Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Manufacturing Progress

Caricato da

ketanhole1Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Manufacturing Progress

Caricato da

ketanhole1Copyright:

Formati disponibili

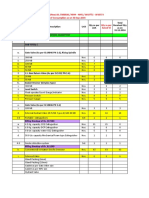

JOB: JOB NO.: SR. NO.

Specification 1 FLASH VESSEL

I PLATE CUTTING II DISH BLANK CUTTING III SHELL ROLLING IV SHELL WELDING V NOZZLE MARKING VI NOZZLE MAKING VII NOZZLE ASSEMBLY VIII SG/LG FITTING IX DISH & SHELL ASSEMBLY X LUGS XI DEMISTER BASE RING XII DEMESTER FITTING XIII CLADDING ON FLANGE XIV GASKET CUTTING XV MANHOLE COVER XVI HYDROTEST XVII BUFFING XVIII NOZZLE BLANKING XIX STENCILING

KUMAR

VENDOR SECOND EFFECT THIRD FIRST

APPOLLO

VENDOR VENDOR SECOND EFFECT THIRD FIRST

BINAYAK

SECOND EFFECT FORTH THIRD FIRST

MAFATLAL

VENDOR SECOND EFFECT FORTH THIRD FIRST

NSL CRP

VENDOR VENDOR SECOND EFFECT FORTH THIRD FIRST

NSL SRP

SECOND EFFECT FORTH THIRD FIRST

SRIKRISHNA VARDHAMAN GREENCHEM-1 REENCHEM-2 G

VENDOR VENDOR VENDOR VENDOR SECOND SECOND SECOND SECOND EFFECT THIRD FIRST EFFECT THIRD FIRST EFFECT THIRD FIRST EFFECT THIRD FIRST

NOTE:

HEATER 1 Shell

I PLATE CUTTING II SHELL ROLLING III SHELL WELDING IV NOZZLE MARKING V NOZZLE MAKING VI NOZZLE ASSEMBLY VII TUBE SHEET CUTTING VIII TUBESHEET MACHINING IX TUBESHEET DRILING X BAFFLE CUTTING XI BAFFLE MACHINING XII BAFFLE DRILLING XIII THERMOWELL XIV TIEROD CUTTING XV SPACER PIPE CUTTING XVI TUBE CLEANING XVII TUBE CUTTING XVIII TUBE BUNDEL MAKING XIX TUBESHEET ASSEMBLY XX LUGS FITTING

XXI TUBE EXPANSION

2 BONNET

I DISH BLANK CUTTING II DISH MAKING III CHANNEL CUTTING IV PARTITION PLATE CUTTING V BODY FLANGE CUTTING VI BODY FLANGE MACHINING VII CHANNEL & DISH ASSEMBLY VIII BODYFLANGE & CHANNEL ASS. IX CLADDING ON FLANGE X BONNET MACHINING XI NOZZLE ON BONNET

3 4 5 6 7 8 9

HYDRO TEST (SHELL SIDE) SHELL TO END ASSEMBLY HYDRO TEST (TUBE SIDE)

SPRAY PAINTING BUFFING NOZZLE BLANKING STENCILING

NOTE:

PRE-HEATER 1 Shell

I PLATE CUTTING II SHELL ROLLING III SHELL WELDING IV NOZZLE MARKING V NOZZLE MAKING VI NOZZLE ASSEMBLY VII TUBE SHEET CUTTING VIII TUBESHEET MACHINING IX TUBESHEET DRILING X BAFFLE CUTTING XI BAFFLE MACHINING XII BAFFLE DRILLING XIII THERMOWELL XIV TIEROD CUTTING XV SPACER PIPE CUTTING XVI TUBE CLEANING XVII TUBE CUTTING XVIII TUBE BUNDEL MAKING XIX TUBESHEET ASSEMBLY XX LUGS FITTING XXI TUBE EXPANSION

2 BONNET

I DISH BLANK CUTTING II DISH MAKING III CHANNEL CUTTING IV PARTITION PLATE CUTTING

V BODY FLANGE CUTTING VI BODY FLANGE MACHINING VII CHANNEL & DISH ASSEMBLY VIII BODYFLANGE & CHANNEL ASS. IX CLADDING ON FLANGE X BONNET MACHINING XI NOZZLE ON BONNET

3 4 5 6 7 8 9

HYDRO TEST (SHELL SIDE) SHELL TO END ASSEMBLY HYDRO TEST (TUBE SIDE)

SPRAY PAINTING BUFFING NOZZLE BLANKING STENCILING

NOTE:

SC/VC 1 Shell

I PLATE CUTTING II SHELL ROLLING III SHELL WELDING IV NOZZLE MARKING V NOZZLE MAKING VI NOZZLE ASSEMBLY VII TUBE SHEET CUTTING VIII TUBESHEET MACHINING IX TUBESHEET DRILING X BAFFLE CUTTING XI BAFFLE MACHINING XII BAFFLE DRILLING XIII THERMOWELL XIV TIEROD CUTTING XV SPACER PIPE CUTTING XVI TUBE CLEANING XVII TUBE CUTTING XVIII TUBE BUNDEL MAKING XIX TUBESHEET ASSEMBLY XX LUGS FITTING XXI TUBE EXPANSION

2 BONNET

I DISH BLANK CUTTING II DISH MAKING III CHANNEL CUTTING IV PARTITION PLATE CUTTING V BODY FLANGE CUTTING VI BODY FLANGE MACHINING VII CHANNEL & DISH ASSEMBLY VIII BODYFLANGE & CHANNEL ASS. IX CLADDING ON FLANGE X BONNET MACHINING

XI NOZZLE ON BONNET

3 4 5 6 7 8 9

HYDRO TEST (SHELL SIDE) SHELL TO END ASSEMBLY HYDRO TEST (TUBE SIDE)

SPRAY PAINTING BUFFING NOZZLE BLANKING STENCILING

NOTE:

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- General SpecificationDocumento12 pagineGeneral Specificationmark100% (4)

- Mech Inspection Checklist PDFDocumento11 pagineMech Inspection Checklist PDFDesigner Forever100% (1)

- Checklist Underground FF Piping InstallationDocumento1 paginaChecklist Underground FF Piping Installationbeho2000Nessuna valutazione finora

- Stock Q-ty Кол- во на стокеDocumento72 pagineStock Q-ty Кол- во на стокеjamilNessuna valutazione finora

- Hydril Blowout Preventers Ram Seal KitsDocumento1 paginaHydril Blowout Preventers Ram Seal KitsJIN WANGNessuna valutazione finora

- Alco Valves DBB Brochure 03-18Documento108 pagineAlco Valves DBB Brochure 03-18Anggi Sujiwo100% (1)

- ADocumento3 pagineAJindal HydraulicsNessuna valutazione finora

- Spare List FFDocumento3 pagineSpare List FFramesh epiliNessuna valutazione finora

- Pipes and Pipe SizingDocumento22 paginePipes and Pipe SizingAhmed Abo RashedNessuna valutazione finora

- Forged Flanges CatalogDocumento48 pagineForged Flanges CatalogaltexsteveNessuna valutazione finora

- Mini ProjectDocumento40 pagineMini Projectshobika100% (1)

- Harvest Rain Water Singapore GuidelineDocumento3 pagineHarvest Rain Water Singapore GuidelineUniwes ServiceNessuna valutazione finora

- MF-03 Modular Valve, Presssure Flow Control ValveDocumento4 pagineMF-03 Modular Valve, Presssure Flow Control ValveYus BewokNessuna valutazione finora

- ITB Measured Price Construction Contract - Section 5 - Pricing Preambles - LOT 01 PDFDocumento16 pagineITB Measured Price Construction Contract - Section 5 - Pricing Preambles - LOT 01 PDFNuwantha UduwageNessuna valutazione finora

- Review API570 Calculations - FirstDocumento38 pagineReview API570 Calculations - FirstnasrNessuna valutazione finora

- Grooved Fittings & Couplings: Mech Flow SuppliesDocumento2 pagineGrooved Fittings & Couplings: Mech Flow SuppliesThanh DoNessuna valutazione finora

- Instrument Installations (Typical)Documento89 pagineInstrument Installations (Typical)ClarkFedele27Nessuna valutazione finora

- b16 10Documento39 pagineb16 10Gustavo FamaNessuna valutazione finora

- Asco Series 214 Gas Shutoff CatalogDocumento8 pagineAsco Series 214 Gas Shutoff CatalogJavier EspinosaNessuna valutazione finora

- K Ball EmersonDocumento36 pagineK Ball EmersonsiskaNessuna valutazione finora

- Offer: Offer Number: 2512127267 M/S: 2012102793 Date TEL Description AddressDocumento4 pagineOffer: Offer Number: 2512127267 M/S: 2012102793 Date TEL Description AddressMuzammilNessuna valutazione finora

- PL CalculationDocumento12 paginePL Calculationarun kurlanNessuna valutazione finora

- WBB Wat Set 20 08 2019Documento59 pagineWBB Wat Set 20 08 2019David FrederickNessuna valutazione finora

- Boq For Toilet Renovation SpectrumDocumento1 paginaBoq For Toilet Renovation SpectrumMohd MujahedNessuna valutazione finora

- Isometric Symbol KeysDocumento91 pagineIsometric Symbol KeysAldo88% (17)

- Flanges Carbon Chrome Blind RTJWN SMDocumento11 pagineFlanges Carbon Chrome Blind RTJWN SMvalli rajuNessuna valutazione finora

- Final Exam - Building Systems DesignDocumento24 pagineFinal Exam - Building Systems DesignChristian John SaludarNessuna valutazione finora

- Diagrama de MoodyDocumento1 paginaDiagrama de MoodyCircus_MaximusNessuna valutazione finora

- Piping Design Part 2 PDFDocumento6 paginePiping Design Part 2 PDFSandra MArrugoNessuna valutazione finora

- Tle Reviewer IDocumento8 pagineTle Reviewer ImaryjeandolinoNessuna valutazione finora