Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PARCOL

Caricato da

ribeiafDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PARCOL

Caricato da

ribeiafCopyright:

Formati disponibili

1-2471 SERIES

ECCENTRIC DISC

CONTROL VALVES

PARCOL

1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

ACA 0201 - 07/10

1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

-2-

PARCOL

1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

1-2471 SERIES

ECCENTRIC DISC

CONTROL VALVES

PARCOL 1-2471 series control valves feature a double

eccentric disc and an easy-to-be changed PTFE or

metal seal ring.

These valves provide flow control with an excellent

shutoff against high pressure drops applied in either

direction.

Body sizes from 3" through 24" compatible with UNI,

DIN, ANSI raised face flanges are available.

Up to DN 1600 available on request.

MAIN FEATURES

BODY

SEAL RING

- construction:

- type:

flangeless.

- sizes:

3" through 24" compatible with UNI, DIN,

ANSI flanges.

- face-to-face

dimensions:

- rating:

- construction

materials:

- temperature

capabilities:

according to ISO 5752, medium series.

UNI PN 10, 16, 25, 40, 64, 100 ANSI 150,

300, 600

see relevant table on next page for the

complete availability - Take into account

that the max pressure and/or temperature

can be affected by bearings and seal ring

materials.

see relevant tabIes - Steel bodies can be cast,

wrought or forged. Other special materials are

available on request (SA352 LCB, AISI 316L,

Hastelloy, Monel, Alloy 20).

DISC

- type:

double-eccentric design which minimize the

contact of disc with seal ring, reducing wear

and torque requirements.

- shutoff

classification:

PTFE seal ring: max leakage is according to

class V IEC 60534.4 limits - IEC code: VL2

metal seal ring: class IV S1 IEC 60534.4 (20

times better than class IV ANSI B16.104) IEC code: IV-S1 L2

- construction:

made in one piece and pinned sidewise to the

disc.

- materials:

17-4-PH, A479 XM 19, AISI 316, AISI

316L

BEARINGS

- construction:

the same as body.

- temperature

capabilities:

- flow

characteristc:

linear from 10% through 90% of rate travel.

P ACKING

- rangeability:

over 100 - see Cv coefficients table.

- rotation:

90 according to the path shown in fig. 2;

60 for special pneumatic actuators

- seal

materials:

- action:

PTFE seal ring: max 200 C.

metal seal ring: max 375 C

The limits vs p are outlined in fig. 4

SHAFT

- construction

materials:

- flow

direction:

PTFE or metal types are available for any

sizes and are interchangeable without any

change up to 12" included.

- design:

standard is with flow into the flat side of the

disc - The opposite direction is permissible

but with reduced performances.

- temperature

capabilities:

PTFE-lined or all-metal bushing.

PTFE-lined bearings may be used up to 250 C;

All-metal bearings may be used up to 375 C.

reinforced PTFE split rings and pure graphite rings.

adjustable by follower and two screws.

graphited PTFE rings: 200 C;

pure graphite: no practical Iimits.

air-to-open and air-to-close with simpleacting actuators. To change action only as-

-3-

ACA 0201 - 07/10

1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

PARCOL

1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

Fig.1: MINIMUM INSIDE DIAMETER OF PIPING FLANGES

DN

in.

min.

mm

3

4

6

8

10

12

14

16

18

20

24

59

84

132

188

238

285

328

377

427

474

572

VALVE BODY AND CONNECTIONS AVAILABILITY

Fig.2: DISC ROTATION

AIR-TO-OPEN

FLOW

ANSI

PN UNI DIN

DN

in.

150

300

600

10

16

25

40

64

100

X (3)

10

X (*)

12

X (4)

X (3)

X (3)

14

(*)

(3)

X (3)

16

X (*)

(*)

X (3)

(*)

18

20

X (*)

X (*)

X (*)

24

X (*)

X (*)

X (*)

(1) the four holes adjacent to valve shaft pass through the

body except where (*) is indicated: in this case holes

are ISO coarse threaded (ANSI B1.1 threads available

on request) with the correspondence stated on table 3

in overall dimensions page;

(2) UNI, DIN raised faces are available on request as special execution; cast UNI DIN bodies face diameters

are unified according to ANSI standard

(3) the four holes adjacent to valve shaft have reduced

diameter, see table 2 in overall dimensions page

AIR-TO-CLOSE

LUG version is available on request

WARNING

The use of Parcol butterfly valves to perform closure

in dead-end pipe is FORBIDDEN!

MOUNTING

-

Check the flow direction outlined on the plate fixed on the

body. Be careful the standard flow direction is on opposite

shaft side.

To prevent interference with the travel of the valve disc

the connected piping shall have an inside diameter

greater than the one shown on relevant table of figure 1.

FLOW

For further information see the instructions and maintenance

book.

ACA 0201 - 07/10

1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

-4-

PARCOL

1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

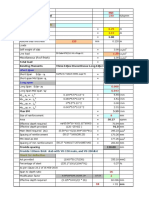

FLOW COEFFICIENT Cv (1)

DN

in.

DN

mm

Cv max

90

10

3

4

6

8

10

12

14

16

18

20

24

80

100

150

200

250

300

350

400

450

500

600

130

280

730

1780

3300

5000

6700

9100

11650

14100

21000

0.8

1.8

4.7

12

22

33

44

60

77

93

138

5.1

11

29

65

113

156

189

230

259

272

405

20

Valve opening (2)(3)

30

40

50

60

70

80

17

37

97

206

324

466

591

756

909

1028

1531

32

70

183

365

527

756

954

1216

1455

1638

2440

89

192

502

1067

1690

2459

3159

4106

5020

5790

8623

112

242

631

1397

2328

3447

4512

5983

7474

8821

13137

127

274

715

1160

2924

4407

5874

7935

10104

12163

18116

49

106

277

546

770

1110

1410

1810

2183

2480

3694

67

145

377

768

1143

1654

2111

2725

3306

3780

5630

RECOVERY FACTOR FL

DN

in.

DN

mm

FL

90

10

20

30

3

4

6

8

10

12

14

16

18

20

24

80

100

150

200

250

300

350

400

450

500

600

0.70

0.67

0.65

0.59

0.56

0.52

0.52

0.52

0.52

0.53

0.52

0.96

0.96

0.96

0.95

0.95

0.95

0.95

0.95

0.95

0.95

0.95

0.94

0.94

0.94

0.93

0.93

0.93

0.93

0.93

0.94

0.94

0..94

0.91

0.90

0.89

0.88

0.88

0.87

0.87

0.88

0.88

0.89

0.89

0.87

0.86

0.84

0.83

0.84

0.82

0.83

0.84

0.84

0.85

0.85

Valve opening

40

50

0.83

0.81

0.80

0.78

0.80

0.77

0.79

0.79

0.80

0.81

0.81

0.80

0.77

0.75

0.73

0.74

0.71

0.73

0.73

0.74

0.75

0.75

60

70

80

0.76

0.73

0.71

0.68

0.68

0.65

0.66

0.67

0.67

0.69

0.68

0.73

0.70

0.67

0.63

0.62

0.59

0.60

0.60

0.60

0.61

0.61

0.71

0.68

0.65

0.60

0.58

0.54

0.55

0.55

0.55

0.55

0.55

COEFFICIENT OF INCIPIENT CAVITATION XFZ (4)

(1)

(2)

(3)

(4)

DN

in.

DN

mm

XFZ

90

10

20

30

3

4

6

8

10

12

14

16

18

20

24

80

100

150

200

250

300

350

400

450

500

600

0.35

0.30

0.26

0.20

0.17

0.13

0.14

0.14

0.14

0.14

0.14

0.87

0.86

0.85

0.84

0.84

0.83

0.83

0.83

0.83

0.82

0.82

0.83

0.82

0.80

0.78

0.77

0.76

0.77

0.78

0.78

0.79

0.79

0.74

0.72

0.69

0.66

0.66

0.62

0.64

0.64

0.65

0.67

0.66

0.65

0.61

0.58

0.55

0.57

0.53

0.55

0.56

0.57

0.59

0.59

DN

in.

DN

mm

XT

90

XT

10

3

4

6

8

10

12

14

16

18

20

24

80

100

150

200

250

300

350

400

450

500

600

0.32

0.29

0.27

0.23

0.20

0.17

0.18

0.18

0.18

0.18

0.18

0.82

0.82

0.81

0.80

0.80

0.79

0.80

0.80

0.81

0.82

0.82

Cv are expressed in U.S. gallons/min. of water with p=1 psi

Rangeability can be calculated as Cv max/Cv 5

Tollerance according to IEC 60534-2-4

IEC 60534-8-4

Valve opening

40

50

0.57

0.53

0.49

0.46

0.49

0.44

0.46

0.47

0.48

0.51

0.50

0.50

0.46

0.42

0.39

0.39

0.35

0.37

0.38

0.39

0.41

0.40

60

70

80

0.44

0.39

0.35

0.31

0.30

0.26

0.28

0.28

0.29

0.31

0.30

0.38

0.33

0.30

0.25

0.23

0.19

0.20

0.20

0.21

0.22

0.22

0.35

0.30

0.27

0.21

0.19

0.15

0.16

0.16

0.16

0.16

0.16

FIG.3

DN 10 FLOW

CHARACTERISTIC

-5-

ACA 0201 - 07/10

1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

PARCOL

1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

1-2471 SERIES VALVE ASSEMBLY

PTFE SEAL RING

METALLIC SEAL RING FOR DN 12

METALLIC SEAL RING FOR DN > 12

ITEM

1

2

3

4

6

7

8

9

10

11

12

13

14

15

16

17

1-2471 SERIES VALVE DN 10" WITH 1-X-271 SERIES PNEUMATIC

DIAPHRAGM ACTUATOR

ACA 0201 - 07/10

1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

-6-

PART NAME

BODY

DISC

SHAFT

BEARING

STOP RING

SCREW

SEAL RING

SUPPORT RING

ADJUSTING RING

SCREW

LOCK WASHER

COVER

SCREW

PACKING RING

PACKING FOLLOWER

PACKING FLANGE

ITEM

18

19

20

21

22

23

24

25

27

28

29

30

31

32

33

34

PART NAME

STUD

NUT

GASKET

PIN

SCREW

BUSHING

ANTIFRICTION RING

FLANGE

PACKING

EYE BOLT

SCREW

SUPPORT

EXTENSION

SCREW

GASKET

BUSHING

PARCOL

1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

1-2471 SERIES LUG VERSION ASSEMBLY

REINFORCED PTFE

LOW TEMPERATURE CONSTRUCTION

PURE GRAPHITE

1-2471 SERIES VALVE DN 10" LUG WITH

1-X-271 SERIES PNEUMATIC DIAPHRAGM ACTUATOR PROVIDED WITH

TOP-DRIVEN HANDWHEEL (OPTIONAL)

-7-

ACA 0201 - 07/10

1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

PARCOL

1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

MATERIALS OF CONSTRUCTION

ITEM PART NAME

BODY

A216 WCB / A 105

DISC

A 216 WCB /

A 105

3

4

6

7

8

9

10

11

12

13

14

20

21

22

24

25

27

28

29

30

31

32

33

34

SHAFT

BEARING

STOP RING

SCREW

SEAL RING

SUPPORT RING

ADJUSTING RING

SCREW

LOCK WASHER

COVER

SCREW

GASKET

PIN

SCREW

ANTIFRICTION RING

FLANGE

PACKING

EYE BOLT

SCREW

SUPPORT

EXTENSION

SCREW

GASKET

BUSHING

BEARING

SEAL RING

SUPPORT RING

AISI 316

01

02

04

ASTM A 564-630 H900

SHAFT

AISI 316

NACE (MR0175 - MR0103)

(A)

(G)

AISI 316L

ASTM A890/A890M 4A

AISI 316L

ASTM A890/A890M 4A

A 216 WCB / A105

22HRC max

A 216 WCB / A105

22HRC max

(ASTM A 564-630 H 1150M)

06

AISI 316

(2)

(22HRC max)

CARBON STEEL + ASTM B 148-955

BRONZE + PTFE

(grade D)

PTFE

AISI 304L

AISI 304

(2)

SUB-CLASS

07

08

XM 19

AISI 316L

(35HRC max)

(2)

(22HRC max)

AISI 316L + PTFE FIBRES

09

(2)

(1)

PACKING TYPE

TFK

GRF

15

PACKING RING

16

17

18

19

PACKING FOLLOWER

PACKING FLANGE

STUD

NUT

23

SPACER RING

TFK - GRF

A-B

14

UNS S31803 (SAF 2205)

(25HRC max)

(2)

INCONEL 625 + PTFE

FIBRES (1)

PTFE

SILVER-PLATED

ITEM PART NAME

AISI 316

22HRC max

AISI 316

22HRC max

SEE SUB-CLASS TABLE

SEE SUB-CLASS TABLE

A 105

AISI 316

AISI 316L UNS S31803 (SAF 2205) A 105 22HRC max AISI 316 22HRC max

AISI 316

SEE SUB-CLASS TABLE

SEE SUB-CLASS TABLE

S 21800

AISI 304

AISI 316

MONEL 400

AISI 304

AISI 304

AISI 316L

AISI 304

A 105

AISI 316

AISI 316L

A 105 22HRC max AISI 316 22HRC max

AISI 304

AISI 316L

AISI 304

INORGANIC COMPOUND T 300 C - ARMOURED GRAPHITE T > 300 C

MONEL K500

AISI 316

MONEL K500

AISI 316 22HRC max

AISI 316

AISI 316L

BSZN 5-BRONZE

AISI 316 22HRC max

A 105

AISI 316

A 105

SEE PACKING TABLE

CARBON STEEL

8.8 UNI 3740

AISI 304

8.8 UNI 3740

AISI 304

CARBON STEEL

AISI 316

AISI 304

AISI 321 + GRAPHITE

S 21.800

ITEM PART NAME

3

BASIC CLASS

G

H

XM 19

(35HRC max) (2)

AISI 316L + PTFE

FIBRES (1)

AISI 304L

AISI 304

SILVER-PLATED

SUB-CLASS

G

H-K

Reinforced PTFE

GRAPHITE

AISI 316

AISI 316L

CARBON STEEL

AISI 316

AISI 304

TFK

GRF

25% Glass loaded PTFE

AISI 316

AISI 316L

SELECTION GUIDE

BASIC CLASS SUB-CLASS

A

B

H

K

(1)

(2)

01

02

01

02

02

04

06

07

14

08

09

TEMPERATURE

-29 C 200 C

-29 C 375 C

-29 C 200 C

-29 C 250 C

-29 C 375 C

-29 C 200 C

-50 C 200 C

-50 C 200 C

-100 C -51 C

-29C 200 C

-29C 200 C

SERVICE

NOT CORROSIVE

NOT CORROSIVE T > 200 C

NOT CORROSIVE

NOT SUITABLE FOR COPPER FREE SERVICE

NOT CORROSIVE T > 200 C

CORROSIVE T > 200 C

CORROSIVE

CORROSIVE (NACE)

CORROSIVE FOR HIGH p (NACE)

CORROSIVE FOR HIGH p, LOW TEMPERATURE, IV - IV S1 SEAL CLASS (NACE)

CORROSIVE (NACE)

SEAWATER (BRINE)

NOT SUITABLE FOR COPPER FREE SERVICE

Not suitable for hydrochloric acid. For strong solvents the compatibility must be checked with bushing manufacturer.

For NACE

ACA 0201 - 07/10

1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

-8-

PARCOL

1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

MAX DIFFERENTIAL PRESSURE ACROSS THE VALVE p - bar

60 OPEN VALVE

CLASS

in. A01 A02 B01 B02 G02 G04 G06 G07 G14 H08 K09

3 40.0 25.0 40.0 25.0 25.0 40.0 38.4 40.0 40.0 30.9 30.9

3 / D25

60 OPEN VALVE - with actuator

CLASS

A01 A02 B01 B02 G02 G04 G06 G07 G14 H08 K09

40.0 25.0 40.0 25.0 25.0 40.0 38.4 40.0 40.0 30.9 30.9

33.4 25.0 33.4 25.0 25.0 33.4 33.4 33.4 33.4 29.2 29.2

4 / D33

33.4 25.0 33.4 25.0 25.0 33.4 33.4 33.4 33.4 29.2 29.2

32.2 25.0 32.2 25.0 25.0 32.2 10.4 32.2 32.2 8.4

8.4

6 / D33

20.6 20.6 20.6 20.6 20.6 20.6 10.4 20.6 20.6 8.4 8.4

21.7 25.0 21.7 25.0 25.0 21.7 13.3 21.7 21.7 10.7 10.7

8 / D39

9.1 9.1 9.1 9.1 9.1 9.1

9.1

9.1 9.1 9.1 9.1

10

13.5 16.0 13.5 16.0 16.0 13.5 5.2 13.5 13.5 4.2

4.2

10 / D39

3.6 3.6 3.6 3.6 3.6 3.6

3.6

3.6 3.6 3.6 3.6

12

11.4 12.3 11.4 12.3 12.3 11.4 3.6 11.4 11.4 2.9

2.9

12 / D46

2.8 2.8 2.8 2.8 2.8 2.8

2.8

2.8 2.8 2.8 2.8

14

8.1

8.1

8.1

8.1

8.1

8.1

2.3

8.1

8.1

1.9

1.9

14 / D46

1.8 1.8 1.8 1.8 1.8 1.8

1.8

1.8 1.8 1.8 1.8

16

5.3

5.3

5.3

5.3

5.3

5.3

1.5

5.3

5.3

1.2

1.2

16 / D46

1.2 1.2 1.2 1.2 1.2 1.2

1.2

1.2 1.2 1.2 1.2

18

9.4 11.0 9.4 11.0 11.0 9.4

3.2

9.4

9.4

2.6

2.6

18 / D63

1.8 1.8 1.8 1.8 1.8 1.8

1.8

1.8 1.8 1.8 1.8

20

8.1

8.1

8.1

8.1

8.1

8.1

2.3

8.1

8.1

1.9

1.9

20 / D63

1.4 1.4 1.4 1.4 1.4 1.4

1.4

1.4 1.4 1.4 1.4

24

4.6

4.6

4.6

4.6

4.6

4.6

1.3

4.6

4.6

1.1

1.1

24 / D63

0.8 0.8 0.8 0.8 0.8 0.8

0.8

0.8 0.8 0.8 0.8

DN

CLOSED VALVE

CLASS

in.

A01 A02 B01 B02 G02 G04 G06 G07 G14 H08 K09

3 40.0 25.0 40.0 25.0 25.0 40.0 31.8 40.0 40.0 30.8 30.8

DN in. /

ACTUATOR

3 - D25

CLOSED VALVE - with actuator

CLASS

A01 A02 B01 B02 G02 G04 G06 G07 G14 H08 K09

36.6 25.0 36.6 25.0 25.0 36.6 31.8 36.6 36.6 30.8 30.8

33.4 25.0 33.4 25.0 25.0 33.4 22.6 33.4 33.4 21.0 21.0

4 - D33

30.4 25.0 30.4 25.0 25.0 30.4 22.6 30.4 30.4 21.0 21.0

21.4 21.4 21.4 21.4 21.4 21.4 9.9 21.4 21.4 8.4

8.4

6 - D33

16.5 16.5 16.5 16.5 16.5 16.5 9.9 16.5 16.5 8.4 8.4

21.7 25.0 21.7 25.0 25.0 21.7 18.6 21.7 21.7 16.1 16.1

8 - D39

15.4 15.4 15.4 15.4 15.4 15.4 15.4 15.4 15.4 15.4 15.4

10

13.5 16.0 13.5 16.0 16.0 13.5 12.7 13.5 13.5 10.6 10.6

10 - D39

9.9 9.9 9.9 9.9 9.9 9.9 9.9 9.9 9.9 9.9 9.9

12

11.4 13.5 11.4 13.5 13.5 11.4 11.4 11.4 11.4 10.2 10.2

12 - D46

11.0 11.0 11.0 11.0 11.0 11.0 11.0 11.0 11.0 10.2 10.2

14

11.1 13.1 11.1 13.1 13.1 11.1 8.9 11.1 11.1 7.0

7.0

14 - D46

8.5 8.5 8.5 8.5 8.5 8.5 8.5 8.5 8.5 7.0 7.0

16

8.4

8.4

6.6

8.4

8.4

5.0

16 - D46

5.5 5.5 5.5 5.5 5.5 5.5 5.5 5.5 5.5 5.0 5.0

18

9.4 11.1 9.4 11.1 11.1 9.4

9.4

9.4

9.4 11.1 11.1

18 - D63

9.4 10.3 9.4 10.3 10.3 9.4 9.4 9.4 9.4 10.3 10.3

20

10.1 11.9 10.1 11.9 11.9 10.1 10.1 10.1 10.1 10.2 10.2

20 - D63

7.6 7.6 7.6 7.6 7.6 7.6 7.6 7.6 7.6 7.6 7.6

24

9.7 11.5 9.7 11.5 11.5 9.7

24 - D63

4.3 4.3 4.3 4.3 4.3 4.3 4.3 4.3 4.3 4.3 4.3

DN

9.9

8.4

9.9

9.9

8.1

9.7

9.7

5.0

6.2

DN in. /

ACTUATOR

6.2

Listed values are applicable up to 100 C. Over this temperature limit p values must be reduced according to materials of

construction limitations.

p/T LIMITS VALUES

FOR USE OF SEAL RING

A1

A2

B1

B2

= PTFE - forward flow (shaft downstream)

= PTFE - reverse flow (shaft upstream)

= INOX - forward flow

= INOX - reverse flow

Fig.4

-9-

ACA 0201 - 07/10

1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

PARCOL

1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

OVERALL DIMENSIONS (mm) AND MASSES (kg)

in.

3

4

6

8

10

12

14

16

18

20

24

DN

mm

80

100

150

200

250

300

350

400

450

500

600

G (1)

MASS (2)

49

56

70

70

76

83

92

102

114

127

154

137

152

217

246

270

315

332

357

410

435

523

215

246

300

357

382

415

432

457

539

579

656

80

102

150

200

250

300

343

392

446

492

592

78

100

146

196

248

297

339

392

442

489

590

16

19.05

25.4

31.75

31.75

34.92

41.27

41.27

50.8

60

70

127

157

216

270

324

381

413

470

533

584

692

90

126

126

176

176

176

176

176

212

212

212

26

38

52

63

73

100

124

144

200

240

296

Tab. 1 - overall dimensions and masses

DN

in.

6"

12"

12"

12"

14"

14"

16"

mm

150

300

300

300

350

350

400

RATING

PN 100

ANSI 300

PN 25

PN 40

PN 25

PN 40

PN 40

std holes

dia.

33

32

30

33

33

36

39

red. holes

dia.

31

31

28

31

31

34.5

38

Tab. 2 - hole diameters

ANSI B1.1 8 UN

dia.

ISO

dia.

1"

1.1/8"

1.1/4"

M27

M30

M33

Tab. 3 - hole threading correspondence

(1)

(2)

If requested, forged bodies are available with UNI, DIN raised faces

Without actuator

ACA 0201 - 07/10

1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

- 10 -

PARCOL

1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

- 11 -

ACA 0201 - 07/10

1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

PARCOL

1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

PARCOL S.p.A. Via Isonzo, 2 - 20010 CANEGRATE (MI) - ITALY

Telephone: +39 0331 413.111 - Fax: +39 0331 404.215

E-mail: sales@parcol.com - http://www.parcol.com

ACA 0201 - 07/10 - 1-2471 SERIES ECCENTRIC DISC CONTROL VALVES

Potrebbero piacerti anche

- The Weir Direct-Acting Feed Pump - Working InstructionsDa EverandThe Weir Direct-Acting Feed Pump - Working InstructionsNessuna valutazione finora

- 1-2471 SERIES Eccentric Disc Control ValvesDocumento12 pagine1-2471 SERIES Eccentric Disc Control ValvesGiovanni PetrizzoNessuna valutazione finora

- Valvula Mariposa Danais 150Documento15 pagineValvula Mariposa Danais 150Oscar CherroNessuna valutazione finora

- Crane - Series.rs Center LineDocumento23 pagineCrane - Series.rs Center LinenedwestNessuna valutazione finora

- FisherDocumento20 pagineFishermanmohansingh1999Nessuna valutazione finora

- Parcol Globe ValveDocumento120 pagineParcol Globe ValveAnderson SiqueiraNessuna valutazione finora

- D 500203 X 012Documento20 pagineD 500203 X 012Aarthi PadmanabhanNessuna valutazione finora

- Naf Pocket ValveDocumento4 pagineNaf Pocket ValveAlfredo Silvi MellaNessuna valutazione finora

- T 80120 CaDocumento16 pagineT 80120 CaVinod KumarNessuna valutazione finora

- 3248 CatalogDocumento8 pagine3248 CatalogpernetiNessuna valutazione finora

- Neojv 0040 enDocumento0 pagineNeojv 0040 enLuis GuevaraNessuna valutazione finora

- Fisher 9500 Butterfly Control ValveDocumento12 pagineFisher 9500 Butterfly Control ValveOscarNessuna valutazione finora

- Top Guide Control ValveDocumento32 pagineTop Guide Control Valveachari_swapnilNessuna valutazione finora

- Crane Katalog-RS AngDocumento29 pagineCrane Katalog-RS AngNNNessuna valutazione finora

- 1-2512 SERIES Butterfly Control ValvesDocumento12 pagine1-2512 SERIES Butterfly Control ValvesGiovanni PetrizzoNessuna valutazione finora

- Fisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesDocumento20 pagineFisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesFabián HerreraNessuna valutazione finora

- D 101363 X 012Documento20 pagineD 101363 X 012AmiroucheBenlakehalNessuna valutazione finora

- 3., 4., & 9. RBXC Catalogue Local 2015Documento16 pagine3., 4., & 9. RBXC Catalogue Local 2015Nilesh RanadeviNessuna valutazione finora

- Vann Air ValveDocumento4 pagineVann Air ValveDedeLesmanaNessuna valutazione finora

- Series 250 Pneumatic Control Valve Type 3256-1 and Type 3256-7 Angle Valve Type 3256Documento14 pagineSeries 250 Pneumatic Control Valve Type 3256-1 and Type 3256-7 Angle Valve Type 3256salamrefighNessuna valutazione finora

- 1-2-3 EN Frese ALPHA SEP 12 PDFDocumento6 pagine1-2-3 EN Frese ALPHA SEP 12 PDFengesam2007Nessuna valutazione finora

- Butterfly Valve: SC Fepa SaDocumento9 pagineButterfly Valve: SC Fepa Satoader56Nessuna valutazione finora

- Deluge ValveDocumento10 pagineDeluge ValvevpnrrajaNessuna valutazione finora

- Valvulas de Control FisherDocumento16 pagineValvulas de Control FisherAnonymous GKTRypNessuna valutazione finora

- Autoclave Subsea Ball ValvesDocumento20 pagineAutoclave Subsea Ball Valvesvp989Nessuna valutazione finora

- Pfeiffer Br26d EngDocumento4 paginePfeiffer Br26d EngAleksandr KrigerNessuna valutazione finora

- Broen Butterfly Valves v9Documento13 pagineBroen Butterfly Valves v9bojanmileticNessuna valutazione finora

- DCV Spirax PDFDocumento2 pagineDCV Spirax PDFVaitheeswaran PalaniNessuna valutazione finora

- 11422Documento10 pagine11422balajivangaruNessuna valutazione finora

- Albion Butterfly ValveDocumento28 pagineAlbion Butterfly ValveZein MubarakNessuna valutazione finora

- PVRVDocumento4 paginePVRVbkkbrazil100% (1)

- Waterworks Irrigation Industry, Fire Protection & Special MaterialsDocumento2 pagineWaterworks Irrigation Industry, Fire Protection & Special Materialswhwy99Nessuna valutazione finora

- v101 v102 Butterfly ValvesDocumento6 paginev101 v102 Butterfly Valvesapi-18982376Nessuna valutazione finora

- p128 22 PDFDocumento3 paginep128 22 PDFFernando CeballosNessuna valutazione finora

- Sapag JHP Valves Jun04 enDocumento18 pagineSapag JHP Valves Jun04 enanwar01Nessuna valutazione finora

- CO2 AnsulDocumento17 pagineCO2 AnsulJorge RVNessuna valutazione finora

- V9271 Fivalco 2902eDocumento6 pagineV9271 Fivalco 2902eharenas7Nessuna valutazione finora

- Válvulas Bola SegmentadaDocumento12 pagineVálvulas Bola SegmentadarehynaldoNessuna valutazione finora

- Purga Fondo BBV 980 A PDFDocumento2 paginePurga Fondo BBV 980 A PDFaugusto7777Nessuna valutazione finora

- Ball ValveDocumento12 pagineBall ValveIdabaNessuna valutazione finora

- Fisher Valvula de Mariposa A41 BoletinDocumento12 pagineFisher Valvula de Mariposa A41 BoletinJossi Perez ANessuna valutazione finora

- CVF-SVF - BaumannDocumento16 pagineCVF-SVF - BaumannMwila ChambaNessuna valutazione finora

- Flow Divertor Ball Valve DN20 - DN32 - DN50: DescriptionDocumento3 pagineFlow Divertor Ball Valve DN20 - DN32 - DN50: Description윤병택Nessuna valutazione finora

- Valves Reference PDFDocumento35 pagineValves Reference PDFJulio RodriguezNessuna valutazione finora

- 220523-General-Duty Valves For Plumbing PipingDocumento9 pagine220523-General-Duty Valves For Plumbing PipingAttef BedaweNessuna valutazione finora

- Iso 9001 CertifiedDocumento4 pagineIso 9001 CertifiedLuis R. Salas SotoNessuna valutazione finora

- Fire HydrantDocumento6 pagineFire HydrantdileepsiddiNessuna valutazione finora

- Fisher v150Documento16 pagineFisher v150Doug LambNessuna valutazione finora

- Double Eccentric Butterfly Valves R1Documento20 pagineDouble Eccentric Butterfly Valves R1Sandi AslanNessuna valutazione finora

- Series RGX "Anti - Surge" Air Release & Vacuum Break Valves: Content Catalogue IndexDocumento40 pagineSeries RGX "Anti - Surge" Air Release & Vacuum Break Valves: Content Catalogue IndexMatthew ButlerNessuna valutazione finora

- BRH Eplug Rotaryshaftvalves GeDocumento28 pagineBRH Eplug Rotaryshaftvalves GeJosh FryNessuna valutazione finora

- SRC Alpha Version1 PDFDocumento26 pagineSRC Alpha Version1 PDFRajat JainNessuna valutazione finora

- Is - 14845Documento17 pagineIs - 14845mechftpNessuna valutazione finora

- Sauter B6R Three-Way Valve With Female Thread, PN 16Documento4 pagineSauter B6R Three-Way Valve With Female Thread, PN 16pitanje1991Nessuna valutazione finora

- Válvula de SeguridadDocumento8 pagineVálvula de Seguridadmark_59Nessuna valutazione finora

- Mini Non-Taco Cat (Rev 10-1-14)Documento8 pagineMini Non-Taco Cat (Rev 10-1-14)api-282678113Nessuna valutazione finora

- Pressure Releif ValveDocumento24 paginePressure Releif Valvemtalha_loveNessuna valutazione finora

- Pocket Guide to Flanges, Fittings, and Piping DataDa EverandPocket Guide to Flanges, Fittings, and Piping DataValutazione: 3.5 su 5 stelle3.5/5 (22)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Feasibility OutlineDocumento20 pagineFeasibility OutlineAlyyssa Julfa ArcenoNessuna valutazione finora

- Automatic Sprinklers: Hanger Spacing For Nonmetallic Pipe: Learning ObjectiveDocumento1 paginaAutomatic Sprinklers: Hanger Spacing For Nonmetallic Pipe: Learning ObjectiveReymart Jaynar ReyesNessuna valutazione finora

- 2G BioEthanol-Civil and Structural Works Spec-BPCL-TCEDocumento415 pagine2G BioEthanol-Civil and Structural Works Spec-BPCL-TCEtsrinivasan5083Nessuna valutazione finora

- Btech7th-CE-Estimating Costing Lab MannualDocumento10 pagineBtech7th-CE-Estimating Costing Lab MannualAnshul SaxenaNessuna valutazione finora

- Steel Column DesignDocumento3 pagineSteel Column DesignGlenn TeNessuna valutazione finora

- 2006 Navistar DT466 Engine Torque ValuesDocumento5 pagine2006 Navistar DT466 Engine Torque ValuesMeadows TruckNessuna valutazione finora

- Fosroc Bitucell: Constructive SolutionsDocumento2 pagineFosroc Bitucell: Constructive SolutionsIna RoseNessuna valutazione finora

- J Strusafe 2014 12 002Documento10 pagineJ Strusafe 2014 12 002manasha majhiNessuna valutazione finora

- PDF Wind Load Calculations As Per Is 875 Part 3xls CompressDocumento85 paginePDF Wind Load Calculations As Per Is 875 Part 3xls CompressNews Side Effects.Nessuna valutazione finora

- 5231R 06Documento13 pagine5231R 06BddbvffffnhebrbbrNessuna valutazione finora

- Structural Design of A Reinforced Box Culvert PDFDocumento33 pagineStructural Design of A Reinforced Box Culvert PDFRaja RajanNessuna valutazione finora

- Fen Do LiteDocumento2 pagineFen Do LiteArmie May RicoNessuna valutazione finora

- Toilet: Layout Toilet With Tanggulan Layout Accesible Toilet With TanggulanDocumento1 paginaToilet: Layout Toilet With Tanggulan Layout Accesible Toilet With TanggulanhendriNessuna valutazione finora

- CF 2Documento2 pagineCF 2fk0205Nessuna valutazione finora

- Washing Machine Manual Kenmore HE5tDocumento76 pagineWashing Machine Manual Kenmore HE5tmachnerdNessuna valutazione finora

- MEP Completion ScheduleDocumento1 paginaMEP Completion ScheduleHmNessuna valutazione finora

- 03 Monthly Progress Report May 2022 Rev 00Documento38 pagine03 Monthly Progress Report May 2022 Rev 00Raj KamatNessuna valutazione finora

- Rate Analysis Multi - Drift 30-05-2022 - R2Documento8 pagineRate Analysis Multi - Drift 30-05-2022 - R2Rajat SharmaNessuna valutazione finora

- Slab Code: Grade of Concrete Permissble Stress in SteelDocumento1 paginaSlab Code: Grade of Concrete Permissble Stress in Steeljuliyet strucNessuna valutazione finora

- Casing Centralizer Series - 1 - Types of Centralizers - Pegasus Vertex, Inc. - BlogDocumento3 pagineCasing Centralizer Series - 1 - Types of Centralizers - Pegasus Vertex, Inc. - BlogNihad PaşazadəNessuna valutazione finora

- Guven Grab SpecDocumento1 paginaGuven Grab Specalex bencyNessuna valutazione finora

- ELECT-TIC-2.1 - (Material Receiving Inspection For MV Power Cables & Accessories)Documento2 pagineELECT-TIC-2.1 - (Material Receiving Inspection For MV Power Cables & Accessories)Muhammad IrfanNessuna valutazione finora

- On-Bottom Stability AnalysisDocumento3 pagineOn-Bottom Stability AnalysisBolarinwaNessuna valutazione finora

- 8 HouseDocumento1 pagina8 HousePraneet NagdevNessuna valutazione finora

- Structural Analysis - IDocumento5 pagineStructural Analysis - IKrishnam RajuNessuna valutazione finora

- Transpallet 1 - Bin Loader KiwiDocumento2 pagineTranspallet 1 - Bin Loader KiwirianNessuna valutazione finora

- Pekerjaan Arsitek Gedung Farmasi: NO Unit Quantity Unit Cost (RP) Amount (RP) DescriptionDocumento8 paginePekerjaan Arsitek Gedung Farmasi: NO Unit Quantity Unit Cost (RP) Amount (RP) DescriptionAnan NurdinNessuna valutazione finora

- Installation Manual: SYSTEM Inverter Air ConditionersDocumento52 pagineInstallation Manual: SYSTEM Inverter Air ConditionersOscar DiazNessuna valutazione finora

- Quikrete Concrete Product GuideDocumento28 pagineQuikrete Concrete Product GuideBurak Yanar100% (1)

- Reinforced Concrete IDocumento188 pagineReinforced Concrete ICesar Andres Peralta Vidal100% (1)