Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ASME VS TRD CODE COMPARISON FOR BOILER DESIGN

Caricato da

sirang07Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ASME VS TRD CODE COMPARISON FOR BOILER DESIGN

Caricato da

sirang07Copyright:

Formati disponibili

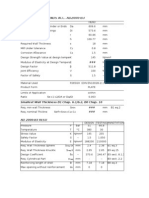

ASME Vs TRD CODE COMPARISON

German Standard TRD (Series 300) American Standard ASME (section I)

Primarly the static loads of the components to Fired pressure vessels,superheaters economizers and other TRD300.Pulsating internal pressure or combined variation pressureized parts attached to boiler without intermediate of pressure and temprature to TRD301 section. valves. Design rules only conside the stresses caused by the internal pressure. Additional forces and moments of significant magnitude shall be seprately considered. The scope covers the actual boiler and the certificate as per ASME code.

TRD 300 item 7.2 .For hot water generators p= permisible For natural and assisted circulation steam generator,design total guage pressure.Design pressure for parts beyond pressure p= maximum allowable working pressure (pp.21 SH.Outlet=Set pressure SH safety valves. &21.2).The maximum allowable working pressure determined by employing the allowable stress values,designed values and dimensions desigentaed in the section (p.21)

Design pressure to TRD300 7.1.For natural circulation steam generators p= Max allowable working pressure p1 + Hydrostatic pressure > 0.05 N/mm 2. Design pressure =p1= Highest drum SV pressure [for drum to SH outlet] Design pressure =p1 + geodectic head [for Economizer inlet to evaporator outlets]

Stress owing to hydrostatic pressures shall be taken in determining minimum thickness. Additional stresses imposed by the effects other than working pressure or static head that increases the average stress by more than 10% of the allowable working stress shall be taken into account including the self weight of the component and method of supports as per p.2.2 For forced circulation steam generator design pressure p= maximum allowable sustained working pressure of any part not less than the maximum over pressure reached when one or more over pressure protection devices are in operation.

For once through boilers p= maximum allowable working pressure at the component at MCR. i.e. superheater outlet pressure p1 +losses between the stop valve and the component

Design temperature = Reference temperature (RT) + at least the temperature allowance (AT)

Design temperature should not be less than the maximum expected mean tube temperature,(arithmetic mean temperature on the outer and inner surfaces) For heated tubes the temperature shall be taken as not less than 700F (371 Degree C)

Reference Temperatures: For water and /or water/steam For unheated tubes the wall temperature equal to the mixture. RT= saturation temperature at p1 or p.Maximum temperature of the working fluid can be taken as a allowable pressure or design pressure basis.Hower,this must be less than the saturation temperature

Potrebbero piacerti anche

- Impact Test Exemptions PEDDocumento7 pagineImpact Test Exemptions PEDoberaiNessuna valutazione finora

- Ped Eam-0526-24-1-2006-03Documento6 paginePed Eam-0526-24-1-2006-03nathachaiNessuna valutazione finora

- PED Allowable Stress CalculationDocumento3 paginePED Allowable Stress Calculationmechengg01100% (1)

- UHX CalcsDocumento5 pagineUHX CalcsRajesh Panchal100% (1)

- AD 2000 Head Under Intenal PressureDocumento3 pagineAD 2000 Head Under Intenal Pressuremechengg01Nessuna valutazione finora

- UG-39 - Flat Head ReinforcementDocumento3 pagineUG-39 - Flat Head ReinforcementAshish DhokNessuna valutazione finora

- MDMT Calculations For A Pressure Vessel - Abdel Halim GalalaDocumento12 pagineMDMT Calculations For A Pressure Vessel - Abdel Halim Galalabego00Nessuna valutazione finora

- Cs & Las Impact Req - Asme Sec Viii Div 2Documento16 pagineCs & Las Impact Req - Asme Sec Viii Div 2AmitNarayanNitnawareNessuna valutazione finora

- Tube Expansion Report Format r.0Documento1 paginaTube Expansion Report Format r.0fizanlamin100% (2)

- AD2000 (31barg) CalculationDocumento10 pagineAD2000 (31barg) CalculationMagdaline Matabang100% (1)

- Asme Sec 1 SimplifiedDocumento16 pagineAsme Sec 1 Simplifiedramundt83% (6)

- Discipline document calculationDocumento20 pagineDiscipline document calculationSivi NallamothuNessuna valutazione finora

- ASME PCC-1 Appendix-O (Assembly of Bolt Stress Determination)Documento2 pagineASME PCC-1 Appendix-O (Assembly of Bolt Stress Determination)Mr Incognito100% (1)

- Ad2000 b5 Fixed Tubesheet-3Documento3 pagineAd2000 b5 Fixed Tubesheet-3akisdassasNessuna valutazione finora

- Comparison of PD 5500, EN 13445, ASME SEC VIII Div 1 & 2Documento7 pagineComparison of PD 5500, EN 13445, ASME SEC VIII Div 1 & 2Ali MhaskarNessuna valutazione finora

- (DIN 28082-2 - 1996-06) - Standzargen Fã R Apparate - Teil 2 - Fuà - Ring Mit Pratzen Oder Doppelring Mit Stegen - Maà - e - 0001.de - enDocumento6 pagine(DIN 28082-2 - 1996-06) - Standzargen Fã R Apparate - Teil 2 - Fuà - Ring Mit Pratzen Oder Doppelring Mit Stegen - Maà - e - 0001.de - enNaveen Suresh KumarNessuna valutazione finora

- AD 2000 Head Under Extenal PressureDocumento2 pagineAD 2000 Head Under Extenal Pressuremechengg01100% (1)

- Design Procedure For Aes He PDFDocumento30 pagineDesign Procedure For Aes He PDFRyan Goh Chuang HongNessuna valutazione finora

- UG-45 Nozzle Sizing Rules SimplifiedDocumento2 pagineUG-45 Nozzle Sizing Rules Simplifiedshabbir626Nessuna valutazione finora

- Calculation of Target Torque for Bolts (ASME PCC-1Documento1 paginaCalculation of Target Torque for Bolts (ASME PCC-1daniel oliveiraNessuna valutazione finora

- S-Stamp Calculation Nozzle ShellDocumento4 pagineS-Stamp Calculation Nozzle ShellmukeshNessuna valutazione finora

- Calculation of Test Pressure Acc. To EN 13445-5Documento1 paginaCalculation of Test Pressure Acc. To EN 13445-5JockoJole100% (1)

- Ad2000 B13Documento2 pagineAd2000 B13akisdassasNessuna valutazione finora

- Design of Leg & Skirt Per EN 13445-3 - 2009 PDFDocumento17 pagineDesign of Leg & Skirt Per EN 13445-3 - 2009 PDFtranhonghakd5533100% (1)

- Rolled Shells (7.4.2) According To Standards EN 13445-3: Values For CalculationDocumento3 pagineRolled Shells (7.4.2) According To Standards EN 13445-3: Values For Calculationmet-calcNessuna valutazione finora

- Tema Asme Section Viii Div1 Section Uhx PDFDocumento20 pagineTema Asme Section Viii Div1 Section Uhx PDFAdrian StoicescuNessuna valutazione finora

- BS 5276-2Documento20 pagineBS 5276-2Ali Alizadeh100% (1)

- Part A1 Chapter 2 - ASME Code Calculations Stayed Surfaces Safety Valves FurnacesDocumento25 paginePart A1 Chapter 2 - ASME Code Calculations Stayed Surfaces Safety Valves Furnacesfujiman35100% (1)

- Asme b31 3 03 PDFDocumento3 pagineAsme b31 3 03 PDFAtallah BoufatahNessuna valutazione finora

- Calculation AD 2000Documento1 paginaCalculation AD 2000Nad Diya100% (1)

- Flange calculation as per ASME Section VIIIDocumento9 pagineFlange calculation as per ASME Section VIIIDarshan PanchalNessuna valutazione finora

- Ibr Stand PipeDocumento11 pagineIbr Stand PipeP s JagatheesanNessuna valutazione finora

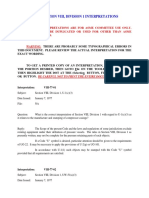

- Asme Section Viii, Division 1 InterpretationsDocumento1.148 pagineAsme Section Viii, Division 1 InterpretationsajitNessuna valutazione finora

- Pd5500 Flange CalculationDocumento6 paginePd5500 Flange CalculationAliNessuna valutazione finora

- VVD Info PDFDocumento6 pagineVVD Info PDFVicky GautamNessuna valutazione finora

- Mawp and MDMT Calculations PDFDocumento5 pagineMawp and MDMT Calculations PDFobuse100% (7)

- Lug Support DesignDocumento3 pagineLug Support DesignSajal KulshresthaNessuna valutazione finora

- En ASME ComparisonDocumento18 pagineEn ASME ComparisonPeterWay100% (1)

- Calculation - ASME VIII Div.1Documento10 pagineCalculation - ASME VIII Div.1bargez100% (1)

- ASME VIII A13 - Vessels of Noncircular Cross Section (Type 13-2 (A) (6) )Documento14 pagineASME VIII A13 - Vessels of Noncircular Cross Section (Type 13-2 (A) (6) )hardik5818100% (1)

- Dissimilar Base Metal ThicknessDocumento5 pagineDissimilar Base Metal ThicknessFERNANDO MIRANDA100% (2)

- AD 2000 HesapDocumento11 pagineAD 2000 HesapBaşarŞenNessuna valutazione finora

- Pd5500 Flange CalculationDocumento6 paginePd5500 Flange CalculationMakrand SakpalNessuna valutazione finora

- SA 516M GR 485: If Actual Thickness of Head After Forming 9 MMDocumento2 pagineSA 516M GR 485: If Actual Thickness of Head After Forming 9 MMMehta MehulNessuna valutazione finora

- AD2000-B Sınıfı Dizayn Hesap ŞablonuDocumento35 pagineAD2000-B Sınıfı Dizayn Hesap ŞablonuSerhatNessuna valutazione finora

- Appendix 41Documento5 pagineAppendix 41Rafael_YevgenyNessuna valutazione finora

- Swing Bolt CalculationDocumento2 pagineSwing Bolt CalculationNicolaSavili100% (2)

- Pressure Part Design (See Also Stresses, Allowable or Permissible in Pressure Parts)Documento3 paginePressure Part Design (See Also Stresses, Allowable or Permissible in Pressure Parts)OmarHddadNessuna valutazione finora

- Pressure Part DesignDocumento3 paginePressure Part DesignOmarHddadNessuna valutazione finora

- Design of Piping Systems by Tengku SyahdilanDocumento115 pagineDesign of Piping Systems by Tengku SyahdilanRagerishcire KanaalaqNessuna valutazione finora

- Pressure Casing DesignDocumento1 paginaPressure Casing DesignJULIO CESARNessuna valutazione finora

- Design Practices - DrumsDocumento32 pagineDesign Practices - Drumsagarwalashwin32100% (2)

- Design of Piping SystemsDocumento115 pagineDesign of Piping SystemsDushyant Varshney100% (2)

- Design & Construction of Piping SystemsDocumento115 pagineDesign & Construction of Piping SystemsSuresh Babu100% (13)

- Design Conditions CriteriaDocumento4 pagineDesign Conditions CriteriaJaldhi PatelNessuna valutazione finora

- A Guideline For Design Pressure - Part 2Documento4 pagineA Guideline For Design Pressure - Part 2Said Ahmed SalemNessuna valutazione finora

- Refinery expansion & upgrading project design criteriaDocumento34 pagineRefinery expansion & upgrading project design criteriafarhadzakerNessuna valutazione finora

- Thermowell Calculations.Documento3 pagineThermowell Calculations.Shiju Kp.Nessuna valutazione finora

- 11 Questions Answers From ASME B313 That A Piping Stress Engineer Must Know PDFDocumento10 pagine11 Questions Answers From ASME B313 That A Piping Stress Engineer Must Know PDFBogdan ChivulescuNessuna valutazione finora

- Design of Pressure ComponentsDocumento34 pagineDesign of Pressure ComponentsYFFernando100% (1)

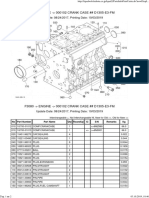

- Kubota Motor D1305-E3Documento46 pagineKubota Motor D1305-E3MMM-MMMNessuna valutazione finora

- Wilo PumpsDocumento40 pagineWilo Pumpsnile_asterNessuna valutazione finora

- Pulsation Dampener ProductsDocumento16 paginePulsation Dampener Productsgekinter100% (1)

- RFL Lined Ball ValveDocumento4 pagineRFL Lined Ball ValveRasaii Flow Lines Pvt. LtdNessuna valutazione finora

- Anti-Surge - Valve - ROI - REXA - 2Documento10 pagineAnti-Surge - Valve - ROI - REXA - 2Hash LalaNessuna valutazione finora

- CO AnalyzerDocumento1 paginaCO AnalyzeruzairNessuna valutazione finora

- PMRC Technical Specification: Ball and Check Valves, Lined, To Manufacturers Standard, FlangedDocumento10 paginePMRC Technical Specification: Ball and Check Valves, Lined, To Manufacturers Standard, FlangedradziNessuna valutazione finora

- Neptune PZ ManualDocumento56 pagineNeptune PZ ManualCGFernandez2014100% (1)

- PB 03 581 03Documento4 paginePB 03 581 03srinivasmanNessuna valutazione finora

- Inspection Check List BoilerDocumento4 pagineInspection Check List BoilerHADINessuna valutazione finora

- Eletrica MF 9690 E 9790Documento43 pagineEletrica MF 9690 E 9790PABLO DOS SANTOSNessuna valutazione finora

- Catalogue ManualDocumento33 pagineCatalogue ManualJaganathan KrishnanNessuna valutazione finora

- Spec-Sheet - LV-104 Surfashowers (Mar 15)Documento7 pagineSpec-Sheet - LV-104 Surfashowers (Mar 15)Frank MartinezNessuna valutazione finora

- Standard Operating Procedure (SOP) Compressor Safety: HeadlinesDocumento5 pagineStandard Operating Procedure (SOP) Compressor Safety: HeadlinesKuliner Ning Fia100% (1)

- 4-Annex III - BOQ For Installation of Equipments and PipingDocumento10 pagine4-Annex III - BOQ For Installation of Equipments and PipingAhmed Ayman AhmedNessuna valutazione finora

- VENTUS Air-Handling Units: Operation and Maintenance ManualDocumento66 pagineVENTUS Air-Handling Units: Operation and Maintenance ManualMohsin RazaNessuna valutazione finora

- Oil and gas industry glossary terms under 40 charactersDocumento20 pagineOil and gas industry glossary terms under 40 characterschanky18Nessuna valutazione finora

- LIT-C Stainless Steel Valves-USA LoResDocumento20 pagineLIT-C Stainless Steel Valves-USA LoResNopNessuna valutazione finora

- WL - TopicsDocumento22 pagineWL - TopicsMohamed100% (1)

- Manual Balanza de Pesos MuertosDocumento42 pagineManual Balanza de Pesos MuertosJaziiel PiinedaNessuna valutazione finora

- Liquid Level Meter Pneumatic Transmitter User's Manual: Model KDP/KKPDocumento20 pagineLiquid Level Meter Pneumatic Transmitter User's Manual: Model KDP/KKPMohammad HosseinNessuna valutazione finora

- Globe Valves Explained: Types and UsesDocumento4 pagineGlobe Valves Explained: Types and UsesMohamed AtefNessuna valutazione finora

- Manuals Control ValveDocumento257 pagineManuals Control Valvetreetree100% (1)

- Catalogue Pricelist Booklet 2020Documento17 pagineCatalogue Pricelist Booklet 2020charles kimeuNessuna valutazione finora

- Fluidchiller ManualDocumento111 pagineFluidchiller Manualknizam1971Nessuna valutazione finora

- Fundamentals of The Anaesthetic Machine Final PDFDocumento19 pagineFundamentals of The Anaesthetic Machine Final PDFNilam PatelNessuna valutazione finora

- TUTORO Auto Workshop Manual Oct 2023Documento48 pagineTUTORO Auto Workshop Manual Oct 2023loginusuarioscribdNessuna valutazione finora

- WATERHAMMER SOLUTIONS IN LONG PENSTOCKDocumento26 pagineWATERHAMMER SOLUTIONS IN LONG PENSTOCKHuy Le QuangNessuna valutazione finora