Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Assignment 2 CAD

Caricato da

kushkimDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Assignment 2 CAD

Caricato da

kushkimCopyright:

Formati disponibili

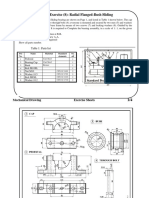

EMG 2204 Computer Aided Drawing ASSIGNMENT 2

Figure 1 shows eight parts of a milling machine tail stock drawn in rst angle orthographic projection. Draw full size in rst angle orthographic projection the following views: (a) A sectional view from the front of tail stock assembly (b) An end view (c) An isometric view (d) Insert a parts list showing all the components.

Assembly Drawings

100 R30 32 36 KEYWAY, 5 2.5 M15

f28 f15 f80

291

18

35 M12

f30

3 R15

18

6

3 35 f40 18

R1 25

125

32

M12

25

30 150

10

1 150

f18

63 5

18

KEYWAY, 52.5

M15 f25

12

60

35

f30

60 132 2 12 Parts list Sl. No. Name Matl. Figure 1: Milling machine tail stock Qty. parts 1 2 3 4 Part 5 16 7 28 CI Case hardened alloy steel Hand wheel Cast steel Table 1: Components list Screw MS Name Matl Screw MS Washer MS Body Cast iron Nut MS Centre alloyMS steel Key Body Centre 1 1 1 1 Qty 1 1 1 1 SLOPE, 1:100 8 35

8

5

M15

2 4

15

f15

R15

1 3 Hand wheel Cast iron 1 Fig. 4 18.19 Milling machine tail-stock 1 Screw Mild steel 5 Bolt Mild steel 1 18.3.7 Revolving Centre Washer When long bars are machined6on a lathe, they are Mild steel on1two centres. one of which is suppported 7 Nut Mild steel 1 called a live centre and the other, a dead centre, fixed in the tail-stock. The live centre fits into the 8the workKey Mild steel the relative motion between the main spindle and revolves with it supports. Because of 1

work piece and the dead centre in the tail-stock barrel, over-heating and wear of the centre takes place in the long run. To eliminate this, the dead centre is replaced with a live or anti-friction bearing centre, which revolves with the work like a live centre. 1 Figure 18.20 shows the details of a revolving centre using antifriction bearings. The radial bearing 6 and thrust bearing 7 used in the design are meant for resisting the possible radial and

M15

20

f32

180

Potrebbero piacerti anche

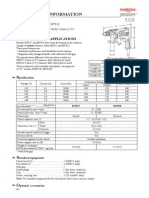

- Echnical Information: Oncept and Main ApplicationsDocumento14 pagineEchnical Information: Oncept and Main ApplicationspopokateNessuna valutazione finora

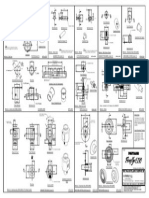

- Exercise (8) : Radial Flanged-Bush Sliding BearingDocumento4 pagineExercise (8) : Radial Flanged-Bush Sliding BearingmemoooNessuna valutazione finora

- Manual Da Furadeira MakitaDocumento10 pagineManual Da Furadeira Makitaani_matrixx4733Nessuna valutazione finora

- Basic Engine: Systems OperationDocumento7 pagineBasic Engine: Systems OperationbejoythomasNessuna valutazione finora

- 242B3 - M.serviceDocumento2.226 pagine242B3 - M.serviceJuliano Daiana Muller SantosNessuna valutazione finora

- Department of Mechanical Engineering Answer Key - Iat-I Subject Name: Manufacturing Technology Year/Sem: II/III Subject Code: 17MECC04 Part-A Answer All The Questions (7x2 14 Marks)Documento7 pagineDepartment of Mechanical Engineering Answer Key - Iat-I Subject Name: Manufacturing Technology Year/Sem: II/III Subject Code: 17MECC04 Part-A Answer All The Questions (7x2 14 Marks)karthik jNessuna valutazione finora

- Yanmar 4tne88 TNE Series PDFDocumento15 pagineYanmar 4tne88 TNE Series PDFluna281068Nessuna valutazione finora

- Whyte - 146-T-120-E-120 Supplementary Service Manual Edn1Documento16 pagineWhyte - 146-T-120-E-120 Supplementary Service Manual Edn1Jamie WatsonNessuna valutazione finora

- 4rCRB Mounting and Maintenance InstructionsDocumento21 pagine4rCRB Mounting and Maintenance InstructionsNishant JhaNessuna valutazione finora

- Assembly Drawings Part-3Documento19 pagineAssembly Drawings Part-3Parameswararao Billa100% (1)

- Ejemplos de Forjado PDFDocumento7 pagineEjemplos de Forjado PDFMarc CervantesNessuna valutazione finora

- Datasheet of Spring Pins and Retaining Rings E-TypeDocumento1 paginaDatasheet of Spring Pins and Retaining Rings E-TypeFrana Harta SuryaNessuna valutazione finora

- Cylindrical Roller Bearings For The Backing Shafts of Cluster MillsDocumento10 pagineCylindrical Roller Bearings For The Backing Shafts of Cluster Millsrochim_putech_126885Nessuna valutazione finora

- Berco AB 651Documento8 pagineBerco AB 651CTN2010Nessuna valutazione finora

- Sebf 8269 Привод 3408Documento16 pagineSebf 8269 Привод 3408mohamed hamedNessuna valutazione finora

- SEBF8155 цил.головка 3500Documento30 pagineSEBF8155 цил.головка 3500Евгений Абрамов100% (1)

- Motor Manufacturing Process FlowDocumento8 pagineMotor Manufacturing Process FlowcmashtamoorthyNessuna valutazione finora

- Me308 Project 2013-v1Documento3 pagineMe308 Project 2013-v1Mustafa Gözay0% (1)

- Shi 2013Documento6 pagineShi 2013amirbakhtiary97Nessuna valutazione finora

- Cojinetes de Generador Renk Manual de AplicacionesDocumento39 pagineCojinetes de Generador Renk Manual de AplicacionesMiguel Angel PonceNessuna valutazione finora

- Right Angle HeadDocumento13 pagineRight Angle Headkwayneolson6081100% (3)

- SEBF 8174 коромысла 3500Documento13 pagineSEBF 8174 коромысла 3500Евгений АбрамовNessuna valutazione finora

- Plummer Block DskatkasndfmDocumento30 paginePlummer Block DskatkasndfmVivek AradhyaNessuna valutazione finora

- Measuring The Cylinder BoreDocumento3 pagineMeasuring The Cylinder BoreRM HaroonNessuna valutazione finora

- DCDocumento24 pagineDCnandhakumarmeNessuna valutazione finora

- CrankDocumento9 pagineCrankKresna BayuNessuna valutazione finora

- 009-010-011-012 Service ManualDocumento52 pagine009-010-011-012 Service Manualhey_hop50% (4)

- Manual F 1300 1600Documento71 pagineManual F 1300 1600Camilo Sanchez VanegasNessuna valutazione finora

- Manufacturing Method of Cotter JointDocumento10 pagineManufacturing Method of Cotter JointAkshay Jadhav33% (6)

- Assignments No. 2 All Equipments Used To Manufacture The Alternator and MotorsDocumento22 pagineAssignments No. 2 All Equipments Used To Manufacture The Alternator and MotorsTE45 Aniket DusaneNessuna valutazione finora

- Mechanical Draughting N4 QP Aug 2019Documento9 pagineMechanical Draughting N4 QP Aug 2019patel.ayushl2018Nessuna valutazione finora

- AZPF - Rexroth PDFDocumento10 pagineAZPF - Rexroth PDFcassiosproj7989Nessuna valutazione finora

- ME6503 DME Question PapersDocumento27 pagineME6503 DME Question PapersSaravanan KumarNessuna valutazione finora

- Sheet Metal Cutting Using Geneva MechanismDocumento27 pagineSheet Metal Cutting Using Geneva MechanismsingamNessuna valutazione finora

- MB07 Service&Repair ManualDocumento54 pagineMB07 Service&Repair Manualenver456Nessuna valutazione finora

- 6 (WG11)Documento22 pagine6 (WG11)Colin SillmanNessuna valutazione finora

- Assign I MD IDocumento3 pagineAssign I MD IAtharva KNessuna valutazione finora

- Backing BearingsDocumento8 pagineBacking BearingsJurun_BidanshiNessuna valutazione finora

- DMX4306 - Session 6. Welded JontsDocumento22 pagineDMX4306 - Session 6. Welded JontsG.G. PRABHATH CHINTHAKANessuna valutazione finora

- Illustrated Parts Catalogue: 52oi/isDocumento40 pagineIllustrated Parts Catalogue: 52oi/isDarren-Edward O'NeillNessuna valutazione finora

- Roll ForgingDocumento6 pagineRoll ForgingSaptarshi SinhaNessuna valutazione finora

- Machine Drawing Question BankDocumento11 pagineMachine Drawing Question BankSheshikanth DonNessuna valutazione finora

- TRIOCATALDocumento13 pagineTRIOCATALVladimir Illich Pinzon100% (1)

- Kisssoft Tut 007 E BearingsDocumento16 pagineKisssoft Tut 007 E BearingsLuis TestaNessuna valutazione finora

- MT955 TeDocumento8 pagineMT955 TeMosqq CharriNessuna valutazione finora

- Especificações Do Bloco Do MotorDocumento5 pagineEspecificações Do Bloco Do MotorPauloNessuna valutazione finora

- Unit 5 Induction Motor: StructureDocumento27 pagineUnit 5 Induction Motor: StructureSivasubramani ShanmugaveluNessuna valutazione finora

- RC2095 3 1Documento1 paginaRC2095 3 1montyviaderoNessuna valutazione finora

- Operation Manual LC-10EDocumento12 pagineOperation Manual LC-10EKevin CaballeroNessuna valutazione finora

- Micro Machine Shop Mods EtcDocumento488 pagineMicro Machine Shop Mods Etcsbarnett38@100% (4)

- NSK Cat E728g 13 (1) LDocumento0 pagineNSK Cat E728g 13 (1) LIvana StevanićNessuna valutazione finora

- Meritor Spindle NutDocumento5 pagineMeritor Spindle NutPhrag MannsteinNessuna valutazione finora

- Crankshaft Main Bearings - Install: Shutdown SISDocumento4 pagineCrankshaft Main Bearings - Install: Shutdown SISOecox Cah DjadoelNessuna valutazione finora

- Demo SM Cat 924H & 924HZ (Ped00001-Up)Documento15 pagineDemo SM Cat 924H & 924HZ (Ped00001-Up)Em sulistio80% (5)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheDa EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheValutazione: 4.5 su 5 stelle4.5/5 (2)

- Pressure Vessel and Stacks Field Repair ManualDa EverandPressure Vessel and Stacks Field Repair ManualValutazione: 4 su 5 stelle4/5 (4)