Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Engine Control (5S-Fe) : System Outline

Caricato da

Chris KalasTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Engine Control (5S-Fe) : System Outline

Caricato da

Chris KalasCopyright:

Formati disponibili

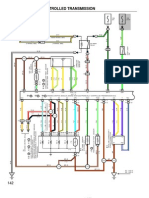

ENGINE CONTROL (5SFE)

SYSTEM OUTLINE

THE ENGINE CONTROL SYSTEM UTILIZES A MICROCOMPUTER AND MAINTAINS OVERALL CONTROL OF THE ENGINE, TRANSMISSION, ETC. AN OUTLINE OF ENGINE CONTROL IS GIVEN HERE.

1. PTIS (INPUT SIGNALS)

(1) WATER TEMP. SIGNAL SYSTEM THE ECTS (WATER TEMP. SENSOR) DETECTS THE ENGINE COOLANT TEMP. AND HAS A BUILTIN THERMISTOR WITH A RESISTANCE WHICH VARIES ACCORDING TO THE WATER TEMP. THUS THE WATER TEMP. IS INPUT IN THE FORM OF A CONTROL SIGNAL TO TERMINAL THW OF THE PCME (ECU). (2) INTAKE AIR TEMP. SIGNAL SYSTEM THE IATS (INTAKE AIR TEMP. SENSOR) IS DETECTS THE INTAKE AIR TEMP., WHICH IS INPUT AS A CONTROL SIGNAL TO TERMINAL THA OF THE PCME (ECU). (3) OXYGEN DENSITY SIGNAL SYSTEM THE OXYGEN DENSITY IN THE EXHAUST EMISSIONS IS DETECTED AND INPUT AS A CONTROL SIGNAL TO TERMINAL OX1 AND OX2 (CALIFORNIA) OF THE PCME (ECU). (4) CRANKSHAFT POSITION SIGNAL SYSTEM CRANKSHAFT POSITION AND ENGINE SPEED ARE DETECTED BY THE PICKUP COIL INSTALLED INSIDE THE DISTRIBUTOR. CRANKSHAFT POSITION IS INPUT AS A CONTROL SIGNAL TO TERMINAL G+, OF THE PCME (ECU), AND ENGINE SPEED SIGNAL IS INPUT TO TERMINAL NE+. (5) THROTTLE POSITION SIGNAL SYSTEM THE THROTTLE POSITION SENSOR DETECTS THE THROTTLE VALVE OPENING ANGLE, WHICH IS INPUT AS A CONTROL SIGNAL TO TERMINAL VTA OF THE PCME (ECU), OR WHEN THE VALVE IS FULLY CLOSED, TO TERMINAL IDL. (6) VEHICLE SPEED SIGNAL SYSTEM THE SPEED METER INSIDE THE COMBINATION METER SENDS A VEHICLE SPEED SIGNAL TO TERMINAL SPD OF THE PCME (ECU) AS A CONTROL SIGNAL. (7) NEUTRAL POSITION SIGNAL SYSTEM (A/T) THE PNS (NEUTRAL START SW) DETECTS WHETHER THE SHIFT POSITION IS IN NEUTRAL AND PARKING OR NOT, AND INPUTS A CONTROL SIGNAL TO TERMINAL NSW OF THE PCME (ECU). (8) A/C SW SIGNAL SYSTEM THE A/C AMPLIFIER INPUTS THE A/C OPERATIONS TO TARMINAL ACA OF THE PCME (ECU) AS A CONTROL SIGNAL. (9) BATTERY SIGNAL SYSTEM VOLTAGE IS CONSTANTLY APPLIED TO TERMINAL BATT OF THE PCME (ECU). WHEN THE IGNITION SW IS TURNED TO ON, VOLTAGE FOR ECU OPERATION IS APPLIED VIA THE EFI MAIN RELAY TO TERMINALS +B AND +B1 OF THE PCME (ECU). (10) INTAKE AIR VOLUME SIGNAL SYSTEM INTAKE AIR VOLUME IS DETECTED BY THE MAP (VACUUM SENSOR) AND IS INPUT AS A CONTROL SIGNAL TO TERMINAL PIM OF THE PCME (ECU). (11) STA SIGNAL SYSTEM TO CONFIRM THAT THE ENGINE IS CRANKING, THE VOLTAGE APPLIED TO THE STARTER MOTOR DURING CRANKING IS DETECTED AND IS INPUT AS A CONTROL SIGNAL TO TERMINAL STA OF THE PCME (ECU). (12) ELECTRICAL LOAD SIGNAL SYSTEM THE SIGNAL WHEN SYSTEMS SUCH AS THE REAR WINDOW DEFOGGER, HEADLIGHTS, ETC. WHICH CAUSE A HIGH ELECTRICAL BURDEN ARE ON IS INPUT TO TERMINAL ELS AS A CONTROL SIGNAL.

2. CONTROL SYSTEM

* MPI (EFI, ELECTRONIC FUEL INJECTION) SYSTEM THE MPI (EFI) SYSTEM MONITORS THE ENGINE REVOLUTIONS THROUGH THE SIGNALS EACH SENSOR (INPUT SIGNALS (1) TO (12)) INPUTS TO THE PCME (ECU). BASED ON THIS DATA AND THE PROGRAM MEMORIZED IN THE PCME (ECU), THE MOST APPROPRIATE FUEL INJECTION TIMING IS DECIDED AND CURRENT IS OUTPUT TO TERMINALS #10 AND #20 OF THE PCME (ECU), CAUSING THE INJECTORS TO OPERATE IT (TO INJECT FUEL). IT IS THIS SYSTEM WHICH, THROUGH THE WORK OF THE PCME (ECU), FINELY CONTROLS FUEL INJECTION IN RESPONSE TO DRIVING CONDITIONS. DURING ENGINE CRANKING (SIGNAL INPUT TO TERMINAL STA) OR FOR APPLOX. 2 SECONDS AFTER NE SIGNAL INPUT, PCME (ECU) OPERATION ENERGIZES (POINT CLOSED) THE FUEL PUMP CIRCUIT INSIDE THE CIRCUIT OPENING RELAY, CAUSING THE FUEL PUMP TO OPERATE.

70

* EI (ESA, ELECTRONIC FUEL ADVANCE) THE EI (ESA) SYSTEM MONITORS THE ENGINE REVOLUTIONS USING THE SIGNALS (INPUT SIGNALS (1, 4, 5, 10, 11)) INPUT TO THE PCME (ECU) FROM EACH SENSOR. BASED ON THIS DATA AND THE PROGRAM MEMORIZED IN THE PCME (ECU), THE MOST APPROPRIATE IGNITION TIMING IS DECIDED AND CURRENT IS OUTPUT TO TERMINAL IGT OF THE PCME ECU. THIS OUTPUT CONTROLS THE IGNITER TO PRODUCE THE MOST APPROPRIATE IGNITION TIMING FOR THE DRIVING CONDITIONS. * ISC (IDLE SPEED CONTROL) SYSTEM THE ISC SYSTEM INCREASES ENGINE SPEED AND PROVIDES IDLING STABILITY FOR FAST IDLEUP WHEN THE ENGINE IS COLD AND WHEN THE IDLE SPEED HAS DROPPED DUE TO ELECTRICAL LOAD, ETC. THE PCME (ECU) EVALUATES THE SIGNALS FROM EACH SENSOR (INPUT SIGNALS (1, 4 TO 8, 11, 12)), OUTPUTS CURRENT TO TERMINALS ISCO AND ISCC, AND CONTROLS THE ISC VALVE. * EGR CONTROL SYSTEM THE EGR CUT CONTROL SYSTEM CONTROLS THE VSV (FOR EGR) BY EVALUATING THE SIGNALS FROM EACH SENSOR INPUT TO THE PCME (ECU) (INPUT SIGNALS (1, 4, 10)) AND BY SENDING OUTPUT TO TERMINAL EGR OF THE PCME (ECU). * A/C CUT CONTROL SYSTEM WHEN THE VEHICLE SUDDENLY ACCELERATES FROM LOW ENGINE SPEED, THIS SYSTEM CUTS OFF AIR CONDITIONER OPERATION FOR A FIXED PERIOD OF TIME IN RESPONSE TO THE VEHICLE SPEED AND THROTTLE VALVE OPENING ANGLE IN ORDER TO MAINTAIN ACCELERATION PERFORMANCE. THE PCME (ECU) RECEIVES INPUT SIGNALS (5, 6), AND OUTPUTS SIGNALS TO TERMINAL ACT. * FUEL PRESSURE CONTROL SYSTEM THE FUEL PRESSURE UP SYSTEM CAUSES THE VSV (FOR FUEL PRESSURE UP) TO COME ON FOR HIGH TEMP. STARTS IN ORDER TO INCREASE THE FUEL PRESSURE, IMPROVE STARTABILITY AT HIGH TEMPERATURES AND PROVIDE STABLE IDLING. THE PCME (ECU) EVALUATES THE INPUT SIGNALS FROM EACH SENSOR (1, 2, 5, 11), OUTPUT CURRENT TO TERMINAL FPU AND CONTROLS THE VSV.

3. DIAGNOSIS SYSTEM

WITH THE DIAGNOSIS SYSTEM, WHEN THERE IS A MALFUNCTION IN THE PCME (ECU) SIGNAL SYSTEM, THE MALFUNCTION SYSTEM IS RECORDED IN THE MEMORY. THE MALFUNCTIONING SYSTEM CAN THEN BE FOUND BY READING THE DISPLAY (CODE) OF THE CHECK ENGINE WARNING LIGHT.

4. FAILSAFE SYSTEM

WHEN A MALFUNCTION OCCURS IN ANY SYSTEM, IF THERE IS A POSSIBILITY OF ENGINE TROUBLE BEING CAUSED BY CONTINUED CONTROL BASED ON THE SIGNALS FROM THAT SYSTEM, THE FAILSAFE SYSTEM EITHER CONTROLS THE SYSTEM BY USING DATA (STANDARD VALUES) RECORDED IN THE PCME (ECU) MEMORY OR ELSE STOPS THE ENGINE.

71

ENGINE CONTROL (5SFE)

R (M/T) RW RW (M/T) RW RW (A/T) I11 IGNITION SW ST2 6 R (M/T) R (A/T) 10 AM2 IG2 9 C9 CLUTCH START SW (M/T) 1 2 R (M/T) 9 IE4 R (M/T) RW (A/T) E3 E3 R (M/T) RW (A/T) 8 EA3 R (A/T) 3 N1 PNS (NEUTRAL START SW) (A/T)

FROM POWER SOURCE SYSTEM (SEE PAGE 48) 2

5 EA1 BO BR B

15A EFI 13 II3 4 IE4 1 BO

E2

B WR BY

BR

WR

BO

WR BY

2 5 1 BR 1 IE2 2 5 3

2 1 IGNITION MAIN RELAY

2 2

2 2 EFI MAIN RELAY 2 3 2

7. 5A AM2

4 2 BR 2

1 2

3 2

4 2 BY 1 2 4 2 5 2

CIRCUIT OPENING RELAY

2 5 1 II1

WB

BR

WB

BR

4 EB1

5 EB1

2 EB1 WB WB GR LB LB

BY

WB

(M/T) GR LB BY W W BR

BR BY 5 8 40A AM2 9 5 (A/T) 15 BM2 (M/T) 2 BM1 WB

BR

BR

E9 BR BR BR BR

LB

1 M 2 F4 FUEL PUMP

I4 INJECTOR NO. 1

I6 INJECTOR NO. 3

I5 INJECTOR NO. 2

5 W

1 W

1 W

1 W

I7 INJECTOR NO. 4

10

1 W WB

FL MAIN 2. 0L W

W E5 E11

(A/T)

BR

WB 6 (USA) 4 (CANADA)

I10 WB

BATTERY

J3 JUNCTION CONNECTOR (FOR EARTH)

WB

IC

ID

BG

72

WB BI

WB B26

* 1 : CANADA USA (A/T) USA (M/T) WITH CRUISE CONTROL, ABS, POWER WINDOW OR WOOFER SPEAKER FROM POWER SOURCE SYSTEM (SEE PAGE 48) RW RW (A/T) (M/T) 7. 5A GAUGE 1 FROM DEFOGGER SW

RY

2 1 RL

J1 JUNCTION CONNECTOR RL 1 13 RL (* 1) 9 3D RL (EX. * 1) 4 A (* 1)

J/B NO. 3

D2 DIODE (FOR ELECTRICAL IDLEUP SYSTEM) 2 RY 1 3A

9 3A

FROM TAILLIGHT RELAY

B WR BY

(A/T) RW (M/T) (A/T) RW (A/T)

J/B NO. 3

2 C11 A , C12 B B 8 IE1 2 A 12 B ELS B CHECK ENGINE WARNING LIGHT [COMB. METER]

2 3C 8 B 15 EA1 GW B20 GW GW 15 IE1 GW

E1 W

E6 A ,E6 B ,E7 F ,E7 C ,E8 D ,E8 E PCME (ENGINE AND ECT ECU (A/T) OR ENGINE ECU (M/T)) (A/T) (M/T) W

12 A 7 B +B

13 A 1 B +B1

1 A 2 B BATT

WR

BY

BY

11 A 2 E STA

22 A NSW

5 A 8 B

EGR

ISCO

ISCC

ISCV

FPU

TE2

TE1

# 20

# 10

FC

7 D 1 E

14 A 4 B

10 D 10 E

9 D 9 E

23 D 23 E

8 D 14 E

11 D 25 E

12 D 12 E

(A/T) (M/T)

14 F 7 C

15 F 15 C

8 F 3 C

VF

B B

RW

GR LB 8 EB1 GB LO C1 DCL (CHECK CONNECTOR) BY LB G R

(A/T)

GR

GB

LO

PL

V2 VSV (FOR EGR SYSTEM)

V3 VSV (FOR A/C IDLEUP SYSTEM) BY

1 I1 IACV (ISC VALVE)

V4 VSV (FOR FUEL PRESSUREUP)

7 TE2

6 TE1

9 VF1

11 OX2

4 OX

FP

+B 2

E1 3 BR

IG 18 BW BW

2 BY BY

BY

E10

BY

E16

BY BW

W W BR

GW

BY

FROM IGNITION COIL BR BR

73

ENGINE CONTROL (5SFE)

V1 MAP (VACUUM SENSOR) 1 BR 2 LGR 3 RL VC 4 RL VTA 3 W IDL 2 P E2 1 BR BR T2 THROTTLE POSITION SENSOR (A/T)

BR

E11

BR

E14 BR

BR

BR

E11

BR

E16

E4 EGRS (EGR GAS TEMP. SENSOR) (FOR CALIFORNIA)

1 E10 P

2 LGR RL FROM CRUISE CONTROL ECU BY W P 12 F 12 C IDL PSCT

BR

16 F 16 C E21

9 F 9 C E2

BR

10 F 13 C THG

2 F 2 C PIM

1 F 11 C VC

11 F 10 C VTA

OX2

OX1

NE+

NE

IGT

G+

5 F 1 C B

6 F 6 C

3 D 3 E

20 D 22 C

5 D 17 E TO TACHOMETER

4 D 4 E

18 D 5 E

17 D 18 E

16 A 7 E (M/T)

PS

15 A 21 E (M/T) LY

9 A 11 B VW (A/T) LY 14 IE1 VW (USA) 10 A 13 II4 (USA) C11 COMBINATION METER 6 A VW 5 SPD VW VW I10

B E5 B

(A/T)

E5 (SHIELDED)

3 EA1 (M/T) B

2 EA1 (M/T) LY

(SHIELDED)

13

IE1 B

(SHIELDED)

WR

IE3 (USA)

IE3 (USA)

5 EA3 O2 OXYGEN SENSOR (SUB) O1 DXYGEN SENSOR (MAIN) 1 1 1 2 B I3 IGNITER 5 3 4 2 1 4 3 P7 POWER STEERING ECU 1

II4 (USA) B

LY

II4 (USA)

D1 DISTRIBUTOR

14 EFI

BW BR BR

BR

BR

IDUP

SPD

IGF

BR

74

BR ID

A9 A/C AMPLIFIER 14 EA3 BR BR E3 BR BR 7 (M/T) 17 (A/T) RW BR 1 IH1 ACA 20 IH1 2 BR A14 A/C THERMISTOR 8 BM1 (M/T) 2 BM2 (A/T) 2 (M/T) RW Y 17 IH1 BW 15 10 PG IH1 PG 8 IE3 PG 21 A 6 B ACT EO1 13 D 13 E BR 26 D 26 E BR BR BR EA EO2 WL 1 2 ACT YG

BM1 BM2

1 I8 IATS (IN AIR TEMP. SENSOR) BR

E3 ECTS (EFI WATER TEMP. SENSOR)

15 EA3 2 Y

6 EA1

RW

(A/T)

(M/T) 6 BM1 (A/T)16 BM2 (M/T) RW BW (A/T) (M/T) 8 A 3 B ACA KNK 13 F 5 C ,E8 E BR (SHIELDED) K1 KNOCK SENSOR B 1 E5 BR E7 BR BR E11 BR BR E16 BR 14 D 24 E E1

4 F 4 C THW

3 F 3 C THA

3 A 14 C THE (A/T) (M/T) ,E8 D

E6

,E6

,E7

,E7 C

PCME (ENGINE AND ECT ECU (A/T) OR ENGINE ECU (M/T))

(SHIELDED) (SHIELDED) (SHIELDED) BR

BR

75

ENGINE CONTROL (5SFE)

SERVICE HINTS

E 6, E 7, E 8

PCME (ENGINE ECU (M/T) OR ENGINE AND ECT ECU (A/T))

VOLTAGE AT PCME (ECU) WIRING CONNECTORS

BATT +B +B1 IDL VC VTA : ALWAYS 9.014.0 VOLTS : 9.014.0 VOLTS (IGNITION SW AT ON POSITION) : 9.014.0 VOLTS (IGNITION SW AT ON POSITION) : 9.014.0 VOLTS (IGNITION SW ON AND THROTTLE VALVE OPEN) : 4.55.5 VOLTS (IGNITION SW AT ON POSITION) : 0.30.8 VOLTS (IGNITION SW ON AND THROTTLE VALVE FULLY CLOSED) : 3.24.9 VOLTS (IGNITION SW ON AND THROTTLE VALVE OPEN) PIM E2 : 3.33.9 VOLTS (IGNITION SW AT ON POSITION) #10, #20 E01, E02 : 9.014.0 VOLTS (IGNITION SW AT ON POSITION) THA E2 : 0.53.4 VOLTS (IGNITION SW ON AND INTAKE AIR TEMP. 20C, 68F) THW E2 : 0.21.0 VOLTS (IGNITION SW ON AND COOLANT TEMP. 80C, 176F) STA E1 : 6.014.0 VOLTS (ENGINE CRANKING) IGT E1 : 0.81.2 VOLTS (ENGINE CRANKING OR IDLING) W E1 : 9.014.0 VOLTS (NO TROUBLE AND ENGINE RUNNING) ACT E1 : 4.55.5 VOLTS (IGNITION SW ON AND AIR CONDITIONING ON) ACA E1 : 03.0 VOLTS (IGNITION SW ON AND AIR CONDITIONING ON) ISCC, ISCOE1 : 9.014.0 VOLTS (IGNITION SW AT ON POSITION) TE1 E1 : 9.014.0 VOLTS (IGNITION SW ON AND DLC (CHECK CONNECTOR) TE1E1 NOT CONNECTED) 03.0 VOLTS (IGNITION SW ON AND DLC (CHECK CONNECTOR) TE1E1 CONNECTED) NSW E1 : 03.0 VOLTS (IGNITION SW ON AND PNS (NEUTRAL START SW) POSITION P OR N RANGE)

9.014.0 VOLTS (IGNITION SW ON AND PNS (NEUTRAL START SW) EX. POSITION P OR N RANGE)

E1 E1 E1 E2 E2 E2

RESISTANCE AT PCME (ECU) WIRING CONNECTORS

(DISCONNECT WIRING CONNECTOR) IDL : INFINITY (THROTTLE VALVE OPEN) 2.3 KW OR LESS (THROTTLE VALVE FULLY CLOSED) VTA E2 : 3.310.0 KW (THROTTLE VALVE FULLY OPEN) 0.20.8 KW (THROTTLE VALVE FULLY CLOSED) VC E2 : 3.07.0 KW THA E2 : 2.03.0 KW (INTAKE AIR TEMP. 20C, 68F) THW E2 : 0.20.4 KW (COOLANT TEMP. 80C, 176F) G+ G : 0.170.21 KW ISCC, ISCO+B, +B1: 19.322.3 W E2

: PARTS LOCATION

CODE A9 A14 C1 C9 C10 C11 C12 D1 D2 E3 E4 E6 A B C A B 26 26 24 (5SFE) 26 26 26 26 24 (5SFE) 26 24 (5SFE) 24 (5SFE) 24 (5SFE) 24 (5SFE) E8 F4 I1 I3 I4 I5 I6 I7 I8 I11 E7 SEE PAGE CODE C F D E 24 (5SFE) 24 (5SFE) 24 (5SFE) 24 (5SFE) 26 24 (5SFE) 24 (5SFE) 24 (5SFE) 24 (5SFE) 24 (5SFE) 24 (5SFE) 24 (5SFE) 26 T2 V1 V2 V3 V4 SEE PAGE CODE J1 J3 K1 N1 O1 O2 P7 A B 26 26 24 (5SFE) 24 (5SFE) 24 (5SFE) 24 (5SFE) 27 24 (5SFE) 24 (5SFE) 24 (5SFE) 24 (5SFE) 24 (5SFE) 24 (5SFE) SEE PAGE

: RELAY BLOCKS

CODE 1 2 5 20 21 21 SEE PAGE RELAY BLOCKS (RELAY BLOCK LOCATION) R/B NO. 1 (LEFT KICK PANEL) R/B NO. 2 (ENGINE COMPARTMENT LEFT) R/B NO. 5 (FRONT LUGGAGE COMPARTMENT RIGHT)

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODE 3A 3C 3D 22 COWL WIRE AND J/B NO. 3 ( (BEHIND COMBINATION METER) ) SEE PAGE JUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

76

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODE EA1 EA3 EB1 IE1 IE2 IE3 IE4 IH1 II1 II3 II4 BM1 BM2 32 34 34 36 36 COWL WIRE AND A/C SUB WIRE (INSTRUMENT PANEL RIGHT) LUGGAGE ROOM WIRE AND COWL WIRE (RIGHT KICK PANEL) COWL WIRE AND LUGGAGE ROOM WIRE (RIGHT KICK PANEL) ENGINE ROOM MAIN WIRE AND COWL WIRE (ROOM PARTITION BOARD LEFT) COWL WIRE AND ENGINE ROOM MAIN WIRE (ROOM PARTITION BOARD LEFT) 32 ENGINE ROOM MAIN WIRE AND COWL WIRE (LEFT KICK PANEL) SEE PAGE 28 (5SFE) 28 (5SFE) 28 (5SFE) JOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION) ENGINE ROOM MAIN WIRE AND ENGINE WIRE (REAR LUGGAGE COMPARTMENT LEFT) ENGINE WIRE AND ENGINE ROOM MAIN WIRE (R/B NO. 2 INNER) ENGINE WIRE AND R/B NO. 2 (R/B NO. 2 INNER)

: GROUND POINTS

CODE EA IC ID BG BI SEE PAGE 28 (5SFE) 32 32 36 36 GROUND POINTS LOCATION INTAKE MANIFOLD INSTRUMENT PANEL BRACE LH RIGHT KICK PANEL UNDER THE LEFT CENTER PILLAR BACK PANEL CENTER

: SPLICE POINTS

CODE E1 E2 E3 E5 E7 E9 E10 28 (5SFE) (5S FE) ENGINE WIRE SEE PAGE 28 (5SFE) (5S FE) WIRE HARNESS WITH SPLICE POINTS ENGINE ROOM MAIN WIRE CODE E11 E14 E15 E16 I10 B20 B26 34 36 COWL WIRE ENGINE ROOM MAIN WIRE SEE PAGE WIRE HARNESS WITH SPLICE POINTS

28 (5SFE) (5S FE)

ENGINE WIRE

77

ENGINE CONTROL (5SFE)

78

Potrebbero piacerti anche

- Electrical Correcting Elements in Automatic Control and Regulation CircuitsDa EverandElectrical Correcting Elements in Automatic Control and Regulation CircuitsNessuna valutazione finora

- Engine Control (4AFE)Documento8 pagineEngine Control (4AFE)Bogári Gergő100% (4)

- Variable Speed AC Drives with Inverter Output FiltersDa EverandVariable Speed AC Drives with Inverter Output FiltersNessuna valutazione finora

- Engine Control (22R-E)Documento8 pagineEngine Control (22R-E)Michael DíazNessuna valutazione finora

- Aerospace Actuators 2: Signal-by-Wire and Power-by-WireDa EverandAerospace Actuators 2: Signal-by-Wire and Power-by-WireNessuna valutazione finora

- 2008-07-31 074935 04 CelicaDocumento10 pagine2008-07-31 074935 04 CelicaCesar Alarcón Solis100% (1)

- Corolla Engine ControlDocumento12 pagineCorolla Engine ControlPatricio ValenciaNessuna valutazione finora

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- 2004 Corolla Electrical Diagram - Engine ControlDocumento12 pagine2004 Corolla Electrical Diagram - Engine ControlNick Baptiste50% (2)

- Engine ControlDocumento8 pagineEngine ControlFSR140750% (2)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- Engine Control Toyota Corolla 2006Documento12 pagineEngine Control Toyota Corolla 2006tsuelectronico100% (2)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Valutazione: 2.5 su 5 stelle2.5/5 (3)

- Engine Control Celica 2000Documento12 pagineEngine Control Celica 2000Giovanni Morales100% (2)

- Engine Control For 1ZZ-FEDocumento10 pagineEngine Control For 1ZZ-FESutikno100% (4)

- Engine Control For 2TR-FE: 90 Toyota Tacoma (Em01D0U)Documento12 pagineEngine Control For 2TR-FE: 90 Toyota Tacoma (Em01D0U)DanielNessuna valutazione finora

- Toyota Sensors Basic WaveformsDocumento6 pagineToyota Sensors Basic Waveformscartronix2010100% (5)

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorDa EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNessuna valutazione finora

- 2uz-Fe Engine Control System - Sfi SystemDocumento4 pagine2uz-Fe Engine Control System - Sfi SystemMortada Alsonni83% (6)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetDa EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetValutazione: 2 su 5 stelle2/5 (1)

- Wire O2 05Documento1 paginaWire O2 05teachnatoNessuna valutazione finora

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetDa EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNessuna valutazione finora

- Engine Control (7A-Fe) : System OutlineDocumento10 pagineEngine Control (7A-Fe) : System OutlineNguyễn Duy HoàngNessuna valutazione finora

- 4runner ElectricalDocumento6 pagine4runner ElectricalGuillermo Amaya Parra100% (1)

- Protection of Substation Critical Equipment Against Intentional Electromagnetic ThreatsDa EverandProtection of Substation Critical Equipment Against Intentional Electromagnetic ThreatsNessuna valutazione finora

- CMP (Phase) MuranoDocumento8 pagineCMP (Phase) MuranoGuillermo RojasNessuna valutazione finora

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Da EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Valutazione: 4.5 su 5 stelle4.5/5 (3)

- 2azfe PinoutsDocumento6 pagine2azfe PinoutsMichael Ali100% (4)

- Flight Test Instrumentation: Proceedings of the Third International Symposium 1964Da EverandFlight Test Instrumentation: Proceedings of the Third International Symposium 1964M. A. PerryNessuna valutazione finora

- 1KR-FE Engine Control SystemDocumento346 pagine1KR-FE Engine Control SystemMortada Alsonni79% (19)

- Toyota Mil CodeDocumento3 pagineToyota Mil CodeinayyerNessuna valutazione finora

- DTC P0505 Idle Control System Malfunction: Circuit DescriptionDocumento3 pagineDTC P0505 Idle Control System Malfunction: Circuit DescriptionRC VilledaNessuna valutazione finora

- M 05 0486Documento0 pagineM 05 0486Vu LeNessuna valutazione finora

- CircuitsDocumento298 pagineCircuitsPeter SookNessuna valutazione finora

- ECU PinoutsDocumento6 pagineECU Pinoutsthaivan_phuthanh85% (72)

- Toyota EcuDocumento13 pagineToyota EcuNeskhy Montoya100% (3)

- 2004 Corolla Electrical Diagram - Cruise ControlDocumento6 pagine2004 Corolla Electrical Diagram - Cruise ControlNick BaptisteNessuna valutazione finora

- Br710-A2 Engine DescriptionDocumento19 pagineBr710-A2 Engine Descriptionmuters100% (1)

- NV and Vanos DME PinoutsDocumento4 pagineNV and Vanos DME Pinoutsrobertobaggio2009Nessuna valutazione finora

- 1kz-Te Pedal TroubleshootDocumento6 pagine1kz-Te Pedal TroubleshootLance Ramai100% (9)

- For3 Sec2 11 2Documento227 pagineFor3 Sec2 11 2orangewedge32Nessuna valutazione finora

- Engine Control (3Vz-E)Documento8 pagineEngine Control (3Vz-E)Fernando AntonioNessuna valutazione finora

- Diagrama D6HDocumento2 pagineDiagrama D6HPepe Alonzo71% (7)

- Fiat Marelli PDFDocumento21 pagineFiat Marelli PDFmazacotesNessuna valutazione finora

- Engine PerformanceDocumento965 pagineEngine Performance5cubero5Nessuna valutazione finora

- EHTC O&M-edn PDFDocumento24 pagineEHTC O&M-edn PDFprasanta_bbsrNessuna valutazione finora

- Diagnostic Trouble CodesDocumento6 pagineDiagnostic Trouble CodesTaras KNessuna valutazione finora

- TFE 731 Chap 76Documento42 pagineTFE 731 Chap 76Egor85100% (4)

- Conectores 2TR-FEDocumento7 pagineConectores 2TR-FERómulo Simón Lizarraga León84% (32)

- 93-94 Altima ECU PinoutDocumento7 pagine93-94 Altima ECU Pinoutmasakp100% (1)

- Computadora Toyota Manual de Pin OutDocumento11 pagineComputadora Toyota Manual de Pin OutAllvaro Torrico100% (2)

- 1MZ-FE Engine Control SystemRX300 99Documento11 pagine1MZ-FE Engine Control SystemRX300 99Jose Calle100% (1)

- Presentation On Electronic Control Unit (ECU) 92,77,83Documento19 paginePresentation On Electronic Control Unit (ECU) 92,77,83sahil k mehta100% (2)

- ABSDocumento4 pagineABSFSR1407Nessuna valutazione finora

- Ecu MappingDocumento8 pagineEcu MappingVitor SegniniNessuna valutazione finora

- 2tne65 EbvaDocumento24 pagine2tne65 Ebvaoleg7962Nessuna valutazione finora

- MGB Competition Preparation ManualDocumento39 pagineMGB Competition Preparation ManualYarg NitramNessuna valutazione finora

- Hamworthy Air Compressor Task ReportDocumento2 pagineHamworthy Air Compressor Task ReportBlair WhyteNessuna valutazione finora

- Parts CatalogDocumento77 pagineParts CatalogBarıs AtayNessuna valutazione finora

- Report On Turbo Cooling SystemDocumento33 pagineReport On Turbo Cooling SystemDeepakKumarNessuna valutazione finora

- Codigos Obd RENAULTDocumento1 paginaCodigos Obd RENAULTedsononoharaNessuna valutazione finora

- Cruiser 250cc Service ManualDocumento221 pagineCruiser 250cc Service ManualJordi Cervia FeliuNessuna valutazione finora

- 10056-2 275gl Packaging Guide 5-19-17 PDFDocumento185 pagine10056-2 275gl Packaging Guide 5-19-17 PDFDIego100% (2)

- JZS161 Toyota Aristo 2JZDocumento23 pagineJZS161 Toyota Aristo 2JZShaukat Zia100% (4)

- Technical Service Bulletin: NoticeDocumento20 pagineTechnical Service Bulletin: Noticekomodo30Nessuna valutazione finora

- Diesel Engine ComponentsDocumento33 pagineDiesel Engine ComponentsMurtaza AhmedNessuna valutazione finora

- Copenhagen: Man Diesel Primeserv Academy New Displays Ecs 0905Documento22 pagineCopenhagen: Man Diesel Primeserv Academy New Displays Ecs 0905Carlos TavaresNessuna valutazione finora

- Perkins 1600 Series Industrial Engine XGB Service Repair Manual 1 1618882555Documento26 paginePerkins 1600 Series Industrial Engine XGB Service Repair Manual 1 1618882555abdo rabo100% (2)

- TD 420 VeDocumento92 pagineTD 420 VepurushmicroNessuna valutazione finora

- Volvo Penta Inboard Diesel: Technical DataDocumento2 pagineVolvo Penta Inboard Diesel: Technical DataAlexNessuna valutazione finora

- 03 Engine Mechanical SystemDocumento161 pagine03 Engine Mechanical SystemUtomo BudidarmoNessuna valutazione finora

- 22-36" Pipe Bending Machine (HPB22-36) Technical Specifications and FeaturesDocumento1 pagina22-36" Pipe Bending Machine (HPB22-36) Technical Specifications and FeaturesAlexander Romero IzquierdoNessuna valutazione finora

- P440 Cylinder Block PDFDocumento3 pagineP440 Cylinder Block PDFNEKHIL MATTAANessuna valutazione finora

- 909J e 959J Parts BookDocumento405 pagine909J e 959J Parts BookGabriely MuriloNessuna valutazione finora

- Perkins 1103 and 1104c Engines Systems Operation Testing and AdjustingDocumento56 paginePerkins 1103 and 1104c Engines Systems Operation Testing and AdjustingSyed Azhar Hussain97% (33)

- 2.4l EngineDocumento237 pagine2.4l EngineRene SanchezNessuna valutazione finora

- DMM3 Us004467 NP-2657489817 CILINDRO PULLDOWN 5.000X3.500Documento2 pagineDMM3 Us004467 NP-2657489817 CILINDRO PULLDOWN 5.000X3.500RPINILLA (EICO S.A.)Nessuna valutazione finora

- Ford Ranger 2010 2.3LDocumento256 pagineFord Ranger 2010 2.3LLuis Ramon Arguello RealNessuna valutazione finora

- Jet Propulsion CycleDocumento5 pagineJet Propulsion CycleAnggita BayuNessuna valutazione finora

- Engine Performance Curve: Rating: Application:MarineDocumento4 pagineEngine Performance Curve: Rating: Application:Marinekman548Nessuna valutazione finora

- QSX15-G9: EPA NSPS CertifiedDocumento3 pagineQSX15-G9: EPA NSPS CertifiedMarcos Batista Dos SantosNessuna valutazione finora

- ECOTEC 2.0L LSJ Chap 1Documento18 pagineECOTEC 2.0L LSJ Chap 1Ailson MoreiraNessuna valutazione finora

- Exhaust Gas RecirculationDocumento4 pagineExhaust Gas RecirculationAjitKumarPandeyNessuna valutazione finora

- 3516C - 2100hp at 1750 Tier 2Documento5 pagine3516C - 2100hp at 1750 Tier 2woodyjumpsNessuna valutazione finora

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerDa EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerValutazione: 4.5 su 5 stelle4.5/5 (54)

- Automotive Electronic Diagnostics (Course 1)Da EverandAutomotive Electronic Diagnostics (Course 1)Valutazione: 5 su 5 stelle5/5 (6)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDa EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesValutazione: 4.5 su 5 stelle4.5/5 (21)

- The RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVDa EverandThe RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVValutazione: 5 su 5 stelle5/5 (2)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDa EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterNessuna valutazione finora

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDa EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestValutazione: 4 su 5 stelle4/5 (28)

- ANSYS Workbench 2023 R2: A Tutorial Approach, 6th EditionDa EverandANSYS Workbench 2023 R2: A Tutorial Approach, 6th EditionNessuna valutazione finora

- Why We Drive: Toward a Philosophy of the Open RoadDa EverandWhy We Drive: Toward a Philosophy of the Open RoadValutazione: 4 su 5 stelle4/5 (6)

- Shorting the Grid: The Hidden Fragility of Our Electric GridDa EverandShorting the Grid: The Hidden Fragility of Our Electric GridValutazione: 4.5 su 5 stelle4.5/5 (2)

- OBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceDa EverandOBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceNessuna valutazione finora

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsDa EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsValutazione: 4.5 su 5 stelle4.5/5 (2)

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionValutazione: 5 su 5 stelle5/5 (1)

- The Official Highway Code: DVSA Safe Driving for Life SeriesDa EverandThe Official Highway Code: DVSA Safe Driving for Life SeriesValutazione: 3.5 su 5 stelle3.5/5 (25)

- CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]Da EverandCDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]Valutazione: 5 su 5 stelle5/5 (2)

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceDa EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceNessuna valutazione finora

- Tips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)Da EverandTips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)Nessuna valutazione finora

- A Pathway to Decarbonise the Shipping Sector by 2050Da EverandA Pathway to Decarbonise the Shipping Sector by 2050Nessuna valutazione finora

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsDa EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNessuna valutazione finora

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDa EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideValutazione: 4.5 su 5 stelle4.5/5 (8)

![CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]](https://imgv2-2-f.scribdassets.com/img/audiobook_square_badge/710834945/198x198/00b81cbbd3/1714482720?v=1)