Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

DR400 Manual 2011

Caricato da

3Oktober2011Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

DR400 Manual 2011

Caricato da

3Oktober2011Copyright:

Formati disponibili

CEAPR

1, route de Troyes

21121 DAROS

FRANCE

Tl. +33 (0) 380 35 25 22 Fax: +33 (0) 380 35 25 25

Web site: www.ceapr.com

- SSUE 3 -

Document n 1001606 GB

- 3

rd

Edition -

July 1995

Amendment 10 dated April 19

th

, 2011

Document no. 1001606 GB

C.E.A.P.R.

1, route de Troyes - 21121 Darois - FRANCE

Tel: +33 (0)3 80 35 25 22 Fax: +33 (0)3 80 35 25 25

Website: www.ceapr.com

MAINTENANCE MANUAL ROBIN DR400

3rd edition - July 1995 Amendment 9 dtd February 16

th

, 2011 page 0 - 1

SECTION 0

PRESENTATION

This manual covers the entire range of DR400 aircraft except for the DR400/500 and

DR400 RP.

It is divided into 16 sections for easy reference. The table of contents on the following

pages will guide users straight to the relevant paragraph. Section 16 deals with the special

features of the DR400/200R.

This document has been produced in good faith to be both thorough and accurate. It is

intended for use by specialist personnel in approved workshops. It is first and foremost an

aid to maitaining aircraft in an airworthy condition.

To improve maintenance and so increase flight safety users are invited to send any

comments or suggestions to:

C.E.A.P.R.

1, route de Troyes - 21121 Darois - FRANCE

Tl: +33 (0)3 80 25 22 Fax: +33 (0)3 80 35 25 25

Website: www.ceapr.com

COPYRIGHT STATEMENT

ALL RIGHTS RESERVED

This manual concerns exclusively DR400 aircraft followed up by C.E.A.P.R. It may not, in

whole or in part, be copied, photocopied, reproduced, translated, or reduced to any

electronic medium or machine readable form without prior consent, in writing, from

C.E.A.P.R.

WARNING: Improper or unauthorized applications of the information contained in

this manual may result in losses or damages to the user.

The accuracy and applicability of this manual has not been verified for any assembly,

component or part not manufactured by C.E.A.P.R. Any use of this manual for other than

its intended purpose or for performing any maintenance, replacement, adjustment or

inspection of any assembly, component or part not manufactured by C.E.A.P.R. is not

approved.

No liability will be assumed by C.E.A.P.R. for actual, consequential or other types of

damages directly or indirectly resulting from the unauthorized use of this manual for other

than its stated purposes.

When performing, maintenance, replacement, adjustment, inspection of any C.E.A.P.R.

assembly, component or part, it is imperative that the latest revision of the appropriate

manual or product support document be referenced. Contact C.E.A.P.R. to be sure you

have the latest manual or support document revision before performing any work.

All reasonable attempts were made to make this manual as complete and accurate as

possible. If you have any questions, comments, corrections or require clarification of any

information contained herein, please write:

C.E.A.P.R.

1, route de Troyes - 21121 Darois - FRANCE

MAINTENANCE MANUAL ROBIN DR400

page 0 - 2 Amendment 10 dtd April 19

th

, 2011 3rd edition - July 1995

LIST OF PAGES

Pages Amdt Date

First page 10 April 19

th

, 2011

0-1 9 February 16th, 2011

0-2 10 April 19

th

, 2011

0-3 5 June 1

st

, 2007

0-4 9 February 16th, 2011

0-5 10 April 19

th

, 2011

0-6 to 0-10 10 April 19

th

, 2011

1-1 to 1-5 - July 1995

1-6 to 1-8 6 July 27

th

, 2007

2-1 to 2-2 1 July 2006

3-1 to 3-2 - July 1995

3-3 8 July 01

st

, 2008

3-4 to 3-5 - July 1995

3-6 9 February 16th, 2011

3-5 to 3-8 - July 1995

4-1 to 4-5 - July 1995

4-6/a to 4-6/e 2 October 2006

4-7 to 4-12 - July 1995

5-1 to 5-11 - July 1995

5-12 10 April 19

th

, 2011

5-13 to 5-16 - July 1995

5-17 to 5-19 9 February 16th, 2011

5-20 to 5-21 - July 1995

5-22 1 July 2006

5-23 to 5-26 - July 1995

5-27 10 April 19

th

, 2011

5-28 to 5-42 - July 1995

5-43 6 July 27

th

, 2007

5-44 to 5-50 - July 1995

6-1 to 6-15 - July 1995

6-16 1 July 2006

6-17 to 6-21 - July 1995

6-22 8 July 01

st

, 2008

Pages Amdt Date

6-23 to 6-26 - July 1995

6-27 1 July 2006

6-28 - July 1995

7-1 to 7-12 - July 1995

7-13 1 July 2006

7-14 - July 1995

7-15 1 July 2006

7-16 - July 1995

7-17 1 July 2006

7-18 1 July 2006

7-19 to 7-20 - July 1995

8-1 to 8-18 - July 1995

9-1 to 9-20 - July 1995

9-21 to 9-24 10 April 19

th

, 2011

10-1 to 10-6 - July 1995

10-7 to 10-8 7 May 17

th

, 2008

11-1 to 11-2 - July 1995

12-1 to 12-13 - July 1995

12-14 8 July 01

st

, 2008

12-15 to 12-21 - July 1995

12-22 to 12-23 3 December 14

th

, 2006

12-23a 8 July 01

st

, 2008

12-24 5 June 1

st

, 2007

12-24a 8 July 01

st

, 2008

13-1 to 13-2 - July 1995

14-1 to 14-2 - July 1995

15-1 to 15-19 - July 1995

15-20 to 15-22 4 May 16

th

, 2007

15-23 8 July 01

st

, 2008

15-24 & 15-26 4 May 16

th

, 2007

16-1 to 16-23 - July 1995

16-24 to 16-25 3 December 14

th

, 2006

MAINTENANCE MANUAL ROBIN DR400

3rd edition - July 1995 Amendment 5 dtd June 01

st

, 2007 page 0 - 3

LIST OF AMENDMENTS

Amdt

n

Description of the amendment

Pages

amended

Date Approval

- List of pages

- List of amendments

0-2

0-3

- Update of Manufacturer address 1st, 01

- Description of Maintenance

Schedule

2-1, 2-2

- Installation torque for spark plugs

and lead nuts

3-3, 5-22

- SB95 & AD F-1982-145 taken

into account

6-16

- Updating of fig. 6.10 6-27

1

- Oleo-strut and wheel inflation

values

7-13, 7-15, 7-17

& 7-18

July

2006

The technical content

of the original French

version of this

document is

approved under the

authority of DOA

nr. EASA.21J.213.

- List of pages

- List of amendments

0-2

0-3

2

- Updating (following DET040703)

of 4.4.2.4. Adhesive bonding

p 4-6 suppressed

p 4-6/a to 4-6/e

inserted

October

2006

The technical content

of the original French

version of this

document is

approved under the

authority of DOA

nr. EASA.21J.213.

- Aircraft concerned

- List of pages

- List of amendments

0-1

0-2

0-3

3

- Updating of section 12 (following

DET060602R1 "Instruments and

cabin light). Electrical wiring

diagrams inserted.

12-14

12-22

16-24

Inserted pages:

12-23, 12-24 and

16-25

December

14

th

, 2006

The technical content

of the original French

version of this

document is

approved under the

authority of DOA

nr. EASA.21J.213.

4

- 1st page

- List of pages

- List of amendments

- Updating of Summary

- Updating of section 15

(DET020304 "Autopilot

S-TECH30: extended to other

models of DR400").

0-2

0-3

0-8

15-20

New pages:

15-21 to 15-26

May 16

th

,

2007

The technical content

of the original French

version of this

document is

approved under the

authority of DOA

nr. EASA.21J.213.

5

- 1st page

- List of pages

- List of amendments

- Updating of section 24

(DET070203 "Correction of

Electrical diagram 62-18-29").

0-2

0-3

12-24

June 01

st

,

2007

The technical content

of the original French

version of this

document is

approved under the

authority of DOA

nr. EASA.21J.213.

MAINTENANCE MANUAL ROBIN DR400

page 0 - 4 Amendment 9 dtd February 16

th

, 2011 3rd edition - July 1995

LIST OF AMENDMENTS (contd)

Amdt

n

Description of the amendment

Pages

amended

Date Approval

6

- 1st page

- List of pages

- List of amendments (Contd)

- Updating of sections 01 and 05

(DET020206) Lycoming engine

O-360 A1P taken into account for

DR400/180 and DR400/180R.

0-2

0-4

1-6 to 1-8

5-43

July 27

th

,

2007

The technical content

of the original French

version of this

document is

approved under the

authority of DOA

nr. EASA.21J.213.

7

- 1st page

- List of pages

- List of amendments (Contd)

- Summary

- Updating of sections 10

(DET040301) DR400 -

Instruments Magneti Marelli.

0-2

0-4

0-7

10-7 and 10-8

May 17

th

,

2008

The technical content

of the original French

version of this

document is

approved under the

authority of DOA

nr. EASA.21J.213.

8

- 1st page

- List of pages

- List of amendments (Contd)

- Updating of sections 3:

Torque setting of tightening

clamps for very low pressure

circuit hoses.

Special tools, reference of

drawings.

- Updating of sections 6

(DET060102 DR400 - Update of

pulley support tube)

- Updating of sections 12

(DET070306 DR400 - DC

generation - JPC Aviation

regulator). Insertion of electrical

diagrams.

- Updating of sections 15:

manufacturers name

0-2

0-4

3-3

3-6

6-22

12-14

12-23a

12-24a

15-23

July 01

st

,

2008

The technical content

of the original French

version of this

document is

approved under the

authority of DOA

nr. EASA.21J.213.

9

- 1st page

- List of pages

- List of amendments (Contd)

- Updating of sections (SB 100703

Powerplant Air intake Air

filter)

0-2

0-4

3-6

5-17 to 5-19

February

16th, 2011

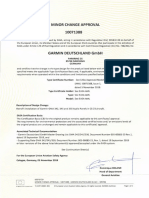

DET 100703

Major change

approval

EASA nr.10034051

Dtd 02.03.2011

MAINTENANCE MANUAL ROBIN DR400

3rd edition - July 1995 Amendment 10 dtd April 19

th

, 2011 page 0 - 5

LIST OF AMENDMENTS (contd)

Amdt

n

Description of the amendment

Pages

amended

Date Approval

10

- 1st page

- List of pages

- List of amendments (Contd)

- Summary

- Updating of section 5

(SB031104)

- Updating of section 9 (insertion of

Tank cap)

0-2

0-5, 0-6

0-7, 0-10

5-12, 5-27

9-21 to 9-24

April 19

th

,

2011

DET 031104

Major change

approval

EASA

nr.10034673

Dtd 19.04.2011

MAINTENANCE MANUAL ROBIN DR400

page 0 - 6 Amendment 10 dtd April 19

th

, 2011 3rd edition - July 1995

PAGE INTENTIONALLY LEFT BLANK

MAINTENANCE MANUAL ROBIN DR400

3rd edition - July 1995 Amendment 10 dtd April 19

th

, 2011 page 0 - 7

SUMMARY

Section, Title Wording

1 GENERAL CHARACTERISTICS 1.1 DESCRIPTION

1.2 AVAILABLE MODELS

1.3 DIMENSIONS

2 MAINTENANCE SCHEDULE

3 MAINTENANCE REQUIREMENTS, 3.1 MAINTENANCE REQUIREMENTS

INSPECTIONS AND REPAIRS 3.2 WEIGHING AND CENTRING

3.3 TORQUING (screwed components)

3.4 CONTROL SURFACE BALANCING

3.5 REPAIRS

3.6 PROTECTION

3.7 SPECIAL TOOLS

3.8 TECHNICAL CARE PRODUCTS

4 AIRFRAME 4.1 INTRODUCTION

4.2 FUSELAGE

4.3 FIREWALL

4.4 CANOPIES

4.5 WINGS

MAINTENANCE MANUAL ROBIN DR400

page 0 - 8 Amendment 10 dtd April 19

th

, 2011 3rd edition - July 1995

5 POWER-PLANT 5.1 ENGINE COMPRESSION - VERIFICATION

5.2 ENGINE AND ACCESSORIES - REMOVAL

(S/N < 2212)

5.3 ENGINE - SWIVELLING (S/N > 2212)

5.4 ENGINE AND ACCESSORIES - REMOVAL

(S/N 2212 and later)

5.5 CARBURETTOR

5.6 FUEL SYSTEM - ENGINE COMPARTMENT

5.7 ENGINE OIL SYSTEM

5.8 ENGINE AIR INTAKE

5.9 IGNITION

5.10 ENGINE CONTROLS

5.11 ENGINE SUPERVISION

5.12 EXHAUST

5.13 ENGINE MOUNT, ENGINE SHOCK MOUNTS

5.14 STARTER

5.15 ALTERNATOR

5.16 PROPELLERS

5.17 ENGINE BAFFLES

5.18 ENGINE STORAGE

5.19 OPERATING DEFECTS

6 FLIGHT CONTROLS AND 6.1 GENERAL, DESCRIPTION

CONTROL SURFACES 6.2 STABILATOR CONTROL

6.3 STABILATOR

6.4 STABILATOR TRIM

6.5 RUDDER BARS (Pre-1988 aircraft)

6.6 RUDDER BARS (Post-1988 aircraft)

6.7 RUDDER

6.8 AILERON CONTROL

6.9 AILERONS

6.10 FLAP CONTROL

6.11 FLAPS

6.12 OPTIONS

7 LANDING GEAR 7.1 DESCRIPTION

7.2 NOSE LANDING GEAR

7.3 MAIN LANDING GEAR

7.4 WHEELS

7.5 FLUID AND HYDRAULIC LANDING GEAR - FILLING

7.6 FAULT-FINDING

MAINTENANCE MANUAL ROBIN DR400

3rd edition - July 1995 Amendment 10 dtd April 19

th

, 2011 page 0 - 9

8 BRAKING SYSTEM 8.1 DRUM BRAKES - MAIN WHEEL ASSEMBLY

8.2 DISC BRAKES - MAIN WHEEL ASSEMBLY

8.3 BRAKE UNIT - PRE-1988 AIRCRAFT

8.4 BRAKE UNIT - 1988-1989 VERSION

8.5 BRAKE UNIT - 1989-1992 VERSION

8.6 BRAKE UNIT - POST-1992

8.7 MASTER CYLINDER AND PARKING BRAKE

VALVE SEALS - REPLACEMENT

8.8 BRAKE SYSTEM - DRAINING / BLEEDING

8.9 BRAKE FLUID RESERVOIR

8.10 FAULT-FINDING

9 FUEL SYSTEM 9.1 DESCRIPTION, GENERAL POINTS

9.2 110 LITRE MAIN FUEL TANK

9.3 WING TANK (S/N < 2137 & 2145, 2146)

9.4 WING TANK (S/N 2137 except 2145, 2146)

9.5 AUXILIARY FUEL TANKS

9.6 FUEL GAUGE

9.7 FUEL LEVEL SENDER ADJUSTMENT

9.8 FINGER SCREENS, FILTERS AND DRAINS

9.9 FUEL SELECTOR VALVES AND CONTROL

9.10 ELECTRICAL PRIMER PUMP

9.11 FUEL LINES, CONNECTIONS

9.12 TANK CAP

9-13 FAULT FINDING

10 INSTRUMENTS 10.1 GENERAL POINTS

10.2 PITOT-STATIC SYSTEM

10.3 VACUUM SYSTEM

10.4 TACHOMETER

10.5 FUEL PRESSURE INDICATOR

10.6 WESTACH OIL TEMPERATURE INDICATOR

11 INSTRUMENT PANEL, CONSOLE 11.1 GLARESHIELD

11.2 GLOVE COMPARTMENT

11.3 INSTRUMENT PANEL

11.4 CENTRE CONSOLE

11.5 FACIA PANEL

MAINTENANCE MANUAL ROBIN DR400

page 0 - 10 Amendment 10 dtd April 19

th

, 2011 3rd edition - July 1995

12 ELECTRICAL SYSTEM 12.1 WET ELECTROLYTE BATTERY

12.2 DRY BATTERIES (GEL)

12.3 BATTERY AND STARTER RELAY

12.4 REGULATOR AND OVERVOLTAGE RELAY

12.5 LANDING AND TAXI LIGHTS

12.6 GENERAL POINTS - WIRING

12.7 WIRING DIAGRAMS

13 HEATING AND VENTILATION 13.1 HEATING: DESCRIPTION - OPERATION

13.2 VENTILATION

13.3 HEATING SYSTEM MAINTENANCE

14 SEATS - PANELLING 14.1 FRONT SEATS

14.2 REAR SEATS

14.3 SEAT BELTS

14.4 SIDE PANELLING

14.5 CARPETS

15 OPTIONS - ACCESSORIES 15.1 NAVIGATION LIGHTS - ANTI-COLLISION LIGHTS

15.2 RADIO-NAVIGATION SETS

15.3 AUXILIARY FUEL TANKS

15.4 BAGGAGE COMPARTMENT DOOR

15.5 ROLL STABILISER

15.6 RUDDER TRIM

15.7 SILENCERS - EXHAUST FLUTES

15.8 TOW HOOK (DR400/180R & DR400/200R)

15.9 ADJUSTABLE REAR VIEW MIRROR

15.10 FIXED REAR VIEW MIRRORS

15.11 CABLE WINDER (MAAG Type RPM 01/88)

15.12 GROUND POWER SOCKET (NATO type)

15.13 S-TEC 20/30 AUTOPILOT

16 DR400/200R 16.1 GENERAL POINTS - PRESENTATION

16.2 ENGINE

16.3 PROPELLER

16.4 ENGINE AIR INTAKE

16.5 ENGINE CONTROLS

16.6 ENGINE COWL FLAP

16.7 EXHAUST AND SILENCER

16.8 FUEL SYSTEM

16.9 ELECTRICAL SYSTEM

16.10 HEATING - VENTILATION

MAINTENANCE MANUAL ROBIN DR400

page 1 - 6 Amendment 6 dtd July 27

th

, 2007 3rd Edition - July 1995

AIRCRAFT

LYCOMING

ENGINE

TYPE

NORMAL

RATED

POWER

CARBURAT.

setting

DISPLACEMENT

COMPR.

RATIO

FIRING

ORDER

DR400/100 O-235 L2A

118 HP

2800 RPM

MA3 PA

10.51.42

10.52.20

3769 cm

3

233.3 cu.in

8.5 :1 1-3-2-4

DR400/2+2

O-235 H2C

or C2C

108 HP

2600 RPM

MA3 PA

10.50.50

3769 cm

3

233.3 cu.in

6.75:1 1-3-2-4

DR400/120

O-235 L2A

or K2A or

K2B

118 HP

2800 RPM

MA3 PA

10.51.42

10.52.20

3769 cm

3

233.3 cu.in

8.5 :1 1-3-2-4

DR400/120A

O-235 L2A

or K2A or

K2B

118 HP

2800 RPM

MA3 PA

10.51.42

10.52.20

3769 cm

3

233.3 cu.in

8.5 :1 1-3-2-4

DR400/120D

O-235 L2A

or K2A or

K2B

118 HP

2800 RPM

MA3 PA

10.51.42

10.52.20

3769 cm

3

233.3 cu.in

8.5 :1 1-3-2-4

DR400/125

O-235 F2B

or J2A

125 HP

2800 RPM

MA3 PA

10.51.26

3769 cm

3

233.3 cu.in

9.7:1 1-3-2-4

DR400/140 O-320 E2A

150 HP

2700 RPM

MA4SPA

10.50.09

5240 cm

3

320 cu.in

7.0:1 1-3-2-4

DR400/140B O-320 D2A

160 HP

2700 RPM

MA4SPA

10.49.10

10.51.35

10.52.17

5240 cm

3

320 cu.in

7.0:1 1-3-2-4

DR400/160 O-320 D2A

160 HP

2700 RPM

MA4SPA

10.49.10

10.51.35

10.52.17

5240 cm

3

320 cu.in

8.5:1 1-3-2-4

DR400/160D O-320 D2A

160 HP

2700 RPM

MA4SPA

10.49.10

10.51.35

10.52.17

5240 cm

3

320 cu.in

8.5:1 1-3-2-4

DR400/180

O-360 A3A

or A1A or

A1P

180 HP

2700 RPM

MA4S

10.38.78

5900 cm

3

361 cu.in

8.5:1 1-3-2-4

DR400/180S O-360 A3A

180 HP

2700 RPM

MA4S

10.38.78

5900 cm

3

361 cu.in

8.5:1 1-3-2-4

DR400/180R

O-360 A3A

or A1P

180 HP

2700 RPM

MA4S

10.38.78

5900 cm

3

361 cu.in

8.5:1 1-3-2-4

DR400/200R

IO-360

A1B6

200 HP

2700 RPM

INJECTION

RSA-5AD1

5900 cm

3

361 cu.in

8.7:1 1-3-2-4

DR400/NGL O-360 A3A

180 HP

2700 RPM

MA4S

10.38.78

5900 cm

3

361 cu.in

8.5:1 1-3-2-4

TABLEAU 1.1 DR400 CHARACTERISTICS (ALL MODELS)

MAINTENANCE MANUAL ROBIN DR400

3rd Edition - July 1995 Amendment 6 dtd July 27

th

, 2007 page 1 - 7

MAGNETOS *** FUEL

AIRCRAFT

LYCOMING

ENGINE

TYPE LEFT RIGHT

SPARK

OCCURS

OCTANE

MINI

TOTAL

QUANTITY

UNUSABLE

FUEL QTY

DR400/100 O-235 L2A

S4LN-21

or 4372

S4LN-20

or 4370

20BTC 100/100LL MAIN: 110 L 10 L **

DR400/2+2

O-235 H2C

or C2C

4251

or 4371

4250 25BTC 80/87

MAIN: 110 L

Option : 50 L

10 L **

DR400/120

O-235 L2A

or K2A or

K2B

S4LN-21

or 4372

S4LN-20

or 4370

20BTC 100/100LL

MAIN: 110 L

Option : 50 L

10 L **

DR400/120A

O-235 L2A

or K2A or

K2B

S4LN-21

or 4372

S4LN-20

or 4370

20BTC 100/100LL

MAIN: 110 L

Option : 50 L

10 L **

DR400/120D

O-235 L2A

or K2A or

K2B

S4LN-21

or 4372

S4LN-20

or 4370

20BTC 100/100LL

MAIN: 110 L

Option : 50 L

10 L **

DR400/125

O-235 F2B

or J2A

S4LN-1227

or 4373

S4LN-1209

or 4370

25BTC 100/100LL

MAIN: 110 L

Option : 50 L

10 L **

DR400/140 O-320 E2A

S4LN-21

or 4373

S4LN-20

or 4370

25BTC 80/87

MAIN: 110 L

Option : 50 L

10 L **

DR400/140B O-320 D2A

S4LN-21

or 4373

S4LN-20

or 4370

25BTC

91/96 or

100/130

MAIN: 110 L

Option : 50 L

10 L **

DR400/160 O-320 D2A

S4LN-21

or 4373

S4LN-20

or 4370

25BTC

91/96 or

100/130

MAIN: 110 L

WING : 2x40 L

Option : 50 L

10 L **

2x1L

DR400/160D O-320 D2A

S4LN-21

or 4373

S4LN-20

or 4370

25BTC

91/96 or

100/130

MAIN: 110 L

WING : 2x40 L

Option : 50 L

10 L **

2x1L

DR400/180

O-360 A3A

or A1A or

A1P

S4LN-21

or 4373

S4LN-20

or 4370

25BTC

91/96 or

100/130

MAIN: 110 L

WING : 2x40 L

Option : 50 L

10 L **

2x1L

DR400/180S O-360 A3A

S4LN-21

or 4373

S4LN-20

or 4370

25BTC

91/96 or

100/130

MAIN: 110 L

WING : 2x40 L

Option : 50 L

10 L **

2x1L

DR400/180R

O-360 A3A

or A1P

S4LN-21

or 4373

S4LN-20

or 4370

25BTC

91/96 or

100/130

MAIN: 110 L

Option : 50 L

10 L

DR400/200R

IO-360

A1B6

S4LN-1227

or 4372

or 4373

S4LN-1209

or 4370

20BTC * 100/130

MAIN: 110 L

Option : 50 L

1 L

DR400/NGL O-360 A3A

S4LN-21

or 4373

S4LN-20

or 4370

25BTC

91/96 or

100/130

MAIN: 110 L

WING : 2x40 L

Option : 50 L

10 L **

2x1L

* NOTE : depends on the engine serial number

** NOTE : aircraft serial number 2212 and up: unusable fuel quantity of the main tank: 1 litre

*** NOTE : Magnetos SLICK or BENDIX might be fitted

TABLEAU 1.2 DR400 CHARACTERISTICS (ALL MODELS) (continued)

MAINTENANCE MANUAL ROBIN DR400

page 1 - 8 Amendment 6 dtd July 27

th

, 2007 3rd Edition - July 1995

ENGINE OIL

AIRCRAFT

LYCOMING

ENGINE

TYPE

OIL SUMP

CAPACITY

MINI SAFE

QUANTITY

CONSUMP.

Litres/h

MAXIMUM

PRESSURE

MINIMUM

PRESSURE

MAXIMUM

TEMP.

DR400/100 O-235 L2A

5,7 litres

6 Qts

1,9 litres

2 Qts

0,29 l/h

75% rated

6,2 BAR

90 PSI

4,13 BAR

60 PSI

118 C

245 F

DR400/2+2

O-235 H2C

or C2C

5,7 litres

6 Qts

1,9 litres

2 Qts

0,28 l/h

75% rated

6,2 BAR

90 PSI

4,13 BAR

60 PSI

118 C

245 F

DR400/120

O-235 L2A

or K2A or

K2B

5,7 litres

6 Qts

1,9 litres

2 Qts

0,28 l/h

75% rated

6,2 BAR

90 PSI

4,13 BAR

60 PSI

118 C

245 F

DR400/120A

O-235 L2A

or K2A or

K2B

5,7 litres

6 Qts

1,9 litres

2 Qts

0,28 l/h

75% rated

6,2 BAR

90 PSI

4,13 BAR

60 PSI

118 C

245 F

DR400/120D

O-235 L2A

or K2A or

K2B

5,7 litres

6 Qts

1,9 litres

2 Qts

0,28 l/h

75% rated

6,2 BAR

90 PSI

4,13 BAR

60 PSI

118 C

245 F

DR400/125

O-235 F2B

or J2A

5,7 litres

6 Qts

1,9 litres

2 Qts

0,28 l/h

75% rated

6,2 BAR

90 PSI

4,13 BAR

60 PSI

118 C

245 F

DR400/140 O-320 E2A

7,6 litres

8 Qts

1,9 litres

2 Qts

0,35 l/h

75% rated

6,2 BAR

90 PSI

4,13 BAR

60 PSI

118 C

245 F

DR400/140B O-320 D2A

7,6 litres

8 Qts

1,9 litres

2 Qts

0,35 l/h

75% rated

6,2 BAR

90 PSI

4,13 BAR

60 PSI

118 C

245 F

DR400/160 O-320 D2A

7,6 litres

8 Qts

1,9 litres

2 Qts

0,35 l/h

75% rated

6,2 BAR

90 PSI

4,13 BAR

60 PSI

118 C

245 F

DR400/160D O-320 D2A

7,6 litres

8 Qts

1,9 litres

2 Qts

0,35 l/h

75% rated

6,2 BAR

90 PSI

4,13 BAR

60 PSI

118 C

245 F

DR400/180

O-360 A3A

or A1A or

A1P

7,6 litres

8 Qts

1,9 litres

2 Qts

0,42 l/h

75% rated

6,55 BAR

95 PSI

3,8 BAR

55 PSI

118 C

245 F

DR400/180S O-360 A3A

7,6 litres

8 Qts

1,9 litres

2 Qts

0,42 l/h

75% rated

6,55 BAR

95 PSI

3,8 BAR

55 PSI

118 C

245 F

DR400/180R

O-360 A3A

or A1P

7,6 litres

8 Qts

1,9 litres

2 Qts

0,42 l/h

75% rated

6,55 BAR

95 PSI

3,8 BAR

55 PSI

118 C

245 F

DR400/200R

IO-360

A1B6

7,6 litres

8 Qts

1,9 litres

2 Qts

0,48 l/h

75% rated

6,55 BAR

95 PSI

3,8 BAR

55 PSI

118 C

245 F

DR400/NGL O-360 A3A

7,6 litres

8 Qts

1,9 litres

2 Qts

0,42 l/h

75% rated

6,55 BAR

95 PSI

3,8 BAR

55 PSI

118 C

245 F

TABLEAU 1.3 DR400 CHARACTERISTICS (ALL MODELS) (continued).

MAINTENANCE MANUAL ROBIN DR400

3rd Edition - July 1995 Amendment July 2006 page 2 - 1

SECTION 2

MAINTENANCE SCHEDULE

The maintenance programme is covered by a separate document entitled:

"AIRWORTHINESS LIMITATIONS & MAINTENANCE SCHEDULE"

(document no. 1001586 GB)

The Maintenance Schedule is made up of six headings:

Section 1 GENERAL INSTRUCTIONS

Section 2 TIME BETWEEN INSPECTIONS

Section 3 COMPONENTS AND EQUIPMENTS MAINTENANCE, USE AND

STORAGE PRACTICES

Section 4 SPECIAL MAINTENANCE INSPECTIONS

Section 5 CONTROL FLIGHT

Section 6 MAINTENANCE OPERATIONS TABLE

MAINTENANCE MANUAL ROBIN DR400

page 2 - 2 Amendment July 2006 3rd Edition - July 1995

PAGE INTENTIONALLY LEFT BLANK

MAINTENANCE MANUAL ROBIN DR400

3rd edition - July 1995 Amendment 8 dtd July 01

st

, 2008 page 3 - 3

3.3 - TORQUING (screwed components)

3.3.1 - Tightening on wood

When at least one of the components to be assembled is made of wood (frequently

the case on the DR400) assembly screws, bolts and nuts shall be torqued in

accordance with the rules of the art.

Reminder:

Wood varies in volume with atmospheric conditions (especially moisture).

CAUTION

Repeated tightening on wood causes non-negligible deformation of the support and the nut may

damage the last thread of the bolt.

CHECK NO SUCH DAMAGE OCCURS (engine mount attachment, landing gear attachment, nose

gear bracket, etc.). ADD A WASHER UNDER THE NUT WHERE NECESSARY.

3.3.2 - Tightening on metal components

General rule (values shown for self-locking nuts)

STANDARD TORQUE VALUES FOR STEEL NUTS AND BOLTS*

NOMINAL LUBRICATED UNLUBRICATED

DIMENSION m.daN in.lbs m.daN in.lbs

dia. 5 mm 0.3 26 0.5 44

dia. 6 mm 0.5 44 0.9 80

dia. 8 mm 1.2 106 2.0 177

dia. 10 mm 2.5 220 4.0 354

* Tolerance: 0, +15%

3.3.3 - Special torque settings

Propellers: refer exclusively to the manufacturer's manual or the indications on the

propeller placard.

Engine shock mount bolts: 5 - 5.7 m.daN (450 - 500 in.lbs).

Installation torque for spark plugs: 420 lbf.in (35 lbf.ft) 4,75 daN.m (see Lycoming

SI 1042).

Installation torque for lead nuts (see Lycoming SI 1042):

- nut 5/8 - 24 : 80-90 lbf.in 0,9 - 1,0 daN.m

- nut 3/4 - 20 : 110-120 lbf.in 1,24 - 1,36 daN.m

Tightening clamps for very low pressure circuit hoses (fuel circuit before pumps) and

connections of air ducts for cabin air (warm and cold) and for air heat exchanger

(cooling of oil): 5 N.m or 0.5 daN.m (44.25 lbf.in or 3.69 lbf.ft), tolerance 0, +15% for

hoses in good condition.

3.4 - CONTROL SURFACE BALANCING

Any repair work on the ailerons or stabilator must be carried out with stringent

observance of the balancing requirements defined in fig. 3.2. Balance shall

therefore be checked after such operations.

This operation is performed with the control surface disconnected and set on

friction-free axes (e.g. knife edge support).

No weight may be added to or removed from these components without written

consent from the manufacturer.

MAINTENANCE MANUAL ROBIN DR400

page 3 - 6 Amendment 9 dtd February 16

th

, 2011 3rd edition - July 1995

3.6 - PROTECTION

All components are protected when new (varnish, paint, cadmium-plating,

electrolytic plating, etc.).

This protection may disappear over time or with wear possibly entailing serious

deterioration of the airframe (wood rot, metal corrosion, etc.).

It is therefore important to remedy matters as soon as possible.

Electrochemically protected components (cadmium or electrolytic plating, etc.) must

be renewed.

3.7 - SPECIAL TOOLS

Drawing (1)

- Aileron test template ..........................................

- Stabilator adjustment template...........................

- Anti-balance tab adjustment template................ 96-18-02

- Rudder adjustment template..............................

- Flap adjustment template...................................

- Shimmy damper test sleeve.................................. 96-18-01

- Valve core extractor (Schrader 30456-01)

- Swivel mount pin protector .................................... 96-18-00

- Vacuum regulator valve wrench............................ 96-18-03

These tools can be ordered from C.E.A.P.R. Parts department.

(1) Drawings are available on C.E.A.P.R. website.

3.8 - TECHNICAL CARE PRODUCTS

See table 3.1 on the next page.

There may be equivalent products to those listed (e.g. other brands) but the

manufacturer's approval must be obtained before use.

MAINTENANCE MANUAL ROBIN DR400

3rd edition - July 1995 page 4 - 5

4.4.2.2 - Rivet fastening

- Drill out the rivets (diameter 3.2 mm) all around the edge.

- Pull off the old Plexiglas taking care to cut the adhesive beads as you work.

Take care not to unstick the panelling.

- Take the opportunity to change the weatherstrips at the same time.

- Before fitting the new Plexiglas check the canopy frame thoroughly.

- Scrape off any adhesive, bonding compound or sealant and renew the protection

if necessary (zinc chromate).

- Lay on the Plexiglas with the weatherstrip (if any) held in place (adhesive tape)

and mark it out for trimming (narrow adhesive tape). Final fitting is to be done

with the canopy closed.

Have suitably sized washers ready for fitting between the Plexiglas and the

frame (when riveting) so the mating surfaces can be aligned.

- The Plexiglas must be trimmed around the wooden dome (ahead of the

instrument panel) to leave a constant 5 mm clearance (except for the sides

which must be well clear of the guides fixed to the front of the fuselage).

- Drill the Plexiglas by transparency (3.2 mm diameter pilot hole - final hole in

Plexiglas only: diameter 6 mm).

- Rivet (with packing washers as required), coating the rivet with polyurethane

sealant so the assembly is watertight.

- Apply a bead of black silicone sealant around the inner edges and smooth out

(damp cloth and finger).

- Refit the cover strip, handles, etc. making sure the seals are watertight

(polyurethane sealant or equivalent).

- Repaint.

REMINDER: Drill at high speed using a slow helix bit with a ground tip. See fig. 4.2.

NOTE: Remove the old rivets and other debris from the canopy anchor stud

compartments so they cannot interfere with the canopy jettison system.

4.4.2.3 - Screw fastening

Same procedure as for rivets except:

- Use new screws and seals (see spares catalogue).

- Final hole in Plexiglas: 8 mm diameter (be sure to use a drill bit with a ground

tip).

NOTE: Sealing washers may be replaced by polyurethane sealant applied in

sufficient quantity when fitting the screw to ensure a watertight seal.

MAINTENANCE MANUAL ROBIN DR400

page 4 - 6/a Amendment 2 - October 2006 3rd edition - July 1995

4.4.2.4 - Adhesive bonding

This process is used for polyesters domes, plexiglas REAR side panels and the doors of

baggage compartment of planes after 1988. It was extended to all canopy transparent

sheet and polyesters fastening processes since 1993 (serial no. 2212 and later).

At the beginning, the bonding of canopy has been made by means of compound

SIKAFLEX 260 or BETASEAL HV3 product.

The BETASEAL HV3 product, totally disappeared from the market, has been replaced by

the BETAMATE 7120.

Compounds BETAMATE 7120 or SIKAFLEX 260 can be used for the bonding of the

plexiglas of canopy by applying the respective instructions (see appendices below).

Limitations of use.

For the record:

Plexis glued with BETASEAL HV3 can be replaced and reglued with BETAMATE

7120. If this bonding is performed on the residues of cut joint (normal procedure), a

reactivating product 4000 or 4001 of the same manufacturer must be used.

Plexis glued with the SIKAFLEX 260 can be replaced and reglued with the

SIKAFLEX 260, provided that the remaining residues are not granular and perfectly

adhering to supports. Should the opposite occur, it is necessary to eliminate

mechanically any trace of the previous product.

Reglueing with a product of different brand from that of origin is unknown

and therefore unacceptable.

Consult the Individual Register of Control (RIC Registre Individuel de Contrle) to

possibly identify the type of glue used in production.

When the identification of the glue of origin is not possible, it is necessary to totally

clean the area to be glued.

General

a) Removal of the former plexiglas:

The used compound can only be removed mechanically. Cut the joint on its whole width

and all around by means of sharp blades (there are electric or pneumatic sharp devices).

NOTE: there might be locally washers to assure the thickness of the joint.

Cut away any remaining adhesive. However, it is not necessary to clean to bare support;

a thin layer of adhesive may remain.

CAUTION

Where the adhesive is applied directly to the fabric-covered wood (rear side panels,

plastic dome) special care must be taken not to damage the support.

MAINTENANCE MANUAL ROBIN DR400

3rd edition - July 1995 Amendment 2 - October 2006 page 4 - 6/b

b) Trimming the new plexiglas:

Hold the new sheet in place and trim around it roughly so it can be clamped in its final

position and marked out (narrow adhesive tape) for final cutting.

c) Preparation of surfaces:

See instructions specific to each compound (see appendix below).

d) Application of the compound bead:

Put down in a continuous and uniform way a preferably triangular bead (preparation of the

extremity of the syringe) of following dimension (mm):

e) Fitting of the element to be glued:

Guide and position so as to avoid any sliding.

Put in contact and press on the bead in such a way that it flows under pressure.

The pressed bead can be maxi 3 mm thick as long as the width of bonding is minimum

10 mm.

In the case of bonding of big length with products having very different coefficients of

expansion: the thickness of the bead will preferably have to be at least 1 mm.

Note: adhesives of polyurethane type such as Betamate 7120 or Sikaflex 260 are

incompatible with silicone type adhesives or silicone type compound throughout curing.

Wait approximately 48 hours before using such products (smoothed fillets).

f) Protecting against delamination:

Fit a screw at each corner of the Plexiglas.

g) Paint finish:

It is essential to widely paint over the bonded areas.

h) Protection:

If the bonding concerns a transparent, an anti-UV protection must be applied to all the

glued zone.

i) Record in the maintenance documents the glue used when replacing the canopy.

8 to 10

8 to 10

MAINTENANCE MANUAL ROBIN DR400

page 4 - 6/c Amendment 2 - October 2006 3rd edition - July 1995

Appendix 1

APPLICATION OF BETAMATE 7120 COMPOUND

The information of the technical cards of these products is applicable.

INDUSTRIAL HYGIENE AND SAFETY

Refer to the safety cards published by the manufacturer for each of the products.

ASSOCIATED PRODUCTS

The compound is necessarily used with a primer after cleaning grease off.

The grease remover is the BETACLEAN 3900. It is possible to use isopropylique alcohol.

The primer is BETAPRIME 5402 or 5404 for the following supports:

gelcoat side of polyester

fiber side of polyester

aluminium with acrylic-polyurethane painting

aluminium with phosphating primer

steels with acrylic - polyurethane painting

steel with phosphating primer

Altuglas and plexiglas

PREPARATION OF SURFACES

Maskings of zones to be protected.

Slight abrasive paper sandind of surfaces to be glued with Adhesive Tape Brite medium

grain (any type of support).

Degreasing.

Minimum drying 5 minutes in ambient temperature.

Application of the primary on the surface with a paintbrush in the thinner possible single

layer (do not paint again).

Minimum drying approximately 30 seconds in ambient temperature following technical

index card. The film must be perfectly dry.

Particular case: on fabric-covered wood: bonding directly on the fabric so that the

compound crosses this one, thus not painted fabric. For the record, the adhesive

resistance on this substratum is weak and has to be the object of a particular study.

MAINTENANCE MANUAL ROBIN DR400

3rd edition - July 1995 Amendment 2 - October 2006 page 4 - 6/d

Appendix 2

MASTIC - GLUE SIKAFLEX 260 APPLICATION

The information of the technical index card of this product is applicable.

HYGIENE AND SAFETY(SECURITY)

Refer to the safety cards published by the manufacturer for each of the products.

ASSOCIATED PRODUCTS

The mastic sticks is necessarily used with a primer after cleaning grease off (except on

fabric-covered wood)

The grease remover is the SIKA 205, possibility of using isopropylique alcohol.

The primer is SIKA 209 for the following supports:

aluminium with acrylic - polyurethane painting

aluminium with phosphating primer

steels with acrylic - polyurethane painting

steel with phosphating primer

Altuglas and plexiglas

The primer is SIKA 210T for the following supports:

gel coat side of polyester

fiber side of polyester

PREPARATION OF SURFACES

Masking of zones to be protected;

Slight abrasive paper sandind of surfaces to be glued with Adhesive Tape Brite medium

grain (any type of support).

Degreasing

Minimum drying 10 minutes in ambient temperature.

Application of the primary on the surface with a paintbrush in the thinner possible single

layer (do not paint again).

Minimum drying 30 minutes in ambient temperature

Particular case: on fabric-covered wood: bonding directly on the fabric so that the

compound crosses this one, thus not painted fabric. For the record, the adhesive

resistance on this substratum is weak and has to be the object of a particular study.

MAINTENANCE MANUAL ROBIN DR400

page 4 - 6/e Amendment 2 - October 2006 3rd edition - July 1995

PAGE INTENTIONALLY LEFT BLANK

MAINTENANCE MANUAL ROBIN DR400

page 5 - 12 Amendement 10 dtd April 19

th

, 2011 3rd edition - July 1995

5.7 - ENGINE OIL SYSTEM

5.7.1 - Oil change

- The oil is changed with the engine warm.

- Whenever the oil is changed, the strainer (screen) must be examined and

cleaned. It is located in the sump at the rear of the engine and fastened by four

screws. Renew the flat seal whenever it is removed.

- Authorized oils are listed on Textron Lycoming SI 1014.

Refer to the latest edition.

Reminder: required oil quantity

O-235 engine 6 Qts = 5.7 litres

O-320 engine 8 Qts = 7.6 litres

O-360 engine 8 Qts = 7.6 litres

IO-360 engine 8 Qts = 7.6 litres

5.7.2 - Oil cooler

5.7.2.1 - Maintenance, verification

- Check the cooler support brackets are in good condition and properly fixed.

- Make sure there are no leaks from the connectors. The fittings have taper

threads and must be moderately tight (max. 3 m.daN) as the internal thread is

made of aluminium.

If removed apply anti-seize compound systematically (cf. care products) to

prevent binding.

- Remove the plastic (or metal) diffuser from above the cooler. Clean and inspect

the cooling fins.

- Check that the grill on the baffle is clean.

5.7.2.2 - Oil cooler - replacement

No repairs to the oil cooler are authorized.

The cooler must be replaced if a leak is detected.

5.7.3 - Oil pressure

- The pressure sender is located:

S/N < 2212: right hand side, fastened to the firewall;

S/N 2212: right hand side, fastened to a side tube on the engine mount.

- The oil line that supplies the sender must be clean for it to work properly. In case

of malfunction, perform a careful cleaning of the oil hose and connectors,

including the restricted fitting and make sure to bleed any air from the line when

refitting.

5.7.4 - Oil temperature

The oil temperature sensor is located on the sump containing the strainer on the

accessory housing at the back of the engine.

See the electrical wiring diagram for connections.

MAINTENANCE MANUAL ROBIN DR400

3rd edition - July 1995 Amendment 9 dtd February 16

th

, 2011 page 5 - 17

5.8.4 - Intake assembly type C

5.8.4.1 - Air filter

The air filter is the "mesh and fabric" ring type located under the carburettor and

can be reached by removing the circular cover under the air intake box.

Clean thoroughly and check the general condition of the fabric in particular.

5.8.4.2 - Carburettor air intake box

Check the condition of the flap and bearings. Make sure there are no cracks in the

box and that the safety diaphragm (rubber) is flexible.

5.8.5 - Intake assembly type D

5.8.5.1 - Air filter

The air filter has an elliptic shape and is of the car type.

The first version of the air filter (P/N 56.23.02.000) which was not reversible has

been replaced in 2011 with filter (P/N 56.23.02.200) opened on both ends in order

to suppress any risk of back-to-front installation.

When installing the second version of the filter (P/N 56.23.02.200), the securing

plate (new plate with no hole) was to be replaced as well (refer to SB 100703).

5.8.5.2 - Carburettor air intake box

- Make a special check that the carburettor heat flap is in good condition. Remove

it to examine concealed areas, especially the areas adjacent to the welds.

- Check for cracks and flaking paint.

- Condition of bearings and pins.

5.8.6 - Intake assembly type E

5.8.6.1 - Air filter

The air filter is of the accordion fold "mesh and fabric" type.

The first version of the air filter (P/N 56.28.10.000) which was not reversible has

been replaced in 2011 with filter (P/N 56.28.10.200) with mesh on both sides in

order to suppress any risk of back-to-front installation.

5.8.6.2 - Carburettor air intake box

- Make a special check that the carburettor heat flap is in good condition. Remove

it to examine concealed areas, especially the areas adjacent to the welds.

- Check for cracks and flaking paint.

- Condition of bearings and pins.

MAINTENANCE MANUAL ROBIN DR400

page 5 - 18 Amendment 9 dtd February 16

th

, 2011 3rd edition - July 1995

5.8.7 - Intake assembly type F

5.8.7.1 - Air filter

The air filter is located in a recess in the lower cover and is a paper filter on a cell

type support. Clean with a compressed air line only and replace in accordance with

the maintenance schedule.

5.8.7.2 - Intake conduit

- This is a rubber gaiter fastened to the rear of the filter housing. Check it is in

good condition and that the metal trim inside is fitted to retain its shape.

5.8.7.3 - Carburettor air intake box

- Make a special check that the carburettor heat flap is in good condition. Remove

it to examine concealed areas, especially the areas adjacent to the welds.

- Check for cracks and flaking paint.

- Condition of bearings and pins.

5.8.8 - Intake assembly types G & H

5.8.8.1 - Air filter

The air filter is made of open cell foam which comes in two grades (regular and

severe fouling).

The filter may be cleaned with a compressed air line, and possibly with fuel. It must

be replaced at least every 100 hours in accordance with the maintenance schedule.

5.8.8.2 - Conduit from air filter to air intake box

- The conduit is made of flameproof reinforced plastic: it may only be repaired with

flameproof resin.

5.8.8.3 - Carburettor air intake box

- The box is fastened under the carburettor with a thick aluminium shim and a flat

washer on either side: see 5.3.3.

- It can be removed by taking off the bottom cover.

- The closure flap can be removed for inspection or replacement: it is held on its

pivots by two countersunk screws (head at felt side), washers and nuts.

NOTE: the screw heads are in contact with the flap (the felt is cut clear). The torque

value must be 0.4 - 0.5 m.daN.

- The felt is slightly larger than the flap and overlaps at the top by 3-4 mm

providing an airtight seal in the "carburettor heat" position.

Make regular checks (every 100 hours) that the overlap cannot be folded inside

the box when worn.

- The four bottom corners of the box are deliberately left open to prevent any fuel

accumulating whatever the attitude of the aircraft: make sure the openings are

not fouled.

MAINTENANCE MANUAL ROBIN DR400

3rd edition - July 1995 Amendment 9 dtd February 16

th

, 2011 page 5 - 19

5.8.9 - Intake assembly type J

5.8.9.1 - Air filter

The air filter is made of open cell foam which comes in two grades (regular and

severe fouling).

The filter may be cleaned with a compressed air line, and possibly with gasoline. It

must be replaced at least every 100 hours in accordance with the maintenance

schedule.

5.8.9.2 - Conduit from air filter to air intake box

- The conduit is made of flameproof reinforced plastic: it may only be repaired with

flameproof resin.

5.8.9.3 - Carburettor air intake box

- The box is fastened to the carburettor: see 5.3.3.

- It can be removed by taking off the bottom cover.

- The closure flap can be removed for inspection or replacement: it is held on its

pivots by two countersunk screws (head at felt side), washers and nuts.

NOTE: the screw heads are in contact with the flap (the felt is cut clear). The torque

value must be 0.4-0.5 m.daN.

- The felt is slightly larger than the flap and overlaps at the top by 3-4 mm

providing an airtight seal in the "carburettor heat" position.

Make regular checks (every 100 hours) that the overlap cannot be folded inside

the box when worn.

- The four bottom corners of the box are deliberately left open to prevent any fuel

accumulating whatever the attitude of the aircraft: make sure the openings are

not fouled.

MAINTENANCE MANUAL ROBIN DR400

page 5 - 22 Amendment July 2006 3rd edition - July 1995

5.9.1.4 - Spark plugs - fitting

Before fitting the spark plugs make sure that the cylinder head thread is clean and

undamaged.

a) Apply anti-seize compound to the spark plug threads, fit the gasket over the

thread and insert the spark plug. Screw by hand as far as possible to ensure

the threads are correctly engaged.

Installation torque for spark plugs: 420 lbf.in (35 lbf.ft) 4,75 daN.m (see

Lycoming SI 1042).

b) Insert the ignition lead ends carefully. Tighten the end nuts.

Installation torque for lead nuts (see Lycoming SI 1042):

- nut 5/8 - 24 : 80-90 lbf.in 0,9 - 1,0 daN.m

- nut 3/4 - 20 : 110-120 lbf.in 1,24 - 1,36 daN.m

5.9.2 - Ignition leads

When replacing the ignition harness refer to the diagram on the preceding page for

correct connection. Mark the position of the clamps and fastenings so the cables

can be fixed to the same places as before.

5.9.2.1 - Harnesses - removal

a) Detach the clamps fastening the various leads of the harness to the engine and

accessories. Remove the grommets isolating the harness from the baffle

passage points.

b) Unscrew the screw caps of the ignition leads on the spark plugs. Disconnect

the ignition leads. Take care not to damage the contact springs that penetrate

the spark plug connector wells.

c) Fit insulator caps to the free end of each ignition lead (insulator and spring).

d) Remove the rear protective cover from the magneto block noting its position.

e) Remove the ignition harnesses.

5.9.2.2 - Ignition harnesses - Refitting

NOTE: For standard connection: The cylinder number matches the number on the

hexagonal end nut of the ignition cable. The number on the nut is followed by T

(top) for the upper spark plugs and B (bottom) for the lower spark plugs.

a) Route each harness so each end corresponds to the relevant spark plug (see

fig. 5.5).

b) Refit the magneto block cover in position (noted when removed).

c) Fit the ignition lead clamps and insert the grommets into the engine baffles.

d) Reconnect the harness leads to the spark plugs.

Installation torque for lead nuts (see Lycoming SI 1042):

- nut 5/8 - 24 : 80-90 lbf.in 0,9 - 1,0 daN.m

- nut 3/4 - 20 : 110-120 lbf.in 1,24 - 1,36 daN.m

MAINTENANCE MANUAL ROBIN DR400

3rd edition - July 1995 Amendment 10 dtd April 19

th

, 2011 page 5 - 27

5.11 - ENGINE SUPERVISION

5.11.1 - Tachometer

Periodically check that the tachometer cable end is correctly fastened (screw fitting)

to the rear of the engine and that it is correctly routed and clipped.

5.11.2 - Low fuel pressure alarm

The pressure switch is factory set at 0.080 bars. Below this value the instrument

panel warning light comes on.

No adjustment: if it does not work, check the electrical connections and replace if

necessary.

5.11.3 - Low oil pressure alarm

The pressure switch is set to trigger when pressure falls below 1.0 bar.

No adjustment: if it does not work, check the electrical connections, perform a

careful cleaning of the oil hose and connectors, including the restricted fitting and

replace if necessary.

5.12 - EXHAUST

5.12.1 - Two-in-one exhaust manifolds (All types S/N 2212)

- Check all the manifolds for any cracking especially at the fastening clamps, heat

exchanger shrouds and component welds.

- Check the clamps are held in position and airtight.

- Replace clamp screws at the slightest sign of weakening or serious corrosion.

- The clamps on the exhaust manifold must not be blocked. They must allow 2

cm sideways deflection of the end of the manifold.

NOTE: Some cracks may be repaired by welding. Consult the manufacturer.

MAINTENANCE MANUAL ROBIN DR400

3rd edition - July 1995 Amendment 6 dtd July 27

th

, 2007 page 5 - 43

5.17 - ENGINE BAFFLES

5.17.1 - Maintenance, repair

- Check all the baffles are in good condition: cracks, wear, deformation.

- Make sure that the passage ways for ducts, ignition cables and fluid lines are in

perfect condition and that the rubber grommets are correctly fitted.

- Repairs: Any cracks can be repaired by adding a strengthener locally in

accordance with the rules of the art outside the air space above the cylinders.

The strengthener must not be more than 12 cm

2

.

5.17.2 - Baffles - removal (S/N 2212)

All attachments may be removed to take off the baffles. Mark the screws and

brackets before removal.

5.17.3 - Side baffles- removal (S/N > 2212)

The gap between the baffles and engine is filled with sealant. To prevent the

sealant adhering to the rocker cover coat the rocker cover with a thin film of grease

(vaseline) when refitting before making the sealant bead.

5.17.4 - Lycoming O-360 A1P engine particularity (S/N 2207)

Engine baffles depend on the engine model: O-360 A3A or O-360 A1P.

When replacing the engine, make sure to install the appropriate baffles.

MAINTENANCE MANUAL ROBIN DR400

page 6 - 16 Amendment July 2006 3rd edition - July 1995

6.5.5. - Rudder cables - removal

a) Cut the safety wire and unscrew the rudder cable turnbuckle barrels at the

rudder lever.

b) Slacken the stabilator cables.

c) Attach a sufficiently long string to the end of the cables so the new cable can be

routed easily through the airframe.

d) Remove the centre console and the tunnel between the front and rear seats.

e) Remove the cable guides from the seat boxes.

f) Through the fuselage inspection hatch, remove the shaft from the pulley block

behind the fuel tank. Note the position of the cables on the pulleys so they can

be fitted in their proper places.

g) Disconnect the cable terminals from the rudder bars and remove the cables

through the front. Untie the string and leave it in place for refitting.

6.5.6 - Rudder cables - inspection

Check condition of the cables and replace if defective: worn, bent, elementary

strand broken. Fit new cables complying with the specified definition.

6.5.7 - Rudder cables - refitting

a) Draw the cables into position with the string left in place on removal.

b) Fix the ends of the cables to the rudder bars.

c) Refit the cable guides and the pulley block.

CAUTION

THE RUDDER CABLES CROSS OVER BETWEEN THE FRONT AND REAR

SEATS.

Note: It must be noted that these cables must slide smoothly, with a slight friction,

in their guide. If this is not the cae, check the components of the hole system, the

alignment of pulleyv support brackets and cable tensioning. in case of particular

anomaly, contact the manufacturer.

d) Adjust the control surface with the appropriate tools.

e) Safety the cable turnbuckles and refit the tunnel and centre console.

f) Check the deflection and that the rudder is working properly.

MAINTENANCE MANUAL ROBIN DR400

page 6 - 22 Amendment 8 dtd July 01

st

, 2008 3rd edition - July 1995

6.8.6 - Push rod

Inside each wing, the aileron control crosswheel (pulleys item 1) are attached on a push rod

(item 2).

Caution, the right hand and left hand push rods (item 2) are symetrical at rear spar support

bracket level (item 3).

Since February 2008, each push rod assembly is marked with a letter D for Right Hand

(Droite) or G for Left Hand (Gauche) located close to the pulley fixation holes.

Before any removal, clearly identify the position of the push rod assy at fixation level on the

wing rear spar.

6.8.7 - Aileron control - adjustment

NOTE: The neutral position of the aileron trailing edge is not in line with the trailing

edge of the flaps.

a) Place the adjustment template (cf. tools) on the wing upper surface parallel to

the centre line of the aircraft inserting the graduated section between the flap

and the aileron.

b) Make sure that aileron deflection corresponds to fig. 6.1.

c) Adjust the aileron cables to the tension shown in 6.1.3, setting the control

stick to neutral and making sure that the ailerons are in the neutral position too

(template).

d) Adjust the tension of the interlocking cable making sure that the ailerons remain

strictly in the neutral position. If necessary, adjust the aileron cables.

e) Check aileron deflection again and safety the turnbuckles.

MAINTENANCE MANUAL ROBIN DR400

3rd edition - July 1995 Amendment July 2006 page 6 - 27

FIG. 6.10 - RUDDER - STABILATOR CABLE GUIDE ARRANGEMENT

MAINTENANCE MANUAL ROBIN DR400

3rd edition - July 1995 Amendment July 2006 page 7 - 13

7.4.1.4 - Nose wheel - refitting

a) Fit the inner tube inside the tyre with the marks aligned (red or yellow mark on

inner tube opposite red mark on tyre). However, if the inner tube is unmarked

position the valve on the opposite side to the red tyre mark.

b) Fit the tyre and inner tube assembly onto the inboard wheel rim to which the

studs are attached. Match up the outboard wheel rim inserting the valve into

the hole provided.

c) Fasten the washers and nuts onto the bolts and tighten them (torque value:

1.5-2 m.daN) taking care NOT TO NIP the inner tube. Inflate the tyres.

DR400/120, DR400/100,

DR400/2+2,

DR400/120D,

DR400/125

DR400/140, DR400/140B,

DR400/160, DR400/160D,

DR400/180, DR400/180S,

DR400/180R

DR400/200R

DR400/500

DR400/NGL

Nose

wheel

1.6 bar 1.8 bar 1.8 bar 2.0 bar

Nota: Inflating wheels means the removal of fairings which allow cleaning them

from mud.

d) Paint a red mark on the wheel perimeter and extend it onto the tyre wall. This

mark is used to check for creep between tyre and wheel with use.

e) Lubricate.

f) Slide the complete wheel onto the axis. Position the wheel fairing bracket (8)

and fix it in place with the bolts (9), washers and nuts.

7.4.2 - Main wheel with disc brakes (fig. 7.5)

Limit of wear: see 8.2.1.

NOTE: There are two versions of wheel rims and disc brakes. Version A: older model; Version N:

new model. Only wheel rim removal is different (studs or bolts).

7.4.2.1 - Main wheel - removal

a) Jack up the aircraft so the wheels are completely clear of the ground. Release

the brakes.

b) Remove the wheel fairing.

c) Remove the two screws (15) and washers fixing the outer caliper jaw (13) and

remove it.

d) Remove the wheel fairing brackets (8) by extracting the two bolts (9), washers

and nuts.

e) Slide the wheel and disc brake (5 or 1) assembly off the axle.

7.4.2.2 - Main wheel - dismantling

a) Deflate the inner tube completely.

b) Remove the four nuts and washers fixed to the bolts and which hold the two

wheel rims (3 & 4) and (6 & 7) together. Remove the tyre and inner tube.

c) Remove the six countersunk screws and the corresponding washers and nuts

holding the brake disc (1) on the wheel rim (4) (Version A).

MAINTENANCE MANUAL ROBIN DR400

3rd edition - July 1995 Amendment July 2006 page 7 - 15

7.4.2.3 - Main wheel - verification (disc brake)

a) Check all the components for wear, cracks and any faults (see maintenance

schedule).

b) Check the assembly bolts or studs for weaknesses or sundry faults.

c) Examine the tyre for cuts, faults or poor internal condition.

d) Check the condition of the valve and the inner tube for friction or wear.

e) Check that the brake disc is in good condition, flat and correctly fixed to the

wheel rim.

f) Check the bearings and journals.

7.4.2.3 - Main wheel - refitting (disc brake)

a) Fit the inner tube into the tyre, matching up the marks (red or yellow mark on

inner tube opposite red mark on tyre) and add talc. If there is no mark on the

inner tube, position the valve on the opposite side to the red tyre mark.

b) Fit the brake disc onto the inboard wheel rim and fasten it with the six

countersunk screws, washers and nuts (Version A). On Version N the brake

disc is assembled at the same time as the two wheel rims.

c) Fit the tyre and inner tube assembly onto the inboard wheel rim. Fit the

outboard wheel rim, inserting the valve into the hole provided.

d) Fit the washers, nuts and bolts (studs) and tighten (torque value 1.5-2 m.daN)

taking care NOT TO NIP the inner tube. Inflate.

DR400/120, DR400/100,

DR400/2+2,

DR400/120D, DR400/125

DR400/140, DR400/140B,

DR400/160, DR400/160D,

DR400/180, DR400/180S,

DR400/180R

DR400/200R

DR400/500

DR400/

NGL

Main

wheels

1.8 bar 2.0 bar 2.0 bar 3.0 bar

e) Paint a red mark on the wheel perimeter and extend it onto the tyre wall. This

mark is used to check for creep between tyre and wheel with use.

f) Lubricate the bearings if not sealed and the journals taking care not to get

grease on the brake disc or pads.

g) Slide the complete wheel onto the axle. Put on the wheel fairing bracket and fix

it.

h) Replace the outer caliper jaw and fix it with the two screws.

7.4.3 - Main wheel with drum brakes (fig. 7.6)

7.4.3.1 - Main wheel - removal (drum brake)

a) Jack up the aircraft so the wheels are completely clear of the ground. Release

the brakes.

b) Remove the wheel fairing.

c) Remove the wheel fairing bracket (1) by removing the tapered pin (2) secured

by the split pin (3).

d) Slide the complete wheel off the axle.

MAINTENANCE MANUAL ROBIN DR400

3rd edition - July 1995 Amendment July 2006 page 7 - 17

7.4.3.2 - Main wheel - dismantling (drum brake)

a) Deflate the inner tube completely.

b) Remove the four nuts and washers fastened to the studs (6) holding the

inboard (5) and outboard (9) wheel rims together. Separate the two parts.

7.4.3.3 - Main wheel - verification

a) Check all the components for wear, cracks and any faults.

b) Check the assembly studs (6) for weaknesses or faults.

c) Examine the tyre for cuts, faults or poor internal condition.

d) Check the condition of the valve and the inner tube (wear).

e) Check the brake drum for wear (ring in inboard wheel rim (5)).

f) Check the bearings (4) and journals.

7.4.3.4 - Main wheel - refitting (drum brake)

a) Fit the inner tube into the tyre, matching up the marks (red or yellow mark on

inner tube opposite red mark on tyre) and add talc. If there is no mark on the

inner tube, position the valve on the opposite side to the red tyre mark.

b) Fit the tyre and inner tube assembly onto the inboard wheel rim (5). Fit the

outboard wheel rim (9), inserting the valve into the hole provided.

c) Fit the washers (7) and nuts (8) onto the studs (6) and tighten them taking care

NOT TO NIP the inner tube. Inflate.

DR400/120, DR400/100,

DR400/2+2,

DR400/120D, DR400/125

DR400/140, DR400/140B,

DR400/160, DR400/160D,

DR400/180, DR400/180S,

DR400/180R

DR400/200R

DR400/500

DR400/

NGL

Main

wheels

1.8 bar 2.0 bar 2.0 bar 3.0 bar

d) Paint a red mark on the wheel perimeter and extend it onto the tyre wall. This

mark is used to check for creep between tyre and wheel with use.

e) Lubricate the bearings (4) and journals taking care not to get grease on the

brake shoes (10) or the brake drum (internal part of wheel rim (5)).

f) Slide the complete wheel onto the axle. Put on the wheel fairing bracket (1) and

fix it with the tapered pin (2) which is secured by the split pin (3).

MAINTENANCE MANUAL ROBIN DR400

page 7 - 18 Amendment July 2006 3rd edition - July 1995

7.5 - FLUID AND HYDRAULIC LANDING GEAR - FILLING

(APR landing gear only)

7.5.1 - General points - precautions

- The level of fluid in the shock absorber also determines the volume of air and is

therefore decisive for optimum energy absorption.

- It is compulsory to fill the shock absorbers with the aircraft jacked up and the

wheels completely clear of the ground.

7.5.2 - Procedure

a) With no stress on the strut: deflate the shock absorber by depressing the valve,

then remove the valve core (tool).

b) Connect a flexible fluid line onto the valve tube and fill the shock absorber

completely with the recommended hydraulic fluid.

Drain any fluid from the flexible line (and reconnect).

c) Depress the strut (which expels the excess fluid) by the following amounts:

Nose gear shock absorber: 110 mm (approximately 1.15 litres remaining)

Main gear shock absorbers: 130 mm (approximately 0.6 litres remaining).

d) Drain any fluid from the flexible line and extend the oleo-strut fully: the quantity

of air is therefore the volume displaced by the oleo-strut stroke whose value

features in (c) above.

e) Refit the valve core with the appropriate tool. Inflate the shock absorber as

described in 7.5.3.

7.5.3 - Inflating

DR400/120,

DR400/100,

DR400/2+2,

DR400/120D,

DR400/125

DR400/140, DR400/140B,

DR400/160, DR400/160D,

DR400/180, DR400/180S,

DR400/180R

DR400/200R

DR400/500

DR400/

NGL

Nose landing

gear

4.0 bar 5.0 bar 6.5 bar 5.5 bar

Main landing

gear

6.0 bar 6.0 bar 10.0 bar 6.5 bar

- Inflate with no stress on the struts (aircraft jacked up).

- If the valve core has been removed, make sure the seal is airtight with a leak

detector product (or soapy water).

- Screw the valve cap on FINGER TIGHT ONLY - THE VALVE CAP MUST BE

FITTED.

7.6 - FAULT-FINDING

See table 7.1

MAINTENANCE MANUAL ROBIN DR400

3rd edition - July 1995 Amendment 10 dtd April 19

th

, 2011 page 9 - 21

9.10 - ELECTRICAL PRIMER PUMP (fig. 9.5)

9.10.1 - Maintenance, general points

- Unscrew the pump base (bayonet) after snipping the safety wire and clean the

filter cartridge mesh (and decanting bowl for aircraft < 1988).

- The pump must be changed if it fails or there are doubts about its operation. It

cannot be repaired under any circumstances.

9.10.2 - Electrical pump - removal

a) Close the fuel valve and drain the part of the system between the valve and the

mechanical fuel pump via the fuel strainer drain valve.

b) Remove the fuel system inspection cover.

c) Disconnect the electrical leads to the anti-interference unit after noting their

position and remove the screw fastening the unit to the side of the recess.

d) Disconnect the two banjo unions from the electric pump.

e) Remove the two bolts fastening the electric fuel pump to the recess side

(captive nut on other side) and remove the pump.

9.10.3 - Electrical pump - installation

a) Position the pump in the recess under the fuselage and fix it with the two bolts.

b) Reconnect the two banjo unions to the electrical fuel pump inlet and outlet.

c) Fix the anti-interference unit to the side of the recess and reconnect the

electrical wires to the unit in the positions marked when removing.

d) Open the selector valve to make sure there are no leaks.

e) Refit the fuel system inspection cover and test the engine by running the

electric fuel pump and the fuel system in general.

9.11 - FUEL LINES, CONNECTIONS

Fitting with flared rigid pipe

Whenever removed, as a minimum, the pipe flares are to be examined very

carefully for any deformation or cracks which would affect mechanical soundness.

Fitting with biconcial olive (see fig. 9.6)

- These must be moderately tight (depending on design diameter).

- If deformed or leaking, the complete pipe must be changed as the olive is

crimped and cannot be removed.

Fittings with flat washers

Renew the flat washers each time they are removed.

Fittings with O-rings

Make sure the O-ring bearing surfaces are free from impurities, scratches and

deformations.

REMINDER: The O-rings used are all of appropriate quality for their purpose. USE

AVIONS ROBIN LISTED O-RINGS ONLY.

MAINTENANCE MANUAL ROBIN DR400

page 9 - 22 Amendment 10 dtd April 19

th

, 2011 3rd edition - July 1995

9.12 - TANK CAP

Figure 9.7

The tank cap assembly (P/N 52.11.34.030) consists of 4 parts:

1. The cap

2. The handle

3. The handle securing screw

4. The gasket

The handle is glued on the cap. The cap is drilled (air vent hole).

Figure 9.8

The assembly is done as follows:

o Install the handle on the cap by means of the screw.

o Slightly tighten the screw so as to allow modifying the position of the handle.

o Do not put the gasket in place.

o Set the cap on the tank filler neck (closed position).

o Direct the handle in flight direction, the bigger part of the handle towards the front

of the airplane.

o Mark the handle outline on the cap using a scribe.

MAINTENANCE MANUAL ROBIN DR400

3rd edition - July 1995 Amendment 10 dtd April 19

th

, 2011 page 9 - 23

o Remove the cap from the tank.

o Prepare the area to be glued.

o Protect the cap with adhesive tape; leave the glue area free.

o Dry clean the area to be glued.

o Glue the handle on the cap with Epoxy adhesive and tighten the securing screw.

o Remove the protecting tape.

o Drill the air vent hole per following scheme: diameter 2.5 mm located at 20 mm

from the axis.

Figure 9.9

o Proceed to finishing (cleaning, painting) then insert the gasket.

MAINTENANCE MANUAL ROBIN DR400

page 9 - 24 Amendment 10 dtd April 19

th

, 2011 3rd edition - July 1995

9.13 - FAULT FINDING

FAULT CAUSE REMEDY

FUEL FAILS TO REACH

ENGINE

Obstruction in system

Electrical or mechanical fuel

pump failure

Selector valve not properly

open

Bleed and clean fuel system.

Check and replace if

necessary.

Check valve and valve

control.

FUEL GAUGE NOT

WORKING

Break in gauge electrical

circuit

Gauge indicator out of order

Float pierced and full of fuel

Circuit breaker tripped

Incorrect ground connection

Float or float arm detached

from sender unit

Check entire circuit and

repair.

Replace indicator

Renew float.

Check circuit and reset.

Check ground connection.

Check sender. Repair or

renew.

GAUGE WRONGLY

SHOWS TANK IS FULL

Sender conductor shorted to

ground

Check gauge sender electrical

circuit. Repair or renew.

NO FUEL PRESSURE

INDICATION

Valve out of order

Tank empty

Electrical or mechanical pump

defective

Defective pressure indicator

Check and replace if

necessary.

Check and fill.

Check each pump carefully.

Replace pressure indicator.

FUEL PRESSURE LOW

OR JERKY

Obstruction in circuit ahead of

pump

Electrical or mechanical pump

defective

Pump power supply failure

Check fuel system.

Check and renew if

necessary.

Check electric circuit and

repair.

UNIDENTIFIED LEAK Fuel pipe damaged or wrongly

fitted

Locate leak and repair.

LEAK FROM VALVE Damaged seals Send valve to repair centre.

TABLE 9.2 - FUEL SYSTEM FAULT FINDING

MAINTENANCE MANUAL ROBIN DR400

3rd edition - July 1995 Amendment 7 dtd May 17

th

, 2008 page 10 - 7

10.6 - WESTACH OIL TEMPERATURE INDICATOR.

In 2008, Magneti Marelli oil temperature indicators have been replaced by Westach oil

temperature indicators 2C9-2 or 2A9-2 (DET 040301). To make sure of the good aging of

these last ones, a follow-up of the evolution of their response curve is to be made at

intervals.

10.6.1 - General

The indicator verification periodicity is defined in the maintenance programme.

The follow-up consists in measuring the resistance which induces a definite movement of

the needle on the indicator then comparing it with the "reference" initial value.

The "reference" values are the values of resistance made by Apex Industries before the

installation of the indicator on the plane. They are supplied on the placard stuck on the

indicator.

When the difference between the measured values and the "references" values is greater

than 10 %, the indicator is considered as out of order.

10.6.2 - Mesurement

ALIMENTATION ou BATTERIE

POWER SUPPLY or BATTERIE

10 V < U < 15 V

+

-

Rsistance multitour

Multitour potentiometer

2000 ohms

Indicateur temperature huile

Oil temperature indicator

WESTACH 2C9-2

WESTACH 2A9-2

2

5

4

Installation diagram

SRemove indicator from airplane (pay attention to the spacer located under RH

lower screw).

SConnect the equipments. The power supply may be replaced with a battery. The

variable resistor must be adjustable from 0 to 2000 ohms at least (example:

Radiospare multitour potentiometre P/N. 5222996).

SCheck with multimetre that power supply voltage is between 10 and 15 VDC.

SAdjust the variable resistor in order to have 140F displayed on the indicator.

SDisconnect the resistor. Measure the value of resistance with multimtre. Log in the

table of results.

SRepeat measurement of the resistance for each of the following indications: 180,

200, 220 and 240 F, then log in the table of results.

MAINTENANCE MANUAL ROBIN DR400

page 10 - 8 Amendment 7 dtd May 17

th

, 2008 3rd edition - July 1995

Table of results (example)

Temp.

displayed

(F)

Resistance measured (ohms)

reference

meter

reading

reference

+ 10%

reference

- 10%

Meter

reading

2

Meter

reading

3

Meter

reading

4

Meter

reading

...

140

180

200

220

240

Date and

flight hours

SCheck resistance values at each check interval are within the range:

Reference - 10% Meter reading Reference + 10%

SWhen the values are not within the range reference 10%, replace the oil

temperature indicator.

MAINTENANCE MANUAL ROBIN DR400

page 12 - 14 Amendment 8 dtd July 01

st

, 2008 3rd edition - July 1995

12.6 - GENERAL POINTS - WIRING

12.6.1

The onboard electrical system is powered by the alternator with a direct current

supply. As the aircraft is made of wood, the ground is routed either by dedicated

cables or by shielded cables. A battery is included in the circuit to power the starter

and store energy in case of alternator failure. The battery and alternator power the

bus bar which supplies all the electrical equipment, except for the starter which

draws energy directly from the battery via the starter relay.

The system can be cut either by the manual battery cut-out or by a battery relay

operated by a switch on the instrument panel.

12.6.2 - Reminders