Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Impact Analysis of Mini Baja

Caricato da

yashvirsingh21Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Impact Analysis of Mini Baja

Caricato da

yashvirsingh21Copyright:

Formati disponibili

International Journal of Applied Engineering Research ISSN 0973-4562 Volume 6, Number 23-24 (2011) pp.

2595-2600 Research India Publications http://www.ripublication.com/ijaer.htm

Impact Analysis of Mini BAJA Vehicle Roll Cage using Finite Element Analysis

Yashvir Singh1*, Nishant Kr. Singh2 and Puneet Mangla3

1*,2,3

Hindustan College of Science and Technology, Mathura, U.P., India *Corresponding Author E-mail: yashvirsingh21@gmail.com

Abstract The objective of this research work is the prediction of fatigue life span and durability loading of the chassis frame of Mini BAJA vehicle. The Mini BAJA Vehicle is an off-road race vehicle powered by a small gasoline engine. As is such the combination frame and roll cage must be equally strong and light. In an effort to fulfill the rules set down by the governing body and ensure proper integration, strength, and weight minimization; it is imperative to properly analyze the material properties and geometry as well as the overall design geometry. Thus, fatigue study and life prediction on the chassis is necessary in order to verify the safety of this chassis during its operation. Stress analysis using Finite Element Method (FEM) can be used to locate the critical point which has the highest stress. This critical point is one of the factors that may cause the fatigue failure. The magnitude of the stress can used to predict the life span of the vehicle chassis. Keywords: Stress analysis, Finite Element Method, Vehicle Chassis

Introduction

Mini BAJA is a collegiate competition sponsored by the Society of Automotive Engineers (SAE). The objective is for a team of students to design, fabricate and race an off-road vehicle powered by a ten horsepower Briggs and Stratton gasoline engine. The vehicle is required to have a combination frame and roll cage consisting of steel members. As weight is critical in a vehicle powered by a small engine, a balance must be found between the strength and weight of the design. To best optimize this balance the use of solid modeling and finite element analysis (FEA) software is extremely useful in addition to conventional analysis.

2596

Yashvir Singh et al

M. Fermer et al [1] investigated the fatigue life of Volvo S80 Bi-Fuel using MSC/Fatigue. F.A. Conle et al [2] did research about fatigue analysis and the local stress-strain approach in complex vehicular structures. Structural optimization of automotive components applied to durability problems has been investigated by W. G. Ferreira et al [3]. M. Fermr and H. Svensson [4] studied on industrial experiences of FE-based fatigue life predictions of welded automotive structures. R. R. P. Filho et al [5] have investigated and optimized a chassis design for an off road vehicle with the appropriate dynamic and structural behavior, taking into account the aspects relative to the economical viability of an initial small scale production. The design of an off-road vehicle chassis has optimized by increasing the torsional stiffness, maintenance of center of gravity, total weight of structure and simpler geometry for reduction of production cost. N. Ye et al [6] have investigated the static and fatigue behavior of aluminium box stiffener/ web frame connections using Finite Element Analysis (FEA) to provide a connection solution that can reduce the fabrication costs by changing the cutting shapes on the web frame and correspondingly the weld process meanwhile sufficient fatigue strength can be achieved. The following paper outlines the design and analysis of the Northeastern Mini BAJA vehicles frame design. It will cover the design constraints required by SAE, material selection, initial design, and structural analysis and design modifications.

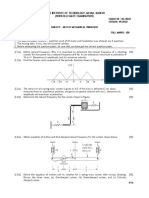

Analysis of chassis

Design constraints The design of the Mini BAJA frame is defined by the design safety rules set out by the SAE. These rules are updated yearly to address new safety concerns. These rules define the frame design in two ways. First, the rules set specific requirements on the building materials material type and geometry. They also define the specific requirements of the frame geometry. The requirements were referenced when making decisions regarding the material selection, design geometry and any additional modifications to the design. A thorough review of the design and rules were made at the end of the design stage before fabrication. This review included not only the letter of the guideline but also a discussion of the intent. In any cases in which the clarity or meaning of a rule was in doubt, the SAE rules committee was contacted to ensure compliance. It is important that the reader understand that these constraints were in place during the design of the vehicle frame, as well as the interaction between the frame design and other factors, such as drivetrain, suspension, and driver safety and restraint. Model of chassis The model of the chassis is drawn with the help of solid works. The model is depicted in figure 1. The model has length of 2.35 m and width of 1.24 m. The material of chassis is AISI 1018 Mild Steel which is class of carbon steel with 386 MPa of yield strength and 634 MPa of tensile strength. The other properties of chassis material are tabulated in Table 1.

Impact Analysis of Mini BAJA Vehicle Roll Cage Table 1: Properties of chassis material Properties Elasticmodulus(Pa) Density(Kg/m3) Poissonsratio Tensilestrength(Mpa) Yieldstrength(Mpa) Value 210x109 8030 0.3 634 386

2597

Figure 1: Model of chassis

Loading The chassis model is analyzed for the effect of impact forces from the front and the rear portion of the vehicle. For this model, the maximum force is 5500 N. The load is assumed as a uniform pressure obtained from the maximum loaded weight divided by the total contact area from the front and the rear side. Detail loading of model is shown in Figure 2 and 3. In both the cases, when force is applied the degree of freedom have to be fixed in opposite direction.

Figure 2: Impact force from front side.

2598

Yashvir Singh et al

Figure 3: Impact force from rear side

Results and discussions

Front impact force analysis The figure 4 shows the maximum axial displacement. During the front impact analysis, the value of maximum displacement will be 2.3 mm. The value of maximum lateral displacement will be 1.7 mm. The figure 5 shows the lateral displacement of the bars of the chassis. The figure 6 shows the maximum Von Misses stress. The stress magnitude of critical point is 50 MPa. The maximum stress occurs at the side of the vehicle near the drivers cabin.

Figure 4: Axial displacement plot during front impact loading

Figure 5: Lateral displacement plot during front impact loading

Impact Analysis of Mini BAJA Vehicle Roll Cage

2599

Figure 6: Maximum Von Stress plot during front impact loading

Rear impact force analysis The figure 7 shows the maximum axial displacement. During the rear impact analysis, the value of maximum displacement will be 5.5 mm. The value of maximum lateral displacement will be 2.7 mm. The figure 8 shows the lateral displacement of the bars of the chassis. The figure 9 shows the maximum Von Misses stress. The stress magnitude of critical point is 100 MPa. The maximum stress occurs at the rear side of the vehicle where engine will be placed.

Figure 7: Axial displacement plot during rear impact loading

Figure 8: Lateral displacement plot during rear impact loading

2600

Yashvir Singh et al

Figure 9: Maximum Von Stress plot during rear impact loading

Conclusion

Numerical simulation result shows that the critical point of stress occurred at side of the chassis during front loading and at rear side near the place where engine is placed. The magnitude of highest stress is critical because the value of SF is below than the recommended value. Since fatigue failure started from the highest stress point, it can be concluded that this critical point is an initial to probable failure. Thus, it is important to take note to reduce stress magnitude at this point.

References

[1] M. Fermer, G. McInally and G. Sandin, Fatigue Life Analysis of Volvo S80 BiFuel using MSC/Fatigue, Worldwide MSC Automotive Conference, Germany, September, 1999. [2] F. A. Conle and C.-C. Chu, Fatigue Analysis and the Local Stress-strain Approach in Complex Vehicular Structures, International journal of fatigue, 1997. [3] W. G. Ferreira, F. Martins, S. Kameoka, A. S. Salloum, and J. T. Kaeya, Structural Optimization of Automotive Components Applied to Durability Problems, SAE Technical Papers, 2003. [4] M. Fermr and H. Svensson, Industrial Experiences of FE-based Fatigue Life Predictions of Welded Automotive Structures, Fatigue & Fracture of Engineering Materials and Structures 24 (7), 2001, 489500. [5] R. R. P. Filho, J. C. C. Rezende, M.de F. Leal, J. A. F. Borges, Automotive Frame Optimization, 12th International Mobility Technology Congress and Exhibition, Sao Paulo, Brasil, November 18 20, 2003. [6] N. Ye and T. Moan, Static and Fatigue Analysis of Three Types of Aluminium Box- Stiffener/Web Frame Connections, International Journal of Fatigue 29 (2007) 14261433.

Potrebbero piacerti anche

- Discrete Element Method to Model 3D Continuous MaterialsDa EverandDiscrete Element Method to Model 3D Continuous MaterialsNessuna valutazione finora

- Lapox Epoxy Resin l12 With Hardener K 6 1 1 KG PackingDocumento2 pagineLapox Epoxy Resin l12 With Hardener K 6 1 1 KG PackingKarthick MuruganNessuna valutazione finora

- Mqa CepDocumento8 pagineMqa Cepfaryad artist100% (1)

- Biotribology SeminarDocumento25 pagineBiotribology Seminarsatyambhuyan_5338070Nessuna valutazione finora

- 11 Chapter 5 Gear Trains Tabular Method VTU ExamDocumento37 pagine11 Chapter 5 Gear Trains Tabular Method VTU Examghanshyamverma19100% (2)

- Solutionmanual7!8!150303094025 Conversion Gate01Documento12 pagineSolutionmanual7!8!150303094025 Conversion Gate01Omar BahgatNessuna valutazione finora

- Design and Analysis of Crankshaft With Different CompositeDocumento9 pagineDesign and Analysis of Crankshaft With Different CompositeSAI CHARANNessuna valutazione finora

- Central Institute of Plastics Engineering and Technology, LucknowDocumento12 pagineCentral Institute of Plastics Engineering and Technology, Lucknowkiran yadavNessuna valutazione finora

- Truss Imp QuestionsDocumento3 pagineTruss Imp QuestionsIrfan ShaikhNessuna valutazione finora

- ME524 1st Midterm Exam Spring 2022 Model SolutionDocumento3 pagineME524 1st Midterm Exam Spring 2022 Model SolutionSulaiman AL MajdubNessuna valutazione finora

- MCQs On SCBDocumento9 pagineMCQs On SCBjigardesai100% (1)

- ME3112-1 Lab Vibration MeasurementDocumento8 pagineME3112-1 Lab Vibration MeasurementLinShaodunNessuna valutazione finora

- CE6402-Strength of Materials PDFDocumento12 pagineCE6402-Strength of Materials PDFSathz FlynnNessuna valutazione finora

- CM7202-Applied Materials EngineeringDocumento6 pagineCM7202-Applied Materials EngineeringJayaraman TamilvendhanNessuna valutazione finora

- Sisal and BannanaDocumento13 pagineSisal and BannanavinothkumarNessuna valutazione finora

- Unit-III, Advanced Mechanisms PDFDocumento41 pagineUnit-III, Advanced Mechanisms PDFvamsi krishnaNessuna valutazione finora

- PPT4. PlasticityIITKDocumento70 paginePPT4. PlasticityIITKKartik Shankar KumbhareNessuna valutazione finora

- Strength of Materials-II 2-2 Set-1 (A)Documento18 pagineStrength of Materials-II 2-2 Set-1 (A)Sri D0% (1)

- Fracture of Cracked MembersDocumento21 pagineFracture of Cracked MembersZach DeLukeNessuna valutazione finora

- Module 2Documento7 pagineModule 2sathiaNessuna valutazione finora

- C PROGRAM of Machine DesignDocumento12 pagineC PROGRAM of Machine DesignPiyush Baid100% (1)

- PDFDocumento3 paginePDFRajkumar ANessuna valutazione finora

- Hounsfield Tensometer 20%Documento4 pagineHounsfield Tensometer 20%Niyusha Toosi100% (1)

- Multipurpose Robotic ArmDocumento7 pagineMultipurpose Robotic ArmIJRASETPublicationsNessuna valutazione finora

- School of Mechanical and Building Sciences: MEE-3001: Design of Machine ElementsDocumento106 pagineSchool of Mechanical and Building Sciences: MEE-3001: Design of Machine ElementsRamesh Kavitha Sanjit 18BME0677Nessuna valutazione finora

- Lab 3 VibDocumento3 pagineLab 3 VibAvenger4Nessuna valutazione finora

- LAB VIVA QuestionsDocumento4 pagineLAB VIVA QuestionsKh Bappi ShahriarNessuna valutazione finora

- Mechanical Vibration PDFDocumento51 pagineMechanical Vibration PDFEric Kerr100% (1)

- r05320305 Design of Machine Members IIDocumento9 paginer05320305 Design of Machine Members IISRINIVASA RAO GANTANessuna valutazione finora

- Project Mom ReportDocumento18 pagineProject Mom ReportIhtesham ArifNessuna valutazione finora

- Lecture38 PDFDocumento20 pagineLecture38 PDFabhi aroteNessuna valutazione finora

- Mechanical Testing-Bending Shearing and Torsion TestDocumento10 pagineMechanical Testing-Bending Shearing and Torsion TestAsif AliNessuna valutazione finora

- E1 Tensile TestDocumento13 pagineE1 Tensile TestFirzana AmiraNessuna valutazione finora

- DOM ProblemsSolvedinClassDocumento129 pagineDOM ProblemsSolvedinClassrukmini_ramkiNessuna valutazione finora

- To Determine The Moment of Inertia of A FlywheelDocumento2 pagineTo Determine The Moment of Inertia of A FlywheelCHEE HONG CHANNessuna valutazione finora

- Deflection of A Coil SpringDocumento7 pagineDeflection of A Coil SpringMoetassem Saraya100% (2)

- ME 2354 Automobile Engineering 2009 6th Semester Anna UniversityDocumento2 pagineME 2354 Automobile Engineering 2009 6th Semester Anna UniversityParanthaman GanapathyNessuna valutazione finora

- Univ Lab Set - 1 Me8711 Sa LabDocumento5 pagineUniv Lab Set - 1 Me8711 Sa LabAsst.Prof MECH100% (1)

- Quiz 3 Solid MaterialDocumento6 pagineQuiz 3 Solid Materialehsanzkr_499329029Nessuna valutazione finora

- Tensile Testing of Ferrous and Non-Ferrous AlloyDocumento7 pagineTensile Testing of Ferrous and Non-Ferrous Alloyrama100% (1)

- Velocity of MechanismDocumento10 pagineVelocity of Mechanismرعد العكيليNessuna valutazione finora

- Practical 10 - Shear CentreDocumento4 paginePractical 10 - Shear CentreTbyTanNessuna valutazione finora

- Mechanism of Machinery Velocity Analysis WorksheetDocumento4 pagineMechanism of Machinery Velocity Analysis WorksheetAgare Tube0% (1)

- Review On Process Parameter Optimization For Forging ProcessDocumento3 pagineReview On Process Parameter Optimization For Forging ProcessIRJMETS JOURNALNessuna valutazione finora

- Pre-Planning FunctionDocumento10 paginePre-Planning FunctionSandeep ChoudharyNessuna valutazione finora

- Amatconrep PPT 8 DT and NDTDocumento30 pagineAmatconrep PPT 8 DT and NDTMark Jovince CardenasNessuna valutazione finora

- PHD Thesis Ana GiraoDocumento370 paginePHD Thesis Ana GiraoMassimo LatourNessuna valutazione finora

- Dom Unit II Imp QuestionsDocumento2 pagineDom Unit II Imp QuestionsSree MurthyNessuna valutazione finora

- Iare - Fluid Mechanics - Tutorial - Question - Bank PDFDocumento12 pagineIare - Fluid Mechanics - Tutorial - Question - Bank PDFShaik Asif AliNessuna valutazione finora

- Finite Element Model Question PaperDocumento4 pagineFinite Element Model Question PaperSrinivasan SriniNessuna valutazione finora

- 2 Marks With AnswersDocumento16 pagine2 Marks With AnswersKarthik SoundarrajanNessuna valutazione finora

- Mechanics of Material Lab Report Angle of TwistDocumento6 pagineMechanics of Material Lab Report Angle of TwistAhsan MumtazNessuna valutazione finora

- Noise and Vibrations Question BankDocumento19 pagineNoise and Vibrations Question BankAbhijit DakareNessuna valutazione finora

- Size and Topological Optimization of Cantilever BeamDocumento6 pagineSize and Topological Optimization of Cantilever BeamseventhsensegroupNessuna valutazione finora

- Engineering Materials Questions and AnswersDocumento4 pagineEngineering Materials Questions and AnswersEmıły WınıfredNessuna valutazione finora

- ME7327 MECHANICAL VIBRATION Question PaperDocumento2 pagineME7327 MECHANICAL VIBRATION Question PaperFaisal RahmaniNessuna valutazione finora

- Structural Performance Analysis of Formula Sae Car: Jurnal Mekanikal December 2010, No. 31, 46 - 61Documento16 pagineStructural Performance Analysis of Formula Sae Car: Jurnal Mekanikal December 2010, No. 31, 46 - 61Piyush SoodNessuna valutazione finora

- ReviewDocumento4 pagineReviewAnonymous 7eSIXWYMNessuna valutazione finora

- Experimental and Finite Element Stress Analysis of Three Wheeler Front FenderDocumento7 pagineExperimental and Finite Element Stress Analysis of Three Wheeler Front FenderNithin SunnyNessuna valutazione finora

- Structural Analysis of Automotive Chassis Considering Cross-Section and MaterialDocumento7 pagineStructural Analysis of Automotive Chassis Considering Cross-Section and MaterialNima NaNessuna valutazione finora

- 7 - DiffusionDocumento13 pagine7 - Diffusiontaak41Nessuna valutazione finora

- Form10C Instructions EngDocumento3 pagineForm10C Instructions EngWazidAliNessuna valutazione finora

- Article 52177Documento8 pagineArticle 52177yashvirsingh21Nessuna valutazione finora

- Journal of Agriculture and CropsDocumento4 pagineJournal of Agriculture and Cropsyashvirsingh21Nessuna valutazione finora

- Assignment 2 2015-2016Documento1 paginaAssignment 2 2015-2016yashvirsingh21Nessuna valutazione finora

- Presentation 1 Engineering GraphicsDocumento3 paginePresentation 1 Engineering Graphicsyashvirsingh21Nessuna valutazione finora

- Presentation 1 Engineering GraphicsDocumento3 paginePresentation 1 Engineering Graphicsyashvirsingh21Nessuna valutazione finora

- Assignment 03Documento1 paginaAssignment 03yashvirsingh21Nessuna valutazione finora

- Chapter 01 IntroductionDocumento57 pagineChapter 01 Introductionyashvirsingh21Nessuna valutazione finora

- Internal Combustion EnginesDocumento44 pagineInternal Combustion Enginesyashvirsingh21Nessuna valutazione finora

- Engineering Materials: (Hi) Wrought IronsDocumento1 paginaEngineering Materials: (Hi) Wrought Ironsyashvirsingh21Nessuna valutazione finora

- Model Paper 1Documento2 pagineModel Paper 1yashvirsingh21Nessuna valutazione finora

- Rame 2012Documento2 pagineRame 2012yashvirsingh21Nessuna valutazione finora

- Model Paper 1Documento2 pagineModel Paper 1yashvirsingh21Nessuna valutazione finora

- BatteryDocumento2 pagineBatteryyashvirsingh21Nessuna valutazione finora

- Diesel Power Plant: Yashvir SinghDocumento22 pagineDiesel Power Plant: Yashvir Singhyashvirsingh21Nessuna valutazione finora

- Engine ComponentsDocumento21 pagineEngine Componentsyashvirsingh21Nessuna valutazione finora

- Curing Back Pain NaturallyDocumento37 pagineCuring Back Pain Naturallyyashvirsingh2150% (2)

- Tidal Energy 2Documento14 pagineTidal Energy 2Radha Krishnan PNessuna valutazione finora

- Equilibrium and CompatibilityDocumento2 pagineEquilibrium and Compatibilitymantoo vermaNessuna valutazione finora

- Seismic Isolation, Structural Health Monitoring, and Performance Based Seismic Design in Earthquake Engineering PDFDocumento361 pagineSeismic Isolation, Structural Health Monitoring, and Performance Based Seismic Design in Earthquake Engineering PDFzdravac9220100% (4)

- Sheet Pile Wall IntroductionDocumento19 pagineSheet Pile Wall IntroductionSâu HeoNessuna valutazione finora

- Newcombe, 2010, Multistorey TimberDocumento86 pagineNewcombe, 2010, Multistorey Timberprisciliano1Nessuna valutazione finora

- Problem 10-20Documento1 paginaProblem 10-20Piraveen 17Nessuna valutazione finora

- Design Strength of Tension MembersDocumento72 pagineDesign Strength of Tension MembersSurja Gain50% (2)

- Introduction To Earthquake Resistant Design..Earthquake and Urbanization - History of Major International and Philippine Earthquake. The Ring of FireDocumento19 pagineIntroduction To Earthquake Resistant Design..Earthquake and Urbanization - History of Major International and Philippine Earthquake. The Ring of FireJeffry VargasNessuna valutazione finora

- Wrana 2015 4Documento197 pagineWrana 2015 4Raihan LutfiantoNessuna valutazione finora

- Assignment 1Documento3 pagineAssignment 1Pawan Kumar GoyalNessuna valutazione finora

- Fracture and Fatigue (ME514) : 1 IIT Ropar, PunjabDocumento9 pagineFracture and Fatigue (ME514) : 1 IIT Ropar, PunjabgidlavinayNessuna valutazione finora

- Exam Paper-FinalDocumento5 pagineExam Paper-FinalLebusa PosholiNessuna valutazione finora

- Euler's Theory of Columns Study Notes For Mechanical Engineering - ESE & GATE MEDocumento8 pagineEuler's Theory of Columns Study Notes For Mechanical Engineering - ESE & GATE MERabia ZulqarnainNessuna valutazione finora

- Piping Failure Modes 01 24Documento24 paginePiping Failure Modes 01 24Victor SodréNessuna valutazione finora

- STRUCTURAL ANALYSIS Report Janak Raj GhimireDocumento60 pagineSTRUCTURAL ANALYSIS Report Janak Raj GhimireLilu ThapaNessuna valutazione finora

- Flip Nepal Final ReportDocumento85 pagineFlip Nepal Final ReportKishor Paudel0% (1)

- Fundamentalconceptsofsoilreinforcement-Anoverview IJGE 2009 Shukla SivakuganandDasDocumento15 pagineFundamentalconceptsofsoilreinforcement-Anoverview IJGE 2009 Shukla SivakuganandDassaleh ehmouda99Nessuna valutazione finora

- Shear Connection DesignDocumento355 pagineShear Connection Designandyhr0% (1)

- Expansive Soil PaperDocumento32 pagineExpansive Soil PaperAnonymous ELujOV3Nessuna valutazione finora

- Isolated Footing Using Mathcad PrimeDocumento5 pagineIsolated Footing Using Mathcad PrimeYan YanNessuna valutazione finora

- Strength of Materials by F L Singer 4 Ed SolutionsDocumento314 pagineStrength of Materials by F L Singer 4 Ed SolutionsKhalid Yousaf83% (54)

- Seismaic Behaviour of Isloated BridgesDocumento41 pagineSeismaic Behaviour of Isloated Bridgespraveenpv7100% (1)

- Module 4 Shear Force Bending MomentDocumento32 pagineModule 4 Shear Force Bending MomentTarun Kumar100% (1)

- 3 B1 B2 MeanDocumento1 pagina3 B1 B2 MeanMaumoon SaleemNessuna valutazione finora

- Effect of Defects On Mechanical Properties of 2-D Material: A Project Report Submitted byDocumento40 pagineEffect of Defects On Mechanical Properties of 2-D Material: A Project Report Submitted byMukul JoshiNessuna valutazione finora

- T01 04 Gil-Martin - Hernandez-Montes - GNP2020Documento8 pagineT01 04 Gil-Martin - Hernandez-Montes - GNP2020Kenan KajosevicNessuna valutazione finora

- Zeeshan Rashool (18-CLE-62)Documento6 pagineZeeshan Rashool (18-CLE-62)56-2k18 Muhammad Abdullah100% (1)

- Tieu Chuan Thiet Ke-Fem-10-2-07-July-2004 PDFDocumento204 pagineTieu Chuan Thiet Ke-Fem-10-2-07-July-2004 PDFvongocsanhNessuna valutazione finora

- Raft FoundationDocumento11 pagineRaft FoundationUmer Farooq100% (1)

- Stress & Strain LectureDocumento5 pagineStress & Strain LectureVincentNessuna valutazione finora