Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

01-Distributor Ignition System - Diagnosis and Testing - AutoZone

Caricato da

Nato DlAngelesDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

01-Distributor Ignition System - Diagnosis and Testing - AutoZone

Caricato da

Nato DlAngelesCopyright:

Formati disponibili

2/17/2011

1993 Toyota Corolla 1.6L EFI DOHC 4c

Toyota Corolla 1988-1997 Repair Guide

Diagnosis and Testing

SPARK TEST SIGNAL GENERATOR AIR GAP INSPECTION

If ignition problems or a no start condition are encountered, first perform an "On Vehicle Inspection Spark Test''. Check that spark occurs, if no spark occurs, follow the correct diagnostic flow chart (engine and year) and necessary service procedures.

SPARK TEST

4A-F, 4A-FE and 7A-FE Engines See Figures 1, 2, 3 and 4 1. Tag and disconnect the spark plug wires from the spark plugs. 2. Remove the spark plugs and install the spark plug wires to each spark plug. 3. Ground (do not hold spark plug) the spark plug; check if spark occurs while engine is being cranked.

Crank the engine for no more than 2 seconds at a time to prevent flooding the engine with gasoline. 4. If good spark does not occur, follow the correct diagnostic flow chart (engine and year) and necessary service procedures.

autozone.com//repairGuideContent.

1/9

2/17/2011

1993 Toyota Corolla 1.6L EFI DOHC 4c

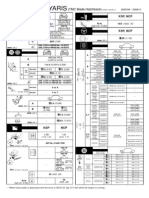

Fig. Fig. 1: System test-1988-89 4A-F engine

Fig. Fig. 2: System test-1990-92 4A-FE engine

Fig. Fig. 3: System test-1993-95 4A-FE and 7A-FE engines

autozone.com//repairGuideContent. 2/9

2/17/2011

1993 Toyota Corolla 1.6L EFI DOHC 4c

Fig. Fig. 4: System test-1996-97 4A-FE and 7A-FE engines 4A-GE Engines See Figures 5 and 6 1. On 4A-GE engine disconnect the coil wire from distributor. Hold the coil wire end about 1 / 2 inch from a good body ground; check if spark occurs while engine is being cranked.

Crank the engine for no more than 2 seconds at a time to prevent flooding the engine with gasoline. 2. If good spark does not occur, follow the correct diagnostic flow chart (engine and year) and necessary service procedures.

autozone.com//repairGuideContent.

3/9

2/17/2011

1993 Toyota Corolla 1.6L EFI DOHC 4c

Fig. Fig. 5: System test-1988-89 4A-GE engine

Fig. Fig. 6: System test-1990-91 4A-GE engine

SIGNAL GENERATOR (PICK-UP) RESISTANCE TEST

4A-F Engines See Figure 7 1. Using a suitable ohmmeter, check the resistance of the signal generator. 2. Pick up coil resistance should be 140-180 ohms.

autozone.com//repairGuideContent.

4/9

2/17/2011

1993 Toyota Corolla 1.6L EFI DOHC 4c

Fig. Fig. 7: Check the pick-up coil resistance at these terminals-4A-E engine 3. If the resistance is not correct, replace the pick-up coil.

4A-FE and 7A-FE Engines 1988-92 MODELS See Figure 8 1. Using a suitable ohmmeter, check the resistance between terminals G1 and G- and NE and G- of the signal generator.

Fig. Fig. 8: Check the pick-up coil resistance at these terminals-1988-92 4A-FE engine 2. The signal generator (pick-up coil) resistance cold should be 205-255 ohms. 3. If the resistance is not correct, replace the distributor housing.

1993-95 MODELS See Figure 9 1. Using a suitable ohmmeter, check the resistance between terminals G+ and G- and NE+ and NE- of the signal generator.

autozone.com//repairGuideContent.

5/9

2/17/2011

1993 Toyota Corolla 1.6L EFI DOHC 4c

Fig. Fig. 9: Check the pick-up coil resistance at these terminals-1993-95 4A-FE and 7A-FE engines 2. The signal generator (pick-up coil) resistance cold should be 185-275 ohms on G+ and G-; and 370550 ohms cold on NE+ and NE-. Check the chart for reference. 3. If the resistance is not correct, replace the distributor housing.

1996-97 MODELS See Figure 10 1. Using a suitable ohmmeter, check the resistance between terminals G+ and G- and NE+ and NE- of the signal generator.

Fig. Fig. 10: Check the pick-up coil resistance at these terminals-1996-97 4A-FE and 7A-FE engines 2. The signal generator (pick-up coil) resistance cold should be 185-275 ohms on G+ and G-; and 1630autozone.com//repairGuideContent. 6/9

2/17/2011

1993 Toyota Corolla 1.6L EFI DOHC 4c

2740 ohms cold on NE+ and NE-. Check the chart for reference. 3. If the resistance is not correct, replace the distributor housing.

4A-GE Engine See Figure 11 1. Using a suitable ohmmeter, check the resistance of the two signal generators between terminals G+ and G- and NE+ and NE- of the signal generator.

Fig. Fig. 11: Check the pick-up coil resistance at these terminals-4A-GE engine 2. The signal generators resistance should be 1988-89; 140-180 ohms. and on 1991 models; 205-255 ohms. 3. If the resistance is not correct, replace the distributor housing.

SIGNAL GENERATOR AIR GAP INSPECTION

See Figures 12, 13, 14 and 15 1. Remove the distributor cap.

autozone.com//repairGuideContent. 7/9

2/17/2011

1993 Toyota Corolla 1.6L EFI DOHC 4c

2. Measure the gap between the signal rotor and the pick-up coil projection, by using a non-ferrous feeler gauge (use paper, brass or plastic gauge).

Fig. Fig. 12: Inspection of the air gap-4A-F engine

Fig. Fig. 13: Inspection of the air gap-4A-GE engine

autozone.com//repairGuideContent.

8/9

2/17/2011

1993 Toyota Corolla 1.6L EFI DOHC 4c

Fig. Fig. 14: Inspection of the air gap-1988-92 4A-FE and 7A-FE engines

Fig. Fig. 15: Inspection of the air gap-1993-97 4A-FE and 7A-FE engines 3. The air gap should be 0.008-0.0016 in. (0.2-0.4mm). 4. If the air gap is not correct, replace the distributor housing.

Back to Top

autozone.com//repairGuideContent.

9/9

Potrebbero piacerti anche

- Identification: Avalon (1999), Camry 3.0L, Camry Solara 3.0L & SiennaDocumento54 pagineIdentification: Avalon (1999), Camry 3.0L, Camry Solara 3.0L & SiennaJuan Carlos Martinez NuñezNessuna valutazione finora

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualDa EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNessuna valutazione finora

- Ignition System: 1988 Toyota CelicaDocumento7 pagineIgnition System: 1988 Toyota CelicaToua Yaj100% (1)

- Ta1248 PDFDocumento38 pagineTa1248 PDFbad_boyz1989Nessuna valutazione finora

- Toyota Prius 2010 Cruise ControlDocumento9 pagineToyota Prius 2010 Cruise ControlBrais Diaz SanchezNessuna valutazione finora

- Throttle Body Dan TPS Corolla 88-97Documento4 pagineThrottle Body Dan TPS Corolla 88-97Fitri Wibowo100% (1)

- PS - Power SteeringDocumento58 paginePS - Power SteeringKatu2010100% (2)

- Mazda 6 2014 OBD2 PinDocumento2 pagineMazda 6 2014 OBD2 Pinoak2147Nessuna valutazione finora

- 2AZ-FE Emission ControlDocumento25 pagine2AZ-FE Emission ControlLuks FernandezNessuna valutazione finora

- 4afe O2sensor TestDocumento3 pagine4afe O2sensor Testkkg4782Nessuna valutazione finora

- Toyota YarisDocumento5 pagineToyota YarisMohammed Yusuf100% (1)

- 1993 Toyota Corolla ABSDocumento22 pagine1993 Toyota Corolla ABSAsepPopyHermawan100% (1)

- 1989 Nissan Sentra 1.6L Automatic Manual Transmission OverhaulDocumento29 pagine1989 Nissan Sentra 1.6L Automatic Manual Transmission OverhaulRubenNessuna valutazione finora

- S8094TA User ManualDocumento59 pagineS8094TA User ManualMohammadFaisalAmjad0% (1)

- P1656 PDFDocumento3 pagineP1656 PDFTalleban TalNessuna valutazione finora

- Toyota Altezza Ecu Side Terminal (TP5-7Base) Refer The Following For Special Setting When Modifying The Wiring, EtcDocumento9 pagineToyota Altezza Ecu Side Terminal (TP5-7Base) Refer The Following For Special Setting When Modifying The Wiring, EtcAlifNessuna valutazione finora

- Technical Service Bulletin: - DescriptionDocumento4 pagineTechnical Service Bulletin: - Description08088338Nessuna valutazione finora

- Trouble Codes MitsubishiDocumento12 pagineTrouble Codes Mitsubishirustyshakel100% (1)

- A32 at PDFDocumento293 pagineA32 at PDFOmar RodriguezNessuna valutazione finora

- 4 AfeDocumento36 pagine4 AfeJuan ContrerasNessuna valutazione finora

- w58 RebuildDocumento49 paginew58 RebuildtfphoenixNessuna valutazione finora

- Fuse Box Toyota Corolla E100Documento9 pagineFuse Box Toyota Corolla E100alvin.mitrakreasiNessuna valutazione finora

- Ignition SystemDocumento40 pagineIgnition Systemhenisetiawan100% (1)

- Mitsubishi FTODocumento14 pagineMitsubishi FTOJhonatan JalluranaNessuna valutazione finora

- Transmission Fluid PDFDocumento5 pagineTransmission Fluid PDFLv2mackNessuna valutazione finora

- Toyota 4a Fe Engine Reference PDFDocumento57 pagineToyota 4a Fe Engine Reference PDFeviton luisNessuna valutazione finora

- How To Read Toyota Wiring DiagramsDocumento23 pagineHow To Read Toyota Wiring DiagramsRanieri Benčić100% (1)

- Engine Control: System OutlineDocumento14 pagineEngine Control: System OutlineHernanCalderonDíaz100% (1)

- Diagnosis and Testing: Automatic Transmission (Automatic Shifting Manual Transmission/Transaxle)Documento60 pagineDiagnosis and Testing: Automatic Transmission (Automatic Shifting Manual Transmission/Transaxle)GabrielNessuna valutazione finora

- Electrochemi Toyota Land Cruiser Prado 2004 DemoDocumento15 pagineElectrochemi Toyota Land Cruiser Prado 2004 DemoVinsensius Agus Priyono100% (1)

- Greddy E Manage Instalcion en MitsubishiDocumento11 pagineGreddy E Manage Instalcion en MitsubishiFelipe Cortes0% (1)

- Toyota Yaris IIIDocumento2 pagineToyota Yaris IIIIoniță Sorin CristianNessuna valutazione finora

- Yaris SDSDocumento10 pagineYaris SDSGilbert Vasquez SagunNessuna valutazione finora

- AVEO 2007-2010/wave - 07-10/engine Mechanical - 1.5L/Repair Instructions - On VehicleDocumento86 pagineAVEO 2007-2010/wave - 07-10/engine Mechanical - 1.5L/Repair Instructions - On VehicleArley HernandezNessuna valutazione finora

- DTC Check ClearDocumento2 pagineDTC Check ClearDaniel Mamani ParedezNessuna valutazione finora

- Toyota Rav4 Ecu Recall Euc Problem PDFDocumento4 pagineToyota Rav4 Ecu Recall Euc Problem PDFرشيد الحربيNessuna valutazione finora

- Computer Control SystemDocumento67 pagineComputer Control SystemToua YajNessuna valutazione finora

- 1996 Toyota Corolla Owners Manual PDFDocumento195 pagine1996 Toyota Corolla Owners Manual PDFhanzhio elNessuna valutazione finora

- Galant CH 2 Engine Electrical PDFDocumento14 pagineGalant CH 2 Engine Electrical PDFjustcheerfulNessuna valutazione finora

- '02 - '04 Camry (2AZ-FE) (Non PZEV) Technical Service BulletinDocumento5 pagine'02 - '04 Camry (2AZ-FE) (Non PZEV) Technical Service BulletinElvin Domingo100% (1)

- Thai OctanesDocumento27 pagineThai OctanesAce SpadeNessuna valutazione finora

- 2uztrd PDFDocumento33 pagine2uztrd PDFbob loblawNessuna valutazione finora

- TRD Supercharger InstallationDocumento42 pagineTRD Supercharger InstallationErnesto Lopez100% (2)

- System Wiring Diagrams Cooling Fan Circuit, A/TDocumento1 paginaSystem Wiring Diagrams Cooling Fan Circuit, A/TcjtrybiecNessuna valutazione finora

- Re4F04A and Re4F04V Automatic Transmission (A/T) - Solenoid Valve Replacement ProceduresDocumento3 pagineRe4F04A and Re4F04V Automatic Transmission (A/T) - Solenoid Valve Replacement ProceduresfulltransmissionNessuna valutazione finora

- 2AZ-FE FuelDocumento43 pagine2AZ-FE FuelAdedeji OluwatobilobaNessuna valutazione finora

- WorkDocumento17 pagineWorkRam Krishan SharmaNessuna valutazione finora

- DTC Troubleshooting: Before You Troubleshoot, Review The General Troubleshooting InformationDocumento32 pagineDTC Troubleshooting: Before You Troubleshoot, Review The General Troubleshooting InformationpaniyaNessuna valutazione finora

- Celica ECM PinoutDocumento9 pagineCelica ECM PinoutYen N Chia100% (2)

- Rx8 SteeringDocumento56 pagineRx8 SteeringwillyhuaNessuna valutazione finora

- Ignition SystemDocumento37 pagineIgnition SystemdwcdiscoNessuna valutazione finora

- Instrument Panel Yaris 2008Documento89 pagineInstrument Panel Yaris 2008Pat NeenanNessuna valutazione finora

- FaultCodeReaderINST PDFDocumento78 pagineFaultCodeReaderINST PDFTawanda NyakupindaNessuna valutazione finora

- Toyota Camry IgDocumento56 pagineToyota Camry IgKulasekaran Amirthalingam100% (1)

- This Tutorial Will Help To Test The Throttle Position Sensor On Your 1989 To 1997 1Documento7 pagineThis Tutorial Will Help To Test The Throttle Position Sensor On Your 1989 To 1997 1HERBERT SITORUS100% (1)

- Control Engine 1kd FTV and 2kd FTDDocumento41 pagineControl Engine 1kd FTV and 2kd FTDMuxumad Cabdulahi0% (1)

- Repair Guides Distrib. CorollaDocumento5 pagineRepair Guides Distrib. CorollacardenascontrerasaaNessuna valutazione finora

- Sienna SparkPlug RemovalDocumento17 pagineSienna SparkPlug Removalazeemm1Nessuna valutazione finora

- Montero INSTRUMENT PANELDocumento51 pagineMontero INSTRUMENT PANELHernando MontenegroNessuna valutazione finora

- Check Timing-Engine - Mechanical - 5s-FeDocumento1 paginaCheck Timing-Engine - Mechanical - 5s-FeNato DlAngelesNessuna valutazione finora

- Set Timing Engine - Mechanical - 5s-Fe-2Documento2 pagineSet Timing Engine - Mechanical - 5s-Fe-2Nato DlAngelesNessuna valutazione finora

- Efi-Main Fuse-SfiDocumento2 pagineEfi-Main Fuse-SfiNato DlAngelesNessuna valutazione finora

- 5sfe-Timing BeltDocumento14 pagine5sfe-Timing BeltNato DlAngelesNessuna valutazione finora

- Diagnostics-5sfe Fuel Pump Control CircuitDocumento1 paginaDiagnostics-5sfe Fuel Pump Control CircuitNato DlAngelesNessuna valutazione finora

- 5sfe-Fuel Pump-Fuel Pressure RegulatorDocumento3 pagine5sfe-Fuel Pump-Fuel Pressure RegulatorNato DlAngelesNessuna valutazione finora

- BarTender Software End-User AgreementDocumento1 paginaBarTender Software End-User AgreementNato DlAngelesNessuna valutazione finora

- 5sfe-Fuel PumpDocumento8 pagine5sfe-Fuel PumpNato DlAngelesNessuna valutazione finora

- A 240Documento89 pagineA 240Mario Diaz Lopez100% (1)

- SKT Series Set-Up Parameter (V08 - 20100826)Documento32 pagineSKT Series Set-Up Parameter (V08 - 20100826)medmedNessuna valutazione finora

- Aegis Ring Shaft Grounding RingDocumento20 pagineAegis Ring Shaft Grounding RingDerry Ma KasihNessuna valutazione finora

- Vitotrans 300 01 2019Documento4 pagineVitotrans 300 01 2019radusettNessuna valutazione finora

- TPS70928DBVT PDFDocumento20 pagineTPS70928DBVT PDFLukaszNessuna valutazione finora

- Intertek UL 508A Standard UpdatesDocumento2 pagineIntertek UL 508A Standard UpdatesWilfredo MolinaNessuna valutazione finora

- 832017Documento12 pagine832017Agung SetiawanNessuna valutazione finora

- A SectionDocumento102 pagineA Sectionmarc5278Nessuna valutazione finora

- Materiales IntegracionDocumento18 pagineMateriales IntegracionEzequiel BrionesNessuna valutazione finora

- Plug in Time Delay Relays C System PDFDocumento4 paginePlug in Time Delay Relays C System PDFAndré CrowleyNessuna valutazione finora

- Car Engine PartsDocumento20 pagineCar Engine PartsHealth Club100% (2)

- Pre-Insertion Resistor and Grading Capacitor in Multi Break Circuit Breaker - Electrical ConceptsDocumento15 paginePre-Insertion Resistor and Grading Capacitor in Multi Break Circuit Breaker - Electrical ConceptsSheraz KhanNessuna valutazione finora

- LC300 - Online Brochure 202110291Documento30 pagineLC300 - Online Brochure 202110291JORGE LUIS TRIANA RODRIGUEZNessuna valutazione finora

- Chapter 25 Equipment - FurnishingDocumento63 pagineChapter 25 Equipment - FurnishingHartomo DK.Nessuna valutazione finora

- Server RakitanDocumento22 pagineServer RakitanadebsbNessuna valutazione finora

- A3G Block Diagram: File ListDocumento57 pagineA3G Block Diagram: File ListRommel LoayzaNessuna valutazione finora

- Surge Arresters: Subject Document Revision No. Sheet No. Equipment Specification Surge Arresters 1 1Documento5 pagineSurge Arresters: Subject Document Revision No. Sheet No. Equipment Specification Surge Arresters 1 1PRAKASH SNessuna valutazione finora

- Rubycon Al Eectrolytics DatasheetDocumento2 pagineRubycon Al Eectrolytics DatasheetEdgar DauzonNessuna valutazione finora

- Dreame T20 Cordless Vacuum Cleaner User ManualsDocumento79 pagineDreame T20 Cordless Vacuum Cleaner User ManualsIgnacio SeisdedosNessuna valutazione finora

- Transformers Ideal: Dr. Walid A. M. GhoneimDocumento20 pagineTransformers Ideal: Dr. Walid A. M. Ghoneimwalidghoneim1970Nessuna valutazione finora

- Application Specific Intelligent Power Modules - A Novel Approach To System Integration in Low Power DrivesDocumento15 pagineApplication Specific Intelligent Power Modules - A Novel Approach To System Integration in Low Power DriveschandooNessuna valutazione finora

- 2.2.1 Ach580 For Hvac Catalog 3aua0000186691 Revf enDocumento37 pagine2.2.1 Ach580 For Hvac Catalog 3aua0000186691 Revf enTrunghieu LeNessuna valutazione finora

- 21-19700-120 Reintjes Product Guide 2021 - Final - LowDocumento186 pagine21-19700-120 Reintjes Product Guide 2021 - Final - LowLaodenovriNessuna valutazione finora

- d002 Pd17004 Reve Datasheet NcuDocumento20 pagined002 Pd17004 Reve Datasheet Ncuelson brito juniorNessuna valutazione finora

- Full Report For Gasoline Fuel System For Toyota CorollaDocumento19 pagineFull Report For Gasoline Fuel System For Toyota Corollaaliashour123Nessuna valutazione finora

- HPR-2Documento12 pagineHPR-2v2nssysy6fNessuna valutazione finora

- Ems s6 TroubleshootingDocumento14 pagineEms s6 TroubleshootingHari50% (2)

- Design and Construction of A Solar Powered Metro Vehicle. (Update) (2) .Docx 31-1-2019Documento52 pagineDesign and Construction of A Solar Powered Metro Vehicle. (Update) (2) .Docx 31-1-2019kawsar ahmmedNessuna valutazione finora

- 2ME705-4-Hydraulic and Pneumatic SystemsDocumento2 pagine2ME705-4-Hydraulic and Pneumatic SystemsDev Chauhan100% (1)

- 3L Tdi PDFDocumento108 pagine3L Tdi PDFDUARTE FLORENCIO100% (1)

- KeNHA PORTAL - Dashboard PDFDocumento2 pagineKeNHA PORTAL - Dashboard PDFPhoebe NyamariNessuna valutazione finora