Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Above Ground Piping

Caricato da

Christopher RothDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Above Ground Piping

Caricato da

Christopher RothCopyright:

Formati disponibili

FIRE PROTECTION BUREAU PLAN REVIEW PO Box 42600 Olympia WA 98504-2600 (360) 596-3911 FAX: (360) 596-3934

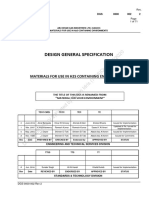

CONTRACTORS MATERIALS AND TEST REPORT FOR ABOVEGROUND PIPING

PROCEDURE Upon completion of work, inspection and test shall be made by the contractors representative and witnessed by an owners representative. All defects shall be corrected and system left in service before contractors personnel finally leave the job. A certificate shall be filled out and signed by both representatives. Copies shall be prepared for approving authorities, owners, and contractor. It is understood the owners representatives signature in no way prejudices any claim against contractor for faulty material, poor workmanship, or failure to comply with approving authoritys requirements or local ordinances.

PROPERTY NAME DATE

PROPERTY ADDRESS

ACCEPTED BY APPROVING AUTHORITIES (NAME)

ADDRESS PLANS INSTALLATION CONFORMS TO ACCEPTED PLANS EQUIPMENT USED IS APPROVED IF NO, EXPLAIN DEVIATION HAS PERSON IN CHARGE OF FIRE EQUIPMENT BEEN INSTRUCTED AS TO LOCATION OF CONTOL VALVE AND CARE AND MAINTENANCE OF THIS NEW EQUIPMENT? IF NO, EXPLAIN INSTRUCTIONS HAVE COPIES OF THE FOLLOWING BEEN LEFT ON THE PREMISES: 1. SYSTEM COMPONENTS INSTRUCTIONS 2. CARE AND MAINTENANCE INSTRUCTIONS 3. NFPA 13 LOCATION OF SYSTEM SUPPLIES BUILDINGS MAKE MODEL YEAR OF MANUFACTURE ORIFICE SIZE QUANTITY TEMPERATURE RATING YES YES NO NO

YES

NO

YES YES YES

NO NO NO

SPRINKLERS

TYPE OF PIPE PIPE AND FITTINGS

TYPE OF FITTINGS

ALARM DEVICE TYPE ALARM VALVE OR FLOW INDICATOR MAKE MODEL

MAXIMUM TIME TO OPERATE THROUGH TEST CONNECTION MINUTES SECONDS

3000-450-001 7/07

Page 1

DRY VALVE MAKE MODEL SERIAL NO. MAKE

QUICK OPENING DEVICE MODEL SERIAL NO.

DRY PIPE OPERATING TEST WITHOUT Q.O.D. WITH Q.O.D. IF NO, EXPLAIN OPERATION

TIME TO TRIP THRU TEST CONNECTION MIN SEC

WATER PRESSURE PSI

AIR PRESSURE PSI

TRIP POINT AIR PRESSURE PSI

TIME WATER REACHED TEST OUTLET MIN SEC

ALARM OPERATED PROPERLY YES NO

PNEUMATIC YES NO

ELECTRIC

HYDRAULIC YES YES NO NO

PIPING SUPERVISED

DETECTING MEDIA SUPERVISED IF NO, EXPLAIN

DOES VALVE OPERATE FROM THE MANUAL TRIP AND/OR REMOTE CONTROL STATIONS? DELUGE & PREACTION VALVES IS THERE AN ACCESSIBLE FACILITY IN EACH CIRCUIT FOR TESTING? YES MAKE MODEL NO DOES EACH CIRCUIT OPERATE VALVE RELEASE? YES NO DOES EACH CIRCUIT OPERATE SUPERVISION LOSS ALARM? YES NO

MAXIMUM TIME TO OPERATE RELEASE YES NO

TEST DESCRIPTION

HYDROSTATIC: Hydrostatic levels shall be made at not less that 200 psi (13.6 bars) for two hours of 50 psi (3.4 bars) above static pressure in excess of 150 psi (10.2 bars) for two hours. Differential dry-pipe valve clappers shall be left open during test to prevent damage. All aboveground piping leakage shall be stopped. PNEUMATIC: Establish 40 psi (2.7 bars) air pressure and measure drop which shall not exceed 1 psi (0.1 bars) in 24 hours. Test pressure tanks at normal water level and air pressure and measure air pressure drop which shall not exceed 1 psi (0.1 bars) in 24 hours ALL PIPING HYDROSTATICALLY TESTED AT FOR HRS IF NO, STATE REASON DRY PIPING PNEUMATICALLY TESTED YES NO EQUIPMENT OPERATES PROPERLY YES NO DO YOU CERTIFY AS THE SPRINKLER SYSTEM CONTRACTOR THAT ADDITIVES AND CORROSIVE CHEMICALS, SODIUM SILICATE OR DERIVATIVES OF SODIUM SILICATE, BRINE OR OTHER CORROSIVE CHEMICALS WERE NOT USED FOR TESTING SYSTEMS OR YES NO STOPPING LEAKS? RESIDULE PRESSURE WITH VALVE IN TEST DRAIN READING OF GAGE LOCATED NEAR WATER SUPPLY TEST PSI CONNECTION OPEN WIDE: PSI TEST CONNECTION: UNDERGROUND MAINS AND LEAD IN CONNECTIONS TO SYSTEM RISERS FLUSHED BEFORE CONNECTION MADE TO SPRINKLER PIPING. VERIFIED BY COPY OF THE U FORM NO 85B YES NO FLUSHED BY INSTALLER OF UNDERGROUND SPRINKLER PIPING IF NO, EXPLAIN NUMBER USED LOCATIONS YES NO

TESTS

BLANK TESTING GASKETS

NUMBER REMOVED

WELDED PIPING YES NO IF YES, COMPLETE BELOW DO YOU CERTIFY AS THE SPRINKLER CONTRACTOR THAT WELDING PROCEDURES COMPLY WITH THE REQUIREMENTS OF AT LEAST AWS D10.9, LEVEL AR-3? WELDING DO YOU CERTIFY THAT THE WELDING WAS PERFORMED BY WELDERS QUALIFIED IN COMPLIANCE WITH THE REQUIREMENTS OF AT LEAST AWS D10.9, LEVEL AR-3? DO YOU CERTIFY THAT WELDING WAS CARRIED OUT IN COMPLIANCE WITH A DOCUMENTED QUALITY CONTROL PROCEDURE TO ENSURE THAT ALL DISCS ARE RETRIEVED, THAT OPENINGS IN PIPING ARE SMOOTH, THAT SLAG AND OTHER WELDING RESIDUE ARE REMOVED, AND THAT THE INTERNAL DIAMETERS OF PIPING ARE NOT PENETRATED? DO YOU CERTIFY THAT YOU HAVE A CONTROL FEATURE TO ENSURE THAT ALL CUTOUTS (DISCS) ARE RETRIEVED? DOES AHJ REQUIRE A FUNCTIONAL FLOW TEST OF RESIDENTIAL SPRINKLERS? WERE FUNCTIONAL FLOW TEST RESULTS SATISFACTORY? IF NO, EXPLAIN NAME PLATE PROVIDED YES NO

YES

NO

YES

NO

YES

NO YES YES YES NO NO NO

CUTOUTS (DISCS) FUNCTIONAL FLOW TEST HYDRAULIC DATA NAMEPLATE REMARKS

DATE LEFT IN SERVICE WITH ALL CONTROL VALVES OPEN: NAME OF SPRINKLER CONTRACTOR CONTRACTOR LICENSE # DATE

SIGNATURES PROPERTY OWNER OR REPRESENTATIVE

TESTS WITNESSED BY TITLE DATE

3000-450-001 7/07

Page 2

Potrebbero piacerti anche

- Flanges - Introduction: Flanges I Boltings I Gaskets I Flanged Fittings FlangesDocumento6 pagineFlanges - Introduction: Flanges I Boltings I Gaskets I Flanged Fittings FlangesshyamNessuna valutazione finora

- S# Item Qty Unit Index Plant - Sloc Shortfall Remarks Availablt QtyDocumento1 paginaS# Item Qty Unit Index Plant - Sloc Shortfall Remarks Availablt QtyAtif HusaynNessuna valutazione finora

- Piping Arrangement Piping Isometric-SpoolDocumento33 paginePiping Arrangement Piping Isometric-Spooldian septiadiNessuna valutazione finora

- Copia de EPCDocumento32 pagineCopia de EPCPeter RodriguezNessuna valutazione finora

- Input Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)Documento12 pagineInput Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)ibmsherNessuna valutazione finora

- Piping Work 5Documento17 paginePiping Work 5Sastra WinataNessuna valutazione finora

- Project: Date Jobno: Designed ACTIVITY: Utility Pipe/ Valve Workshop Checked SheetDocumento36 pagineProject: Date Jobno: Designed ACTIVITY: Utility Pipe/ Valve Workshop Checked SheetGeorge Georgian100% (1)

- Reflected in WPS If Accepted: FCC BCC HCP FCC Ductile BCC FCC TightDocumento3 pagineReflected in WPS If Accepted: FCC BCC HCP FCC Ductile BCC FCC TightAnonymous DMdGdsOENessuna valutazione finora

- TLV - Manifolds Vapor y Condensado PDFDocumento4 pagineTLV - Manifolds Vapor y Condensado PDFsirballesterosNessuna valutazione finora

- Valve DetailDocumento5 pagineValve DetailRakesh RanjanNessuna valutazione finora

- Piping QTDocumento51 paginePiping QTSaif Ul Haq Mohammed100% (1)

- DGS 0000 002 Rev 2Documento71 pagineDGS 0000 002 Rev 2Anoop NairNessuna valutazione finora

- Autocad Tip - Line, Spline or Polyline? Creating Linework: SurveyDocumento3 pagineAutocad Tip - Line, Spline or Polyline? Creating Linework: SurveyAnonymous dh6DITNessuna valutazione finora

- Febolt: Hexagon Covernut Type "Febolt"Documento1 paginaFebolt: Hexagon Covernut Type "Febolt"Tuntun TatNessuna valutazione finora

- Structural Equivalency SheetDocumento73 pagineStructural Equivalency Sheetboim1234Nessuna valutazione finora

- Piping ForemanDocumento3 paginePiping ForemanManoj MissileNessuna valutazione finora

- Steel Member SizesDocumento265 pagineSteel Member SizesMubashar HassanNessuna valutazione finora

- Sample2 DrawingDocumento1 paginaSample2 DrawingSourav HaitNessuna valutazione finora

- Piping FabricationDocumento5 paginePiping FabricationTa AndiniNessuna valutazione finora

- Plaster Calculation V6Documento34 paginePlaster Calculation V6bedianchoiNessuna valutazione finora

- Metric Fine Screw Threads Taper Pipe ThreadsDocumento1 paginaMetric Fine Screw Threads Taper Pipe Threadsmanuelq9100% (1)

- Engineering All in OneDocumento245 pagineEngineering All in OneozchrisNessuna valutazione finora

- Tank Design and DetailingDocumento17 pagineTank Design and DetailingFuatNessuna valutazione finora

- Drawing List: Rev. Date: API650 STORAGE TANK Chilled Water Tank (05T009) Irpc Plc. Technip (Thailand) B 7/22/2013Documento4 pagineDrawing List: Rev. Date: API650 STORAGE TANK Chilled Water Tank (05T009) Irpc Plc. Technip (Thailand) B 7/22/2013chompink6900Nessuna valutazione finora

- Pigging Valves PDFDocumento8 paginePigging Valves PDFmarkobilo100% (1)

- Short List of Applied Piping Standard PDFDocumento3 pagineShort List of Applied Piping Standard PDFmohamad3010Nessuna valutazione finora

- Wall Thickness Calculations - Using B31.4 Code: T P D S FDocumento1 paginaWall Thickness Calculations - Using B31.4 Code: T P D S FRamalingam PrabhakaranNessuna valutazione finora

- How To Order Alfa ValveDocumento0 pagineHow To Order Alfa ValveZoebairNessuna valutazione finora

- CouplingsDocumento6 pagineCouplingsSherif AdelNessuna valutazione finora

- Tori SphericalDocumento62 pagineTori SphericalWebsoft Tech-HydNessuna valutazione finora

- Tips For Piping Designer Interviews. - Piping Designer Jobs - IndeedDocumento5 pagineTips For Piping Designer Interviews. - Piping Designer Jobs - Indeedprakhar agarwalNessuna valutazione finora

- 7-13-0001 Rev 6Documento1 pagina7-13-0001 Rev 6cynideNessuna valutazione finora

- Thermowell Calculation Guide V1.3Documento19 pagineThermowell Calculation Guide V1.3AymanelorbanyNessuna valutazione finora

- Method Statement For Fabrication, Installation, Testing and Flushing of Aboveground Metallic PipingDocumento30 pagineMethod Statement For Fabrication, Installation, Testing and Flushing of Aboveground Metallic Pipingsarsan nedumkuzhi maniNessuna valutazione finora

- Dots in ASME B36.10 Under Schedule TableDocumento5 pagineDots in ASME B36.10 Under Schedule TableIbrahim BashaNessuna valutazione finora

- S o P-PipingDocumento17 pagineS o P-PipingPrakash TiwariNessuna valutazione finora

- Piping Coordination SystemsDocumento17 paginePiping Coordination SystemsSyed FarhanNessuna valutazione finora

- Design Criteria FOR Centrifugal Compressors: Saudi Arabian Oil CompanyDocumento19 pagineDesign Criteria FOR Centrifugal Compressors: Saudi Arabian Oil CompanyNicolaMasteNessuna valutazione finora

- TRAN PICE Development 1 1Documento1 paginaTRAN PICE Development 1 1mohdnazirNessuna valutazione finora

- Ansul F-85154Documento2 pagineAnsul F-85154jlvega18Nessuna valutazione finora

- Reducing-Tee Mechanical Piping PDFDocumento4 pagineReducing-Tee Mechanical Piping PDFanjargoklithNessuna valutazione finora

- Manhour StandardsDocumento6 pagineManhour StandardsErick EnriquezNessuna valutazione finora

- Piping Designers Vessel OrientationDocumento13 paginePiping Designers Vessel OrientationkazishidotaNessuna valutazione finora

- Bom Storage Tank (M.S.)Documento8 pagineBom Storage Tank (M.S.)Varun MalhotraNessuna valutazione finora

- Bend Pipes (1996 N3.2)Documento2 pagineBend Pipes (1996 N3.2)dmitos100% (1)

- Annual Report HELLENIC PETROLEUM 2010Documento77 pagineAnnual Report HELLENIC PETROLEUM 2010AbdelmotelbElbannaNessuna valutazione finora

- Kamos Gasket For PipelineDocumento3 pagineKamos Gasket For PipelineKenn Way LeeNessuna valutazione finora

- Presentation For KOM Vendor-SubcontDocumento19 paginePresentation For KOM Vendor-Subcontahmad kusumaNessuna valutazione finora

- 010 Subsea Hose PDFDocumento16 pagine010 Subsea Hose PDFJhonatan FerreiraNessuna valutazione finora

- PVC Vs Polyurethane A Tubing ComparisonDocumento8 paginePVC Vs Polyurethane A Tubing ComparisonAdnan SheikhNessuna valutazione finora

- Piping Rate ListDocumento12 paginePiping Rate Listshawanqureshi1706160Nessuna valutazione finora

- Asme Ix - Welder Id Rev.2Documento5 pagineAsme Ix - Welder Id Rev.2Joseph Peter100% (1)

- Wrapping Material CalculationDocumento1 paginaWrapping Material CalculationBiginchNessuna valutazione finora

- Mto ProcedureDocumento3 pagineMto ProcedureakilasrivatsavNessuna valutazione finora

- Putting It All Together: OperationsDocumento34 paginePutting It All Together: OperationsIbrahim FaqaihNessuna valutazione finora

- NDT Request Form (Piping) : Wara Pressure Maintenance ProjectDocumento7 pagineNDT Request Form (Piping) : Wara Pressure Maintenance ProjectVimin PrakashNessuna valutazione finora

- VALVES - NotesDocumento17 pagineVALVES - NotesPortifer Harrison Ray Mubanga100% (1)

- Level WBS Code WBS NameDocumento2 pagineLevel WBS Code WBS NameAlwanNessuna valutazione finora

- ContractorsAbovegroundPiping PDFDocumento2 pagineContractorsAbovegroundPiping PDFIvan SFNessuna valutazione finora

- Certificate Aboveground PipingDocumento5 pagineCertificate Aboveground Pipingsajeed76740Nessuna valutazione finora

- PWPS MultiDrive PotablePump Control Sequence-Rev3Documento5 paginePWPS MultiDrive PotablePump Control Sequence-Rev3md_rehan_2Nessuna valutazione finora

- Oxygen and Argon SeparationDocumento8 pagineOxygen and Argon SeparationazizkhouribgaNessuna valutazione finora

- Welcome To: MMUP Engineers Registration Exam Preparation CourseDocumento101 pagineWelcome To: MMUP Engineers Registration Exam Preparation CourseHanda Bin AdiNessuna valutazione finora

- Biogas Upgrading Haffmans Case-Study Schaap-Tirns enDocumento2 pagineBiogas Upgrading Haffmans Case-Study Schaap-Tirns enVinicius NoronhaNessuna valutazione finora

- Hydrostatic Pressure Test Safety CheckDocumento3 pagineHydrostatic Pressure Test Safety CheckSreekumar K SNessuna valutazione finora

- Paper - 2 - SetB - QADocumento14 paginePaper - 2 - SetB - QANataraj Singh SardarNessuna valutazione finora

- Manual Bomba de Aceite 1701053Documento9 pagineManual Bomba de Aceite 1701053ventas freyreNessuna valutazione finora

- Cooling Tower Exp 2 Students' ManualDocumento23 pagineCooling Tower Exp 2 Students' ManualDAYANG NUR SYAZANA AG BUHTAMAMNessuna valutazione finora

- Existing Skid Details For Existing Corrosion Inhibitor Injection SkidsDocumento1 paginaExisting Skid Details For Existing Corrosion Inhibitor Injection SkidsMohamed Wasim ShaikhNessuna valutazione finora

- Chapter 13 Fluids Conceptual Problems PDFDocumento76 pagineChapter 13 Fluids Conceptual Problems PDFTransAm FajariansyahNessuna valutazione finora

- Type 441 - Standard & High Pressure SeriesDocumento16 pagineType 441 - Standard & High Pressure SeriesnagarajhebbarNessuna valutazione finora

- Tutorial 6 Question ThermodynamicsDocumento3 pagineTutorial 6 Question ThermodynamicsWaheeda SainiNessuna valutazione finora

- Grreenhouse Experiment Lab ReportDocumento3 pagineGrreenhouse Experiment Lab ReportMaria AbregoNessuna valutazione finora

- Stator Cooling PumpDocumento10 pagineStator Cooling Pumpfelix asadeNessuna valutazione finora

- Rig HydraulicsDocumento9 pagineRig Hydraulicsmihir1810100% (1)

- LabReport Gas DiffusionDocumento21 pagineLabReport Gas DiffusionSharing Caring83% (6)

- (8.3) Distillation ColumnDocumento21 pagine(8.3) Distillation ColumnAsad SaeedNessuna valutazione finora

- Study The Water Hammer Phenomena It's Causes and Solutions: M.SC. Mudafer Kadum Kredi M.SC. Lammia'a Abdulrudah AbdDocumento25 pagineStudy The Water Hammer Phenomena It's Causes and Solutions: M.SC. Mudafer Kadum Kredi M.SC. Lammia'a Abdulrudah AbdYazNessuna valutazione finora

- Turbo-Compressor Aerodynamic Test at A Turbine Altitude Test FacilityDocumento9 pagineTurbo-Compressor Aerodynamic Test at A Turbine Altitude Test FacilityMiguelMazzucchelliNessuna valutazione finora

- Basic Operations of Pumps, Valves, and FittingsDocumento24 pagineBasic Operations of Pumps, Valves, and FittingsMichelle BinwagNessuna valutazione finora

- C-SCP360H38B R410aDocumento8 pagineC-SCP360H38B R410aRaúl RodríguezNessuna valutazione finora

- Wet Gas Measurement ISO TR 11583Documento36 pagineWet Gas Measurement ISO TR 11583Aldrin HernandezNessuna valutazione finora

- VentilationDocumento29 pagineVentilationGaurika GroverNessuna valutazione finora

- Sonatrach: JOB NO.: J6404Documento56 pagineSonatrach: JOB NO.: J6404Rabah AmidiNessuna valutazione finora

- Air Velocity MeasurementDocumento8 pagineAir Velocity Measurementfakursanat3618Nessuna valutazione finora

- Engineering & Installation ManualDocumento61 pagineEngineering & Installation ManualThameem AnsariNessuna valutazione finora

- ABE-36 MIR Request LogDocumento180 pagineABE-36 MIR Request LogFranklyn GenoveNessuna valutazione finora

- Mass, Energy and Momentum BalancesDocumento10 pagineMass, Energy and Momentum BalancesHaidee Ramos EdaNessuna valutazione finora

- 4915 PDFDocumento79 pagine4915 PDFyyamidNessuna valutazione finora

- Quiz PHASE EQUILIBRIA (Set 2)Documento4 pagineQuiz PHASE EQUILIBRIA (Set 2)Supia NazmaNessuna valutazione finora