Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Engineering Formulas: Nominal Design Parameters

Caricato da

bashist1969Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Engineering Formulas: Nominal Design Parameters

Caricato da

bashist1969Copyright:

Formati disponibili

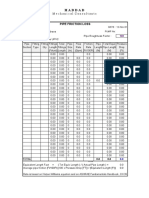

Engineering Formulas

Nominal Design Parameters

Chillers: 2.4GPM/Ton @ 10 F

12,000 BTU/HR/Ton 20 F - 60 F Standard Supply Range Rating at 50 F Supply Temperature 85 F Water Cooled Condenser 95 F Air Cooled Condenser

T Flow Rate

Cooling Tower = 15,000 BTU/HR/Ton

3 GPM per Ton 85 F Leaving Water Temperature 95 F Entering Water Temperature 78 F Wet Bulb Tower water make-up requirements: Untreated 2% of flow rate Treated 1.5% of flow rate

Weighted Water Test Chiller Ton = GPMx (Delta Temp) 24

Injection Molding 30#/hr H.D. Polyethlene = 1 ton 35#/hr L.D. Polyethlene = 1 ton 35#/hr Polypropylene = 1 ton 75#/hr PVC = 1 ton 50#/hr ABS= 1 ton 50#/hr Polystyrene= 1 ton 40#/hr Nylon= 1 ton 35#/hr Acrylic= 1 ton 40#/hr Polyurethane = 1 ton 50#/hr Acetal= 1 ton 40#/hr PPO= 1 ton 40#/hr PET= 1 ton 50#/hr Polycarb= 1 ton

Tower Ton = GPMx 30 Chiller Sizing

Extrusion 45#/hr H.D. Polyethlene = 1 ton 45#/hr L.D. Polyethlene = 1 ton 45#/hr Polypropylene = 1 ton 75#/hr Polystyrene = 1 ton 75#/hr PVC = 1 ton Blown Film 105 CFM (50 F @ 78 F WBT)= 1 ton Blow Molding

T (Delta Temp)

40#/hr Polyolefins= 1 ton

Chiller Capacity Loss/Gain

Decrease nominal tonnage by approximately 2% per degree below a 50 F leaving water temperature. Increase nominal tonnage approximately 2% per degree above 50 F leaving water temperature up to 55 F

Other Equipment

Air Compressor w/no after cooler =.1 ton/Hp Air Compressor w/after cooler =.2 Ton/Hp Vacuum Pump =.1 ton/Hp Hydraulic Cooling =.1 ton/Hp Barrel Cooling =.1 ton/in screw Dia. Hot Runner Mold = 1 ton/10.5KW Water Pump in Circuit =.2 Ton/Hr Feed Throat 400Ton Machine or above 1 Ton Below 400 Ton - 1/2 Ton

Extrusion Equipment

Gear Box Cooling =1 Ton/100Hp Feed Throat 3" Screw or Less =1 Ton Above 3" Screw =2 Tons Barrel or Screw Cooling =1 Ton/Inch of Screw Diameter

Pipe Sizing Guide

(Based on 5' - 7' feet/second velocity) 1/2" = 6 GPM 3/4" = 10 GPM 1" = 15 GPM 1 1/4" = 30 GPM 1 1/2" = 40 GPM 2" = 70 GPM 2 1/2" = 100 GPM 3" = 150 GPM 4"= 275 GPM 6" = 600 GPM 8" = 1,000 GPM

Metric Conversion Chart To Convert

Unit Volume US GPM Liters/Min 3.785 US GPM Cum/Hr CFM CFM .2271 FT/Lb/SEC Watts KW BTUH

To Convert

Power 1.356 342 33475 2545 .7457

Liters/Min 28.317 Cum/hr 1.6992 Unit Weight

Boiler HP BTUH HP HP BTUH KW

Lb/Ft Lbs/Sq in Lbs/Sq in Lbs/Sq in Lbs/Sq in

Kg/m gr/sq cm kPA

1.4881 70.31 6.894 BTU BTU/LB BTU/SQ FT BTU/CU FT Kg-cal Kg-cal gr-cal/sq cm Kg-cal/Cum Weight Grains Ounces* LBS grams grams kg .0648 28.350 .4536 Heat .252 .5556 .2713 8.899

Kg/Sq Cm .07031 gr/cu cm 27.68 Length

Inches Feet Yards Miles

cm meters meters km

2.540 .3048 .9144 1.609

Volume Cu. Inches Cu. Inches cu cm liters 16.387 .01639 .02832 28.317

US tons US Tons

kg Tonnes

907.2 .9072 1016 Area

Long Tons kg

Cu Feet cu meter Cu Feet liters

SQ Inches sq cm SQ Years sq meters SQ Miles sq km

6.452 .8361 2.590

Cu Years cu meters .7646 Fl cu cm 29.57 Ounces US cu meters .003785 Gallon US liters 3.785 Gallon

*Auoirdupois pounds and ounces Temperature

F 0 5 10 C -17.8 -15 -12.2 F 35 40 45 C 1.7 4.4 7.2 F 15 20 30 C -9.4 -6.7 1.1 F 50 55 60 C 10.0 12.8 15.6

F to C = (F - 32) x .55 =C Flow Rate Vs. Temp Differences Per Ton

C to F = (C x 1.8) + 32 =F % Ethylene Glycol by Volume vs Freeze Protection

1.2 GPM = 20 F 2.4 GPM = 10 F 4.8 GPM = 5 F 9.6 GPM = 2.5 F

10% 25F 20% 15F 30% 0F 40% -15F 50% -40F Abbreviations, Equivalents & Formulas T T T T

T = Delta Temperature = Temperature Differential PSI = Pounds per square inch 1 Cooling Tower Ton= 15,000BTU/HR GPM = Gallons per Minute EWT = Entering Water Temperature LWT = Leaving Water Temperature BTU = British Thermal Unit BTU/HR = GMP x 500 x . T (water) 1 HP = 2544 BTU/HR Ft. H.D. = PSI x 2.31 Q=4.5 x CFM x H = BTUH (Air Cooling) 1 Refrigerant Ton = 12,000 BTU/HR 1 Gallon = 8.33 lbs (water) 1 Cubic Foot = 7.48 gallons 1 Mil = .001" 1 Bar = 14.7 PSI 1 KW = 3413 BTU/HR 1 KW = 1.34 HP PSI= Ft of head/2.31 KW = Amps x Volts x 0.85 x 1.73 1,000

Pump HP= . GPM x P (Ft.H.D) . 3960 x (0.65 to 0.75) (Pump Eff)

Head in Feet to PSI Conversions calculator Filtration Chart

Mesh 4 8 10 14 18 20 25 30 Micron 5205 2487 1923 1307 1000 840 710 590 Inches 0.2030 0.0970 0.0750 0.0510 0.0394 0.0331 0.0280 0.0232 Mesh 80 100 120 140 170 200 230 270 Micron 177 149 125 105 88 74 62 53 Inches 0.0070 0.0059 0.0049 0.0041 0.0035 0.0029 0.0024 0.0021

35 40 45 50 60 70

500 420 350 297 250 210

0.0197 0.0165 0.0138 0.0117 0.0098 0.0083

325 400 550 800 1250

44 37 25 15 10 5

0.0017 0.0015 0.0009 0.0006 0.0004 0.0002

Potrebbero piacerti anche

- Basic Data EntryDocumento12 pagineBasic Data EntryVimal Anbalagan0% (1)

- Lecture 1-2 Vacuum SystemDocumento113 pagineLecture 1-2 Vacuum SystemMehreen AkmalNessuna valutazione finora

- Motor Engineering FormulasDocumento1 paginaMotor Engineering FormulasRezaahParkerNessuna valutazione finora

- Steam Tables DLL Developer's GuideDocumento17 pagineSteam Tables DLL Developer's GuidepetritaNessuna valutazione finora

- AHU SizingDocumento8 pagineAHU Sizingmohammad hamdanNessuna valutazione finora

- Motor Starting Voltage ImpactDocumento8 pagineMotor Starting Voltage ImpactVíctor RojasNessuna valutazione finora

- Custom Engineered Piping Data ReportDocumento94 pagineCustom Engineered Piping Data ReportshaonaaNessuna valutazione finora

- Calculate Gas Compressibility Excel FunctionDocumento2 pagineCalculate Gas Compressibility Excel FunctionCHANADASNessuna valutazione finora

- Physical properties data tables and referencesDocumento32 paginePhysical properties data tables and referencesmidooooo198767% (3)

- Orifice Flow Calculator For Gases, Steam, and VaporsDocumento2 pagineOrifice Flow Calculator For Gases, Steam, and Vaporsbakhtyar21Nessuna valutazione finora

- Piping PDSDocumento2 paginePiping PDSsunii19847908Nessuna valutazione finora

- Thermal Properties of Matter: Internal Energy, Heat Capacity, Phase ChangesDocumento79 pagineThermal Properties of Matter: Internal Energy, Heat Capacity, Phase ChangesHafiza JaweriaNessuna valutazione finora

- How To Use The Excel "Linest" Function For Linear Regression Models With Multiple Input Variables XDocumento8 pagineHow To Use The Excel "Linest" Function For Linear Regression Models With Multiple Input Variables XANIL PALNessuna valutazione finora

- Angus SolutionDocumento8 pagineAngus SolutionBen Karthiben NathanNessuna valutazione finora

- Viscosity (SI)Documento6 pagineViscosity (SI)Liem Handi Wijaya SusantoNessuna valutazione finora

- Convert Between Energy Units Like Btu, Therm and Cubic FeetDocumento3 pagineConvert Between Energy Units Like Btu, Therm and Cubic FeetSurya Budi WidagdoNessuna valutazione finora

- CSB DetailsDocumento52 pagineCSB DetailsVelmurugan ElumalaiNessuna valutazione finora

- Conversion Factors: A Comprehensive Guide to Measurement UnitsDocumento11 pagineConversion Factors: A Comprehensive Guide to Measurement Unitsmicro kidNessuna valutazione finora

- Excel PolynomialDocumento5 pagineExcel Polynomial______.________Nessuna valutazione finora

- Engineering MathsDocumento84 pagineEngineering MathsNagaraju SambuNessuna valutazione finora

- Chapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocumento4 pagineChapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallReza SaeeNessuna valutazione finora

- Boundary Conditions: To Computational Fluid DynamicsDocumento31 pagineBoundary Conditions: To Computational Fluid Dynamicschandravadiyaketan1504100% (1)

- Enthalpy / Entropy DiagramDocumento34 pagineEnthalpy / Entropy DiagramMara TrofinNessuna valutazione finora

- Piping Specialty Worksheets IndexDocumento110 paginePiping Specialty Worksheets IndexmanhngoducNessuna valutazione finora

- Che 2Documento25 pagineChe 2Jaynie Lee VillaranNessuna valutazione finora

- Conversion Factors - Gas IndustryDocumento2 pagineConversion Factors - Gas IndustryKailas Nimbalkar100% (3)

- Determining Specific Heat Capacity Using a Heating CoilDocumento32 pagineDetermining Specific Heat Capacity Using a Heating CoilMartinNessuna valutazione finora

- Solid Bulk DensityDocumento21 pagineSolid Bulk DensityMauricio RodriguezNessuna valutazione finora

- Apendice 2Documento12 pagineApendice 2JA UMAN1Nessuna valutazione finora

- Tank Schematic: Horizontal Cylinder: Dimensions of The TankDocumento4 pagineTank Schematic: Horizontal Cylinder: Dimensions of The Tankabhay_joshi2002Nessuna valutazione finora

- Pneumatic Conveying Design CalculationsDocumento4 paginePneumatic Conveying Design CalculationsfunloverjhaNessuna valutazione finora

- Library WebDocumento128 pagineLibrary WebVikash AgarwalNessuna valutazione finora

- Water - Dynamic and Kinematic ViscosityDocumento3 pagineWater - Dynamic and Kinematic ViscosityManik KandanNessuna valutazione finora

- "Solutions For The Plastics Industry": Co. IncDocumento4 pagine"Solutions For The Plastics Industry": Co. IncminiongskyNessuna valutazione finora

- Understanding Distillation Using Column Profile MapsDa EverandUnderstanding Distillation Using Column Profile MapsNessuna valutazione finora

- Yaws Chapter 1Documento1 paginaYaws Chapter 1basana siamremareNessuna valutazione finora

- Solution Manual For Introduction To Process Technology 4th Edition Thomas 9781305251472Documento17 pagineSolution Manual For Introduction To Process Technology 4th Edition Thomas 9781305251472gregory100% (1)

- Multivariable Predictive Control: Applications in IndustryDa EverandMultivariable Predictive Control: Applications in IndustryNessuna valutazione finora

- Psychrometrics 2017030200Documento3 paginePsychrometrics 2017030200Jawoto Nur RafifNessuna valutazione finora

- Column and Wall Load Take Down Spreadsheet v1.0 - CLDocumento28 pagineColumn and Wall Load Take Down Spreadsheet v1.0 - CLBilal KhattabNessuna valutazione finora

- FD Fan Sizing CalculationDocumento3 pagineFD Fan Sizing CalculationkumarananyarupeshNessuna valutazione finora

- Sizing Duct Work SheetDocumento4 pagineSizing Duct Work SheetMaulana MaftuhiNessuna valutazione finora

- FANUC Robot R-2000iB SeriesDocumento4 pagineFANUC Robot R-2000iB SeriesChandan KanuNessuna valutazione finora

- Technological Institute of The PhilippinesDocumento25 pagineTechnological Institute of The PhilippinesJohn Leonard FazNessuna valutazione finora

- Pinch Spreadsheet Nov06 FinalDocumento97 paginePinch Spreadsheet Nov06 FinalmadrasahNessuna valutazione finora

- Heat Chap07 035Documento16 pagineHeat Chap07 035Kerem GönceNessuna valutazione finora

- Interfacing Electrification and System ReliabilityDocumento29 pagineInterfacing Electrification and System Reliabilityพี่จิน ยศเนืองนิตย์Nessuna valutazione finora

- Part Ii - Particular Technical Specifications Chapter 13 - Permanent Access Bridge 13. PERMANENT ACCESS BRIDGE........................................................ 13-1Documento11 paginePart Ii - Particular Technical Specifications Chapter 13 - Permanent Access Bridge 13. PERMANENT ACCESS BRIDGE........................................................ 13-1Anonymous KHIyWRIWmaNessuna valutazione finora

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationDa EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNessuna valutazione finora

- Wet Air Properties Calculation Sheet: at Low PressureDocumento2 pagineWet Air Properties Calculation Sheet: at Low Pressurezsmith0% (1)

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Da EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Nessuna valutazione finora

- PC Pump ManualDocumento540 paginePC Pump ManualtelephonicaNessuna valutazione finora

- Formulas: Nominal Design ParametersDocumento4 pagineFormulas: Nominal Design Parametersehtesham314Nessuna valutazione finora

- 01 - Transfer Pumps & Texsteam PDFDocumento26 pagine01 - Transfer Pumps & Texsteam PDFlidia ayuNessuna valutazione finora

- Universiti Tunku Abdul Rahman (Utar) Faculty of Engineering and Green Technology (Fegt)Documento26 pagineUniversiti Tunku Abdul Rahman (Utar) Faculty of Engineering and Green Technology (Fegt)khairulNessuna valutazione finora

- CE Refresher: Steam Tables and Typical Liquid VelocitiesDocumento1 paginaCE Refresher: Steam Tables and Typical Liquid Velocitieshugo mendozaNessuna valutazione finora

- Thermocompressors Improve Paper Machine Dryer DrainageDocumento8 pagineThermocompressors Improve Paper Machine Dryer DrainageclintoncNessuna valutazione finora

- PH DiagramDocumento41 paginePH Diagramsubratoraj100% (1)

- Air PropertiesDocumento2 pagineAir PropertiesThanh ThuanNessuna valutazione finora

- Numeriek PDF For Chemical EngineersDocumento172 pagineNumeriek PDF For Chemical EngineersJonathan van der MeerNessuna valutazione finora

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesDa EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesNessuna valutazione finora

- Insights into Chemical Engineering: Selected Papers of P.V. DanckwertsDa EverandInsights into Chemical Engineering: Selected Papers of P.V. DanckwertsNessuna valutazione finora

- Thermal Tech EquipmentcoDocumento5 pagineThermal Tech EquipmentcoSaleem UddinNessuna valutazione finora

- Engineering Formulas: Nominal Design ParametersDocumento4 pagineEngineering Formulas: Nominal Design Parametersehtesham314Nessuna valutazione finora

- Chilled Water Design PerametersDocumento4 pagineChilled Water Design PerametersSatya N.GNessuna valutazione finora

- Managerial EconomicsDocumento22 pagineManagerial EconomicsPulkit Gupta0% (1)

- Managerial EconomicsDocumento22 pagineManagerial EconomicsPulkit Gupta0% (1)

- March05 AEreviewDocumento36 pagineMarch05 AEreviewbashist1969Nessuna valutazione finora

- Booklet Indian VegetablesDocumento8 pagineBooklet Indian Vegetablesbashist1969Nessuna valutazione finora

- DechlorDocumento1 paginaDechlorbashist1969Nessuna valutazione finora

- Flouride Removal 1Documento2 pagineFlouride Removal 1bashist1969Nessuna valutazione finora

- 2016 Popsicle Stick Bridge RulesDocumento6 pagine2016 Popsicle Stick Bridge RulesMahendra DewasiNessuna valutazione finora

- Mks ConfigDocumento5 pagineMks ConfigGabura TaniaNessuna valutazione finora

- Carbon Dioxide in RespirationDocumento1 paginaCarbon Dioxide in Respirationlolay01Nessuna valutazione finora

- ANSI-IsA 77.13.01-1999 Fossil Fuel Power Plant Steam Turbine Bypass SystemDocumento42 pagineANSI-IsA 77.13.01-1999 Fossil Fuel Power Plant Steam Turbine Bypass SystemArzu AkarNessuna valutazione finora

- Software Development Handbook Transforming For The Digital Age PDFDocumento75 pagineSoftware Development Handbook Transforming For The Digital Age PDFdreamer4077Nessuna valutazione finora

- Technical Information HANSA-FLEX Hose ConnectionsDocumento75 pagineTechnical Information HANSA-FLEX Hose ConnectionshorsanicuNessuna valutazione finora

- Adf Interview Questions and AnsewrsDocumento85 pagineAdf Interview Questions and Ansewrsleninbabus100% (2)

- Elsa CableDocumento2 pagineElsa CableJay WangNessuna valutazione finora

- PM IS - 12818 June2021Documento10 paginePM IS - 12818 June2021Mahendra AhirwarNessuna valutazione finora

- Electric Rolling Bridge, Scientific American 24 August 1889 p120Documento2 pagineElectric Rolling Bridge, Scientific American 24 August 1889 p120Rm1262Nessuna valutazione finora

- Calcium Sulfate Crystallization in Phosphoric Acid PDFDocumento133 pagineCalcium Sulfate Crystallization in Phosphoric Acid PDFabderrahimnNessuna valutazione finora

- PTH Crusher GBDocumento16 paginePTH Crusher GBElvis Eberth Huanca MachacaNessuna valutazione finora

- Partition WallDocumento24 paginePartition WallSHRADDHA GHUGENessuna valutazione finora

- ECOSYS M6526cdn Fax SetupDocumento204 pagineECOSYS M6526cdn Fax SetupAnonymous gn8qxxNessuna valutazione finora

- Assist. Prof. DR - Thaar S. Al-Gasham, Wasit University, Eng. College 136Documento49 pagineAssist. Prof. DR - Thaar S. Al-Gasham, Wasit University, Eng. College 136Hundee HundumaaNessuna valutazione finora

- Computer Science & Engineering Department ElectivesDocumento13 pagineComputer Science & Engineering Department Electivesnitro gtnaNessuna valutazione finora

- Billing No. 4 Accomplishement ReportDocumento1 paginaBilling No. 4 Accomplishement ReportGOB ConstructionNessuna valutazione finora

- 04 Metal and Glass-Wood PolicyDocumento1 pagina04 Metal and Glass-Wood Policykitek100% (1)

- Bunker SiloDocumento3 pagineBunker SiloManju Civil PNessuna valutazione finora

- PE Electromagnetic Pump Unit PE GB T1101 01-02-182Documento4 paginePE Electromagnetic Pump Unit PE GB T1101 01-02-182li geneNessuna valutazione finora

- Final Page Size: A5 (148mm X 210mm)Documento20 pagineFinal Page Size: A5 (148mm X 210mm)RJ BevyNessuna valutazione finora

- Vol 4 Div G ODS Part 1 of 2-Pages-18-55Documento38 pagineVol 4 Div G ODS Part 1 of 2-Pages-18-55debapriyoNessuna valutazione finora

- Netsys NVF-200EKIT User Guide 1.0.6Documento19 pagineNetsys NVF-200EKIT User Guide 1.0.6pkramellaNessuna valutazione finora

- Maximo Sandbox SettingsDocumento6 pagineMaximo Sandbox SettingsChandra SekharNessuna valutazione finora