Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PRDS Basics

Caricato da

Avik BanerjeeDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PRDS Basics

Caricato da

Avik BanerjeeCopyright:

Formati disponibili

On the Modification of Spray Line in Pressure Reducing and

Desuperheating Station at Thermal Power Stations

Dr S Shanmugam, Fellow

S Sakthivel, Member

In thermal power stations, the temperature at pressure reducing and desuperheating station (PRDS) header is sometimes

unable to contain within a specific limit. This causes instability in PRDS that leads to unsatisfactory performance of the

auxiliary systems, resulting in shut down. The cause of the problem is identified, analysed and remedial measures are

suggested that spray water for desuperheating the main steam supplied to PRDS can be tapped from the condensate

extraction pump discharge line instead of from the boiler feed pump discharge line being practiced. Analyses show that

a sum of Rs 20 744 can be saved per day in addition to a substantial saving in the layout cost.

Keywords: PRDS; Condensate extraction pump; Boiler feed pump

INTRODUCTION A, inside area of the pipe through which the fluid flows; and v,

In thermal power stations, the requisite operating parameters the velocity, m/s. The steam has the velocity of 41.44 m/s

of PRDS is obtained by desuperheating the steam, which is flowing at a rate of 350 t/h. The steam is tapped usually by

tapped from main steam line. The water from boiler feed providing a T arrangement2. The entire arrangement of the

pump is utilised for desuperheating after reducing its pressure existing system is divided into five stages as it is seen in the

in an appropriate pressure control valve. The desuperheated Figure 1. The steam coming out of the pressure control valve is

steam is then distributed to different parts of the auxiliary at a temperature of 480° C with a pressure of 17 bar. The

steam consumption headers, such as, fuel atomising station, reduction in pressure from 135.1 bar (Stage I) to 17 bar (Stage III)

soot blowers steam consumption point, starting and main is obtained on the assumption that the 100% line is in service.

steam ejector lines. It is essential that there should not be any

It is noted that there is only about 11% reduction in

disturbances in the parameters, especially in temperature, in

temperature of steam. The high temperature steam is then

PRDS for efficient operation of thermal power stations. But

many a time it has been experienced that there is instability in admitted to the cooler where it is supposed to be

the values of parameters of steam in PRDS units, resulting in desuperheated to a little less than or equal to 200° C . The

failure to achieve the performance of the power station. The required quantity of water for desuperheating is tapped from

problem of instability can be overcome by tapping spray water the boiler feed pump discharge line. In 210 MW power

from the part where the pressure and temperature are stations, the spray water is supplied at a rate of 1.4 kg/s. The

conducive to the efficient operation of power stations. This desired temperature limits are normally between 180° C and

paper presents a useful suggestion to avoid the aforesaid 200° C but the maximum limit should not be greater than

problem by analysing the important parameters of PRDS in 200 ° C 3 . The pressure control valve (PCV-2) closes

210 MW power stations in India. The same can be extended to automatically if the temperature exceeds 200° C , causing no

higher capacity power stations too. supply of steam to the PRDS system.

EXISTING SYSTEM

The temperature at the PRDS header is not maintained within

A line diagram of the existing system of PRDS in 210 MW the desired limits and at times it goes up a few degrees Celsius

power stations is given in Figure 1. The superheated steam is beyond 200 ° C . The temperature could not be brought down

tapped from both the main lines that carry steam to the to a desired value even if the quantity of spray water supply

turbine. The pressure and temperature in each line are 135.1 bar from the boiler feed pump discharge line is increased to

and 540 ° C , respectively (Stage I). The velocity of the steam is maximum possible. The reason could be due to mixing of

given by the expression1, spray water at 167° C with steam at 480° C . Greater the supply

& = ρAv

m (1) of this water, less likely will it reduce the temperature. There

is thus an increase in the temperature at steam consumption

& is mass flow rate of fluid, m/s; ρ , the density, kg/m3;

where m headers, such as, soot blowers, oil heating station, fuel oil

Dr S Shanmugam is with the Department of Mechanical Engineering, atomising station, main and starting ejectors lines, which

National Institute of Technology Tiruchirappalli, Tiruchirappalli 620 015;

while S Sakthivel is with Inspectorate of Boilers, PWD Compound, reduces the unit load. This has sometimes compelled entire

Kumarasamy Patty, Salem 636 007. power generation to be stopped. With great difficulty, the

This paper was received on April 22, 2004. Written discussion on the paper will temperature can be controlled manually too but it usually

be entertained until December 31, 2005. takes much time. Besides, in the existing system there must be

Vol 86, October 2005 145

ine

16 o g/s kg

Dimensions in mm

mL

T - 1.4 k 3 kJ/ r

m 686. .4 ba

80

50

Not to Scale

133

tea

73 ×

h - 180

lve

in S

7C

EL

5

P : Pressure

T - 5 7.2 kg /kg

m -9 447 k ar

4.5

Va

P-

f2

.4 b

Ma

40 o /s

00

J

h : Enthalpy

5

ray

4.5

260

&

.4

m : Mass Flow Rate

Sp

3

×

1

I

f3

EL

T : Temperature

EL 24500

h-3

5.4

P-

EL : Elevation

20

f2

×

PCV : Pressure Control Valve

08

30

SV : Safety Valve

f1

×

59

V

f1

5000

EL 2

EL 2 Flow

2250 Nozz P - 19.62 bar

0 le h - 232 kJ/kg

EL 2 PRD

r

m -1.01 kg/s

ole

2300 P-1 S He

35 ader

h - 3 .1 bar

Co

T - 55oC

409 k

&

m-4 J/

.2 kg kg

T - /s

0

530 o IV

6.4

50

f 15 II C

24

9×

×

30

73

EL

PCV-2

f2

f 32 P-1

3.9 4

× 37 SV-1

SV-2 h - 2 .17 bar Existing

7

m& - 97 kJ/k

5 g Proposed

f 60 × 11

f 273

× 6.4 T - 2 .56 kg/

00 oC s

f 15

9× P - 17 bar III

EL 30 f 27

3×6

22 PCV-1 h - 3427 kJ/kg .4

15

0 m - 4.17 kg/s

EL 2

f 15 T - 480oC 2280

9×

30

Figure 1 Different stages at PRDS with proposed system

an exclusive pressure reducing station as the water pressure is same time, the temperature is also less (55 ° C ), which has the

to be reduced from 180.4 bar to about 20 bar4. The problem advantage of consuming less quantity of water. The enthalpy

can be avoided by introducing a little change in the spray of water is 231.9 kJ/kg and the heat content of the water in the

water tapping as explained here. proposed system is 454 kJ/kg less than that of the existing

system. The temperature at the PRDS header is always kept

PROPOSED SYSTEM

below 200° C because the water at 55 ° C is sprayed to the

Careful studies of the layout of the piping and the parameters steam at 480 ° C . The supply of spray water also is not

of different lines have indicated that there is only one disturbed even when the plant is being shut down as the

possibility of tapping spray water at a very low pressure and running of the CEP is continuous and this facilitates efficient

temperature in the power station. It is the condensate operation of the auxiliary units.

extraction pump (CEP) discharge line in which the pressure

In the proposed system, there is no change in the first four

and temperature of the water are 19.62 bar and 55 ° C , stages of the existing system (Figure 1). In the fifth stage the

respectively5. The proposed system is denoted as dotted line in spray water is admitted to the cooler, taken from the CEP

the Figure 1 and this line is directly taken from the condensate discharge line. The diameter of the pipes is calculated using the

extraction pump (CEP) discharge line. Figure 2 depicts the equation (1). The values of diameter and properties6 are

proposed system. presented in Table 1. The diameter of the spray water line in

the fifth stage in the proposed system is about 42.2% less than

The spray water line in the existing system is modified with

that of the existing system, as the values of the parameters of

tapping from the CEP discharge line. By providing a suitable

the spray water admitted to the cooler are very much less. The

arrangement in the CEP discharge line the water is taken to spray water velocity before the cooler is 2.02 m/s which is

the cooler and sprayed for desuperheating the steam. The 17.4% greater than the velocity of water from boiler feed

water has a low pressure (19.62 bar) and therefore there is no pump discharge line. This will obviously facilitate the process

need for having a separate pressure reducing station. At the of mixing in the cooler.

146 IE (I) JournalMC

Table 1 Comparison of spray water properties in existing and proposed &sh

m

stages in PRDS cos t c = cc (2)

Cv

Parameter Unit Stage V

Existing Scheme Proposed cos t w = 24 m& w c w (3)

Before After system

entering leaving

where cost refers to total cost; h, specific enthalpy of steam;

Pressure, P bar 180.40000 20.000000 19.620000 Cv , the calorific value of coal generally used in power stations;

suffixes c, w and s refer to coal water and steam, respectively

Temperature, T °C 167.00000 140.000000 55.000000

and c refers to respective cost. The calorific value of coal is

Mass flow rate, m kg/s 1.40000 1.400000 1.010000

assumed as 12560 kJ/kg and the cost of coal is Rs 2.50/kg and

Enthalpy, h kJ/kg 685.90000 590.200000 231.900000 the cost of demineralised water is Rs 0.30/kg. Using equations (2)

Diameter, D mm 33.40000 33.400000 25.400000 and (3), respective components are calculated and are

Density, r kg/m3 917.40000 926.780000 986.190000 presented in Table 2. There is a saving of over 71% in layout

Velocity, V m/s 1.74000 1.720000 2.020000 cost owing to the elimination of an exclusive pressure

Specific volume, v m3/kg 0.00109 0.001079 0.001014

reducing station in the existing system. As the water is

admitted to the cooler at much reduced temperature ( 55 ° C ),

the proposed system certainly consumes 72.14% of water,

Economic Analysis

resulting in an additional saving of 27.86% in water cost.

As the modified system eliminates the requirement of a

Besides, there is a substantial saving in coal consumption too.

separate pressure reducing station, it needs one isolation valve

It is possible to save 4.254 t of coal daily by merely following

at the tapping end and one regulation valve at the water-

spraying end. It means less cost of equipment and easier the proposed system.

maintenance.

Main Steam Line

EN : Non-return Valve

CEP : Condensate Extraction Pump

P - 180.4 bar

h - 686 kJ/kg Condenser Condenser

& - 1.4 kg/s

m Main Steam Line

T - 167oC

20 m

Cooler

m& - 5.56 kg/s

P - 1962 bar

T - 200oC h - 207 kJ/kg

m& - 1.01 kg/s E 1 2 E 2 E 3

1 3

T - 55oC

CEP1 CEP2 CEP3

Condensate

Flow

PRDS

Header '0' m

EN1 EN2 EN3

EN4 EN5 EN6

From Boiler Feed Pump

Figure 2 Schematic layout of the proposed system

Vol 86, October 2005 147

Table 2 Computation of different cost components l easy erection of spray water pipe lines and their

maintenance; and

Description Existing Proposed Savings,

system system % l continuous availability of the system.

Energy CONCLUSIONS

Enthalpy of steam, kJ/h 3069360.0 843188.4 72.53

Introducing the proposed system, thermal power stations of

Coal consumption, kg/day 5865.0 1611.0 72.53

210 MW capacities can be efficiently operated with full load

Cost of coal consumed/day, Rs 14662.5 4027.5 72.53

and without any disturbances in the auxiliary steam supply

Water consumption systems.

Quantity, kg/h 5040.0 3636.0 27.86 (i) There is a saving of Rs 20 744/day and a reduction in

Daily consumption cost of layout cost of Rs 1 97 500 can be achieved.

demineralised water, Rs 36288.0 26179.0 27.86

(ii) Though the study has been done with reference to

Lay out cost, Rs 2 77 500.0 80 000.0 71.20 210 MW power stations, the suggestion can be

effectively implemented in other capacity power

Total savings, Rs stations as well, for the nature of the problem is

Savings per day, Rs 20 744.00 similar.

Layout cost, Rs 19 7 500.00

(iii) The low temperature in the spray water may cause

some cold cracks in the seat of the cooler valve and

Features cold water spraying in the opposite wall of the pipe

The salient features in brief on eliminating existing spray may also introduce cold cracks in future. The

water scheme and introducing proposed system in power formation of cold cracks can be slowed down by

plants are: slightly increasing the temperature of the spray water

stabilisation of PRDS header can be achieved; before it is admitted to the cooler. An increase in

l

temperature of about 8° C can be achieved by passing

l trouble free operation of the auxiliary steam the spray water pipe line through the flash tank in the

consumption systems is ensured; turbine region. The problem of the cracking in the

l frequent lifting of safety valves and their seat failure opposite wall can also be avoided by providing a high

can be avoided; alloy steel sleeve.

l frequent failure of the gaskets in between the joints of REFERENCES

flanges in non-return valves, branch valves etc can also 1. Flow of Fluids through Valves, Fittings and Pipe. Crane Ltd, 11-12 Bouverie

be avoided; Street, London EC4Y 8AH, UK, 1979.

l reduction in the rate of erosion in the seat of the spray 2. The Schematic Diagrams of 210 MW Power Station. Power Engineers

control valve can be achieved; Training Society, 1983

3. Operation and Maintenance Manual for Control Valve. Mosaneilone Valve

l instability of pressure in pressure control station and

Ltd, 1988.

in spray water line is completely eliminated;

4. Operation and Maintenance of Pressure Reducing Station. Combustion

l steady operation of power station; Engineers, UK, 1982.

5. Construction and Operation of 210 MW Turbine. Combustion Engineers,

l reduced energy consumption;

UK, GF3 GEF3 3.4.

l reduction in the consumption of de-mineralised 6. C P Kothandaraman and S Subramanian. Heat and Mass Transfer Data

water; Book. 4th Edition, New Age International Pvt Ltd, Chennai, 1997.

148 IE (I) JournalMC

Potrebbero piacerti anche

- Book-1 - Basic Machinery Vibrations PDFDocumento172 pagineBook-1 - Basic Machinery Vibrations PDFAvik Banerjee50% (2)

- Vacuum Breaker ValveDocumento2 pagineVacuum Breaker ValveRaghunath YeturiNessuna valutazione finora

- Introduction to the simulation of power plants for EBSILON®Professional Version 15Da EverandIntroduction to the simulation of power plants for EBSILON®Professional Version 15Nessuna valutazione finora

- Pyramids of MontaukDocumento363 paginePyramids of MontaukRob Gray100% (11)

- LPbypass SystemDocumento43 pagineLPbypass Systemamulya1981Nessuna valutazione finora

- PRDSDocumento14 paginePRDSSrinivas N GowdaNessuna valutazione finora

- Terminal Points (TBWES & Toshiba) JSPL, 8 X 660 MWDocumento6 pagineTerminal Points (TBWES & Toshiba) JSPL, 8 X 660 MWpunitg_2Nessuna valutazione finora

- Extraction Condensing Steam Turbine PDFDocumento2 pagineExtraction Condensing Steam Turbine PDFAaronNessuna valutazione finora

- Airflow in Boiler PDFDocumento89 pagineAirflow in Boiler PDFSiddhant SatpathyNessuna valutazione finora

- VAM System DesignDocumento11 pagineVAM System DesigngenipankajNessuna valutazione finora

- Afbc Vol-IiDocumento81 pagineAfbc Vol-IiVijay RajNessuna valutazione finora

- Write Up On Aux PrdsDocumento6 pagineWrite Up On Aux PrdsYousuf AliNessuna valutazione finora

- Stator Water System Monitoring For Large Turbo-Generator-A User'S PerspectiveDocumento12 pagineStator Water System Monitoring For Large Turbo-Generator-A User'S PerspectiveUmesh HadiyaNessuna valutazione finora

- CW Pumps Tripping On Over Load, 210 MW Unit, 02-03Documento5 pagineCW Pumps Tripping On Over Load, 210 MW Unit, 02-03Charu ChhabraNessuna valutazione finora

- DehDocumento34 pagineDehAnand Swami100% (1)

- Turbine Trip LogicDocumento2 pagineTurbine Trip Logicdilbagh_scribd50% (2)

- Chapter 5 Steam TurbineDocumento78 pagineChapter 5 Steam TurbineGloria Del Carmen MuñozNessuna valutazione finora

- TURBINE Logics and Interlocks PDFDocumento62 pagineTURBINE Logics and Interlocks PDFLakshmi Narayan100% (1)

- WHRB Interlocks: S. No Boiler Equipment Logic For InterlocksDocumento2 pagineWHRB Interlocks: S. No Boiler Equipment Logic For InterlocksAmeer MeerNessuna valutazione finora

- 330mw DEHDocumento22 pagine330mw DEHkeerthi dayarathnaNessuna valutazione finora

- Plant Instrument Air System - Design TipsDocumento7 paginePlant Instrument Air System - Design Tipsdavid_diaz_sNessuna valutazione finora

- 500MW-Boiler - Salient FeatureDocumento7 pagine500MW-Boiler - Salient FeatureAhemadNessuna valutazione finora

- HP/LP Bypass Automation: Function DescriptionDocumento14 pagineHP/LP Bypass Automation: Function DescriptionMohit GohilNessuna valutazione finora

- Recommended Schemes & Writeup of Auto ControlsDocumento25 pagineRecommended Schemes & Writeup of Auto ControlsShirshendu RoyNessuna valutazione finora

- HPBPDocumento14 pagineHPBPrnumesh1Nessuna valutazione finora

- BFP TDDocumento22 pagineBFP TDArvind ShuklaNessuna valutazione finora

- NPTI O M Anual PDFDocumento208 pagineNPTI O M Anual PDFVelmurugan0% (1)

- An Overview of FBC Boiler: Compiled BY S.S.AcharyaDocumento56 pagineAn Overview of FBC Boiler: Compiled BY S.S.AcharyaMusycal Fynnc100% (1)

- Tanjung Jati B Training PA-FD-ID FansDocumento53 pagineTanjung Jati B Training PA-FD-ID FansFauzan Kurnia100% (1)

- 8.water CirculationDocumento33 pagine8.water CirculationSatadru HalderNessuna valutazione finora

- Introduction PRDS and APRDSDocumento13 pagineIntroduction PRDS and APRDSPrudhvi RajNessuna valutazione finora

- TTD PerformanceDocumento5 pagineTTD PerformanceSriraja RajapNessuna valutazione finora

- Governing 11Documento35 pagineGoverning 11rahul100% (2)

- Globe Valve Bs 1873 and Api 602: ASME B16.10Documento7 pagineGlobe Valve Bs 1873 and Api 602: ASME B16.10swapnil PATILNessuna valutazione finora

- 023 CepDocumento12 pagine023 Cepjp mishraNessuna valutazione finora

- Advantages of Hydrogen Cooling in Generators or Alternators - Electrical Theory and Practice TestsDocumento5 pagineAdvantages of Hydrogen Cooling in Generators or Alternators - Electrical Theory and Practice TestsUsMan ZaFarNessuna valutazione finora

- Proper Steam Bypass System Design Avoids Steam Turbine OverheatingDocumento6 pagineProper Steam Bypass System Design Avoids Steam Turbine Overheatingsanjeevnn100% (1)

- Seal Steam RegulatorDocumento10 pagineSeal Steam RegulatorBiplab DasNessuna valutazione finora

- Power Plant Familiar Is at Ion V - IIIDocumento164 paginePower Plant Familiar Is at Ion V - IIISiva Kumar Tutika100% (2)

- Controls & InstrumentationDocumento23 pagineControls & Instrumentationसचिन उरुणकर100% (1)

- My Latest CV - EngineerDocumento3 pagineMy Latest CV - EngineersasibhushanNessuna valutazione finora

- Bhel LP-HP Bypass OrderDocumento32 pagineBhel LP-HP Bypass OrderGiriDharanNessuna valutazione finora

- CondensateDocumento47 pagineCondensateSam50% (2)

- Operation Manual: Lqs-Iicsa Refrigerating Hydrogen DryerDocumento35 pagineOperation Manual: Lqs-Iicsa Refrigerating Hydrogen Dryerdsinghrpd100% (1)

- DAM DesuperheaterDocumento4 pagineDAM DesuperheaterangeloNessuna valutazione finora

- Stim-03.006 - en Control FluidDocumento17 pagineStim-03.006 - en Control Fluidbikendiaguirre100% (1)

- SCHROEDAHL Automatic Recirculation ValveDocumento12 pagineSCHROEDAHL Automatic Recirculation ValveJaebeom YiNessuna valutazione finora

- Turbine Side PumpsDocumento25 pagineTurbine Side PumpsPrakash Choudhary67% (3)

- What Is The Work of Accumulator in Turbines - QuoraDocumento4 pagineWhat Is The Work of Accumulator in Turbines - QuoraEr Suraj KumarNessuna valutazione finora

- Back Pressure TurbinesDocumento4 pagineBack Pressure TurbinesSharath Kota100% (1)

- Critical Speed of TurbineDocumento8 pagineCritical Speed of Turbinezeon100% (1)

- CDQ Layout 567Documento1 paginaCDQ Layout 567Amit BalotNessuna valutazione finora

- 500 MW Turbine CycleDocumento8 pagine500 MW Turbine CycleAhemadNessuna valutazione finora

- Boiler Flow Diagram With Drain and Vent HeaderDocumento3 pagineBoiler Flow Diagram With Drain and Vent HeaderRAJKUMARNessuna valutazione finora

- Protection & InterlocksDocumento18 pagineProtection & InterlocksSanjay GuptaNessuna valutazione finora

- Applications To Thermal Engg - CopyDocumento80 pagineApplications To Thermal Engg - CopySajid KhanNessuna valutazione finora

- Process Heating Nov 2013Documento4 pagineProcess Heating Nov 2013Franklin Santiago Suclla PodestaNessuna valutazione finora

- BOWMAN - Exhaust Gas Heat ExchangerDocumento8 pagineBOWMAN - Exhaust Gas Heat Exchangerryan pratiktoNessuna valutazione finora

- V. Ganapathy. Simplify Heat Recovery Steam Generator Evaluation PDFDocumento7 pagineV. Ganapathy. Simplify Heat Recovery Steam Generator Evaluation PDFgonzalezpcjNessuna valutazione finora

- AFBC BoilerDocumento12 pagineAFBC BoilerNaman Sharma0% (1)

- HP-LP Bypass SystemDocumento20 pagineHP-LP Bypass SystemHunter NoVa100% (4)

- Firetube Heaters: FIG. 8-31 Convection HeaterDocumento7 pagineFiretube Heaters: FIG. 8-31 Convection Heatery149487Nessuna valutazione finora

- Custody TransferDocumento16 pagineCustody Transferwsjouri2510Nessuna valutazione finora

- TD OPTIFLEX2200 en 120601 4000621802 R02Documento44 pagineTD OPTIFLEX2200 en 120601 4000621802 R02Avik BanerjeeNessuna valutazione finora

- Online Proving System FR GasmeterDocumento6 pagineOnline Proving System FR GasmeterAvik BanerjeeNessuna valutazione finora

- Oil and Gas Custody Transfer PetroleumDocumento5 pagineOil and Gas Custody Transfer PetroleumMohammad OkourNessuna valutazione finora

- Oimlr117 2 2CDDocumento181 pagineOimlr117 2 2CDNilson Eduardo TorresNessuna valutazione finora

- Application Note - Crude Oil MeteringDocumento2 pagineApplication Note - Crude Oil MeteringAvik BanerjeeNessuna valutazione finora

- Regulations For Custody Transfer Liquid Meters SmitsDocumento25 pagineRegulations For Custody Transfer Liquid Meters SmitsAvik BanerjeeNessuna valutazione finora

- Stamolys CA71SI: Technical InformationDocumento16 pagineStamolys CA71SI: Technical InformationAvik BanerjeeNessuna valutazione finora

- Flow MeasurementDocumento245 pagineFlow MeasurementOlanshile100% (1)

- Oimlr117 2 2CDDocumento181 pagineOimlr117 2 2CDNilson Eduardo TorresNessuna valutazione finora

- Power SectorDocumento54 paginePower SectorAvik BanerjeeNessuna valutazione finora

- Anatel PAT700 Low Rez Brochure PDFDocumento6 pagineAnatel PAT700 Low Rez Brochure PDFAvik BanerjeeNessuna valutazione finora

- NIST H-004 Series 2Documento6 pagineNIST H-004 Series 2Satit hunsaNessuna valutazione finora

- Gs01e20d01 01eDocumento56 pagineGs01e20d01 01eAvik BanerjeeNessuna valutazione finora

- Technical Information Ousaf22Documento12 pagineTechnical Information Ousaf22Avik BanerjeeNessuna valutazione finora

- Yokogawa ADMAG AXF Magnetic FlowmeterDocumento133 pagineYokogawa ADMAG AXF Magnetic Flowmeter1234567890Nessuna valutazione finora

- NIST Sp250-49 CalSrvcsGasFlowDocumento49 pagineNIST Sp250-49 CalSrvcsGasFlowMaxwellhlNessuna valutazione finora

- X Product Guide: Control Solution For Stand-Alone or Distributed Turbomachinery ApplicationsDocumento16 pagineX Product Guide: Control Solution For Stand-Alone or Distributed Turbomachinery ApplicationsAvik Banerjee100% (1)

- FMR230 To 245 TIDocumento92 pagineFMR230 To 245 TIAvik BanerjeeNessuna valutazione finora

- 1.1 Expansive SoilDocumento9 pagine1.1 Expansive SoilYatin JethiNessuna valutazione finora

- 1 - Hand Tool Ergonomics - Tool DesignDocumento51 pagine1 - Hand Tool Ergonomics - Tool Designwandira_121Nessuna valutazione finora

- Design of An Acoustic Anechoic Chamber For Application in Hearing Aid REsearchDocumento6 pagineDesign of An Acoustic Anechoic Chamber For Application in Hearing Aid REsearchJude SudarioNessuna valutazione finora

- Sade-5tnqzd r12 enDocumento9 pagineSade-5tnqzd r12 enPop-Coman SimionNessuna valutazione finora

- Ferro CementDocumento236 pagineFerro Cementpbharadwaj545Nessuna valutazione finora

- Velocity Analysis and Statics CorrectionsDocumento192 pagineVelocity Analysis and Statics CorrectionsKim PerezNessuna valutazione finora

- Lab Report On AdsorptionDocumento12 pagineLab Report On AdsorptionElizabeth Polancos BruaNessuna valutazione finora

- Dooms Day and Life After Death PDFDocumento289 pagineDooms Day and Life After Death PDFGhulam Mustafa100% (1)

- RosemountDocumento24 pagineRosemountVirgilio VillonNessuna valutazione finora

- Olympic 2018 - Tien Giang 11Documento17 pagineOlympic 2018 - Tien Giang 11Trần Quốc ToảnNessuna valutazione finora

- D Angelo Dongre 2009 Practical Use of Multiple Stress Creep and Recovery Test Characterization of Styrene ButadieneDocumento10 pagineD Angelo Dongre 2009 Practical Use of Multiple Stress Creep and Recovery Test Characterization of Styrene Butadienebn23cem3r15Nessuna valutazione finora

- 3rd - Sem-Ct-23-Chemical EngineeringDocumento3 pagine3rd - Sem-Ct-23-Chemical EngineeringJay RanjanNessuna valutazione finora

- Design of A New Low Cost ROV VehicleDocumento6 pagineDesign of A New Low Cost ROV VehicleMuhammad Yasar JavaidNessuna valutazione finora

- Firewater Hydraulic Study Report Detailed Engineering Design Oml-24 Crude Storage Tanks and De-Watering ProjectDocumento22 pagineFirewater Hydraulic Study Report Detailed Engineering Design Oml-24 Crude Storage Tanks and De-Watering ProjectPatrick AyanNessuna valutazione finora

- Xavier University - Ateneo de Cagayan University College of Engineering Electronics Engineering DepartmentDocumento9 pagineXavier University - Ateneo de Cagayan University College of Engineering Electronics Engineering DepartmentMor DepRzNessuna valutazione finora

- Ch4 Fluid KinematicsDocumento30 pagineCh4 Fluid Kinematicsa u khan100% (1)

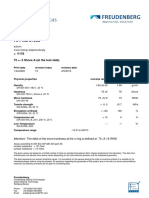

- FST - 70 FKM 37508 enDocumento2 pagineFST - 70 FKM 37508 enXavierNessuna valutazione finora

- Electric Motor Problems & Diagnostic TechniquesDocumento12 pagineElectric Motor Problems & Diagnostic Techniquesjuanca249Nessuna valutazione finora

- A Field Method For Measurement of Infiltration PDFDocumento31 pagineA Field Method For Measurement of Infiltration PDFHamza MamiNessuna valutazione finora

- Apa PR l238 I Joist - LPDocumento14 pagineApa PR l238 I Joist - LPRodrigo CandeoNessuna valutazione finora

- Assignment - Tension Member - Session 2019Documento3 pagineAssignment - Tension Member - Session 2019Hammad Hassan AbdullahNessuna valutazione finora

- UST - PHD Program PDFDocumento60 pagineUST - PHD Program PDFhp2020Nessuna valutazione finora

- Class 12physics - Electric Charges and Fields - McqsDocumento16 pagineClass 12physics - Electric Charges and Fields - Mcqskhushi GoyalNessuna valutazione finora

- Moving Charges and Magnetism 2Documento43 pagineMoving Charges and Magnetism 2Mavn LoginNessuna valutazione finora

- ClabDocumento123 pagineClabScribd UserNessuna valutazione finora

- PPTC Operating Principle 11 04 2016 RaychemDocumento20 paginePPTC Operating Principle 11 04 2016 Raychemsvgl123Nessuna valutazione finora

- Gem Lesson 1Documento17 pagineGem Lesson 1Ritheria100% (1)

- Martini L4 TemperatureControlDocumento11 pagineMartini L4 TemperatureControlJubaer JamiNessuna valutazione finora