Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Polacel SQ Cooling Tower

Caricato da

woowk0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

501 visualizzazioni20 pagineTitolo originale

32. Polacel SQ Cooling Tower

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

501 visualizzazioni20 paginePolacel SQ Cooling Tower

Caricato da

woowkCopyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 20

polacel COOLING TOWER

.

iy

SQ_-SERIES

RVUYUTK

WEVBVUVUYVYVVOVVVVUVGUVUY YG BUV GV VG GUSTY GV U GU U GOVE VU EG

BSVVVS VVVVOLVVVVEBEPE GOEEGESCE ESCO SESE,

COOLING TOWER

INSTITUTE

Certificate of Membership

This & to certify that

POLACEL B.V.

is @ member of the Cooling Tower Institute « non-profit self-

governing association of companies, dedicated to improvement in

the technology, design, performance, and maintenance of water

cooling towers, and as a member agrees to support and abide by

the Constitution, Bylaws and Declaration of Principles.

ow duly 1985 Yoh Zrcerttl sever

chase Tas Prades

“This ceniicate remains the propery of Cooling Tower Inattaea und is mbjece vo ect at any cme,

:

|

:

GENERAL INFORMATION

ee Eee

OPERATING PRINCIPLE

Polacel cooling tower type SQ-T operates according to the cross flow principle. The hot water

to be cooled is fed into the hot water basin. The hot water distribute evenly through holes into

PVC in fill. The falling water transfers heat to the air sucked in by an axial fan by evaporation

and conduction. The cooled water is collected in the cold water basin at the bottom of the tower

for circulation,

MATERIALS OF CONSTRUCTION

Casing

The casing of the cooling tower is made of glassfibre reinforced polyester panels which are

connected with SS-bolts to hot dip galvanized frames,

Hot and Cold Water Basins

The hot and cold water basins are made of glassfibre reinforce polyester. The basins of the

cooling tower are very easy to clean.

Cooling Tower Fill

The cooling tower fill is made of PVC sheets which are suitable for a maximum water

temperature of 55°C, The low pressure along of the cross flow packing causes low energy costs.

Air Inlet Blinds

In order to keep splash water losses and water losses during strong gusts of wind to a minimum,

aluminium louvers are mounted between the vertical frame of the cooling tower. It can be easily

dismantled by loosen the bolts mounted onto the frame,

Fan Unit

A fan hood of glassfibre reinforced polyester ensures an aerodynamically smooth flow of water-

vapour saturated air towards the fan. The axial fan itself is made of FRP or cost aluminium alloy.

‘The fan motors used are specially developed for the use in very humid environments (IP 55)

Low Maintenance Costs

The cooling tower being equipped with an inspection door. The water distribution system and

the internal parts of the cooling tower are easily accessible, Through the exclusive materials

which we use, the cooling towers meet with the requirements of being completely corrosion and

chemicals resistant

SELECTION OF POLACEL COOLING TOWER MODEL SQ-T

Design conditions example:

Weter Circulating Flowrate = $00 m'/HR

T, Hot Water Temperature = 36°C

Tz Cold Water Temperature = 31°C

To Ambient Wet Bulb Temperature = 27°C

Selection Procedure

1.) Determine Temperature Range (AT) = Ty - Ty

= 36°C - 31°C

= °C

2.) Determine Approach = Tot,

= 31°C -27°C

= 4c

3.) Determine Cooling Capacity = Water Flowrate (mY/HR) \ AT(°C) x 1000Keal/HR

= $00.x 5 x 1000 Keal/HR.

= 2500000 Keal/HR

4.) Find the correction factor in the selection table for a wet bulb temperature of 27°C

Correction Factor = 0.88

5.) Divide the design cooling capacity by the selected correction factor.

2500000 kK ca/HR

0.88

= 2840909 KeaV/HR

Result

6.) Select the cooling tower from the SQ - T table taking into account the cooling capacity in

the table is greater or equal to result obtained under point 5.

‘The model of cooling tower select shall be SQ 800T (Q = 3120,000 Keal/HR)

Wet Bulb Temperature To = 25°C

—

eee

et ella

ce 3 061 | 0.65 | 0.70

4 069 | 077 | 062

Es aes

069 | 077 | 089

‘oso [077 | 080

le

Wet Bulb Temperature To

‘APPROACH

‘TEMPERATURE.

TWs-To ¢c) | 30 | a5 | 40 | 46 | so | se | co] os | zo] 75 | 20 | 25 | 90 | 95 | 100

ese 086 | 061 | os | 071 | 075 | 077 | 079 | os2 | 064 | 087 | 089 | om: | 093 | 095 | one

086 | os | 079 | 08s 090 [ose] oe | 102] 108 x08 | tio v2 ate vie | 147

086 | 063 | o70 | 090 | 100] 106 [11 | 116 | 121 | 126] 120] 122} +35

a6 | 063 | 070 | 092] sa] 112 [121] 128) 1a8| 130/10) 1a fost

oss | oes | 070 | 092 | 102] 112] 121] 128 | 134] 146] 158] 161

oss [oss |ore | oo2| 12} siz] iar] tae tae] 148] 158 [161

086 | oss | 070 | 092] 102] 112] 121 | 126] 104] 146 | 1568 { 16r] 176] 190 | 201

056 [oss [ove] oa] roa riz) 120 | 128} 194) ta | 158] vet | 176] 190 [201

Wet Bulb Temperature 27°C

“APPROACH RANGE OF TEMPERATURE TWs -TWs_(A7)

‘TEMPERATURE

Tws-te te) | 30 | a6] a0 | ae | to] es] ro | rs] oo | o8 | 90 | 08 | 00

2 078 082 | 085 | 087 | 089 | ost | 03 | 094 | os | ove

= sa [ase [oar voo| to vax [uae uae ue [6-1

= 1100 ssa] 448 | 1.22 | 126 [130 [ 132 [ 135 | 197 | 139

é ot 420 [129 | 136 [141 [146180] 153 | 158 | 157

= [ror fs] 120 [120] 136] 148 | 160] 16¢| 100 [ 17 | 76

+ sor [tat | 121 | 129| 136140 [961] 1.65 | ie] tea] 107

a6 sor] s.st | 421 | 120 | 1.36 | 149 | 161 | 155 | 181 | 199 | 204

0 sor Pat] 12i | 29 [38] ras | rei | es] vat | 193 | 208

APPROACH Twa

‘TEMPERATURE

Ws Te Cc) 1s

2 on

‘ 140

: oer 128

* oer 1

5 ‘059 | 070 | o8t 147

s 050 | 0.70 | 08% 147

# | 0%0| 070 | 081 | 038 var |

0 fase} o70 | oar | oss 1a

PHYSICAL SPECIFICATIONS

eee Ee

MODELS SQ 100T & SQ 125T

ARE

cAL-FLOW

DAWETER

NUMBER OF BLADES

IFAN SPEED

loRive svsTeM

free

Jpower source ‘3 PHASE 415V SoH

JateD oureuT 22x1 37x1

[RATED CURRENT 92x1 48xt

MODELS SQ 150T & SQ 175T

ee = sa.160r saweT

[cooune capacmry Ry 150 175

HEAT LOAD ean] ‘585,000 682500

ccapaciry [ciRCULATING WATER | i? 1965

HOT WATER TEMPERATURE ‘| 7

[COLD WATER TEMPERATURE *c Zee.

[AMBIENT WET-BULB TEMPERATURE ‘| @

OveRau [LENGTH A) 1800

Dimension |wiotH ow) 3500

OVERALL HEIGHT (a) 3600)

feasins FRE

FRAMEWORK. BASIN FRAME STEEL (HOT-OIP GALVANIZED)

Func ace Pvc

MATERIALS |oISTRIBUTION BASIN FRE %

FRE

COLD WATER BASIN

Louvers

‘PVC ALUMINIUM

FAN BLADE: FRP, HUB! ALUMINIUM CAST ALLOY

FAN STACK FRP

ype AXIAL-FLOW.

DIAMETER 15001

FAN NUMBER OF BLADES =

[FAN SPEED 70 560

FAN loRive system V-BELT DRIVE

ASSEMBLY [rrr ‘TOTALLY ENCLOSED FAN-COOLED OUTDOOR

‘3 PHASE INDUCTION MOTOR 4POLE

|POwER souRcE ‘3 PHASE 475v SoHE

motor RATED ourpuT 37x41 55x1

[RATED CURRENT 15x1 2x1

fauantiry 1

[DISTRIBUTION SYSTEM (OPEN GRAVITY TYPE

HOT WATER INLET HOLE 10042

pipmig [COLD WATER INLET PIPE 15081

DIAMETER |oRAIN PIPE & OVERFLOW PIPE 65AX1

— Axs

\UTOMATIC MAKE-UP WATER INLET PIPE

MANUAL MAKE-UP WATER INLET PIPE AXA

MaKe. _ [EVAPORATION Loss. | 087

UP jonirr Loss ‘| LESS THANO2

weight |DEA0 WEIGHT a 1010 1020

[OPERATING WEIGHT ‘a 2200 280

PHYSICAL SPECIFICATIONS

MODELS SQ 200T & SQ 225T

a Se sazst

[COouNG caPacrTY 25

HEAT LOAD 877,500

eapacry |CIRCULATING WATER 1755

JHOT WATER TEMPERATURE

|COLD WATER TEMPERATURE

[AMBIENT WET-BULB TEMPERATURE

OvER ALL [LENGTHY 2100

DIMENSION |wi0TH (w) 3900

[OVERALL HEIGHT (H) 3600.

jeasine FRP,

FRAMEWORK. BASIN FRAME ‘STEEL (HOT-OIP GALVANIZED)

FIUNG i "V

MATERIALS DISTRIBUTION BASIN = = 5

|COLD WATER BASIN FRE.

|Louvers PVC / ALUMINIUM. is

FAN BLADE! FRP, HUB: ALUMINIUM CAST ALLOY

hj rag ea Se

rye. ‘AXIAL-FLOW

DIAMETER 2 mm 3700 x4

FAN |NUMBER OF BLADES: 6

FAN SPEEO ‘| 60 60

FAN lORIVE sysTeM V-BELT ORIVE

‘ASSEMBLY TOTALLY ENCLOSED FAN-COOLED OUTDOOR

‘3 PHASE INDUCTION MOTOR 4 POLE

lPoweR SOURCE ‘3 PHASE 415 Sokz

motor [RATED OUTPUT ve 55x1

[RATED CURRENT ‘ASooHE Exu

fauantiry 1

[bisTRIBUTION SYSTEM OPEN GRAVITY TYPE.

[HOT WATER INLET HOLE 125AX2

piping [COLDWATER INLET PIPE 200 X4

DIAMETER Jonain piPE & OVERFLOW PIPE BOAXA

|AUTOMATIC MAKE-UP WATER INLET PIPE 40AX1

(UAL MAKE-UP WATER INLET PIPE AKT

Make. [EVAPORATION Loss | 0.87

up __|onirrtoss | LESS THAN 02

weigHT [DEAD WEIGHT '] 1250 1450

JOPERATING WEIGHT a] 2800) 3370

MODELS SQ 250T & SQ 300T

SSE ae

eaneeeT reees =

ee alae ae

capaciry |cIRCULATING WATER | 195 are

ee ame = -

oe aes =

ie ae ea a :

en isl rae =

ori ane =

uoeis eae =

eee =

oan Teme me

|Fiunc Fc

Se xroaon =

[COLD WATER BASIN RP =

LOVERS PVC J ALUMINIUM

ae oe eens

rs z

We rar

er ral aan ce

eee :

ee See z

i = a

LY pre TOTALLY ENCLOSED FAN-COOLED OUTDOOR

eee

EE Serer

Fira coed etioee |al ae

eee aT

Pe css rr crore a

DIAMETER’ [DRAIN PIPE & OVERFLOW PIPE BOA aes

JAUTOMATIC MAKE-UP WATER INLET PIPE AXA

MANUAL MAKE-UP WATER INLET PIPE “aoaxd

waxe. [EVAPORATION Loss.

up _|orirrioss

Wweict |oEAD weicHT

zlsle ls

g

8

JOPERATING WEIGHT

PHYSICAL SPECIFICATIONS

MODELS SQ 350T & SQ 400T

eg = sastor saseor

[cOouNG CAPACITY yl 350 0

eat Loan teat] 1,385,000 1.580.000

capacity |cincuLarTinG WATER won| 23 32

HOT WATER TEMPERATURE a

JCOLD WATER TEMPERATURE * 2

JAWeKENT WET-BULB TEMPERATURE | 7

vena [LENGTH | 3600 200

DIMENSION | WiOTH cw) am 3500 3700

JOVERALL HEIGHT @H) ol 600 ar)

Jeasine FRP

JFRAMEWORK, BASIN FRAME STEEL (HOT-DIP GALVANZED)

ruins Pve

warertars [DISTRIBUTION BASIN FRP

coup WATER BASIN FRE a

Louvers ve / ALUN

ran BLADE: FAP, HUB: ALUMINIUM CAST ALLOY

Fan STACK FR CZ

fee. AXALFLOW

DIAMETER 2 ral 1g00%2 i00%2

FAN [NUMBER OF BLADES °

Iran SPEED ‘pa ES 0

FAN VSELT DRIVE

ASSEMBLY ‘TOTALLY ENCLOSED FAN-COOLED OUTDOOR

‘3 PHASE INDUCTION MOTOR POLE

Power SOURCE ‘3 PHASE 415V 50H

Motor [RATED OUTPUT ‘ 55x2

JRATED CURRENT ASooHz 2x2

fauanriry 2

JeisTaiBUTION svsTEM OPEN GRAVITY TYPE

JpoT WATER INLET HOLE to0ax4 125AK4

prema [COLD WATER INLET PIPE 2OOA 250aXt

BUMETER [oRAW PIPE & OVERFLOW PIPE BAKA BAX1

JAUTOMATIC MAKE-UP WATER INLET PIPE PAxt SOA

MANUAL MAKE-UP WATER INLET PIPE AX ‘SOAK

wane. [EVAPORATION Loss | 087

Ue Jorirrioss * Less THANO?

WeieiT [DEAD WEIGHT : | :

JOPERATINGWEIGHT |

-10-

MODELS SQ 450T & SQ 500T

— sa4sor $Q.500T

fed0uns capaci 7 © Ea

ear Lox = 135000

cannery [onc uaTnG WATER rh =i 0

tor WATER TewrenaTURE = =

c010 WATER TenenaTURE | 2

vient wersu.s TeveeRATURE | =

orenane [ENGTHCD aoe om

mension fo cn rea] eo 0

[overaueci G9 real so 0

exsnis rap

FRAME WOR aASN FRAME STEEL HOT.0F GALNANGED)

[FILING z Pye il

MATERIALS [DISTRIBUTION BASIN 5 FRE

OLD WATER BASH “re

OUVERS a PVC/ALUMINIUM

ran BADE Fa, ALuMUM GRSTALLOY

JFAN STACK 5 FRE

ive "REAL FLOW

aweren San] ioe BeoK?

ran |euwaen oF aoes 3

avers | ny =

ran love svevem = WELT DRE

‘ASSEMBLY JTvPE TOTALLY ENCLOSED FAN-COOLED OUTDOOR

SABE NoUCTION MeTOR APoLE

owen sounce OPASE stv ee

wore |rareo oureur [a 75K

JRATED CURRENT ‘AsoeoHe | x2 axa |

uae 2

rstmauriow sveTen eA TE

OT WATER LET HOLE Taaxe

Piping [COLDWATER INLET PIPE. ‘2B0AXt

DIAMETER | DRAIN PIPE & OVERFLOW PIPE. = z ‘BOA X1

sToMATiC HARE uP WATER WET PE saxt

JMANUAL MAKE-UP WATER INLET PIPE ad ee SOAX)

mane [EVAPORATION Oss 5 087

hail |ORIFT LOSS = sl LESS THANO.2

Went [oeA0 weicir vo] 0 sao

[orerarwi weionr dD eee

oie

PHYSICAL SPECIFICATIONS

MODELS SQ 600T, SQ 700T & SQ 750T

ae Se ee sas00T sa 700T/Sa750T

re

coun cara |e 72

[HEAT LOAD s kcal] 2,340,000 2,730,000

camry [enews waren ef =e ee

lewaren ewrensTone < a

A WATER TEIPERATRE =a =

ENT WET-BULB TEMPERATURE sc 7

orem [ex=9 =f =

ones fv laa a8

Sea TH lain a8

FRAMEWORK. BASIN FRAME STEEL (HOT-DIP GALVANIZED)

MATERIALS |OISTRIBUTION BASIN: FRE me

|COLD WATER BASIN FRE 73 =

louvers PVC / ALUMINIUM

lean BLADE: FRP, HUB: ALUMINIUM CAST ALLOY

panes RSs eee a) ee pms ee

[ree RoALALOW

oaneren mal oT

FAN [NUMBER OF BLADES: see 6

|FAN SPEED en] 460 m 300

ra lone rere Year oe

‘ASSEMBLY [rye TOTALLY ENCLOSED FAN-COOLED OUTDOOR

Siace nacnonscron soar

owen source mse ave

woron_ rare oureut ci esx

paren cunnenT nave wxa

eum 3

nsrenuTon evra Sra RNATT

fotwaren ner voce 0

pena |Cou0waTeR mer re owe

DIAMETER |opain PIPE & OVERFLOW PIPE ‘8OAK2

|AUTOMATIC MAKE-UP WATER INLET PIPE Zi Be. 0A K2

WANUAL MAKE-UP WATER INLET PIPE HOAKZ =

aes feveronnon oss 4 oer

ur _|orirrioss | LESS THAN

cs eS =

PERATING WEIGHT = ‘a 8400 10470

“2

MODELS SQ 800T & SQ 1000T

SS WoDEL

ae sascor sa 10007

[COOLING caPaciTy | 1000

[HEAT LOAD teat] 3,120,000 3,900,000

ccapacrry |ciRCULATING WATER rl 700

HOT WATER TEMPERATURE “| 5 7

[COLD WATER TEMPERATURE “|

[AMBIENT WET-BULB TEMPERATURE |

ovens [LENGTH () mm] 8400 9800

imension [wioTs ow) : mn 3700 4000

OVERALL HEIGHT mm] 9800 3700

casing FR

FRAMEWORK BASIN FRAME STEEL (HOT-OIP GALVANIZED)

Faun ea ve

MATERIALS [DISTRIBUTION BASIN Se FRE |

COLDWATER BASIN FRE

Louvers E PVE ALUNANIUN

FAN ‘BLADE: FRP, HU: ALUMINIUM CAST ALLOY

[FAN STACK ree

frvee -AXALFLOW

lbiaweTeR mn] 1700x4

ran [NUMBER OF aLADES %

FAN SPEED pal ~ Ws!

Fan, DRIVE SYSTEM

-ASSEMBL| pre ‘TOTALLY ENCLOSED FAN-COOLED OUTDOOR

‘3 PHASE INDUCTION MOTOR 4POLE

POWER SOURCE PHASE 415 sot

moror |RATED OUTPUT = S5x4 75x4

RATED CURRENT ‘ASISOHZ “2x4 2x4

lauanriry 4

[bisTRisGTIoN SYSTEM ‘OPEN GRAVITY TYPE

HOT WATER INLET HOLE 125AXG

pio [COLDWATER MET PIPE 250Ax2

DIAMETER [DRAIN PIPE & OVERFLOW PIPE = ‘BOA x2

[AUTOMATIC MAKE-UP WATER INLET PIPE axe

[MANUAL MAKE-UP WATER INLET PIPE Saxe

Wake. [EVAPORATION Loss *| 087

ue Jonirrioss 4 Less THANG?

WeigHT [DEAD WEIGHT va] 600 5260

[OPERATING WEIGHT il 11900 13700

Be

NOISE LEVEL

LOUVRE SIDE

easumne omecron

CASING SIDE

Measune. oiRecriON.

(oerasire oF uoroR

Save side)

SQ -T ( SUPER QUIET TYPE )

NOTE: OM = FAN DIAMETER

-15-

DIMENSIONAL DATA

Lene ee eee nnn e es

MODELS SQ 100T, 125T, 150T, 175T, 200T, 225T, 250T

a

= 9

3500 | 1800

2600,

360 | 2100"

"500 | 2100

3700 | 2480

28°

eg

i

| wor warts

ses ae)

BEBE

woror

|

Ly set EF

Ee ee aL

FOUNDATION CONCRETE BEAMS

lo)

EESSSs/-

7500

"1900

"2100

2100

r=

4

SS

eo! 2450

e

a

| a ree

sot IN | ==

MODELS SQ 300T, 350T, 400T, 450T, 500T

oA

Sa soot | Seon | Sor 00

| saasor | ono’| sero | se00

yor wate -sawoor | 3600/00 | 3700

Betts) oe teste

ES sto | «900 | 4000

Pas 000

so. waxe-op

yh

wna wrt | |, Koetio ove

COLD WATER OUTLET ee

FOUNDATION CONCRETE BEAMS

wove [A] ee

‘sas00T | 3030] 508 | 1030

Sasser | tos 10 | mo

‘Sadoor | ta30 | 1500 | 1030 |

‘Saasor_| 1030 760 | 1030

2888 se

a8 8/8 §\-|

sasoor | 1000 | 1200 | 1030

"NOTE" ALL DNENSIONS ARE Nar

Foun uPeam Ue 38

DIMENSIONAL DATA

MODELS SQ 600T, 700T & 750T

FOUNDATION CONCRETE BEAMS

MODELS SQ 800T & 1

5 Se

ax oune0

or ance,

saa 8)

polacel

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT PRIOR NOTICE

Potrebbero piacerti anche

- Pentaksiran Teori-Assignment DMC 3113Documento4 paginePentaksiran Teori-Assignment DMC 3113sharifahsalmah50Nessuna valutazione finora

- Acson Catalogue Ducted Blower Standard CAT-ADB-1301Documento20 pagineAcson Catalogue Ducted Blower Standard CAT-ADB-1301Dak SerikNessuna valutazione finora

- ElbaDocumento17 pagineElbacathytingNessuna valutazione finora

- YK Style G Optiview Centrifugal Liquid Chiller Operation Manual (Form 160.54-O1)Documento206 pagineYK Style G Optiview Centrifugal Liquid Chiller Operation Manual (Form 160.54-O1)ANGEL MURILLONessuna valutazione finora

- Chapter 1 - Aircond & VentilationDocumento54 pagineChapter 1 - Aircond & Ventilationepy87Nessuna valutazione finora

- Manual Portable Aircond MideaDocumento18 pagineManual Portable Aircond Mideamalaikat maut100% (1)

- DEE 3323.02 Pengenalan PLCDocumento33 pagineDEE 3323.02 Pengenalan PLCnabilo20Nessuna valutazione finora

- Service Manual - KX4 & KXR4Documento45 pagineService Manual - KX4 & KXR4davincebeo100% (3)

- Flushing Air Conditioner ProcedureDocumento3 pagineFlushing Air Conditioner Proceduredimchien100% (1)

- Penyejukan Dan Penyamanan UdaraDocumento38 paginePenyejukan Dan Penyamanan UdararusilaNessuna valutazione finora

- Cooling Tower TDPDocumento34 pagineCooling Tower TDPjayan perkasaNessuna valutazione finora

- WCFX-V R134a 50-60Hz MS04100D-1016 LoDocumento24 pagineWCFX-V R134a 50-60Hz MS04100D-1016 LoaftabNessuna valutazione finora

- Service Manual FDA Series SplitsDocumento48 pagineService Manual FDA Series SplitsJorge BravoNessuna valutazione finora

- 1319 3 Guidelines For WeldingDocumento64 pagine1319 3 Guidelines For Weldingg_sanchetiNessuna valutazione finora

- O M ManualDocumento131 pagineO M Manualagniva dattaNessuna valutazione finora

- Secondary RefrigerantsDocumento15 pagineSecondary Refrigerantse4erkNessuna valutazione finora

- JKR C 1 S: Oka Concrete Industries Sdn. BHDDocumento1 paginaJKR C 1 S: Oka Concrete Industries Sdn. BHDGnabBangNessuna valutazione finora

- Air Cond Maintenance Unit RatesDocumento4 pagineAir Cond Maintenance Unit RatesBenjamin Ling0% (1)

- Cooling TowersDocumento22 pagineCooling TowersvsrajguruNessuna valutazione finora

- Flash Steam SystemDocumento4 pagineFlash Steam SystemAnonymous CX51waINessuna valutazione finora

- Acson Mini Chiller Application Manual 2.0Documento128 pagineAcson Mini Chiller Application Manual 2.0Dota NgNessuna valutazione finora

- 3.CWP Startup ProcedureDocumento6 pagine3.CWP Startup Procedurecdq powerplantNessuna valutazione finora

- Saint Gobain Sluice ValvesDocumento2 pagineSaint Gobain Sluice ValveskibzeamNessuna valutazione finora

- TM-AFCU (Iii) PDFDocumento121 pagineTM-AFCU (Iii) PDFZacke EsmaNessuna valutazione finora

- Piawai Jambatan BombaDocumento5 paginePiawai Jambatan BombaKeen LoongNessuna valutazione finora

- Twi CrossflowDocumento8 pagineTwi CrossflowDota NgNessuna valutazione finora

- Acson Mini ChillerDocumento189 pagineAcson Mini ChillerMax Woon100% (1)

- Lesson Introduction and Classification: Sub ObjectiveDocumento7 pagineLesson Introduction and Classification: Sub Objectivemister pogiNessuna valutazione finora

- Jet Diffuser PDFDocumento4 pagineJet Diffuser PDFJf OngNessuna valutazione finora

- KX6Documento70 pagineKX6phibaodalatNessuna valutazione finora

- Nota PemampatDocumento49 pagineNota PemampatweafareezNessuna valutazione finora

- Bry-Air Dehumidifier FFB SeriesDocumento6 pagineBry-Air Dehumidifier FFB Seriesmfisol2000Nessuna valutazione finora

- EarthingDocumento65 pagineEarthingAzura Abu100% (1)

- JKR 4.4 TABC - Air Cooled Package SystemDocumento22 pagineJKR 4.4 TABC - Air Cooled Package SystemAniq AimanNessuna valutazione finora

- KP KPV Internet 74005Documento60 pagineKP KPV Internet 74005Udomsin WutigulpakdeeNessuna valutazione finora

- Hvac Preventive Maintenance ChecklistDocumento2 pagineHvac Preventive Maintenance ChecklistAlpesh Jain100% (1)

- DC Motor ControllerDocumento7 pagineDC Motor ControllerJan MicahNessuna valutazione finora

- Chapter 2 - Air Generation and DistributionDocumento10 pagineChapter 2 - Air Generation and DistributionUdin AnuarNessuna valutazione finora

- LAKOS ROI Standard Cooling Tower CalculatorDocumento7 pagineLAKOS ROI Standard Cooling Tower CalculatorMohamed SabryNessuna valutazione finora

- TEKNOLOGI ELEKTRIK 1 - VoltageDocumento10 pagineTEKNOLOGI ELEKTRIK 1 - Voltagehazreen othman100% (1)

- Formula ElektrikDocumento0 pagineFormula ElektriksofyanshahNessuna valutazione finora

- Yodp 1012 eDocumento12 pagineYodp 1012 eckyee88Nessuna valutazione finora

- Erection Procedure PDFDocumento5 pagineErection Procedure PDFAshwani DograNessuna valutazione finora

- Course Jj618 Engineering Plant TechnologyDocumento6 pagineCourse Jj618 Engineering Plant Technologyweafareez100% (1)

- Dunham Bush Package UnitsDocumento8 pagineDunham Bush Package UnitsStephanie StewartNessuna valutazione finora

- 0405Documento27 pagine0405miguelin226Nessuna valutazione finora

- Objective of PumpsDocumento6 pagineObjective of PumpsTomide OlasupoNessuna valutazione finora

- 50PVB ProductDocumento29 pagine50PVB Producthakimmunas100% (1)

- Safety Relief Valve - Selection, Operation & TroubleShootingDocumento2 pagineSafety Relief Valve - Selection, Operation & TroubleShootingMohamed AlkhawagaNessuna valutazione finora

- York Start-Up Check List - Air Handling UnitsDocumento2 pagineYork Start-Up Check List - Air Handling UnitsBen MusimaneNessuna valutazione finora

- Mechanical Seal Replacement InstructionsDocumento1 paginaMechanical Seal Replacement InstructionsGiorgio FerNessuna valutazione finora

- Vibration of Cooling Tower Par PDFDocumento17 pagineVibration of Cooling Tower Par PDFsanjai yadav100% (1)

- Fire FightingDocumento9 pagineFire FightingtanyaNessuna valutazione finora

- Diving TablesDocumento5 pagineDiving TablesAlexander Miranda100% (6)

- 00 02partslistDocumento12 pagine00 02partslistfpcitroenNessuna valutazione finora

- Pioneer SX-828 Service ManualDocumento54 paginePioneer SX-828 Service ManualChris HutchingsNessuna valutazione finora

- Wrapped in Crotchet - PatternsDocumento119 pagineWrapped in Crotchet - Patternsaparnaparinam100% (1)

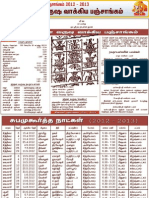

- Tamil Panchangam Tamil 12-13Documento32 pagineTamil Panchangam Tamil 12-13drjperumalNessuna valutazione finora

- Statistics Case Study SEM-1Documento8 pagineStatistics Case Study SEM-1Craig WilliamsNessuna valutazione finora

- Juk - DDL 555 4Documento28 pagineJuk - DDL 555 4RHoskaNessuna valutazione finora

- Automatic Transmission ReportDocumento15 pagineAutomatic Transmission ReportDinesh ChahalNessuna valutazione finora

- Hauling EquipmentsDocumento4 pagineHauling EquipmentsThushar PrakashNessuna valutazione finora

- India Vs Pakistan - Google SearchDocumento1 paginaIndia Vs Pakistan - Google SearchAujlaPlaysNessuna valutazione finora

- Total Overdose Cheats, Cheat Codes, Hints, TipsDocumento3 pagineTotal Overdose Cheats, Cheat Codes, Hints, Tipsjaipal reddyNessuna valutazione finora

- Especificaciones TecnicasDocumento43 pagineEspecificaciones TecnicasCarlos Andrès Enríquez RodríguezNessuna valutazione finora

- Service Electric TV Channel ListDocumento1 paginaService Electric TV Channel List薛冠扬Nessuna valutazione finora

- PlayerDocumento246 paginePlayerronhoNessuna valutazione finora

- H) Adaptation of Fuel Injection and Ignition Maps With Resistance Trimming PlugDocumento3 pagineH) Adaptation of Fuel Injection and Ignition Maps With Resistance Trimming Plugalexcus1539Nessuna valutazione finora

- The Complete Book of Beer Drinking Games TQW - DarksidergDocumento124 pagineThe Complete Book of Beer Drinking Games TQW - DarksidergKo Voskuilen100% (3)

- MST Removing and Installing Both Front Brake DisksDocumento4 pagineMST Removing and Installing Both Front Brake DisksNeeDog20Nessuna valutazione finora

- Homeworkout ReadyDocumento20 pagineHomeworkout ReadyDean ManteNessuna valutazione finora

- P eDocumento5 pagineP eEd Garcia AngelesNessuna valutazione finora

- Motoring SchoolsDocumento3 pagineMotoring Schoolsdiegoesquinca.7Nessuna valutazione finora

- Final Step-A BookletDocumento110 pagineFinal Step-A BookletanushaNessuna valutazione finora

- Test 8A: 1 Look at The Picture of Rachel. What's She Wearing? Write (Yes) or (No)Documento6 pagineTest 8A: 1 Look at The Picture of Rachel. What's She Wearing? Write (Yes) or (No)Denis DimovskiNessuna valutazione finora

- Finone Adib AdibDocumento1.275 pagineFinone Adib AdibahmadNessuna valutazione finora

- 03cf2 Clevo w760s w765s Axioo Neon MNCDocumento39 pagine03cf2 Clevo w760s w765s Axioo Neon MNCWong CilikNessuna valutazione finora

- A Truck Mounted Drilling RigDocumento2 pagineA Truck Mounted Drilling Rigมนต์ชัย บุญธนลาภNessuna valutazione finora

- Big Block Chevy Info - Grumpys Performance GarageDocumento104 pagineBig Block Chevy Info - Grumpys Performance GarageAsad Khan100% (1)

- Main Production Company List CanadaDocumento35 pagineMain Production Company List CanadaJim BankeeNessuna valutazione finora

- Raymond's Run TextDocumento5 pagineRaymond's Run Textnathanhelland100% (2)

- WCDF Revised RulesDocumento7 pagineWCDF Revised RulesJenna CallenNessuna valutazione finora

- Formula Vehicle Drive CalcDocumento1 paginaFormula Vehicle Drive CalcTejaswi VermaNessuna valutazione finora

- Land Rover Defender - Wikipedia, The Free EncyclopediaDocumento12 pagineLand Rover Defender - Wikipedia, The Free EncyclopediaaltilayNessuna valutazione finora

- Bill Seno-Pushing For PowerDocumento43 pagineBill Seno-Pushing For Powerbamabob1Nessuna valutazione finora

- Listofvoters2017 PDFDocumento18 pagineListofvoters2017 PDFajilani2014Nessuna valutazione finora

- Wushu Youth Class Brochure of Haruka Wushu Culture InstituteDocumento2 pagineWushu Youth Class Brochure of Haruka Wushu Culture InstituteHarukaQingxiangNessuna valutazione finora

- Spherical Dome 20151 PDFDocumento45 pagineSpherical Dome 20151 PDFChandan Narang100% (1)

- The Paw Print: Getting To Know Mrs. MackDocumento4 pagineThe Paw Print: Getting To Know Mrs. Mackpamela_lippy2113Nessuna valutazione finora

- DeckDocumento1 paginaDeckhelicopter512100% (1)