Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Si Films Fab

Caricato da

Nilesh BarangeDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Si Films Fab

Caricato da

Nilesh BarangeCopyright:

Formati disponibili

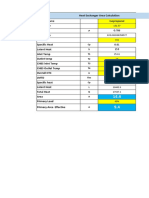

Fabrication process Steps

Name of the Start Date

User:

No. of

Samples:

Sample

Names:

S. Process Purpose Specifications Facility/System Remarks

No. Step Used

Parameters Suggested

1 Wafer Silicon Type p

Specificati wafer Orientation 100

ons

Resistivity 4-7 Ω-cm

Polish One side

Size 2"

2 RCA Cleaning RCA 1 1:02:07

Cleaning of wafer Solution 180 ml DI water +25 Chemical bench

ml NH4OH

Heating 75 °C for 5 min

Remove from hot 50 ml H2O2 (30%)

plate and add

Wait for bubbles 1-2 min

Insert wafers

Heat 6-8 min at 75 °C

cool 8 to 10 min

DI Water rinsing 3 times

HF Dip

30 sec HF dip 2% (192 ml DI water +

8 ml 49% HF)

DI Water rinsing 3 times

RCA 2 1:02:07

Solution 180 ml DI water +25

ml HCl

Heating 75°C for 5 min

Remove from hot 50 ml H2O2 (30%)

plate and add

Wait for bubbles

Insert wafers

Heat 3-6 min at 75 °C

cool 8 to 10 min

DI Water rinsing 3 times

HF Dip

30 sec HF dip 2% (192 ml DI water +

8 ml 49% HF)

DI Water rinsing 3 times

Dry the Wafers Luminar bench

dryer

3 Oxidation Isolation Thickness 3000 Å

of Silicon oxide Method Wet

wafer

Temperature 1000°C

Time

Gases used N2,O2,H2

Gas flow rate N2-0.5ppm, O2-

250ml/min/div, H2-

600ml/min/div

Pressure Atmospheric pressure

(760 Torr)

4 Microcryst Thickness 50 nm

alline Method PECVD

silicon

Substrate 200°C

Temperature

Time

Gases used SiH4/SiH4 + H2

Gas flow rate 50 sccm

Pressure 0.5 Torr

6 Ultrafine Thickness 50 nm

Poly c-Si Method PECVD

Substrate 200°C

Temperature

Time

Gases used SiH4/SiH4 + H2

Gas flow rate

Pressure 0.5 Torr

7 a-Si:H Thickness 50 nm

Method PECVD

Substrate 200°C

Temperature

Time

Gases used SiH4/SiH4 + H2

Gas flow rate

Pressure 0.5 Torr

Potrebbero piacerti anche

- DL6 2020-10-01 at 11-16-24 Joint 1.dl6Documento2 pagineDL6 2020-10-01 at 11-16-24 Joint 1.dl6kevmenarNessuna valutazione finora

- GASMET SpecsDocumento2 pagineGASMET SpecsNikola MisicNessuna valutazione finora

- Introduction To Semiconductor Manufacturing Technology: T. S. Chao Dept. of ElectrophysicsDocumento81 pagineIntroduction To Semiconductor Manufacturing Technology: T. S. Chao Dept. of ElectrophysicsMichael KaoNessuna valutazione finora

- Circulating Fluidized Bed BoilerDocumento60 pagineCirculating Fluidized Bed Boilermeharrafaqatali123Nessuna valutazione finora

- 764707sonawane Patil Analysis of Fire Boiler Influenced by Dissolved Solids in Feed WaterDocumento7 pagine764707sonawane Patil Analysis of Fire Boiler Influenced by Dissolved Solids in Feed WaterZaheer MehmoodNessuna valutazione finora

- 2X70 Power Plant Technical SpecificationDocumento53 pagine2X70 Power Plant Technical SpecificationChanna BasavaNessuna valutazione finora

- Heat Exchanger Area & Boilup Rate CalculationDocumento19 pagineHeat Exchanger Area & Boilup Rate CalculationNitin KurupNessuna valutazione finora

- Rexmed AutoclaveDocumento2 pagineRexmed AutoclaveShaif ZahrahNessuna valutazione finora

- The Use of Silica-Fume and PEG To Enhance Sintering of LLDPE Powders in Rotomolding ProcessDocumento56 pagineThe Use of Silica-Fume and PEG To Enhance Sintering of LLDPE Powders in Rotomolding ProcessMohsen SaidiNessuna valutazione finora

- DL6 2022-05-19 at 17-23-41 Joint 38.dl6Documento2 pagineDL6 2022-05-19 at 17-23-41 Joint 38.dl6Kevin MendozaNessuna valutazione finora

- Cold Storage Details For Simulation 09.03.2018Documento6 pagineCold Storage Details For Simulation 09.03.2018ShanmugaSundaram AnandanNessuna valutazione finora

- Ammonia and Carbon Dioxide in Water On Rtx®-Volatile Amine: Peaks TR (Min)Documento1 paginaAmmonia and Carbon Dioxide in Water On Rtx®-Volatile Amine: Peaks TR (Min)Ritesh AgarwalNessuna valutazione finora

- EtchingDocumento47 pagineEtchinghrishikeshdeka18Nessuna valutazione finora

- Process of Making PlasterboardDocumento22 pagineProcess of Making PlasterboardPrameela PNessuna valutazione finora

- Auto Tube ReportDocumento6 pagineAuto Tube ReportRao UsamaNessuna valutazione finora

- Graphite FoamsDocumento59 pagineGraphite Foamsvkr91@yahoo.comNessuna valutazione finora

- Boiler & Water Treatment PlantDocumento55 pagineBoiler & Water Treatment PlantAndara Asifa YudianaNessuna valutazione finora

- Kandhari Beverages Pvt. LTD.: (Coca Cola)Documento27 pagineKandhari Beverages Pvt. LTD.: (Coca Cola)Veeraprasad CGNessuna valutazione finora

- GasMask Filter A2B2E2K2HgP3-EN-2Documento3 pagineGasMask Filter A2B2E2K2HgP3-EN-2hutmicsNessuna valutazione finora

- DL6 2023-01-25 at 09-43-20 Joint 7.dl6Documento2 pagineDL6 2023-01-25 at 09-43-20 Joint 7.dl6DavidNessuna valutazione finora

- Boiler Water Treatment Slides by Reso Engineering SB UTHM 101221 UpdatedDocumento70 pagineBoiler Water Treatment Slides by Reso Engineering SB UTHM 101221 UpdatedMohamad Muslihuddin RazaliNessuna valutazione finora

- Phenicon HS: Epoxy Novolac Phenolic Tank LiningDocumento2 paginePhenicon HS: Epoxy Novolac Phenolic Tank Liningapply19842371Nessuna valutazione finora

- NIKISSOCooler Catalogue 1639028732442Documento2 pagineNIKISSOCooler Catalogue 1639028732442John Renzel Rivera IIINessuna valutazione finora

- 9.0-BUL107 1.10 en Water QualityxDocumento2 pagine9.0-BUL107 1.10 en Water QualityxmohamadNessuna valutazione finora

- Plastic Burning Impacts On Atmospheric Fine Particulate Matter at Urban and Rural Sites in The United States and BangladeshDocumento8 paginePlastic Burning Impacts On Atmospheric Fine Particulate Matter at Urban and Rural Sites in The United States and BangladeshDe EstufeedNessuna valutazione finora

- Kristherm - Scroll Heat PumpDocumento12 pagineKristherm - Scroll Heat PumpAbhishek PNessuna valutazione finora

- Assignment No. 2 - PEP 335 - Spring 2023Documento2 pagineAssignment No. 2 - PEP 335 - Spring 2023Mustafa El sayedNessuna valutazione finora

- Roll No 59Documento25 pagineRoll No 59Rahul PandeyNessuna valutazione finora

- PLUMBING PPR-Pipe DesoDocumento11 paginePLUMBING PPR-Pipe DesoOwen Francis Arles MaongatNessuna valutazione finora

- SC-1060U Processing GuideDocumento2 pagineSC-1060U Processing GuideAgus IrawanNessuna valutazione finora

- InstruCalc Flow Element Sizing ProjectDocumento1 paginaInstruCalc Flow Element Sizing ProjectDian Yudistira HadiNessuna valutazione finora

- Clean Keep 5000Documento1 paginaClean Keep 5000ΧΡΗΣΤΟΣ ΓΙΑΝΝΕΙΟΣNessuna valutazione finora

- Ahf TDS-237448Documento4 pagineAhf TDS-237448latiefNessuna valutazione finora

- Spectek Brightener 897 2Documento1 paginaSpectek Brightener 897 2jeganNessuna valutazione finora

- 3M Thermal Transfer Polyester Label Material 7818Documento8 pagine3M Thermal Transfer Polyester Label Material 7818G Luca GrecoNessuna valutazione finora

- 3M Thermal Transfer Polyester Label Material 7818 PDFDocumento8 pagine3M Thermal Transfer Polyester Label Material 7818 PDFG Luca GrecoNessuna valutazione finora

- Hytherm S NewDocumento2 pagineHytherm S NewOliver OliverNessuna valutazione finora

- Pyro Process Equipment PDFDocumento114 paginePyro Process Equipment PDFMohamedNessuna valutazione finora

- Residual Solvents Class 1 Rtx®-624: Restek Corporation 110 Benner Circle Bellefonte, PA 16823Documento1 paginaResidual Solvents Class 1 Rtx®-624: Restek Corporation 110 Benner Circle Bellefonte, PA 16823DrMd IdrisNessuna valutazione finora

- DL6 2020-10-12 at 09-26-02 Joint 1.dl6Documento2 pagineDL6 2020-10-12 at 09-26-02 Joint 1.dl6DavidNessuna valutazione finora

- A.38.cr.20.ap.52.06.4000.80.e.0.s.078.312 - Frio027 - L 4000Documento1 paginaA.38.cr.20.ap.52.06.4000.80.e.0.s.078.312 - Frio027 - L 4000francolamNessuna valutazione finora

- ClO2 ProcessDocumento27 pagineClO2 ProcessBenito de ProcesosNessuna valutazione finora

- APH Datasheets 20112022 882490Documento2 pagineAPH Datasheets 20112022 882490Hamid MansouriNessuna valutazione finora

- Water SystemDocumento2 pagineWater Systemkamlesh thummarNessuna valutazione finora

- Test ProceduresDocumento40 pagineTest ProceduresFarhan AkhterNessuna valutazione finora

- DUPAC-0521®: DescriptionDocumento6 pagineDUPAC-0521®: DescriptionPablo TorresNessuna valutazione finora

- Phenicon HS PDSDocumento2 paginePhenicon HS PDSJose MachadoNessuna valutazione finora

- Bayer Process Chemistry: Dr. M. ColeyDocumento19 pagineBayer Process Chemistry: Dr. M. ColeyToanique HeadmanNessuna valutazione finora

- Pasting MachineDocumento7 paginePasting Machineibrahime mohammedNessuna valutazione finora

- 06 - Water - Tech - Revision - PrintDocumento58 pagine06 - Water - Tech - Revision - PrintLakshmi NarayanNessuna valutazione finora

- Heated Sample Line CalculatorDocumento4 pagineHeated Sample Line CalculatorKevin PratyatamaNessuna valutazione finora

- AG 806.silver EpoxyDocumento1 paginaAG 806.silver EpoxyChad CuaresNessuna valutazione finora

- Chemical Technology Subject Code: CH2001Documento9 pagineChemical Technology Subject Code: CH2001U SANKAR TEJONessuna valutazione finora

- DL6 2021-09-19 at 16-17-40 Joint 6.dl6Documento2 pagineDL6 2021-09-19 at 16-17-40 Joint 6.dl6David Moreno - MIM SRLNessuna valutazione finora

- Heat Exchanger - Preliminary Data SheetDocumento4 pagineHeat Exchanger - Preliminary Data SheetgksakthiNessuna valutazione finora

- Si 1 TechnologyDocumento85 pagineSi 1 TechnologyOana DrăganNessuna valutazione finora

- Tugas Perancangan HEDocumento11 pagineTugas Perancangan HEAnnisa Novita NurismaNessuna valutazione finora

- Komparasi Material RefractoryDocumento2 pagineKomparasi Material Refractoryabet_singkong8930Nessuna valutazione finora

- Ceramics and Ceramic Composites: Materialographic PreparationDa EverandCeramics and Ceramic Composites: Materialographic PreparationNessuna valutazione finora

- Flat Flow KitDocumento4 pagineFlat Flow KitNilesh BarangeNessuna valutazione finora

- This Doc Sontains NothingDocumento11 pagineThis Doc Sontains NothingNilesh BarangeNessuna valutazione finora

- HW 1Documento2 pagineHW 1Nilesh BarangeNessuna valutazione finora

- Cem 419 Exp 1Documento3 pagineCem 419 Exp 1Nilesh BarangeNessuna valutazione finora

- Notes About CourseDocumento2 pagineNotes About CourseNilesh BarangeNessuna valutazione finora

- Direct Solution by 2-D and 3-D Finite Element Method On Forward Problem of Low Frequency Current Fields in Inhomogeneous MediaDocumento10 pagineDirect Solution by 2-D and 3-D Finite Element Method On Forward Problem of Low Frequency Current Fields in Inhomogeneous MediaNilesh BarangeNessuna valutazione finora

- AIRVO v2.5 Disinfection Manual UI-185048125 - DDocumento14 pagineAIRVO v2.5 Disinfection Manual UI-185048125 - DpaionenseNessuna valutazione finora

- Astm A 146 - 04Documento2 pagineAstm A 146 - 04Er WidodoNessuna valutazione finora

- Raksha Myo InositolDocumento16 pagineRaksha Myo InositolRaksha MukhiaNessuna valutazione finora

- Sello Energizados Con ResosrtesDocumento24 pagineSello Energizados Con Resosrteshufuents-1Nessuna valutazione finora

- Pipe Material ASTM CodesDocumento2 paginePipe Material ASTM CodesShreekanthKannathNessuna valutazione finora

- Dual Shield 7100 Ultra: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDocumento3 pagineDual Shield 7100 Ultra: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel Wiresadanmeneses1Nessuna valutazione finora

- Electrodeposited Coatings of Zinc On Iron and Steel: Standard Specification ForDocumento5 pagineElectrodeposited Coatings of Zinc On Iron and Steel: Standard Specification Forkarthik venkatachalamNessuna valutazione finora

- Lecture Guide 3 Conduction-through-a-Homogenous-Cylinder-WallDocumento8 pagineLecture Guide 3 Conduction-through-a-Homogenous-Cylinder-WallCllyan ReyesNessuna valutazione finora

- CO Corrosion Rate Calculation Model: Norsok StandardDocumento20 pagineCO Corrosion Rate Calculation Model: Norsok Standardnorman1968Nessuna valutazione finora

- Phy101 - Note 2Documento9 paginePhy101 - Note 2Kikelomo AjibadeNessuna valutazione finora

- 04 ExtrusionDocumento57 pagine04 Extrusion9811923100% (1)

- HEQEP Project FirojDocumento26 pagineHEQEP Project FirojnebullaNessuna valutazione finora

- All Ceramic Cementation A Key To Successful RestorationDocumento9 pagineAll Ceramic Cementation A Key To Successful RestorationJUDITH ESTHER HIGUERA MESANessuna valutazione finora

- Ethanol Aspen Data BaseDocumento36 pagineEthanol Aspen Data BaseGustavo CestariNessuna valutazione finora

- A Comprehensive Review On PEM Water ElectrolysisDocumento34 pagineA Comprehensive Review On PEM Water ElectrolysisHEGEL JOHAN RINCON LAURENS50% (2)

- API 650 Course MaterialDocumento36 pagineAPI 650 Course MaterialAliDadKhanNessuna valutazione finora

- Energy Integration of A HydrotreatmentDocumento43 pagineEnergy Integration of A Hydrotreatmentvarun kumarNessuna valutazione finora

- KX-21 Training: Main MenuDocumento159 pagineKX-21 Training: Main MenuHuseyn aliyev100% (1)

- FluorCam Operation ManualDocumento78 pagineFluorCam Operation ManualIniNessuna valutazione finora

- Ptt156 - Hysys Lab ManualDocumento41 paginePtt156 - Hysys Lab ManualNguyễn Quyết100% (1)

- Grandma's and Grandpa's Formulas - 108 Timeless Remedies and Formulas PDFDocumento3 pagineGrandma's and Grandpa's Formulas - 108 Timeless Remedies and Formulas PDFAjay J VermaNessuna valutazione finora

- Basic Chemistry 5th Edition Timberlake Test BankDocumento28 pagineBasic Chemistry 5th Edition Timberlake Test Banksamuelfintanult1jj100% (32)

- Review On Treatment Methods of Soft Soil SubgradeDocumento3 pagineReview On Treatment Methods of Soft Soil SubgradeEmilio ArroyoNessuna valutazione finora

- Mergal K10N FT ENDocumento2 pagineMergal K10N FT ENLis AnaNessuna valutazione finora

- Chemistry Class Xii Ut 1 Objective PaperDocumento2 pagineChemistry Class Xii Ut 1 Objective Papergojo satoruNessuna valutazione finora

- Syllabus of Neet 2020 Drill Test Series: Physics Chemistry BiologyDocumento1 paginaSyllabus of Neet 2020 Drill Test Series: Physics Chemistry BiologyRakesh RakiNessuna valutazione finora

- Reaction RateDocumento96 pagineReaction RateSoh Ming LunNessuna valutazione finora

- Grouting Works: Dfcu - HRRL Project, RajasthanDocumento12 pagineGrouting Works: Dfcu - HRRL Project, Rajasthankranthi kumarNessuna valutazione finora

- 1 s2.0 0304386X9190055Q MainDocumento32 pagine1 s2.0 0304386X9190055Q MainJordan Ulloa Bello100% (1)

- Hematology NotesDocumento24 pagineHematology Notesddrei13Nessuna valutazione finora