Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Mercury 15 2t Timing

Caricato da

kapniasDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Mercury 15 2t Timing

Caricato da

kapniasCopyright:

Formati disponibili

No.

88-1

Advanced Service Information 4. Turn idle speed screw inward (clockwise) until it

“just touches” cam follower, then inward an additional

A. Mercury 15 HP Timing/Synchronizing/Ad- 1/2 turn to slightly open throttle plate.

justing

B. Mercury 15 HP Propellers

A. MERCURY 15 HP

TIMING/SYNCHRONIZING/ADJUSTING

Specifications

a

Horsepower 15

Propshaft Kilowatts 11.2

Piston Displacement 16.0 cu. in. (262cc)

Bore 2.375 in. (60.3mm)

Stroke 1.800 in. (45.7mm)

RPM Range at Full Throttle 5000–6000

b

Idle Speed RPM 700–750 23086

(In “Forward” Gear)

Low Speed Mixture Screw

Maximum Timing (W.O.T.) 36° BTDC (3 Dots)

1. Remove access plug (c) from carburetor air in-

Idle Timing 6° BTDC (2 Dots) take cover (d).

Spark Plug NGK BP8 HS–15

Spark Plug Gap 0.060 in. (1.5mm)

1. Place outboard in water.

2. Check tiller handle cable adjustment for full throttle

movement in both “forward” and “reverse” gears. Ad-

just jam nuts for proper travel and to eliminate any

slack.

d

APPROXIMATE INITIAL CARBURETOR

ADJUSTMENTS c

Idle Speed Screw

1. Shift outboard to “NEUTRAL” and place throttle

twist grip to “SLOW”.

2. Push primer/fast idle knob completely in and rotate

knob fully counterclockwise.

3. Back idle speed screw (a) off of cam follower (b).

22669

Printed in U.S.A. -1- 88-1 1287

2. Turn low speed mixture screw (e) slowly inward Maximum Timing Adjustment

(clockwise) until it seats lightly, then back screw

1. Connect timing light (91–99379) to No. 1 (top)

out (counterclockwise) 1–1/2 turns (turning mix-

spark plug lead.

ture screw in tight will damage needle and seat).

2. With engine running in “Forward” gear, fully ad-

3. Do not install access plug at this time.

vance throttle to W.O.T. position.

e 3. Adjust maximum spark advance screw (a) to

align the 36° B.T.D.C. timing mark (3 Dots) on fly-

wheel with timing pointer. Tighten jam nut (b) if so

equipped.

22666

23970

Idle Timing Adjustment

Timing Pointer Location

1. Push primer/fast idle knob completely in and ro-

tate knob fully counterclockwise.

2. With engine running in “Forward” gear, reduce

engine speed to idle.

IMPORTANT: It may be necessary to adjust idle

speed screw to obtain a reasonably stabilized

idle.

3. Adjust idle timing adjustment screw (a) to align

the 6° B.T.D.C. timing mark (2 Dots) on flywheel

with timing pointer.

a

23970

a

a - Timing Pointer

23970

4. Shift to “Neutral” gear and stop engine.

88-1 1287 -2-

Idle Wire Adjustment

a

1. Push primer/fast idle knob completely in and ro-

tate knob fully counterclockwise.

2. Shift outboard to ”Neutral”.

3. Adjust screw (a) to remove all clearance between

idle wire (b) and trigger.

b

a

22666

4. Slowly turn low speed mixture screw clockwise

until cylinders fire evenly and engine picks up

23970

speed.

Idle Adjustment 5. Continue turning mixture screw clockwise until

Low Speed Mixture Adjustment too lean a mixture is obtained and engine slows

down and misfires.

1. Start engine and allow to warm up (run for several

minutes). Throttle engine back to idle for about 6. Set low speed mixture screw halfway between

one minute to allow RPM to stabilize. rich and lean.

2. Push primer/fast idle knob completely in and ro- 7. Do not adjust leaner than necessary to attain rea-

tate knob fully counterclockwise. sonably smooth idling. When in doubt, set mix-

ture slightly rich rather than too lean.

3. With engine running at idling speed while in for-

ward gear, turn low speed mixture screw (a) 8. Check for freedom from 4 cycling between idle

counterclockwise until engine starts to ”load up” and 2000 RPM (in forward gear).

or fire unevenly from over–rich mixture.

-3- 88-1 1287

Idle Speed Adjustment B. MERCURY 15 HP PROPELLERS

1. With engine running at idle in forward gear, make The new Mercury 15 HP model has a new line of pro-

sure primer/fast idle knob is pushed completely pellers.

in and rotated fully counterclockwise to stop.

No. of

2. Adjust idle speed screw (b) to obtain an engine Diameter Pitch Blades Material Part Number

idle speed of 700–750 RPM. 9” 10-1/2” 3 Alum. 48-17874A12*

3. Install access plug into opening in carburetor air 9” 9” 3 Alum. 48-42522A12

intake cover. 9-1/4” 7” 3 Alum. 48-42520A12

9-3/4” 6-1/2” 3 Alum. 48-42524A12

* Standard with Engine

IMPORTANT: For fast–easy identification the

pitch and A12 assembly number will be stamped

on the propeller. This Is necessary because the

b 15 HP propellers (A12) have a firmer rubber hub

than the 6–8–9.9 (All) propellers. Other than this

the propellers appear identical and could be in-

advertently interchanged.

23086

88-1 1287 -4-

Potrebbero piacerti anche

- F50a FT50B FT50CDocumento403 pagineF50a FT50B FT50CMartinez Valladares OscarNessuna valutazione finora

- Service Manual 6y8 Lan GaugesDocumento34 pagineService Manual 6y8 Lan GaugesMiguel GuguNessuna valutazione finora

- Mercury 2.5-3.5 4 Stroke LaterDocumento205 pagineMercury 2.5-3.5 4 Stroke LaterTonyNessuna valutazione finora

- Mercury 150HPDocumento5 pagineMercury 150HP이영석0% (1)

- Mercury 75 - 90 - 115HP 4-Stroke Operation and Maintenance Manual (PDF, ENG, 2.54 MB)Documento62 pagineMercury 75 - 90 - 115HP 4-Stroke Operation and Maintenance Manual (PDF, ENG, 2.54 MB)Carl WilkinsonNessuna valutazione finora

- JS800A9FDocumento255 pagineJS800A9Falexander ortizNessuna valutazione finora

- 31 GM SBC 2001Documento1.096 pagine31 GM SBC 2001The Boat DocturNessuna valutazione finora

- MerCruiser GM4 Manual de ServicioDocumento348 pagineMerCruiser GM4 Manual de ServicioMarianoBonetFeoNessuna valutazione finora

- 30 40 PDFDocumento584 pagine30 40 PDFNicoNessuna valutazione finora

- 30DMH 6K9 28197 Z8 C2Documento384 pagine30DMH 6K9 28197 Z8 C2Julie LafranceNessuna valutazione finora

- Seastar Manual 2004Documento101 pagineSeastar Manual 2004Isaac Rodríguez BetancourtNessuna valutazione finora

- Yamaha 115b 115ADocumento261 pagineYamaha 115b 115AAlexandre Oliveira100% (2)

- Mercury 135:150:175:20:225HP XR6 Magnum II EFI Pro Max Super Magnum 90-824052R2 09:97 PDFDocumento824 pagineMercury 135:150:175:20:225HP XR6 Magnum II EFI Pro Max Super Magnum 90-824052R2 09:97 PDFRandall Petterson100% (4)

- Evinrude E-TEC 200-250 HPDocumento406 pagineEvinrude E-TEC 200-250 HPAlbertNessuna valutazione finora

- Verado 200-275 Workshop-1Documento90 pagineVerado 200-275 Workshop-1Servicios Luna LSNessuna valutazione finora

- Mercury 6 - 8 - 9,9 - 10 - 15HP (1986) Service Manual (PDF, ENG, 2.49 MB) PDFDocumento149 pagineMercury 6 - 8 - 9,9 - 10 - 15HP (1986) Service Manual (PDF, ENG, 2.49 MB) PDFbobNessuna valutazione finora

- 2003-2004 Polaris MSX 110 MSX 150 Personal WatercraftDocumento241 pagine2003-2004 Polaris MSX 110 MSX 150 Personal WatercraftJisu Kim100% (1)

- Yamaha f115Documento261 pagineYamaha f115lucas100% (1)

- Honda Marine Outboard Bf115a Bf130a Owner ManualDocumento130 pagineHonda Marine Outboard Bf115a Bf130a Owner ManualЯрослав БарновскийNessuna valutazione finora

- Mercury Outboard Internal Engine PartsDocumento19 pagineMercury Outboard Internal Engine Partswguenon100% (1)

- YAMAHA OUTBOARD LZ200NETO, LZ200TR Service Repair Manual X 100101 PDFDocumento60 pagineYAMAHA OUTBOARD LZ200NETO, LZ200TR Service Repair Manual X 100101 PDFjhsenfnneNessuna valutazione finora

- Suzuki Outboard DT50 Service Repair Manual PDFDocumento6 pagineSuzuki Outboard DT50 Service Repair Manual PDFsekfsekmddde0% (2)

- Kawasaki Jet Ski Watercraft 1100 STX D.I. '03 (JT1100-G1) - Service ManualDocumento288 pagineKawasaki Jet Ski Watercraft 1100 STX D.I. '03 (JT1100-G1) - Service Manualdale123850167% (3)

- 6b4-28197-5e-11 E15d PDFDocumento168 pagine6b4-28197-5e-11 E15d PDFAlexNessuna valutazione finora

- Suzuki DF60A Service Manual 2010 - 2015Documento336 pagineSuzuki DF60A Service Manual 2010 - 2015PabloAntonioCerdaSotoNessuna valutazione finora

- Merc Service Manual 30Documento355 pagineMerc Service Manual 30Hayduke them100% (6)

- 49 Toc PDFDocumento8 pagine49 Toc PDFAnonymous 31OOGD9Kg0% (1)

- Manual 75 OptimaxDocumento5 pagineManual 75 OptimaxJaime Mks20% (5)

- Number 6: Sterndrive Units R MR Alpha One Alpha One SSDocumento7 pagineNumber 6: Sterndrive Units R MR Alpha One Alpha One SSmarujopeNessuna valutazione finora

- 1200 STX R ServicemanualDocumento289 pagine1200 STX R Servicemanualnoname6184100% (4)

- Outboard Manual 70 75 80 90 100 115Documento391 pagineOutboard Manual 70 75 80 90 100 115Bret Kemp100% (3)

- Servicemanual25 GM v6 1998-2001 CompleteDocumento791 pagineServicemanual25 GM v6 1998-2001 Completerrfam100% (2)

- 2008 Mercruiser Service Manual Index PDFDocumento6 pagine2008 Mercruiser Service Manual Index PDFkujawat11Nessuna valutazione finora

- 8 M 0105246 RDocumento137 pagine8 M 0105246 RJosé Seiça100% (1)

- 135 150dfimanualDocumento522 pagine135 150dfimanualDaniel Bonin80% (5)

- Serial Number 0G960500 and Above EFI Models 0G960500 Thru 0T408999Documento654 pagineSerial Number 0G960500 and Above EFI Models 0G960500 Thru 0T408999Ingo BorchersNessuna valutazione finora

- Suzuki Service Manual - K15-Df100a-115a-115as-140a-99011-90j50-03benDocumento131 pagineSuzuki Service Manual - K15-Df100a-115a-115as-140a-99011-90j50-03benJorge LopesNessuna valutazione finora

- Alarmes SmartcraftDocumento52 pagineAlarmes SmartcraftEdgar PinheiroNessuna valutazione finora

- 10-Pin Blue Data Cable RiggingDocumento6 pagine10-Pin Blue Data Cable RiggingajcapetillogNessuna valutazione finora

- Mefi 4 & 4b Diagnostic Manual (l510005p)Documento337 pagineMefi 4 & 4b Diagnostic Manual (l510005p)2791957Nessuna valutazione finora

- Carburadores ManualDocumento205 pagineCarburadores Manualjorge alonso67% (3)

- Analog Gauge Connections For Digital Optimax ModelsDocumento6 pagineAnalog Gauge Connections For Digital Optimax ModelsGet SmartCraft100% (1)

- Evinrude E-Tec Outboard Motor Service Manual Repair 75hp 90hp 2007 PDFDocumento344 pagineEvinrude E-Tec Outboard Motor Service Manual Repair 75hp 90hp 2007 PDFadolfoc26175% (4)

- Evinrude E-TEC 15-30HP Outboards BuletinDocumento2 pagineEvinrude E-TEC 15-30HP Outboards Buletinfranklarabie100% (2)

- Service Manual #22 4.2 D-Tronic DieselDocumento878 pagineService Manual #22 4.2 D-Tronic DieselPhil B.50% (4)

- Mercruiser Service Manual - 25 GM V6 1998 - 2001Documento225 pagineMercruiser Service Manual - 25 GM V6 1998 - 2001an82mustang100% (3)

- Powerboater's Guide to Electrical Systems, Second EditionDa EverandPowerboater's Guide to Electrical Systems, Second EditionValutazione: 5 su 5 stelle5/5 (1)

- Outboard Engines 2E (PB): Maintenance, Troubleshooting, and RepairDa EverandOutboard Engines 2E (PB): Maintenance, Troubleshooting, and RepairValutazione: 3 su 5 stelle3/5 (1)

- Timing Synchronizing AdjustingDocumento6 pagineTiming Synchronizing AdjustingRyan ActonNessuna valutazione finora

- Electrical and Ignition: Timing/Synchronizing/AdjustingDocumento9 pagineElectrical and Ignition: Timing/Synchronizing/AdjustingJim LassNessuna valutazione finora

- Service: SMCS - 1290 2009/02/17 Electronic Unit Injector - Adjust (SENR9888)Documento2 pagineService: SMCS - 1290 2009/02/17 Electronic Unit Injector - Adjust (SENR9888)SyahdiNessuna valutazione finora

- BS3 Crank TriggerDocumento27 pagineBS3 Crank TriggerdaveplNessuna valutazione finora

- Reglage Allumage 70 CV MercDocumento5 pagineReglage Allumage 70 CV MercasursNessuna valutazione finora

- CAT Compression Brake Lash - AdjustDocumento2 pagineCAT Compression Brake Lash - Adjustbenge henrique100% (2)

- Timing ExerciceDocumento12 pagineTiming Exercicehector eduardo moya benavidesNessuna valutazione finora

- 2004 SR Johnson 2 Stroke 9.9, 15, 25, 30 HPDocumento17 pagine2004 SR Johnson 2 Stroke 9.9, 15, 25, 30 HPPaco Caballero SaorinNessuna valutazione finora

- Panasonic Ey7440 Manual de Usuario Páginas 7 9Documento3 paginePanasonic Ey7440 Manual de Usuario Páginas 7 9Mr. Gonza M.Nessuna valutazione finora

- M9930lu SM Sanyo en TextDocumento15 pagineM9930lu SM Sanyo en TextgoNessuna valutazione finora

- Wks-Sonneboy: Automatic Sun & Wind ControlDocumento2 pagineWks-Sonneboy: Automatic Sun & Wind ControlkapniasNessuna valutazione finora

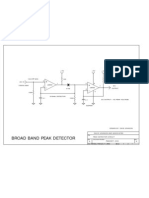

- Peakdet 1Documento1 paginaPeakdet 1ricardoszfNessuna valutazione finora

- Yamaha 2009 Maintenance ChartsDocumento7 pagineYamaha 2009 Maintenance ChartskapniasNessuna valutazione finora

- US-User Manual of DS-7200HVI-ST Series DVRDocumento58 pagineUS-User Manual of DS-7200HVI-ST Series DVRGaćeša BranislavNessuna valutazione finora

- Focus Mk2 Cabin FilterDocumento4 pagineFocus Mk2 Cabin FilterkapniasNessuna valutazione finora

- Yamaha Outboard f350 Suare Guages ManualDocumento72 pagineYamaha Outboard f350 Suare Guages Manualevangalos80% (5)

- Mercury 15 2t TimingDocumento4 pagineMercury 15 2t TimingkapniasNessuna valutazione finora

- Rexroth: Spare Parts ListDocumento20 pagineRexroth: Spare Parts ListIvan BeljinNessuna valutazione finora

- SECTION 2.05: Crankcase Component RemovalDocumento30 pagineSECTION 2.05: Crankcase Component RemovalLUISA FERNANDA TORRES MANOSALVANessuna valutazione finora

- Williams Control - Acelerador ElectronicoDocumento44 pagineWilliams Control - Acelerador ElectronicoGianna Frola100% (1)

- 2017.0050 - DSC 1-50 - BAO MINH - r.00 02-18 - ENDocumento41 pagine2017.0050 - DSC 1-50 - BAO MINH - r.00 02-18 - ENNguyễn Huy CườngNessuna valutazione finora

- Emerging Trends in Mechanical Engineering - 22652 (AE/PG/PT/ME)Documento16 pagineEmerging Trends in Mechanical Engineering - 22652 (AE/PG/PT/ME)Kunal AhiwaleNessuna valutazione finora

- Audi A6 C5 AirConditioner ElectricalTestingDocumento189 pagineAudi A6 C5 AirConditioner ElectricalTestingGlen Gary100% (1)

- Mercury2 8cyl GP Output Priority LayoutDocumento2 pagineMercury2 8cyl GP Output Priority LayoutHonda Civic Wonder IndonesiaNessuna valutazione finora

- LEC - HSE-Generator Inspection StandardDocumento1 paginaLEC - HSE-Generator Inspection StandardSyafriansyahNessuna valutazione finora

- Caterpillar 910 Wheel Loader Operators Manual SN 80u1 and UpDocumento7 pagineCaterpillar 910 Wheel Loader Operators Manual SN 80u1 and Upbambangpadhi7Nessuna valutazione finora

- PN 181745-4 Cradle PW4090 ManualDocumento39 paginePN 181745-4 Cradle PW4090 ManualamroushararaNessuna valutazione finora

- Direction On AssemblyDocumento82 pagineDirection On Assemblybaaska TsetseNessuna valutazione finora

- LionRock Diesel Generator SetsDocumento10 pagineLionRock Diesel Generator SetsKenjoNessuna valutazione finora

- Instruction and Operation Manual: Manual de Instrucción Y Operación Guide D'Instruction Et D'OperationDocumento13 pagineInstruction and Operation Manual: Manual de Instrucción Y Operación Guide D'Instruction Et D'OperationglizamabNessuna valutazione finora

- 1-Kinroad XT250GK-6 Raptor Parts ManualDocumento20 pagine1-Kinroad XT250GK-6 Raptor Parts ManualoakstrNessuna valutazione finora

- Manual WPIL Vertical Turbine PumpsDocumento57 pagineManual WPIL Vertical Turbine PumpsDavid Osores86% (7)

- XRAY NT1 Instruction Manual 6Documento40 pagineXRAY NT1 Instruction Manual 6Vincent ManNessuna valutazione finora

- 203 CDocumento25 pagine203 CДмитрий МураховскийNessuna valutazione finora

- 171711-1 A Betriebsanleitung en-US PDFDocumento46 pagine171711-1 A Betriebsanleitung en-US PDFHadj Ahmed SaoudiNessuna valutazione finora

- @@L1566@ Decal and Plate (Russian) (#32250-) : PC400-6 S/N 30001-UP PC400-6 S/N 30001-UPDocumento316 pagine@@L1566@ Decal and Plate (Russian) (#32250-) : PC400-6 S/N 30001-UP PC400-6 S/N 30001-UPwiluxajuNessuna valutazione finora

- VSC TechnologyDocumento16 pagineVSC Technologymike chenNessuna valutazione finora

- Drum Brake Adjustment PDFDocumento2 pagineDrum Brake Adjustment PDFY. VásquezNessuna valutazione finora

- Front Brake Disc Replacement PDFDocumento3 pagineFront Brake Disc Replacement PDFY. VásquezNessuna valutazione finora

- Plano Electrico Motor 3126E PDFDocumento2 paginePlano Electrico Motor 3126E PDFdavor1414100% (1)

- Ospc GénéralitésDocumento22 pagineOspc GénéralitésKarthikVijayNessuna valutazione finora

- 15-Parts List ELS12 MK2Documento150 pagine15-Parts List ELS12 MK2Mehar Tariq GoheerNessuna valutazione finora

- Diagrama qsx15 PDFDocumento7 pagineDiagrama qsx15 PDFJavier Agudelo F94% (18)

- Section A-A Scale 1 / 2: Pete Lenz 8/21/2010Documento8 pagineSection A-A Scale 1 / 2: Pete Lenz 8/21/2010Manish PatilNessuna valutazione finora

- Forklift Truck ChecklistDocumento1 paginaForklift Truck ChecklistdnmuleNessuna valutazione finora

- MT 3000-2i Offset: Special ClassDocumento19 pagineMT 3000-2i Offset: Special ClassConsorcio El dorado 2019Nessuna valutazione finora

- Ovhd Panel PDFDocumento6 pagineOvhd Panel PDFNickNessuna valutazione finora