Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

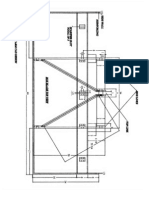

John's 50 Caliber Plans

Caricato da

dougpfaff100%(3)Il 100% ha trovato utile questo documento (3 voti)

2K visualizzazioni44 pagineTitolo originale

John's 50 Caliber Plans[1]

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

100%(3)Il 100% ha trovato utile questo documento (3 voti)

2K visualizzazioni44 pagineJohn's 50 Caliber Plans

Caricato da

dougpfaffCopyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

Sei sulla pagina 1di 44

WOD'USQI]ODA4 FL FMAM

SWa_OS te

[Dasa

SU]d Ady YEq0D OG S,UYOr

USEFUL INFORMATION

* Use centerdrill to start holes to keep more accurate. Drills can walk over.

* Use sharp taps and use tap fluid / oil. Blow out all tapped holes, leaving

no oil, or shaving

* All fasteners required removable loc-tite.

* Torque bolts to proper torque.

* Clean bore before shooting,

* When welding muzzle brake, dont use water to cool.

* Check muzzle brake setscrews before shooting. Never shoot without it.

* Use only good quality ammo from someone you can trust.

* When testing, inspect for loose bolts or cracks in reciever.

* Also if Firing Pin is too long, it can punch hole in primer.

If this happen, the muzzle brake is not as effective. Meaning you will

get a hard kick.

Keep in mind, if ‘a hole is punched in primer, the force from the shell

will try to force out firing pin thru the back of firing block. So make it sure

to install hammer stop.

Blue loc-tite the 10-32 screws on hammer stop. This is important part.

Don't use any hot Roll, mild steel for any parts. Don't drop reciever or hit

with hammer / punch.

AR-15 stock is optional. If you want to cut $40.00 off to your budget,

just use the 1" o.d. aluminum rod. And add butt plate and recoil pad. Paint

1" o.d. aluminum black, you can add stock later.

* Review Photos on floppy before beginning to make parts.

Usefull Information ~

When buying ak-47 parts, buy the import, china stuff, some ak-47

parts are being made in the U.S. The only trouble, is they are harden,

and are tough to drill, and tapping is out of the question. The trigger,

you can weld a .125 pin, in place ,of an 8-32 setscrew. The pin length

would be about .375 long. Its function, is to retain the trigger spring.

Without it, the spring would fall out.

Use only good quality fasteners, such as screws, and bolts. Use blue

removable loc-tite, on all fasteners. Check all fasteners before shooting,

Fasteners could crack, or become loose, check them.

When making parts on firing block page, follow plans exactly. Drill

the .157" hole first, to a depth of .860°. If you drill, the .077" hole

first, it may drift, from it correct location. And always use center

rill, and edge finder. The firing pin can be turned down on a lathe,

just use proper material. To save time, I used an AR-15 firing pin,

and went from there.

All parts should be properly made, and installed properly, before

test firing, or shooting. Use 100 yards of fishing line, to test. Sit

the rifle, on the ground, tie on your line, and load. I recommend

that you be atleast 100 yards away, when firing. Loose parts may

fly off with great force. I hope, you have tighten all your fasteners,

so this should not happen. Parts such as barrel clamp, hammer

stop, muzzle brake, and handle, should always be on rifle, when

shooting.

Always check bore before fring, it should be clean of dirt, grease

or anything, even cleaning solvents. Do this with rifle unloaded.

When loading, cock hammer completely, completely, is when the

trigger catches the hammer. This is the safe way, to cock hammer.

Ifyou hold it, you may let go, and rifle could fire. Cock the hammer

and then insert the round. Make sure to mill small flats, on hammer

cocking shaft, so setscrews will hold. Use removable loc-tite.

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 15 Minute AR15 Trigger JobDocumento5 pagine15 Minute AR15 Trigger Jobdougpfaff100% (4)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Lyman: User's Guide For Black Powder ProductsDocumento48 pagineLyman: User's Guide For Black Powder Productsdougpfaff100% (1)

- 2008 CatalogDocumento40 pagine2008 Catalogdougpfaff67% (3)

- UniqueTek Catalog Rev19Documento2 pagineUniqueTek Catalog Rev19dougpfaff100% (1)

- Sight InstructionsDocumento8 pagineSight Instructionsdougpfaff100% (3)

- Box BladeDocumento6 pagineBox BladedougpfaffNessuna valutazione finora