Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Stage 1 Shroud For FS7001B

Caricato da

teedee1Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Stage 1 Shroud For FS7001B

Caricato da

teedee1Copyright:

Formati disponibili

GE Energy

CONTINUUM Stage 1 Shroud for Frame 7B Turbines

Developed as a direct replacement on 7B turbines, GE Energys stage 1 shroud is made of forged stainless steel, a nickel-aluminum bond coating and a plasma spray top coating. With a Bus Bar shroud seal and pumpkin tooth design, this shroud offers a life expectancy of 72,000 hours and is capable of operating at firing temperatures up to 2055F. Note: Three different kits (or parts packages) are available depending on your existing stage 2 nozzle configuration.

Short sidewall Wide turbine shell interface

fact sheet

Order parts based on existing stage 2 nozzle configuration

For this Existing Nozzle Configuration Long sidewall Order these Parts Narrow Shroud Design: 10 of part #: 678D0446P002 38 of part #: 678D0446P006 Wide Shroud Design: Kit #: 329A3481G002 Shroud Seal Keys: 46 of part #: 172C9090P001 2 of part #: 172C9091P001 Hybrid (Guppy) Shroud Design: Kit #: 329A3444G002 Shroud Seal Keys: 46 of part #: 172C9090P001 2 of part #: 172C9091P001

Features

Forged Stainless Steel Material

This stage 1 shroud is made from forged stainless steel (Grade 310 or 316) that provides excellent high temperature properties, good ductility and weld-ability. It also offers increased oxidation resistance compared to previously used materials.

Short sidewall Narrow turbine shell interface

Note: All three designs are interchangeable with advanced technology HR-120 Stage 1 Shrouds. Refer to GER3571 for information about the new HR-120 material shrouds.

Sealing Designs

The pumpkin tooth seal design provides inter-segment locking between each shroud segment. This design feature along with the Bus Bar shroud seal reduces leakage between shroud segments, resulting in desirable cooling airflow.

Stainless Steel Stage 1 Shroud

Material Bond Coating Top Coating Seal Firing Temp Forged SS-310 or SS-316 Nickel-aluminum Plasma spray Bus Bar and Pumpkin Tooth Up to 2035F

Benefits

Designed life expectancy of three hot gas path inspections (72,000 hours for gas only, dry, base loaded operation) Capable of operation at firing temperatures up to 2035F

Applicability

This offering is applicable for use with frame 7B gas turbines.

To learn more about this product and its applicability to your gas turbine, please contact your GE Energy sales representative.

2006, General Electric Company. All rights reserved. GEA-14188 (05/06)

Potrebbero piacerti anche

- Reinforced Concrete Design Solution Manual 7th Edition PDFDocumento5 pagineReinforced Concrete Design Solution Manual 7th Edition PDFEdmond Orena BautistaNessuna valutazione finora

- Technical Information Letter: Thermal Engineering Product Service TIL 1108-R1Documento7 pagineTechnical Information Letter: Thermal Engineering Product Service TIL 1108-R1Heryanto SyamNessuna valutazione finora

- Abradable Seals GEDocumento12 pagineAbradable Seals GEdimitrisNessuna valutazione finora

- Weld Like a Pro: Beginning to Advanced TechniquesDa EverandWeld Like a Pro: Beginning to Advanced TechniquesValutazione: 4.5 su 5 stelle4.5/5 (6)

- Plastic Films Made From Low-Density Polyethylene and Linear Low-Density Polyethylene For General Use and Packaging ApplicationsDocumento5 paginePlastic Films Made From Low-Density Polyethylene and Linear Low-Density Polyethylene For General Use and Packaging ApplicationsNasrin Akhondi100% (1)

- Encofrado Meva Alufix AvaDocumento42 pagineEncofrado Meva Alufix AvapablopelaNessuna valutazione finora

- Mtu Motoren-And Turbinen-Union Munchen GMBH Munich, GermanyDocumento9 pagineMtu Motoren-And Turbinen-Union Munchen GMBH Munich, Germanyjohnson_regoNessuna valutazione finora

- Shield Assembly and Disassembly: GE EnergyDocumento10 pagineShield Assembly and Disassembly: GE EnergyEduard MachadoNessuna valutazione finora

- Experimental and Numerical Investigations On The Leakage Flow Characteristics of The Labyrinth Brush SealDocumento10 pagineExperimental and Numerical Investigations On The Leakage Flow Characteristics of The Labyrinth Brush SealНиколайNessuna valutazione finora

- Til 1539Documento13 pagineTil 1539Michael JordanNessuna valutazione finora

- Himeji Number 2 Goes CommercialDocumento13 pagineHimeji Number 2 Goes CommercialSujeet KumarNessuna valutazione finora

- Ferrous: AlloysDocumento18 pagineFerrous: AlloyssunsirNessuna valutazione finora

- Avon UTC 1535c3Documento9 pagineAvon UTC 1535c3juanaNessuna valutazione finora

- 06 Advanced Technology OfferingsDocumento27 pagine06 Advanced Technology Offeringsatfrost4638Nessuna valutazione finora

- Mil HDBK 506Documento15 pagineMil HDBK 506Jais JohnNessuna valutazione finora

- ThermallySprayedAbradableCoatings 2012.10Documento9 pagineThermallySprayedAbradableCoatings 2012.10Thanaraj SanmughamNessuna valutazione finora

- Technical Information Letter: Ge Power TIL 2445 Product ServiceDocumento4 pagineTechnical Information Letter: Ge Power TIL 2445 Product ServiceMinhajur Rahman100% (1)

- SB LM2500 Ind 312 R1Documento7 pagineSB LM2500 Ind 312 R1Daniil SerovNessuna valutazione finora

- B7 Versus B16 BoltsDocumento3 pagineB7 Versus B16 BoltsMichael SandersNessuna valutazione finora

- Fouling Preventive CoatingsDocumento3 pagineFouling Preventive CoatingsAnonymous PkeI8e84RsNessuna valutazione finora

- TIL 1304 3 - 9th Stage Stator Casing Hook Fit CrackingDocumento4 pagineTIL 1304 3 - 9th Stage Stator Casing Hook Fit CrackinghernangNessuna valutazione finora

- Man Diesel Gas Turbines PDFDocumento6 pagineMan Diesel Gas Turbines PDFnebojsabraticNessuna valutazione finora

- 2 1 01 Auxiliary Gear BoxDocumento30 pagine2 1 01 Auxiliary Gear BoxHeryanto SyamNessuna valutazione finora

- Turbine Blade FailureDocumento5 pagineTurbine Blade Failuremanojpuru100% (1)

- GER3620L Nov 3 09b 1Documento60 pagineGER3620L Nov 3 09b 1rafieeNessuna valutazione finora

- Türbin Seal SistemleriDocumento72 pagineTürbin Seal SistemleriJoseph100% (1)

- 3.4 Final PaperDocumento22 pagine3.4 Final PaperinterveiwNessuna valutazione finora

- GE 7EA Gas Turbine DetailsDocumento10 pagineGE 7EA Gas Turbine DetailsEnder Galvis100% (1)

- IEC Motor HyundaiDocumento19 pagineIEC Motor HyundaiDendi DenisNessuna valutazione finora

- Igv 7eaDocumento2 pagineIgv 7eaSamir BenabdallahNessuna valutazione finora

- Fact Sheet Til 1292Documento2 pagineFact Sheet Til 1292PervimNessuna valutazione finora

- Applicability Guide PDFDocumento2 pagineApplicability Guide PDFtriplbingaziNessuna valutazione finora

- Gas Turbine Materials - Current Status AnDocumento15 pagineGas Turbine Materials - Current Status Anadepaul62Nessuna valutazione finora

- Coatings Guide: Air Intake Air Intake Exhaust Compressor Compressor Combustor Combustor Turbine TurbineDocumento1 paginaCoatings Guide: Air Intake Air Intake Exhaust Compressor Compressor Combustor Combustor Turbine TurbinefrdnNessuna valutazione finora

- CBN Blade Tip AbradableDocumento8 pagineCBN Blade Tip Abradablebehtam2407Nessuna valutazione finora

- Turbine Blade Repair TechnologiesDocumento4 pagineTurbine Blade Repair TechnologiesuuseppNessuna valutazione finora

- 4Q2005 7EA UsersGrpDocumento19 pagine4Q2005 7EA UsersGrpaxl1Nessuna valutazione finora

- Nilai MK Post-Intermediate Listening 2017Documento6 pagineNilai MK Post-Intermediate Listening 2017Ledi Wakha WakhaNessuna valutazione finora

- Gea32081a LM6000 - Pa - Us - R1 - LRDocumento1 paginaGea32081a LM6000 - Pa - Us - R1 - LRErik Van GroningenNessuna valutazione finora

- Peppers Catalogue PDFDocumento64 paginePeppers Catalogue PDFStone123456789Nessuna valutazione finora

- Technical Paper - SGT400 ASME 2002Documento9 pagineTechnical Paper - SGT400 ASME 2002usaid saifullahNessuna valutazione finora

- Blade-St: The Complete Steam Turbine Blade Analysis ToolDocumento8 pagineBlade-St: The Complete Steam Turbine Blade Analysis Toolramnadh803181Nessuna valutazione finora

- Nickel Base Alloy GTD 222Documento2 pagineNickel Base Alloy GTD 222JJNessuna valutazione finora

- Fuel NozzlesDocumento3 pagineFuel Nozzlesfrancisco_navas4479100% (1)

- Ansaldo Thomassen - CMU (2014)Documento4 pagineAnsaldo Thomassen - CMU (2014)guerrezNessuna valutazione finora

- Industrial Steam Turbine Value Packages: EnergyDocumento30 pagineIndustrial Steam Turbine Value Packages: EnergySina AtabakNessuna valutazione finora

- NIC 12.02 - Rev.01 Axial Displacement Inspection Procedure For Axial Andcentrifugal Compressors PDFDocumento29 pagineNIC 12.02 - Rev.01 Axial Displacement Inspection Procedure For Axial Andcentrifugal Compressors PDFDjaber ElhaicharNessuna valutazione finora

- MHPS D Class GT UpratesDocumento6 pagineMHPS D Class GT Uprateskp pkNessuna valutazione finora

- I A G T C: Ndustrial Pplication OF AS Urbines OmmitteeDocumento13 pagineI A G T C: Ndustrial Pplication OF AS Urbines Ommittee'Izzad AfifNessuna valutazione finora

- 2.4 MBM Combustor Dilution Air SystemDocumento6 pagine2.4 MBM Combustor Dilution Air SystemmiladNessuna valutazione finora

- Peppers Catalogue GlandsDocumento28 paginePeppers Catalogue GlandsVlad Andronache100% (1)

- Gas Turbine Heat Transfer Ten Remaining Hot Gas Path ChallengesDocumento9 pagineGas Turbine Heat Transfer Ten Remaining Hot Gas Path Challengeseankibo100% (1)

- Nasa 1977 TBC FT50 ProgramDocumento60 pagineNasa 1977 TBC FT50 Programatfrost4638100% (1)

- T 1566Documento5 pagineT 1566Erwin Mauricio Alarcon PradenasNessuna valutazione finora

- Gas Turbine Compressor IssuesDocumento9 pagineGas Turbine Compressor IssuesJJNessuna valutazione finora

- Nuovo Pignone Part ListDocumento1 paginaNuovo Pignone Part ListMohammed ElarbedNessuna valutazione finora

- Unsteady Flow Visualisation T Akes The Heat Out of Hot SpotsDocumento2 pagineUnsteady Flow Visualisation T Akes The Heat Out of Hot SpotsDeepak Chachra100% (1)

- Til 1236-R2Documento5 pagineTil 1236-R2makarov.olegNessuna valutazione finora

- Technical Trend of Aircraft BearingsDocumento5 pagineTechnical Trend of Aircraft BearingsnrNessuna valutazione finora

- 4 - Inspection - Interval - Extension W5015DA PDFDocumento12 pagine4 - Inspection - Interval - Extension W5015DA PDFEDBNessuna valutazione finora

- 26, Til 1621 Prevention of Water Accumulation Inside The Atomizing Air SystemDocumento5 pagine26, Til 1621 Prevention of Water Accumulation Inside The Atomizing Air Systemankarao69Nessuna valutazione finora

- 1st Stage BucketDocumento1 pagina1st Stage Bucketteedee1Nessuna valutazione finora

- GE Quantum MV AC Induction Totally Enclosed Fan Cooled MotorsDocumento4 pagineGE Quantum MV AC Induction Totally Enclosed Fan Cooled Motorslbk50Nessuna valutazione finora

- MJB Coating CapabilitiesDocumento3 pagineMJB Coating Capabilitiesteedee1Nessuna valutazione finora

- Edison Gas Turbines - Custom AnimationDocumento34 pagineEdison Gas Turbines - Custom Animationteedee1Nessuna valutazione finora

- GEA14171 RenewAlloyDocumento1 paginaGEA14171 RenewAlloyteedee1Nessuna valutazione finora

- Gea17076 Encover - LRDocumento1 paginaGea17076 Encover - LRteedee1Nessuna valutazione finora

- GEA17077 2nd - 3rdstage - LRDocumento2 pagineGEA17077 2nd - 3rdstage - LRteedee1Nessuna valutazione finora

- 1st Stage BucketDocumento1 pagina1st Stage Bucketteedee1Nessuna valutazione finora

- Is-3002 Partition Nozzle Area Data SheetDocumento2 pagineIs-3002 Partition Nozzle Area Data Sheetteedee1Nessuna valutazione finora

- Turbocare Gas Turbine Symposium 18/19 April 2005 Dallas TXDocumento19 pagineTurbocare Gas Turbine Symposium 18/19 April 2005 Dallas TXteedee1Nessuna valutazione finora

- GT AlignmentDocumento8 pagineGT Alignmentteedee1Nessuna valutazione finora

- 016 - Attachment For Full Scale Shear Pads - 01 Mar 11Documento54 pagine016 - Attachment For Full Scale Shear Pads - 01 Mar 11nadraNessuna valutazione finora

- In Uence of The Cooling Rate On The Ageing of Lead-Calcium AlloysDocumento5 pagineIn Uence of The Cooling Rate On The Ageing of Lead-Calcium AlloysDilfredo RuizNessuna valutazione finora

- Fronius Cold Metal TransferDocumento16 pagineFronius Cold Metal Transferbonmarche28Nessuna valutazione finora

- Concrete Basics - Portland Cement Association (PCA)Documento3 pagineConcrete Basics - Portland Cement Association (PCA)farhanshakeelNessuna valutazione finora

- Billet Internal Cracks InvestigationDocumento11 pagineBillet Internal Cracks InvestigationafzalNessuna valutazione finora

- Pla RubricsDocumento89 paginePla Rubricsapi-313716520Nessuna valutazione finora

- Purchase Spec. For Tubes-Nonferrous (SB111 H55 C70600)Documento5 paginePurchase Spec. For Tubes-Nonferrous (SB111 H55 C70600)Daison PaulNessuna valutazione finora

- 7503-2 - Checklist For Precast StructureDocumento8 pagine7503-2 - Checklist For Precast StructureKannan KamalNessuna valutazione finora

- Ultratech Cement: Particulars Test Results Requirements ofDocumento1 paginaUltratech Cement: Particulars Test Results Requirements ofAashish MIshraNessuna valutazione finora

- R.C. Beam / Slab Inspection ChecklistDocumento1 paginaR.C. Beam / Slab Inspection Checklistctlim88Nessuna valutazione finora

- Zwaluw High Tack enDocumento2 pagineZwaluw High Tack enRichard DNessuna valutazione finora

- Enerpac Hoses CatalogDocumento2 pagineEnerpac Hoses CatalogTitanplyNessuna valutazione finora

- E.1.08.01 Header Safety DevicesDocumento2 pagineE.1.08.01 Header Safety DevicesEdgardo EscribanoNessuna valutazione finora

- Normas AlumínioDocumento45 pagineNormas AlumíniovanessaNessuna valutazione finora

- Bolts,: Threaded Parts TensionDocumento2 pagineBolts,: Threaded Parts TensionMary MarasiganNessuna valutazione finora

- Böhler Fox CM 2 KB: Classifi CationsDocumento1 paginaBöhler Fox CM 2 KB: Classifi CationsBranko FerenčakNessuna valutazione finora

- Hot Forming/Bending: Material BS 806 ANSI B 31.1 DIN 17175 MannessmanDocumento3 pagineHot Forming/Bending: Material BS 806 ANSI B 31.1 DIN 17175 Mannessmandnageshm4n244Nessuna valutazione finora

- Sika MonoSeal 101 H EngDocumento3 pagineSika MonoSeal 101 H Engjpantazis1975Nessuna valutazione finora

- MD (BF) - 1 PDFDocumento5 pagineMD (BF) - 1 PDFMaheswar SethiNessuna valutazione finora

- Prince Product Catalogue 26-08-2021Documento44 paginePrince Product Catalogue 26-08-2021Abhi LyngdohNessuna valutazione finora

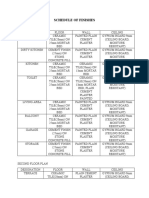

- Schedule of FinishesDocumento35 pagineSchedule of FinishesRA Cruz100% (1)

- Topic 3 - Concrete and MasonryDocumento60 pagineTopic 3 - Concrete and MasonryYoseph BirruNessuna valutazione finora

- Gypsum Board Fire Rated ConstructionDocumento5 pagineGypsum Board Fire Rated ConstructionphrishelNessuna valutazione finora

- Flange Table-3 PDFDocumento1 paginaFlange Table-3 PDFReşat DEMİRNessuna valutazione finora

- Product Catalogue: Leading The Fight Against FireDocumento94 pagineProduct Catalogue: Leading The Fight Against FirecodefinderNessuna valutazione finora

- Nav22 - Welding/Weld Repair Audit ChecklistDocumento23 pagineNav22 - Welding/Weld Repair Audit ChecklistdurraaiNessuna valutazione finora