A-l, F-4

S/AAW

No

4OS2

3116-1.436

1019198

A-2

..

. ,

No

No

Yes SMAW

SMAW

SMAW

Welding

f!llWl

Thickness

Range in.

3/16-0.864

1/16-0.474

Al.F-4 0.280 max.

All Fille,

Welds

AI, F-4

F-43

Fdler

Metal

A&F Nos.

Fdler

Metals

E7018

ENiCrFe-2

(Irico-Weld A)

E7018

Pl,Grp,l to

P-4, Grp. 1

P1. Grp, 1 to

P-44 '

P1. Grp: 1 to

P-4, Grp, 1 '

_____,

Metal

P-Nos.

Bal' Meta"s)

Corbon Steel to

HasteIloye-276

Caibon Steel to

1 114Cr112Mo Sleel

235 Corbon Steel to

1 114Cr1I2Mo Steel

23

- WPS

!:l!l....

22

24 Martensltic Stainless

25 AluminumAlloy

(6061)

P-6,Groupl

P'23

ENiCrPe-2

ER4043

F-43 3/16-1.124

F-23 1/16-112

SMAW

GTAW

Yes

No

No

No

No

No

GTAW

SMAW

GTAW

GMAW

SMAW

1116-0.432

1/16-318 A-l,F-6

A-l, F-6 0.118-0.474

A1, F-4

F-44 ERNiMo-7

ER70S2

P-l, Group 1 '

All

P-44

Seal welding of

threadedpipe joints

Carbon Sleel' Pl. Group 1 ER70S-2

, , ' " E70181

TtllS procedure isqualified forcryogenic service to-SOF.

. "

Hastelloy B'2'j

Corbon Steel

29

28

26

27

30

31

32

33

CarbOn Steel to

Monel 400

Carbon Sleel

SCr.1l2M.o Steel

1 Steel

P-l, Grp, 1 to

P-42

P-l. Gr'!up ,1

P-5. Group 2

P-4, Group I

ENiCu-7

(Monel 60),

ER70!32

'ER502

E502-Xx

ER80S-B2

E8018B2

F-42 1116-3/16

A-l, F-6 1116-0.300

A-4, F-6 ' 1/16-0.864 '

A-4, F-4

A3. F-6 3/16-0.864

A-3.F-4

SMAW

GMAW

GMAW

SMAW

GMAW

SMAW

No

No

Yes

Yes

34 tor arcsprayCoating of

35 CarbonSleel to Pl, Grp. I to

Austenitic Stainless Grp. 1

36 lCrII2Mo Steel to, ' P-4, Grp. 1 to

Austenitic Stainless p-a. Grp. 1

ENiCrFe-3

(IneoneI182)

ENiCrFe3

(InconeI182)

F-43 3/16-1.00

F-43 3/16-9116

SMAW

SMAW

No

No

37 carbon Steel to Pl, Grp, 1 to

Martensltlc Stainless P.fi. Grp. 1

38 Martensitic Stainless to P-6. Grp. 1 to

Austenitic Stainless p-a, Grp. 1

E309'XJ(

E309XJ(

A8. F-5 3/16-13116

A-8. F-5 3/16-13/16

SMAW

SMAW

No

No

39 carbon Steel to Pl, Grp. 1 to

5Cr-112Mo Steel P-5. Grp. 2

40 carbon Steel P-l. Group 1

4051 carbon Steel ,

4OS2 CorbonSteel

P-l. Group I

P-l, Group.l

E80XXB2

E70t8

E7018

E70t8

A-3. F-4 3/16-0.864

,A-l. F-4 3/16-1.436

Al. F-4 3/16-5.00

Al. F-4 3/16-1.436

SMAW

SMAW

SMAW

SMAW

Yes

No

Yes

No

1019198

A2

I

\

....-.;...... --"

of

."

.'

,

. '\ Base

Filler

c .

Metal .

Filler

Met81

.ThIcl<ness Welding Baq,:Me!aICS)

Metals

A&FNos . Rangt jn

e-

PWHT.

4053

Carbon Steel

P-l, Group 2 .

E7018

A-I, F-4

3/16-5118 SMAW

-Yes

.'

J

I'

41

Cerbon Sleel

P-l, Group 1

E6010

A-I, F-3

3/16-1.436 SMAW No' 42

1 1I4Cr-112Mo Slee.1

P-4, Group 1

ER80S-B2

A-3, F-6

3/16-0.475 GMAW Yes

43

Monel 400

P-42

ENICu-7

F-42

1/16-0.560 SMAW No

(Monel 190)

44

Carbon Sleello

P-l, Grp. 110

ENICrFe-2

F-43

1/16-0.560

SMAW No Monel 400

P-42

(Ince-Weld A)

45

Guide 10Hardlacing

P-5, Group 1

AuxCPred

GMAW Yes 5Cr-1I2MoSteel

2OCr-3.5 C

46

soc-so Ni Alloy

SOCr-SONi

1/16-1/8

GTAW No

47

Carbon Steel

P-l, Group 1

E7OT-l

A-I, F-6

3/16-11/4 FJ;;ML

No

48

Carbon Sleel

P-l, Group 1

E7018

A-I, F-4

3/16-11/4

SMAW No

E7OT-l

A-l, F-6

49

2 1I4Cr-1MoSleello

P-5, Grp. 1 10

ENiCrFe-2

F-43

3/16-0.864

SMAW No

Auslenitic Stainless

P-8, Grp. 1

lince-Weld A)

SO

Carbon Sleelto

p

ol,Grp.llo

E309LoXJ(

A-8, F-5

0.100-0.300

SMAW

No StainlessSleeI

P-8, Grp.l

All Fdlel

Welds

51

Carbon-lI2Mo'Sleel

P-3, Group 1

E701a-Al

A-2, F-4

3/16-0.864

SMAW

Yes

/

52

Steel

P-3, Group 1

E7018-Al

A-2, F-4

3/16-0.864

SMAW

No

" 53

Carbon Sleelto

pol, Grps.l.-4

ER3XX

A-8, F-6

GMAW

No

Austenitic Stainless

(Applied 316L Austenitic Stainless Uner)

54

Carbon Steel

P-l, Group 1

ER7OS-6

A-I, F-6

3/16-11/4

GMAW

No

E80T

o7

55

Carbon Sleel

pol, Group 1

ER7OS-2

A-I, F-6

1/16-0.560

GTAW

No

56

Carbon Sleel

pol, Group 1

ER7OS-2

A

ol,

F-6

1/16-0.560

GTAW

No

57

2 1/4Cr-1Mo Steel

P5

E3XJ<-XJ(

A-8, F-5

SMAW

No (Austenitic Stainless Unar RepSir)

,

58

Carbon-ll2Mo SleeI

p

o3,

Group 2

E7018-Al

A-2, F-4

3/16-3.00

SMAW

Yes

' .

Carbon Steel

pol, Group 1

ER705-2

A-I, F-6

3/16-0.864

GTAW

No

(V-insert)

E7018

Al, F-4

SMAW

60

Austenitic Stainless 10

P-8, Grp. 1 10

E3XJ<oXJ(

A-8, F5

3/16-3/4

SMAW

No

Hastelloy Co276 P-44 .

61

Carbon-ll2Mo Sleel

p,{j, GrouP) .

AWSE90T

A-2, F-6

3/16-2.00

FCAW

Yes

62

UnaPipe, API 5LX

API GrOup 1

E701o-G

API Grp.l

3/16-3/4

SMAW

No

GradeX42

. ,

1019198

.-. .

.,ii1":\'5

i

!0tV;'J-s:;L .- j' >t:" '.jit.j":i . ':'".,,3'1:,;. 'fi;, .. <4

I'

\

.'

. ,

1' '

.:S

Base Filler

Metal' Filler Metal Thickness Welding

Base Me!allsl . PNQs. Melals A&FNQs. RaoQ8in

eISU fW!fI

86 HKo4Oto P8. Grp. 2to ERNiCr-3 F-43 3116-314 GTAW No

InooIoy802 None (Inconel 82)

87 HPo4Oto ERNiCrM9-3 F-43 3116-314 GTAW No

InooIoy802 .

. '

86 Carbon-l/2MQ Steel to P3. Grp. 3 to ENiCrFe-2 F-43 Rodar SMAW No

Auslenitic Stainless P8,Grp.l (Inoo-Weld A) Anchor Bolts

89 Ferrilic Stainless P-7. Group 2' , ER430 A-7. F-6 All FlIIet GTAW No

Welds

90 Ferrilic Stainless to P-7. Grp, 2to . ER430 A7. F-6 All AIIet GTAW No

Austenitic Stainless P-8, Grp. 1 Welds

91 InooIoy802 ERNierM0-3 F-43 3116-0.800 . GTAW No

92 Il1CorleI 800 P-43 ERNiCr3 F-43 1/16-0.476 . GTAW No

93 HasltlloY G-276 P8. Grps. 1-4 ERNiCrM0-4 F-44 GTAW No

Overlay on Austenitic

Slainless

. Corrosion Resistant Over1ay"

94 Alloy 25 Overlay on P-8. Grps. 1-4 GTAW No

Austenitic Stainless

Corrosion Resistanl

95 Hastelloy G-?76 P-44 ENiCrM0-4 F-44 3116-0.760 SMAW No

(Haslelloy

G-276)

96 HP-40to ERNiCrM0-3 F-43 1/16-0.800 GTAW' No

AIonized Incoloy 802 (Inoonel 625)

97 HKo4Oto P-8. Grp. 2 te ERNiCr3 F-43 1/16-0.800 GTAW No

A10nlzed InooIoy 602 None (Inconel 82)

96 AIonized Incoloy 802 ERNiCrM9-3 F-43 1/16-0.800 GTAW No

(Inconel 625)

99 Carpenter 20 Cb3 P-45 ER320 F-5 1/16-1/2 GTAW No

100 C8Ibon Steel to P-l. Grp.lto ERNiCr-3 F-43 1/16-1/2 GTAW No

Carpenter20 Cb3 P-45 (Incone1 82)

C8Ibon Steel pol. Group 1 ER7OS-2 A-l. F-6 1/16-11/4 GMAW No

EL12 SAW

102 C8Ibon Steel . pol, Group 1 ER7OS-2 A-l. F-6 1/16-11/4 GMAW Ves

EL12 SAW

103 C8Ibon Steel to P-l. Grp. 1 tQ ERNiCr-3 F-43 1/16-1/2 GTAW No

C8!penter 20 Cb3 P-45

(V-insert)

104 Austenitic Stainless P-8. Group 1 ER3XX A-8. F-6 1/16-0.474 GTAW No

lOS Austenitic Stainless P-8. GrQup 1 ER3XX A-8. F-6 1/16-0A74 GTAW No

E3XX-XX A-8, F-5 SMAW

1019/98

.'

,.

/

.,.

"

Base Filler

WPS Metal Filler Melal thickness, Welding

!:!2...

' Base Meta"s) paNos. Met,ls A&F Nos. Rangt. \D.

- ~ PWHT

0,

106 3 112NiSteel' " P9B, Group 1 ER8QS.NI3 A-l0, F-6 'O.2Bq-O.560 GTAW Ves

E8018-C2 , _A-l0, F-4'

SMAW

This procedure is quafified for cryogenic service to -15O'F.

107 1 1/4C'-112Mo Steel to P-4, Grp. 1 to ER309 A-8, F6 1/16-0.474 GTAW Ves

AUSlenitic Stainless P8, Grp. 1

108 1 1/4C,-112Mo Steel to P-4, Grp. 1 to ER309 A8, F-6 1/16-0.474 GTAW Ves

Austenitic Stainless P-B, Grp. 1 E309-XX '

A8. F5 SMAW

1 ~ C8rb0n S1ee1 to P-l, Grp.l10 ER310 A-9, F-6 1/16-0.474 GTAW No

AUSlenilic Stainless' P8, Grp. 1

This prcedure is qualified for cryogenicservice to -5O'F.

110 C8rbon Steel to Pl, Grp. 1 to ER309 A-B, F-6 1116-0.474 GTAW No

AUSlenitic Stainless P-B. Grp.l E309-XX A-8. F5 SMAW

1I 1 Austenitic Stainless to P8, Grp. 1 to ER309 A'8, F-6 1/16-0.580 GTAW No

.'

3 112NiSteel' P-9B. Grp. 1 E309-16 ' A-8, F5 SMAW

. ~

This procedure is qualified lor ayogenic service to -l35F.

,

112 lCr-II2Mo Steel P-4, Group 1 ER808-B2 A3, F-6 All Follet GTAW No

Welds

113 HK-40 P8, Group 2 ER310HC 1/16-314 GTAW No

114 HK-40 P8, Group 2 ERNiCr-3 F-43 1/16-314 'GTAW No

(inconel 82)

115 HK-40 (new 0' P8, Group 2 ER310HC 1/16-0.700 GTAW No

used tUbes)

116 HK-40 (newor P8, Group 2 ER310 A-9, F-6 1/16-0.700 GTAW No

used lubeS) ER310HC

117 HK-40 (new 0' P-B, Group 2 ERN'tCr3 F-43 1/16-0.700 GTAW No

used tubes) (Inconel 82)

I I a HP-40 Maoaurile 3BX 1/16-0.700 GTAW No

1'9 HP-40 ERNiCr3 F-43 1/16-314 GTAW No /

(Intonel 82)

120 HK-40 10HP-40 , P8. Grp. 210 MaJ1aurile 38X 1/16-314 GTAW No

None

121 HK-40 to HP-40 pe, Grp. 2 to ERNiCr-3 F-43 1/16-314 GTAW No

None

AuS1enllic Stainless "

,

122 P-B. Grp. 1 to ERNiC,3 F-43 1/16-0.474 GTAW No

HK-40 pe. GfP. 2

123 1 l/4Cr-lI2Mo Steel to P-4, Grp. 110 ER309 A8, F-6 1/16-0.474 GTAW NO-

HK-40 P-8, Grp. 2

124 Incoloy 800H P-45 ERNiC,3 F-43 1/16-0.580 GTAW No

:",

125 HK-40to pe. Grp. 210 EElNiCr'3 F-43 1/16-0.580 GTAW No

IncoIoy eOOH P-45

,

.-

L

1019/98 A-a

.

, .

Base

RUer

'.

Metal Filler

Metal Thicl<ness Welding

Re" Meta!("

P-NQS, Metals MF Nos.

Rpnge.!n.

f!s!WI

I

126 IncoIoy 800H 11> P-45to None ERNiCr3

F-43

1/16-0.560 GTAW No

HP-40

127 Ferritic Steinless P-7, Grdup 1 ENiCrFe-3

F-43

1116-3/4 SMAW No

128 1 1/4Cr112Mo Steel to P-4, Grp. 1 to E80XX-B2L A-3, F-4 3/16-2.00 SMAW Ves

MartenslIic Stainless P-6, Grp. 3

129 21/4Cr1MoSteel to P-5, Grp. 1 to E90XX-B3L A-4, F-4 3/16-2.00 SMAW Ves

MartenslIic Stainless P-6, Grp. 3

130 1 1I4Cr112Mo Steel to P-4, Grp. 1 to E90XX-B3L A-4, F-4 3116-2.00 SMAW Ves

MartenslIic Stainless P-6, Grp. 3

131 AustenltIc Stainless P-8, Group 1 ER3XX A-8, F-6 3116-0.864 GTAW No

132 Monel 400 P-42 ERNiCu-7 F-42 1/16-9/16 GTAW No

ENiCu-7 SMAW

/

133 Austenl1lc Stainless P-8, Group 1, ER3XX A-B, F-6 1116-0.397 GMAW No,

',',

E3XX-XX A-B, F-5 SMAW

Aust8nitic StaInleSs to P-B, G.p. 1 to ER3XX , A-8, F-6 1/16-112 'GMAW No

HasteUoy C027B P-44 E3XX-XX A-B, F-5 SMAW

-r

135 Thermax47 Hastelloy S 1/16-0.950 GTAW No

136 Thermax47 . . Thermalloy 63

-

1/16-0.950

. GTAW

No

137 Thermax63 Hastelloy S . . - 1/16-1.10 GTAW No

138 Thermax63 ,ThermallOy 63 -" ' 1/16-1.10 GTAW No

139 Thermax63

. 1/16-1.10 GTAW No

140 1 1/4Cr-112Mo Steel . P-4, Group 1 ER80SB2 .A-3, F-6 1/16-718 GMAW- No

shorling

& sp<ay

141 1 1/4Cr-112Mo Steel . . P-4, Group 1 ERBOS-B2 , A-3, F-6 <, 1/16-7iB GMAW- Ves

shor1ing

& sp<ay

142 CaIbonSteel P-l, Group 2 EM12K, A-I, F-6 518-1112 SAW No

143 CaIbonSteel P-l, Group 2 EM12K A-l, F-6 518-1112 SAW Ves

.44

Supel1herm Hlistelloy S 1/16-1.10 GTAW No

. 45 Supel1herm Techalloy 63Nb 1/16-1.10 GTAW No

146 Supel1herrn

I

Supel1herm 1/16-1.10 GTAW No

147 Supel1herm Supel1herm 1/16-1.10 'GTAW No

SMAW

146 Thermax63. Techalloy 63Nb 1/16-1.10 GTAW No

Merathon 25135R SMAW

:\',

149 CaIbonSteel P-l, Group 2 ESOXX-Cl A-l0, F-4 3116-1112 SMAW No

c): I

101919B A-7

f'

Base

FIller

WPS

Pise

Mef41 Aller

Metal

.'fl1lcI!I1us

Welding

.!:l2.....

P.Ngs.

M$ls AlE NoI, ':.',

BoDg., In. erzm fW!:lI

rl

,carbon Steel P-l. Group,2 E80XX-G2

M,O.F"-4

,

150

" 3/1&-11/2

SMAW No

151

Steet : P,5, Group 2, ' E502-XX A"-4. F"-4'

, ,3/1&-0.864

SMAW Yes

EB6 A"-4. F-6 SAW

152

Carbon-l/2Mo Steel P:3. Group 1

,

, '

E7018-Al A2. F--4

3/1&-0.864 SMAW Yes

EA2 ,A-2. F-6

SAW

153 2 1/4Cr-l Mo Steel P-5. G,oup,1 E9018-B3L A"-4;F-4

3/1&-0.864 SMAW Yes

EB3 A"-4. F-6 ,SAW

154 1 1/4Cr-l/2Mo Steel. P"-4. Group 1 E8018-B2L A-3. F"-4 , 3/1&-0,864

SMAW Yes

EB2 A-3. F-6 '

SAW

155 1 1/4Cr-l/2Mo Steel P-4. Group 1

'EB2 A-3:F-6, 3/1&-0.864; GTAW Yes

SAW

156

2 1I4Cr-1Mo Steel ' P-5.Group 1 EB3 A"-4.F-6 3116-0.864 GTAW Yes

...

SAW

157 SCr-II2Mo Steel p-S. GroUp, 2 EB6 A"-4. F-6, 3/1&-0.864

GTAW Yes

SAW

158 11/4Cr-l/2Mo Steel P-4.Groupl EA80S-B2 A-3. F-6 3/1&-0.864

GMAW Yes

EB2

SAW

159 Carbon-ll2Mo Steel P-3. Group 1 EA805-02 A-2. F-6 3/16-0.864

GMAW Yes

EA2

SAW

160 2 1I4Cr-1Mo Steel P-5. Group 1 EA90S-B3 A"-4. F-6 3/16-0.864

GMAW Yes

EB3 SAW

161 SCrII2Mo Steel P-S. Group 2 EA502 A-4. F-6 3/1&-0.864 GMAW Yes

EB6

SAW

162 2 1I4Cr-1Mo Steel P-S. Group 1 EA90S-B3 A"-4. F-6 3/1&-0.864 ' GMAW Y..

F1OZ-ECB3

SAW

163 1 1/4CrII2Mo Steel P"-4. Group 1 fAa05-B2 A-3. F-6 3/16-0.864

'-

GMAW Yes

F8Z-ECB2

SAW

164 5Cr-II2Mo Steel PS. q,oup,2 ER502 A"-4. F-6 3/16-0.864 GMAW Yes

J;7o-ECB6

SAW

165 carbon-II2Mo Steel P3. Group 1 EA2 A-2. F-6 3/1&-0.864 GTAW Yes

F6PZ-EA2

, SAW

166 Carbon-II2Mo Steel P'3. Group 1 EA805-02 A-2. F-6 3/1&-0.864 GMAW Yes

E70T5-Al

FCAW

167

1 1/4Cr-II2Mo Sleel P-4. Group I' EA80S-B2 A-3. F-6 3/16-0.864 GMAW Yes

E8OT5-B2L

FCAW

168

21/4Cr-1Mo Steel P-5. Group 1 ER90S-B3 A"-4.F-6 3/16-0.864 GMAW Yes

'E90TlB3L

FCAW

169 5Cr-l/2Mo Steel P5. Group 2 EA502 A"-4. F-6 3/16-0.864 GMAW Yes

E502T-l FCAW

170 Austenitic Stainless P-8. Group 1 ER316L A-8. F-6 3/16-0.47S GMAW No

1019198 A8

;.

i

j

.,.

Base Filler

- WPS Metal Filler Metal Thldcness WeIdng

" til!... .

Re"MetilCSl

paNos.

Metals A&FNos. Rangt in f!ga

em!!

171 C8rb0n-l12Mo Steel P-3, Group 1 ERBOS-02 A-2, F-6 3116-0.864 GTAW Ves

EA2

1-72 C8rb0n-l12Mo Steel P-3,Groupl ER70S-G A-2,F-6 3/16-0.864 GTAW No

EA2

173 line Pipe, APII$LX API Group 4' EBOI8-G API Grp. 2 3/16-314 SlolAW No

G.-X70

174 C8rb0n-II2Mo Steel P-3,Groupl ERBOS-02 A-2, F-6 1/18-1.812 GlolAW Ves

17S C8rb0n-112Mo Steel P-3, Group 1 ERBOS-02 A-2, F-6 1/18-1.812 GMAW No

176 1 l/4Cr-lI2Mo Steel P-4,Group 1 ERBOS-B2 A-3, F-6 1/18-1.00 GMAW Ves

ln 1 l/4Cr-lI2Mo Steel P-4, Group 1 ER608-B2 A-3, F-6 .1/18-1.00 GMAW No

I

176 21/4Cr1Mo Steel P'S, Group 1 ER908-83 A-3, F-6 1/18-1.00 GMAW Ves

179 2 lI4Crl Mo Steel PS, Group 1 ER908-83 A-3, F-6 3/18-1.00 GMAW No

160 l;Cr-112MoSteel P'SB, Grp. 1 or 2 ERS02 A-4, F-6 3/18-1.00 GMAW Ves

161 line Pipe, API SLX API Group 2 EB01O-G API Grp. 2 3/18-3/4 SlolAW No

G.-XOO

162 line Pipe, API SLX API Group 2 E701O-G API Grp. 1 3/18-3/4 SMAW No

GradeXOO

183 line Pipe, API SLX API Group 2 E701O-AI API Grp.l 3/18-314 SMAW No

GradeX60

164 line Pipe, API SLX API Group 2 ElOIG-Al API Grp.l 3/18-3/4 SMAW No

G.-XOO

165 Une Pipe, API SLX API Group 2 E701G-Al API Grp. 1 3/16-314 SMAW No

GradeXOO

186 line Pipe, API SLX API Group 2 EB01O-G APIGrp.2 3/18-314 SMAW No

G.-XOO .

, ,

167 Carbon Steel Pl, Gr-up 1 ER7OS-3 A-I. F-6 1/18-0.756 GMAW No

. r;

186 Austenllic siainiesS' P-8, Groupl ER3I6L A-6, F-6 1/16-0.284 GMAW No

, Uses Solar 'B' flux Inplace of a backing gas.

169 26Cr-1Mo Steel Group 1 ER28-1 A-7, F-6 3/18-1,00 GTAW No

190 26Cr-l Mo Steel 1 ERNICr-3 F-43 3/18-1.00 GTAW No

191 line Pipe, API SLX API Group 2 . , EOOl0 API Grp.l 3/18-3/4 . SMAW No

GradeX46 E7018 API

162 line Pipe, API SXL API Group 2 EOOl0 API Grp.l 3/18-3/4, SMAW No

G.-X46

193 Line Pipe, API SXL API Group 2 EOOl0 API Grp.l 3/18-314 SlolAW No

c.

"

1019198

A-9

WPS

1::!2...

Base Melalls)

1'

Base

Metal

PNOI

Filler

Metal'

Filler

Metal

A&FNos

thickness . Welding

Range. In. e- ~

194 I' 1/4Cr-112Mo Steel to . P-4, Grp. I to

Incoloy 800HP-45

ENICrFe-3

(Inconel 182)

F-43

1/16-0.474 SMAW No

195 C8rI;lon-112Mo Steel" P-3, Group 2 E7018-AI A-2, F-4 3116-8.00

ThIs procedures shall not be usedwhere the prevailing Codes require postweld heat Ireatment.

SMAW No

Yes

No

Yes

Yes

Yes

No

No

No

Yes

SMAW

SMAW

SMAW

GTAW

GTAW

GTAW

GTAW

SMAW

FCAW

GTAW

1/16-0.474

1/16-0.474

1116-0.474

1116-0.474

1116-0.474

F-43

F-43

3116-314

F-43

F-43

F-43

A-8, F-6 . 1/16-0.560

A-8, F-5 3116-0.864

F-43 1/16-0.474

F-43 1116-0.474

ERNiCr-3

(Inoonel 82)

ERNICr-3

(Inoonel 82)

ERNICr-3

(Inoonel 82)

ENiCrFe-3

(Inoonel 182)

ENiCrFe-3

(Inoonel 182) ,

.ENICrFe-3

(Inoonel 182)

ERNICr-3

(Inconel 82)

ER316

E3t6-XX

E7IT-GS

E7IT8-K6

. ,

,

P-4, Grp. i to

None

P-4, Grp. I to

P-8, Grp. I

P-8, Grp. I to

None '

P-4, Grp. I to

P-8, Grp. I .

P-8, Grp. I .to

None .

API Group 2

205 Aus1enl1ic Stainless to

IncoIoy802

I 1/4Cr-1I2Mo Sleet to

Aus1en1tic Stainless

Austenl1ic Stainless to

Incoloy802.

I 1/4Cr-II2Mo Steel to

IncoIoy802

204 I 1/4Cr-II2Mo Steel to

_Slainless

203

202

201

198 Aus1enl1ic Stainless P-8, Group l

199 Aus1en11ic Stainless P-8, Group I

200 I 1/4Cr-II2Mo Steel to P-4, Grp. I to

IncoioY 802 None

196 Una Pipe, API 5LX

GradeX60

197 Mertensl1ic Stainless to P-6, Grp. I to

Monel 400 P-42

206 MaI1ensI1ic Stainless to P-6, GrP. I to ENiCrFt-3 F-43 1116-0.474 SMAW No

Monel 400 .. P-42" . .(IncoOeII82) . .

ThIs procedure shall not be used where the prevailing _es require a preheat ar1dIor postweld l)eallrealrnent.

207 Hastelloy 0-276

208 Carbon Steel to

AustenI1ic Staiilless

209 Carbon Steel

210 Carbon Steel to

AustenI1ic Stainless

21I Una Pipe, API 5LX

GradeX52

212 Una Pipe, API5LX

GradeX52

213 line Pipe, API5LX

GradeX52

P-44 '.

P-l, Grp: I. to

P-8, Grp. I

P-l, Group I

/

P-I, Grp. I to

P-8, Grp. I

API Group 2

API Group 2

API Group 2

ERNiCrM0-4

(Hastelloy

0-276)

ER309L

E309L-XX

E60IO

E7018

E309-XX

E60IO

E701o-G

E70lo-G

E701o-G

F-44 1116-0.422

A-8, F-6' 1/16-112

A-8, F-5

A-I, F-3 3116-1.00

A-l, F-4

A-8, F-5 1116-0.560

API Grp. I 3116-314

APIGrp. I

API Grp. I > 314

API Grp. I>314

GTAW

GMAW

SMAW

SMAW

SMAW

SMAW

SMAW

SMAW

No

No

Yes

No

No

No

Yes

(

lo.'8IlI8 A-l0

J' ,

,")

,-

Base

e

WPS

,

Metal Filler Metal

Thieleness Welding

t:!2...

BaSft Metal(sl P-Nos. Metals A&FNos.

Bange, in.

f!2!<m ewt:!!

_r

214 Calbon Steer PI, Group I E60IO A'l, F3

0.432.0.864 SMAW No

E701Q-G

F3

This proCedure is for cryogenic service to :2O'F.

215

Carbon Steel '"

PI, Grp. 110 ER7OS2 A'l, F-6 1/16-0.864 GTAW Yes

1114Cr112M2Steel N, Grp. 1 'E701S Al,F-4,

SMAW

216 Carponler 20 Cb3 P-45 E32Q-16

F5

1/16-0.474 SMAW No

217 Stainless Steel to P'll, Grp,'l to

' '

E316-XX A-8, F5 1/16-0.474 SMAW No

Carpenter 20 Cb3 P-45

218 Austenitic Stainless P8, Group I E316-XX A-8, F5 3116-11/8 SMAW No

2ui Carbon Steel ' Pl, Group 1 E6010 Al, F3 1/16-0.560 SMAW Yes

E7018 Al', F-4 :

220 Gray casllroo, . ENICI SMAW No

Not intended forhydrocarbon service.

221 I 1/4C,I12M2 Steel' P-4, Group I' ERSOSB2 A-3, F-6 3116-0.864 GTAW No

E8018-B2 A-3,F-4 SMAW

. This not beusedwherethe prevailing codesrequire a postwekI heat treatment

222 AusteOltlc Stainless P-8, Group I ER316

,

A-8, F-6' 1/16-0.644 GTAW No

223 AustenitiC StaInlessto P-8. Grp, I to E32o-XX F-5 ,1/16-0.474 SMAW No

Carpenler 20 Cb3 P-45

224 Austenl:IC Stainlessto p-S. Grp. I to ER316 A-8, F-6 1/16-0.474 GTAW No

CarpoOier 20 Cb3 P-45

22S Monel4QO P42 ERNiCu7 F-42 1/16-0.644 GTAW No

226 Monel 400 P-42 ERNiCu-7 F-42 1/16-0.644 GTAW Yes

227 Monel_OO P42 ERNiCu-7 F-42 1/16-0.644 GTAW Yes

ENiCu-7 SMAW

22S Monel_OO P-42 ERNiCu-7 F-42 1/16-0.644 GTAW No

GMAW

229 Monel 400 P-42 ERNiCu-7 F-42 1/16-0.644 GTAW Yes

GMAW

230 Monel 400 P-42 ENiCu7 F-42 1/16-0.644 SMAW Yes

.:

Ha'telloy C276 P-44 ERNiCrMo-4 F-44 3116-1.124 GTAW No

Carbon Steel P1. Group 1 E60IO A-l, F3 1116-0.560 SMAW No

E70lO-G F-3

233 Carbon Steel P-I,Grp.l-4 E60tO A-l, F3 3116-0.864 SMAW Yes

E70tS Al, F-4

234 Line Pipe. API 5L API Group I E60tO API Grp.l 3116-314 SMAW Yes

GradeX42 E701S API Grp.3

-:.. .

s ,:,..: "::.

Base

WPS Metal Fille,' Melal Thk:kness Welding

Base Metallsl P-Nos Metals A&E Nos Bange. In

fmlI

API Grp.'l

,

Une Pipe, API SL API Group 1 E60l'O, 3116-314 SMAW No

GradeX42 E701O-G APIGrp.l.

236 9Or-l MeSteel P-S,GrOup?

"

ER50S A-S, E-8 1/16-314 GrAW Ves

ESOS-XX A-S, E-4 SMAW

237 Austenitic Stainless- P-8, Group 1 E308-XX A-S, E-S 3116-11/16 SMAW No

- This procedure is for cryogenic service to -12S-E.

236 Austenitic Stainless- P-S, Group 1 ER308 A-S, E-8 3116-11/16 GMAW No

E308-XX A-S, E-S SMAW

- This procedure is qualified for cryogenic service to '125-E.

230 Carbon steel 10 P-l, Grp. 110 E309-XX A-8, E-S 3116-0,864 SMAW No

Austenitic SlaInless- P-8, Grp.l

- This procedurais qualified for cryogenic service 10-SOOE.

240 Carbon Steel to P-l, Grp. 1 to ENlC<Fe-3 E-43 1/16-0.560 SMAW Ves

Martensitic Stainless P-6, Grp. 1

241 Austenitic Stiunless P-S, Group 1 ER316L A-S, E-8 1/16-0.606 GMAW No

.42

SAW

Duplex Slainless- P-1OH, Group 1 1/16-0.520 GTAW No

- This procedure is qualified to produce 30-70% ferrite in weld melal for maximum corr"!'iDn IlIOteeIion,

, -

243 Carbon Steer . P-l, Group ER7OS-2 A-I, E-6 3116-0.670 GMAW No

EL12 SAW

- This procedure is qualfied for cryogenic service 10-50"F.

244 Austenitic Stainless P-8, Group 1 ER347 A-8, F-6 3116-1.73 GTAW No

E347-XX A-S, F-S SMAW

245 Line PIpe, Branch E701S 3116-314 SMAW No

and Saddle Connections

246 Carbon Sleel to P-l, Grp. 110 ERNiCr-3 F-43 1/16-0.570 GTAW No

Inconel600 P-43 ENiCrFe-3 SMAW

247 Austenitic Slainless to P-8, Grp. 1 10 Ei'liCrM0-4 F-44 3116-11/16 SMAW No

HUfelloy P-44

"

248 Austenitic Stainless to P-8, Grp. 1 to F-44 1/16-0.610 GTAW No

P-44

249 Austenitic Slainless P-8, Group 1 NOne 0.035-0.070 GTAW No

1

(AutomalIc)

Une PIpe, API SL API Group 1 E701S API Grp.3 3116-314 SMAW No

GradeX42

(Sleeve Repair)

251 Une PIpe, API SL API Group 2 E701S API Grp. 3 .3116-314 SMAW No

GradeX52

(Sleeve Repair) ,

252 HUfelloy 8-2" P-44 ERNiMo-7 E-44 1/16-0.560 GTAW Ves

- See Welding Paramelers end Special NOles.

-

lG18188

, . :

M2

( ..

;1'

Base

_,Co

, Metal Filler

Bese Metallsl P-NQs. Metals

-: -

253 HK-40 to HP-40 P-8, Grp. 2tQ Manaurite 36X

None

254 Una Pipe, API 5L API Group 1 to E6010

Grade B to API Group 2 ' E701a

API 5L Grade X52

,

255 Una Pipe, API 5L API Group 1 E6010

GradeB E701a

256 LinePipe, API 5L API Group 1 E6010 '

Grade Bto

,

API Group 2' E701a

APi 5L Grade X46

257 Una Pipe, API 5L API Group 1 E701a

GradeX42

(Palch Repelr)

258 1 114Cr-II2Mo Steel to P-4, Grp. 1 to ER309

Austenitic Stejnless p-a, Grp. 1

.9

1 114Cr-II2Mo Steel to P-4, Grp. 1 to ERNiCr-3

Incoloy 800HT None

260 Austenitic Stainless to p-a, Grp. 1 te ERNiCrM0-4

Hastelloy C276 P-44

261 Austenitic Stainless pa, Group 1 ERNiCr-3

ENiCrFe-2

262 2114Cr1MQ Sieel to P'5, Grp. 1 te ENiCrFe-3

Austenitic Stainless p-a, Grp. 1

263 Nicl<e' Overlay Qn, P-l,Grps.l-4 ERNiCr-3

Corban Steel

- CorrosIOn Resistant Overlay

264 Nicl<el Overlay on

P,'" Grps. 1-4

ENiCrFe-3

Cerbon Steel

- Corrosion Resistarit Overlay

,

265 Nicl<eIOverlay on P'I, G,ps., 1-4 ENiCrFe-3

Cerbon Steel

-. Corrosion Resistant Overlay

268 Cerbon Steel Pl, GrOup 1 E6010

E7018

~ 7

Una Pipe, API 5L API GrQup,2, E7018

GradeX60

(Slee\le Repelr)

268 Martensitic Stainless to P'6, Grp. 1 to. ER309

Austenitic Stainless p-a, Grp. 1

289 Cerbon Steel P-l, GrQup 2 E7018

'EMI3K

270 Cerbon Stee'- P-l, GrQup 1 ERaOS-Ni1

E701a1

ThIs procedure is qUalified lQr cryogenic service tQ'50F.

-

Filler

Metal Thickness Welding

A&FNQs. Rang@,to

f!llllIB eYil:lI

1/16-3/4 GTAW No

APIGrp.l 3/16-3/4 SMAW Vea

API Grp. 3

API Grp.l 3/16-3/4 SMAW Ves

API Grp.3

API Grp.l 3/16-3/4 SMAW Vea

API Grp.3

API Grp. 3 3/16-3/4 SMAW No

A8, F-6 3/16-0.864 GTAW Vea

F-43 3/16-0.864 GTAW Vea

F-44 3/16-1 1/16 GTAW No

F-43 3/16-1.00 GTAW No

SMAW

F-43 3/16-1.436 SMAW Ves

F-43 NQUmil GMAW No

F-43 NQUmil SMAW No

F-43 NQUmil SMAW No

A-I, F-3 ,3116-1/4 SMAW Ves

A-I, F-4

APIGrp.3 3/16-3/4 SMAW No

Aa, F-6 1/16-0.474 GTAW Ves

A-I, F-4 3/16-a.00 SMAW Ves

A-I, F-6 SAW

F-6 ' 3/16-3/4 GMAW No

A-I, F-4 SMAW

I

\ )

'-/

100000a A-13

" ,:

Base Filler

WPS Melal Filler Melal Thicl<neSs Welding

l:!2....

BaSe Metal's}

P..Nos. . -Metals A&FNos. Range, In.

~ ~

(),

_271

Carbon Steer P-l, Group-l E7018-1 A-I, F-4 1116<1.593: SMAW No

This procedure is qualified for cryogenic service to -50F.

272 Carbon Steer P-l, Group 1 E7018-1 A-l,_F-4 3/16-1.188 SMAW Yes

This prOcedure is qualified for cryogenic service to -WF.

273 Martensitic Stainless P-6, Group 1 ER410 A-6, F-6 3/16-3/4 GTAW Yes

274 line Pipe, API 5l API Group 1 E6010 API Grp.l < 3/16 SMAW No

GradeX42

275 Line Pipe, API 5l API Group 2 E6010 API Grp.l 3/16-3/4 SMAW No

GradeX60 E701O-G APIGrp.l

276 Carbon Stee! to P-l, Grp. 1 to ER80S-Ni3 A-l0, F-6 3/16-0.884 GTAW No

Nickel Steel P-9B, Grp. 1 E6018-C2 A-l0, F-4

SMAW -

This procedure isqualified forcryogenic serviceto"SOOF.

277 Austenitic Stainless P-ll, Group 1 ER347 A-8, F-6 3/16-0.674 GTAW Yes

E347-XX A-8, F-5 SMAW

278 line P,pe. API 5l API Group 4 E8018-C3 API Grp.3 3/16-3/4 SMAW No

Grade X70

(Sleeve Repair)

279 caroon Steel 10 P-l,Grp.lto E6010 A-I, F-3 3/16-2.00 SMAW

- Yes

LInePipe. ApI SL S-I, Grp.l E7018 A-I, F-4

Grade X52

280 Carbon Steel AWS E6013 A-I, F-2 AUFlUet SMAW No

(Underwc'uer) Group I Welds

281 CarbonSteel AWS ENiM9d F-43 AUAllet SMAW No

(Underwaler) Group I Welds

282 CarbOn Steel AWS E6013 A-I, F-2 0.938 max. SMAW No

(Under\tialerj Group[

283 CarbonSteer P-l, Group 1 I'R70S.e A-l, F-6 3/16<1.475 GMAW No

284 Monel 400 to P-42 to ERNiCr3 F-43 1/16-0.474 GTAW No

/

Hastelloy C276 P-44

285 Aluminum Alloy P-21 ERll00 F-21 1/16-3/4 GTAW No

(3003)

286 Aluminum Alloy P-21 sanoo F-21 3/16-1.00 GTAW No

(3003)

287 Aluminum AllOY P-25 ER5183 F-22 3/16-1.00 GTAW No

(5083)

288 Aluminum Alloy P-25 ER5183 F-22 1/16-0.432 GTAW No

(5083)

'-.:

~ \ .

289 line Pipe, API 5LX API Group 3 E60tO APIGrp.l 3/16-3/4 SMAW No

GradeX65 E801o-G API Grp. 2

,

-

101Q/98

, ,:'

A-14

", '

1019198 A15

BaH

Fiue<

WPS

Metal

FlUer

Metal ThIckness Welding

tm.....

Base MeliUs) . ,

peNos:

Metals

A&FNOS, Range in

f!S!WI

eYit!!

310

Aus1enitic Stainless

P-8, Grolip 1

Thyssen

3/16-11/16 GTAW

o'lo

20/25CU

SMAW

311

Aus1enltic Stalnl ....

P-8, Group I

liiyssen

3/16-11/16 SMAW

No

'20/25CU

Ausienltic Stainless-

P-8, Gioup 1

..

-312

ER316L

, A-B; F-6 318-3/4 GTAW No

'.E316L15 A-B, F5 SMAW

- ThIsprocedure Is qualifiedfor C/Y9genic service III .32O'F.

313 Monel 400

P-42

ERNICr-3

F-43 1/16-0.644 GTAW No

ENICrFe-3

SMAW

314

1 1/4CrII2MoSleeI to

P-4, Grp. 1 10

ENiCrFe-2

F-43

1/16-112 SMAW Yes

FerriliC Stainless

P7,Grp,2

315 Ferritic StaInless 10

P'7, G,p.210. ' ENICri:e-2

F-43

1/16-1!:! SMAW No

Austenitic ,Stainless

P-8, Grp.l

316

Cerbon-ll2MoSteeI 10,

PoG, Gip. 1 to

ENICrFe-2

F-43 1/16-3/4 SMAW

No

Ferritic Stainless

P7, Grp.l

Stainless' to

' .

317

P-8, Grp. 1 10

ERNICrMo-3

F-43 1/16-3/4 GTAW No

AL6XN

P-45

31B 904L

P-45

ER38S

1/16-0.474 GTAW No

(Thermann

20125)

319

Austenitic Stillnl8ss to

P-8, Grp. 1 10

Thermann

1/16-0.474 GTAW No

904L

P-45

20125

320 Carbon Steel to,

P'I, Grp. 110

ENiCrFe-2

F-43 1/16-314 SMAW No

Ferritic Stainless

P-7, Grp.l

321 Ferritic Stainless'

P7, Group 1

E309-XX A-B, F-5 1/16-3/4

SMAW No

322 Austenitic Stainless to

P-8, Grp. 1 10

Thermann

1/16-0.474 GTAW No

904L

P-45

20/25

SMAW

323 904L

P-45

ER3B5

1/16-0.474 GTAW No

E385-XX

SMAW

(Thermanit

20125)

,324 Aluminum Alloy

P'23 ER4043

F-23 3/16-1.00 GTAW No

(6061)

-.

325

Carbon to

P-l, Grp.lto

E309-XX

A-B. F-5 1/16-3/4

SMAW No

Ferritic Stainless

P-7, Grp.l

t;

326 LinePipe, API 5L

API Group 1

E701B

APIGIp.3 3/16-3/4 SMAW No

GradeX42

(Weld+End Coupling)

327 Carbon Steel to

Pl, GIp. 2 10

ENICu7

F-42 3/16-1.00

SMAW Yes

Monel 400 P-42

328 Monel 400 P,42

F-42

3/16-1.00

GMAW No

SAW

0'

f

(

Ii

"

1019188

A-16

.1019198 A17

Base Filler

WPS Metal Filfer' Metal Thickness Welding

-"

No. BaseMetaUs) P..Nos Metals A&FNos. Range in. Process PWHT

350 Austenitic Stainless P-8. Group 1 ' ER347 Aa. F6 3116-8.00 GMAW No

SAW

351 2 1I4Cr-1Mo Steel P-5. Group 1 E9018B3L A4. F-4 5/8-2.00 SMAW Yes

352 Austenitic Stainless P8. Group 110 ENiCrMo-3 F-43 1/16-112 SMAW No

P-8, Group 4

353 Line Pipe. API 5L API Group2 E7018 API Grp. 3 3116-314 SMAW No

Grade X46-X60

(Hot Tap)

-

354 Line Pipe, API 5L API Group 2 E7018 API Grp. 3 3116-314 SMAW No

Grade X46-X60 '

(HolTap)

-- 355 Line Pipe. API 5L , API Group 2 E701a API Grp. 3 3116-314 SMAW No

Grade X52

(Sleeve Repair)

356 Carbon Stee.1 Pl. Group 1 E7018 Al, F-4 1141.00 SMAW No

(Hot Tapping for Storage Tanks) . .

357 Carbon Steel

G'roup I or D'.

E7018 Al, F-4 118Unijmitod SMAW No

(01.1 Structural)

, .

358 Austenitic Stainless to P:8. Grp. '1, to

..

ERNiCr3 F-43 1/16-1.00 GTAW No

Monel 400 P-42

359 1 1/4Cr112Mo Steel P-4, Gioup 1. ER80S-B2L A-3, F-6 1/16-0.436 GTAW Yes

E60.18B2L A'3, F-4 SMAW

360 Carbon Steel to Pl, Grp.ll0 ER309 Aa, F6 1116-314 GTAW No

Austentic Stainless pa, Grp. 1..

361 Carbon Steel to Pl. Grp. 1.to ERNiCr3 F-43 1/16-314 GTAW No

Austentic Stainless P-8. Grp. 1

362 Carbon Sleel to P-l. Grp. 110 E309L-16 Aa. F5 .3116-0.550 SMAW Yes

Austenitic StainleSs, P-8. Grp.l

363 Martenistic Stainless 10 P-6, Grp. 1 to ER309 Aa. F-6 1/16-314 GTAW Yes

Austenitic Stainless P-7, Grp. 1

364 Martenisitc Stainless to P-6. Grp. 1 to ER309 A-8. F-6 1/16-314 GTAW No

Ferritic Stainless P-7. Grp.l

365 Martenistic Stainless to P-6. Grp. 1 to E309-16 A-8, F-5 1/16-314 SMAW Yes

Ferritic Stainless P-7. Grp. 1

366 Martensitic Stainless to P-6. Grp. 1 to E309-16 A-8, F5 1/16-314 SMAW No

Ferritic Stainless P7. Grp. 1

367 1 1/4 Crl12Mo Steel to P-4.13rp.l to . ENiCrFe-2 F-43 1/16-314 SMAW No

Martensitic Stainless P-6. Grp. 1

368 21/4 Cr-1Mo Steel to P-5A. Grp. 1 10 ENiCrFe-2 F-43 1/16-314 SMAW Yes

Martensitic Stainless P-6, Grp. 1

1019/98

..

A-la

. 1

Base Filler

WPS Metal Filler Metal Thickness Welding

t!2....

Base Metalls) PNos. Metals A&F Nos, Range In: f!Qw1 pWHT

369 5Cr1 Mo Steel to P5B, Grp. I to ENICrFe2 F-43 1/16-314 SMAW Ve.

Martensitic Stainless P-6. Grp. I

370 Carbon Steel to P_I, Grp. I to ERNiCu-7 F-42 1/16-112 GTAW Ve.

Monel 400 P-42

371 9Cr1 Mo Steel P-5B, Group 1 ER505 A5, F-6 3116-1.188 GMAW Yes

SAW

372 Carbon Sleel P-1, Group1 E6010 A-I, F3 3116-0.864 SMAW Yes

ER70S-2 AI, F-6 GMAW

373 carbon Steel P-l, Grp. I to E7018 AI, F-4 1/16-112 SMAW No

S-I, Grp. 1 E309-16 A8, F-5

374 11/4Cr-II2Mo Steel to P-4, Grp. I to ERNiCr-3 F-43 3116-1.00 GTAW Yes

904L P-45 ENiCrFe-2 3116-8.00 SMAW

375 2 1/4 cr-t Mo Steel to P'5A, Grp. 1 to ERNiCr-3 F-43 3116-1.00 GTAW Ve.

904L P-45 ENiCrFe-2 3116-2.00 SMAW

376 I 1/4Cr-1/2Mo Steel to P-4, Grp. I to ERNiCr-3 F-43 3116-1.00 GTAW Ve.

RA-330 P-46 ENiCrFe-2 3116-8.00 SMAW

377 2 1/4Crl Mo Steel P-5A, Group I E309L16 A8, F5 0.432 min. SMAW Ves

E34716

378 9Cr-1Mo Steel to P'5B, Grp. I to ER309 A-8, F6 3116-0.864 GTAW Yes

Austenitic Stainless P'8, Grp. I E30916 A-8, F-5 SMAW

379 21/4Cr-1Mo Steel 10 P-SA, Grp. I to ER309 A8, F-6 3116-0.864 GTAW Yes

Austenitic Stainless P8, Grp. I E309-16 A8, F-5 SMAW

360 Hastelloy C-276 to P-44 to ERNiCrMo-3 F43 1/16-0.474 GTAW No

carpenter 20 Cb3 P-45

361 21/4CrIMo Steel to P5A, Grp. I to ERNiCr3 F-43 3116-1.00 GTAW Yas

Inconel600 P-43

362 Carbon Steel Pl, Group 1 E7018 A-3, F-4 3116-1.50 SMAW No

383 MartensiticStainlessto P-6, Grp. I to ENiCrFe--2 F-43 1/16-314 SMAW Ves

Ferritic Stainless P-7, Grp. I

364 Austenitic Stainless to P8, Grps. 1-4 to ERNiCrMo-3 F-43 3116-1.00 GTAW No

904L P-45 ENiCrMo-3 SMAW

.-

365 Austenitic Stainlessto poe. Grps. 1-4 to ERNiCrMo-3 F-43 3116-0.910 GMAW No

904L P-45

386 904L

P-45 ERN",CrMo-3 F-43 3116-1.00 GTAW No

ENiCrMcr3 SMAW

387 Carbon Steel P-l, Grps. 1&2 E6010 A-I, F-3 0.118-1.00 SMAW No

E7018-1 A-3, F-4

This procedure is quallfied for cyrogenic service to -50F.

388 1 '1/4Cr-l/2Mo Steel P-4, Grps. 1&2 E6010 A-I,F-3 1/16-314 SMAW Ves

ER70S-2 A-I,F-6 GTAW

1019/98 A19

I .f

Base

FiUer

WPS Metal Filler Metal Thicl<noss Wolding

!:i2.....

Base Metalls) PNQs. Metals A&F Nos.

Range in.

~

PWHT

389 Carbon Steol P-l, Grps. 1-3 E7018 A-3, F-4 Unlimited SMAW Vos

Temper BeadWeldRepairProcedure

390 Duplox Stainloss Pl0H, Group 1. Thonnanit 22/09 1/16-3/4 SMAW No

391 Carbon-ll2Mo Stool P-3, Group 1 E701Q-Al A-3, F-3 1/16-3/4 SMAW No

E7018Al A-3, F-4

382 Carbon-ll2Mo Steol P-3, Group 1 ER80S-D2 A-3, F6 1/16-3/4 GTAW No

393 Nicl<el2oo P-41 ERNil F-41 1/16-1/4 GTAW No

394 Austenitic Stainless P-8, Group 1 ER316L A-8, F-6 0.108-0.864 GTAW No

Thisprocedure is qualified for cryogenic service to 320C'F.

395 Carbon Stoel Pl, Group 1-4 ER70S-2 A-l,F-6 1/16-3/4 GTAW Yes

396 Carbonll2Mo Steel to P-3, Group 13 to ER80SB2L A3, F6 1/16-3/4 GTAW Vos

SCr1/2Mo Steel P'SB, Group 1 E8018B2L A3, F-4 SMAW

397 Carbon Steel to P-l, Group 14 to ENiCrFe3 F-43 3/16-1.00 SMAW No

Carpenter 20 Cb3 P-4S

398 Carpentor 20 Cb3 P-4S E32Q-16 FS 3/16-1.00 SMAW No

399 Carpentor 20 Cb3 P-4S ER320 F6 3/16-1.00 GTAW No

E32Q-16 F-S SMAW

400 Carpentor 20 CQ3 P-4S ER320 F-6 3/16-0.888 GMAW No

E32Q-16 F-S SMAW

401 Carpenter 20 Cb3 P-4S ER320 F-6 3/16-0.888 GMAW No

SAW

402 Hastelloy Xtc P-43 to ERNiCr3 F-43 3/16-1.00 GTAW No

Carpenter 20 Cb3 P-4S

403 Carbon Steel to P'l, Grps. 1-4 ERNiCu7 F42 3/16-2.00 GMAW No

MQne1400

(Applied Monel 400 Unor)

404 Austenitic Stainless to P-8, Group 1-4 to ERNiCr3 F-43 1/16-0.560 GTAW No

HP4S None

405 9Crl Mo Steel PSB, Group 1& ~ ERSOS AS, F-6 1/16-0.560 GTAW Yes

406 9Cr-l Mo Steol P'SB, Group 1&2 ESOS-1S AS, F-4 3/16-1.00 SMAW Vos

407 Carbon Stoel to P-l, Group 1-4 to ERNiCrM0-4 F-44 3/16-0.910 GMAW No

Hastelloy C276 P-44

408 Nickol Ovortay on P-l, Grps.l-4 ERNiCrM0-4 F-44 0.237Unlimited GMAW No

Carbon Steel

--

Corrosion Resistant Overtay

409 1 1/4Cr-112Mo Steel P-4, Group 1&2 ERNiCr3 F-43 3/16-1.50 GTAW Yes

ERNiCrFe-2 SMAW

410 9Crl Mo Sleel P-SB, Group 1&2 . ERSOS A-S, F6 3/16-0.728 GMAW Yes

1019/98

A20

,

-

. 1

Base

Filler

WPS

Metal

Filler

Metal Thickness Welding

No. Base Metalls)

PNos,

Melals

A&F Nos. Range. in.

f!.2W

PWHT

411 9Crl Mo Sleel

P'5B, Group 1&2 ER505

A5, F6

3116-0.728 GMAW Yes

E505Tl

FCAW

412 Zirconium

P62

ERZr-4

F61

1/16-0.686 GTAW Yes

413 AluminumAlloy

P21 to

ER5183

F22 3116-1.00 GTAW No

(3003 to 5083)

P25

414 Aluminum Alloy

P23 to

ER5356

F22 1116-0.674 GTAW

No

(6061 to 5083)

P25

41'5

I 1/4CrII2Mo Sleel

P-4. Group 1&2

ER80SB2L

A3, F6 3116-0.475 GMAW Yes

416

Calbon Steel to

PI, Group 2 10

ER309

A8, F6 O.IQO.O.400 GTAW No

Austenitic Stainless

P8, Group 1

This procedure isqualified for c r y o g e n ~ service to .50

0F

.

417 carbon Steel

PI, Grps. 1-4

ENil

F-41

0.237Unlirnited SMAW

No

Corrosion Resistant Overlay~

ENiCu7

F-42

418 Carbon Steel

P-l, Group 1-4

E6010(5P+)

F3 3116-1.00 SMAW No

E7018

Al, F-4

419 carbon Sleel

P-l, Group 1-4

E6010(5P+)

F3 3116-1.00 SMAW Yes

E7018

A1, F-4

420 Csrbon Steel'

Pl, Group 1&2

E6010(5P+)

F3

0.120-0.960 SMAW No

E7018

Al, F-4

-Thisprocedure isqualified for cryogenic service to 500F.

421 Line Pipe, APi 5L

API Group 2

E7018

API Grp. 3 3116-314 SMAW No

Grade X46-X60

(Sleeve Repair)

422

Calbon Sleel 10

Pl, Group 1410

ER80SB2L

A3. F6 3116-8.00 GTAW Yes

5Cr-II2Mo Steel

P-5B, Group 1&2

E8018-B2L

A3, F-4

SMAW

423 Carbon Sleel

P-l, Group 1-4

E6010(5P+)

F-3 1/16-314

SMAW No

E701Q-G

424 2114CrIMo Steel

PSA, Group 1

ER90SB3L

F6, A-4 3116-8.00

GTAW Yes

E9018-B3L

F-4, A-4

SMAW

425

Carbon Sleel to

P-I, Group 1-410

ENiCrFe-3

F-43

3116-1.00

SMAW No

Carpenter 20 CbJ P-45

I

426

I 1I4CrII2Mo Sleei 10

P-4, Grp. 1&2 10

ER602

F6, A-4

3116-1.60 GTAW Yes

5CrII2Mo Steel

P'5B, Grp. 1&2

E502-16

F4, A-4

SMAW

427 Ferritic Stainless

P7, Grp. 1&2

ERNiCr3

F-43

1/16-314

GTAW

No

428 Line Pipe, API 5L

API Group 4

E8018-G

API Grp. 2 3116-314

SMAW

No

GradeX70

429 carbon Steel 10

Pl, Group 14 to

ENiCrM0-4

F-44

3116-1.50

SMAW No

Hastelloy B P-44

1019198

A21

." r

Base Filler

,

WPS Metal Filler Melal Thickness

Welding

tlQ....

BaseMetal(s) P-Nos. Metals A&FNos. Range in.

~

PWHT

430 Austenitic Stainless to P'8, Grp. 1.4 to ERNiCrCoMo-1 F-43 1/16-0.620 GTAW No

HP45 None

431 Austenitic Stainless to P8, Grp, 1'4 to ERNiCrMo-3 F-43 1/16-0.730 GTAW No

256Mo P-45

432 25-6Mo P-45 ERNiCrMo-3 F43 1/16-0.730 GTAW No

433 25-6Mo P-45 ERNiCrMo-3 F-43 1/16-0.730 GTAW No

ENiCrMo-3 SMAW

434 Carbon Steel P1, Grp. 14 ER70S2 Al, F6 3/16-1.704 GMAW No

ER70S-6

435 Carbon Steel P1,Grp.1-4 ER70S2 A1, F6 3/16-1.704 GMAW Ve.

ER70S6

436 CopperNickel P34 ERCuNi F34 1/16-0.290 GTAW No

437 2 1/4Cr1Mo Ste.el to P5A, Grp. 1 to ER90SB3L A-4, F6 1/16-3/4 GTAW Ves

5Cr112Mo Steel P'5B, Grp. 1&2

438 Line Pipe, API 5L API Group 1 E601015P.) API Grp.1 3/16-3/4 SMAW No

Grade X42 E801D-G API Grp2

439 9Cr1 Mo Steel to P5B, Grp. 1to ERNiCr3 F-43 3/16-1.00 GTAW Ves

Incoloy 800HT P-45

440 Line Pipe, API 5L API Grp. 2 E309-XX API Grp.3 1/16-0.282 SMAW No

Grade X52' E7018

(Slee.e Repliir)

Quelified to CSA Standard Z66294

441 2 1/4Cr1Mo Steel P'5A, Grp.1 E9018B3 A-4, F-4 3/16,8.00 SMAW Ves

442 Austenitic Stainless P'5A, Group 1 E309L16 A8, F5 1.00 to SMAW Ves

Overlay on 2 1/4Cr1 Mo Steel E308L16 Unlimited

CorrosionResistant O v e ~ a y E34717

443 Line Pipe, API 5L API Grp. 1 to ER70S6 API Grp.6 3/16-3/4 GTAW No

Grade X42 to Grade X60 APIGrp.2

444 Aluminum Alloy P23 ER5356 F22 1/16-1/2 GTAW No

(6061-16)

445 Austenitic Stainle.. P8, Grp. 1-4 ERNiCrMo-3 F-43 1/16-3/4 GTAW No

446 Austenitic Stainless P8, Grp. 1-4 ENiCrMo-3 F-43 3/16-1.00 SMAW No

447 Incoloy 825 P-45 ENiCrMo-3 F43 1/16-3/4 SMAW No

448 Austenitic Stainless to

P-S, Grp. 1-4'"

ENiCrMo-3 F-43 1/16-3/4 SMAW No

Incoloy 825 P-45

449 Carpentar 20 Cb3 to P-4510 ERNiCr1 F-41 3/16-1.00 GTAW No

Ni-Reslst None ERNiCr3 F-43

1019/88 A22

-it'"",.

,

-,

,

Base Filler

. ~

Metal Filler Metal Thickness Welding

Base Metalls) PNos. Metals A&F Nos. Range. in. Process PWHT

, . 0 LinePipe, API SL API Grp. 2 E309-t6 3116-314 SMAW No

Grades X46-X60

(Branch and Saddle Connections)

451 Carbon Steel to Pl, Grp. 14 ER70S-2 Al, F6 1'16-314 GTAW No

2 I '4Cr-l MeSteel P'5A, Grp. I E7018 A-t, F-4 SMAW

452 2 I '4Crl Mo Steel to P5A, Grp. 1 to ER90S-B3L A-4, F6 1'16-314 GTAW Yes

9Cr1Mo Steel P'5B, Grp. 1&2 E9018-B3L A4, F4 SMAW

453 Carbon Steel to P'I, Grp. 1-4 to ERNiCrMo-3 F43 0.088 max. GTAW No

IrlCOllel 625 P-43

454 Inoonel625 P43 ERNiCrMo-3 F-43 0.088 max. GTAW No

455 Austenitic Stainless pa, Group 1 ER308L A8, F6 0.120-0.480 GTAW No

Thisprocedure is qualified forcryogenic service to -320F.

456 Duplex Stainless to Pl0H to ERNiCrMo-t 0 F-44 0.255-0.510 GTAW No

InconeI925 P45

Thisprocedure is qualified forcryogenic service to oaF.

~ 7

Aluminum Alloy P21 ER5356 F22 3116-1.00 GTAW No

(3003)

458 Aluminum Alloy P21 ER4043 F-23 31161.00 GTAW No

(3003)

,

10122198 A-23

Potrebbero piacerti anche

- UNS Ferrous Metals and AlloysDocumento4 pagineUNS Ferrous Metals and AlloysAnaruzzaman SheikhNessuna valutazione finora

- Welding of 4140 & 316Documento5 pagineWelding of 4140 & 316Engineer AnasNessuna valutazione finora

- BS 341 - Gas Cylinders-Cylinder Valves - Part-1Documento42 pagineBS 341 - Gas Cylinders-Cylinder Valves - Part-1machinemam29Nessuna valutazione finora

- BS en 26704-1991 (1999) Iso 6704-1982Documento12 pagineBS en 26704-1991 (1999) Iso 6704-1982GT-LUCAS BARCINessuna valutazione finora

- Corrosion Science: Yiming Jiang, Hua Tan, Zhiyu Wang, Jufeng Hong, Laizhu Jiang, Jin LiDocumento8 pagineCorrosion Science: Yiming Jiang, Hua Tan, Zhiyu Wang, Jufeng Hong, Laizhu Jiang, Jin Lipepe martinez100% (1)

- Steel Product CatalogueDocumento3 pagineSteel Product Cataloguehappale2002Nessuna valutazione finora

- DIN 17175 Seamless Steel Pipes, Boiler Tube, Boiler Pipe, Seamless PipeDocumento3 pagineDIN 17175 Seamless Steel Pipes, Boiler Tube, Boiler Pipe, Seamless Pipeprabhatkumar_6657012Nessuna valutazione finora

- ATEX Flyer ElectromachDocumento1 paginaATEX Flyer Electromachhubert_veltenNessuna valutazione finora

- Werkstoff 1.5217 (20MnV6)Documento2 pagineWerkstoff 1.5217 (20MnV6)alextentwentyNessuna valutazione finora

- Swagelok SAF 2507 Write-Up PDFDocumento14 pagineSwagelok SAF 2507 Write-Up PDFSyahirul AlimNessuna valutazione finora

- Flange RotationDocumento1 paginaFlange RotationAnkit LonareNessuna valutazione finora

- The Effect of Large Heat Input On The Microstructure and Corrosion Behaviour of Simulated Heat Affected Zone in 2205 Duplex Stainless SteelDocumento8 pagineThe Effect of Large Heat Input On The Microstructure and Corrosion Behaviour of Simulated Heat Affected Zone in 2205 Duplex Stainless SteelAnonymous Qha8B2Nessuna valutazione finora

- QU AL ITY: Material Data SheetDocumento5 pagineQU AL ITY: Material Data SheetAlex007Nessuna valutazione finora

- Specification Data Sheet AISI 304Documento8 pagineSpecification Data Sheet AISI 304Luis Enrique Carreon TorresNessuna valutazione finora

- Weldolet Weight Table (Unit in KG)Documento2 pagineWeldolet Weight Table (Unit in KG)gfd100% (1)

- Drop Weight Tear Testing of High Toughness Pipeline MaterialDocumento8 pagineDrop Weight Tear Testing of High Toughness Pipeline MaterialKK SinghNessuna valutazione finora

- Iso Metric 32Documento2 pagineIso Metric 32rahul caddNessuna valutazione finora

- Comparison of Preheat Predictive Methods: N. Yurioka Nippon Steel Corporation, Technical Development Bureau (Japan)Documento7 pagineComparison of Preheat Predictive Methods: N. Yurioka Nippon Steel Corporation, Technical Development Bureau (Japan)Erijanio Silva100% (1)

- Infoprd-Geomet 500-gb PDFDocumento2 pagineInfoprd-Geomet 500-gb PDFSannohashi MFGNessuna valutazione finora

- JIS G3452 PipeDocumento0 pagineJIS G3452 PipefaridyeniNessuna valutazione finora

- Chapter 2 Material 2014 PDFDocumento363 pagineChapter 2 Material 2014 PDFGOPINATH KRISHNAN NAIRNessuna valutazione finora

- ISO 3690 2000 HydrogenEN FRDocumento8 pagineISO 3690 2000 HydrogenEN FRShyam Parsana100% (1)

- Worldwide Steel GradeDocumento2 pagineWorldwide Steel Grademyusuf123Nessuna valutazione finora

- ISO 15510 - Part 1Documento5 pagineISO 15510 - Part 1Zdenko MahacekNessuna valutazione finora

- American Society For Testing and Materials Specification: Astm - AMS - Aerospace MaterialDocumento10 pagineAmerican Society For Testing and Materials Specification: Astm - AMS - Aerospace MaterialjleonosNessuna valutazione finora

- En 10250 3 2000Documento16 pagineEn 10250 3 2000Marcos Verissimo Juca de PaulaNessuna valutazione finora

- Australian Standard®Documento10 pagineAustralian Standard®Syed Mahmud Habibur Rahman0% (1)

- MP - S JoseDocumento334 pagineMP - S JoseAskar BashaNessuna valutazione finora

- Tigweldarc Alloys: Certification of TestsDocumento1 paginaTigweldarc Alloys: Certification of TestsArunNessuna valutazione finora

- Alloy286 - ASTM A453 660 DatasheetDocumento2 pagineAlloy286 - ASTM A453 660 Datasheetn1ghtfallNessuna valutazione finora

- Technical Data Sheet Jindal Stainless Steel Grade JSL AUS (J1)Documento5 pagineTechnical Data Sheet Jindal Stainless Steel Grade JSL AUS (J1)Dudung SNessuna valutazione finora

- Specification For Alloy Steel Forgings For Pressure and High-Temperature PartsDocumento10 pagineSpecification For Alloy Steel Forgings For Pressure and High-Temperature PartsAnilNessuna valutazione finora

- Thread Data ChartsDocumento4 pagineThread Data Chartsrasinv100% (1)

- Hydro Aluminium - AlSi7Mg0.6Documento2 pagineHydro Aluminium - AlSi7Mg0.6Raj PrasanthNessuna valutazione finora

- Chemical and Mechanical PropertiesDocumento5 pagineChemical and Mechanical PropertiesAristotle MedinaNessuna valutazione finora

- Evaluation of The Ductile-To-Brittle Transition Temperature in Steel Low CarbonDocumento12 pagineEvaluation of The Ductile-To-Brittle Transition Temperature in Steel Low CarbonBurag HamparyanNessuna valutazione finora

- 4.3. Residual Stresses and Distortion in WeldmentsDocumento11 pagine4.3. Residual Stresses and Distortion in WeldmentsprokulisNessuna valutazione finora

- ASGEpg187 PDFDocumento3 pagineASGEpg187 PDFbkprodhNessuna valutazione finora

- Heat Treatment Lecture NotesDocumento24 pagineHeat Treatment Lecture NotesKhin Aung ShweNessuna valutazione finora

- Iso 3452-5 - 2008Documento12 pagineIso 3452-5 - 2008jesonelite100% (1)

- EASN 2 Si-IG ENDocumento1 paginaEASN 2 Si-IG ENrkstudycNessuna valutazione finora

- BS 1936-2 1991Documento16 pagineBS 1936-2 1991Jonicus-DextoreNessuna valutazione finora

- Welding Standard GOST 5264-80Documento35 pagineWelding Standard GOST 5264-80Linh TranNessuna valutazione finora

- Rules For Carrying Out Non-Destructive Examinations of Welding PDFDocumento43 pagineRules For Carrying Out Non-Destructive Examinations of Welding PDFHasib Ul Haque AmitNessuna valutazione finora

- Ministry of Defence Defence Standard 02-304 Part 3: Issue 2 Publication Date 9 September 2002Documento60 pagineMinistry of Defence Defence Standard 02-304 Part 3: Issue 2 Publication Date 9 September 2002Camilo PachecoNessuna valutazione finora

- Iso TTR 18931 2001 (E)Documento14 pagineIso TTR 18931 2001 (E)marco9991Nessuna valutazione finora

- Material Specifications - ASTM - Werkstoff Nummer - DIN enDocumento3 pagineMaterial Specifications - ASTM - Werkstoff Nummer - DIN enalomejorfofi100% (1)

- High Temperature Austenitic Stainless SteelDocumento12 pagineHigh Temperature Austenitic Stainless SteelCarlos Nombela PalaciosNessuna valutazione finora

- Guideline en 15085Documento22 pagineGuideline en 15085Boran YelkenciogluNessuna valutazione finora

- Manual AURATON 3003 enDocumento20 pagineManual AURATON 3003 enFuckTheXrysiAygiNessuna valutazione finora

- 163 Dimensions of Large Male Female and Small Tongue and Groove Flange Facing Ansi b165 StandardDocumento6 pagine163 Dimensions of Large Male Female and Small Tongue and Groove Flange Facing Ansi b165 StandardQiuniuNessuna valutazione finora

- Joining of Nickel Alloys-ExtractDocumento1 paginaJoining of Nickel Alloys-ExtractrmjiranNessuna valutazione finora

- Nfa 49 310 Grade Tu 52 B Tubes PDFDocumento1 paginaNfa 49 310 Grade Tu 52 B Tubes PDFMitul MehtaNessuna valutazione finora

- Threaded End Connection: Series F Carbon SteelDocumento1 paginaThreaded End Connection: Series F Carbon SteelLuis Francisco Mora DuarteNessuna valutazione finora

- Pamela Anderson'S Smaw & Gtaw Filler Metal Selection GuideDocumento10 paginePamela Anderson'S Smaw & Gtaw Filler Metal Selection GuideJames RodriguezNessuna valutazione finora

- ElectrodeDocumento1 paginaElectrodetechnicalNessuna valutazione finora

- 300 - Model 1415 PDFDocumento2 pagine300 - Model 1415 PDFMEHDINessuna valutazione finora

- FlowBiz Forged Steel Globe ValveDocumento14 pagineFlowBiz Forged Steel Globe ValveFlowBiz Exports Pvt. Ltd.Nessuna valutazione finora

- Garcia Welding: Filler Metal Selection GuideDocumento8 pagineGarcia Welding: Filler Metal Selection GuideGustavo MorilloNessuna valutazione finora

- Material API 610Documento8 pagineMaterial API 610mishraenggNessuna valutazione finora

- Suria Engineering: Welding Summary Report For PipingDocumento2 pagineSuria Engineering: Welding Summary Report For Pipingsuria qaqcNessuna valutazione finora

- WPS 141-121 P460QH To SameDocumento2 pagineWPS 141-121 P460QH To SameakisdassasNessuna valutazione finora

- 3.3.3-Fillet Weld Design 9th Mar 21Documento40 pagine3.3.3-Fillet Weld Design 9th Mar 21Vivek kmNessuna valutazione finora

- Iso 3834-5 2005Documento14 pagineIso 3834-5 2005HARISH KUMAR B MEKINSNessuna valutazione finora

- Haradh and Hawiyah Field Gas Compression Project Rfi Log: SinopecDocumento2 pagineHaradh and Hawiyah Field Gas Compression Project Rfi Log: SinopecvipinNessuna valutazione finora

- Water Heaters - Storage TanksDocumento16 pagineWater Heaters - Storage TanksRebecca TerryNessuna valutazione finora

- ÁDCADocumento16 pagineÁDCAthehoang12310Nessuna valutazione finora

- WpsDocumento2 pagineWpsnaseema1100% (1)

- Lista de Falhas - Transm. Mit W6ajaDocumento236 pagineLista de Falhas - Transm. Mit W6ajaAdriel Maia Do Amaral50% (2)

- Weld Inspection Check List: Defect Type Defect Description/ VisualDocumento16 pagineWeld Inspection Check List: Defect Type Defect Description/ VisualAndreas WirantoNessuna valutazione finora

- Weld DiscontinuitiesDocumento1 paginaWeld DiscontinuitiesHossam Eldien HassanNessuna valutazione finora

- A VK 2284813GB GEA-CAIR-HDE DF 2006-08 150dpiDocumento48 pagineA VK 2284813GB GEA-CAIR-HDE DF 2006-08 150dpiValentin FuleaNessuna valutazione finora

- Shielded Metal Arc Welding NC Ii 3 Final ExaminationDocumento2 pagineShielded Metal Arc Welding NC Ii 3 Final ExaminationJessa AquitanNessuna valutazione finora

- PHR PP QC GG 006 Welding ProcedureDocumento17 paginePHR PP QC GG 006 Welding Proceduremashari budiNessuna valutazione finora

- Technical English Project: Saad Dahlab University of Blida 1 Faculty of Technology Mechanics DepartmentDocumento9 pagineTechnical English Project: Saad Dahlab University of Blida 1 Faculty of Technology Mechanics DepartmentRyad GuiraNessuna valutazione finora

- Registry of Accredited Competency Assessment Centers 082013Documento117 pagineRegistry of Accredited Competency Assessment Centers 082013Erickson CastilloNessuna valutazione finora

- 38eyg 3pdDocumento48 pagine38eyg 3pdBlueSkyMasterNessuna valutazione finora

- Dep 30.10.60.32 - Welding of Metals, Based On Iso StandardsDocumento76 pagineDep 30.10.60.32 - Welding of Metals, Based On Iso StandardsPablo PazNessuna valutazione finora

- Acceptance Criteria Asme B31.3 PDFDocumento1 paginaAcceptance Criteria Asme B31.3 PDFAhmad Rizki100% (1)

- Smaw-Research-Paper 2Documento6 pagineSmaw-Research-Paper 2Jasen SatumcacalNessuna valutazione finora

- Laboratory Exercise-I Spot Welding Objective: AdvantagesDocumento4 pagineLaboratory Exercise-I Spot Welding Objective: AdvantagesAsadRehmanNessuna valutazione finora

- Watlow Immersion HeatersDocumento163 pagineWatlow Immersion HeatersEliasNessuna valutazione finora

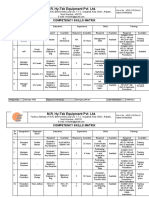

- MRH Competence Skill Matrix - To CheckDocumento7 pagineMRH Competence Skill Matrix - To CheckParag WadekarNessuna valutazione finora

- Progress Card HUMSSDocumento35 pagineProgress Card HUMSSwiljhon sunioNessuna valutazione finora

- JJ203 MECHANICAL PRACTISE Welding-Report (Arc Tee Joint & Cutting & Brazing)Documento9 pagineJJ203 MECHANICAL PRACTISE Welding-Report (Arc Tee Joint & Cutting & Brazing)Ah Tiang100% (1)

- (Welding) MIG-MAG Welding Guide - Lincoln Electric (Ebook, 48 Pages)Documento48 pagine(Welding) MIG-MAG Welding Guide - Lincoln Electric (Ebook, 48 Pages)Ahmad Arafa100% (10)

- Blue Box - Geyser 2Documento90 pagineBlue Box - Geyser 2tzisis100% (1)

- IS 813 Welding SymbolDocumento30 pagineIS 813 Welding SymbolrajeevkumarrajeevNessuna valutazione finora

- Honeywell DDC Panel ManualDocumento512 pagineHoneywell DDC Panel ManualSyed ZakiuddinNessuna valutazione finora

- 3g Tar WPQTR Form Aws d1.1Documento2 pagine3g Tar WPQTR Form Aws d1.1Scott AdkinsNessuna valutazione finora