Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Production of Dietary Fibre From Soyhulls and Okara

Caricato da

Adapa Prabhakara GandhiDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Production of Dietary Fibre From Soyhulls and Okara

Caricato da

Adapa Prabhakara GandhiCopyright:

Formati disponibili

Production of dietary fibre from soyhulls and okara:

Extraction with NaOH:

Soy hull and okara were extracted separately with Sodium hydroxide solution (pH 9) for different

intervals ranging from30,60 and 90 minutes. After washing with water till the last traces of alkali, the

materials thus obtained were dried at 40o C and subsequently analysed for Protein, fat and crue fibre .It was

found that the alkali treatments were effective in lowering the protein and fat levels of both the soy

materials. Longer than 60 minutes was not found to reduce the protein markedly. The reason for this may

be the fact that most of the protein is soluble in alkaline condition and also some saponification might be

taking place to lower the fat contents. The reduction in P is also attributed to the loss of protein and fat as P

forms a part of these. The results are given in Table.1.

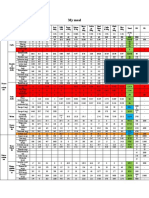

Table.1 : Chemical composition of soy hull and okara as affected by alkali extraction

Component 0 Min 30 Min 60 Min 90 Min

Hull Okara Hull Okara Hull Okara Hull Okara

Protein (g/100g) 13.7 23.7 7.4 11.8 3.5 4.6 3.8 3.8

Fat (g/100g) 3.5 15.8 1.2 7.8 0.8 2.6 0.6 1.7

Phosphorus(mg/ 218.6 146.0 117.5 56.0 63.7 42.0 40.5 35.0

100g)

Crude Fibre 36.6 30.5 30.7 25.8 28.0 27.8 27.6 26.5

(g/100g)

On characterizing these alkali treated materials it was observed that the alkali has effected the lowering of

hemicellulose and acid detergent fibre portion of the fibre. The results are given in Table.2.

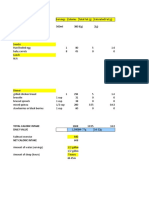

Table.2. Characterization of fibre

Compon 0 Min 30 Min 60 Min 90 Min

ents (%) Hull Okara Hull Okara Hull Okara Hull Okara

NDF 69 65 67 63 61 60 60 58

ADF 45 34 42 32 40 40 40 40

Hemi 24 31 23 31 21 20 20 18

cellulose

Cellulose 43 35 41 42 40 41 40 41

Lignin 3.2 2.9 3.0 2.2 2.6 1.7 2.2 1.6

Crude 35 30 34 30 27 25 26 24

Fibre

(%)

Potrebbero piacerti anche

- Tutorial Lle Ii-1920Documento5 pagineTutorial Lle Ii-1920Muhammad HazwanNessuna valutazione finora

- LAB 5 - Pineapple CordialsDocumento17 pagineLAB 5 - Pineapple Cordialsghostly_form416995% (21)

- Development of HACCP Protocols For The Production ofDocumento48 pagineDevelopment of HACCP Protocols For The Production ofAdapa Prabhakara Gandhi100% (1)

- Development of HACCP Protocols For The Production ofDocumento48 pagineDevelopment of HACCP Protocols For The Production ofAdapa Prabhakara Gandhi100% (1)

- Nutritional Composition: Values From 2003-2004 Feedstuffs Ingredient Analysis Table: Nick M. Dale and Amy B. BatalDocumento2 pagineNutritional Composition: Values From 2003-2004 Feedstuffs Ingredient Analysis Table: Nick M. Dale and Amy B. Batalasole azoxNessuna valutazione finora

- Susut ProteinDocumento5 pagineSusut ProteinMinanda713Nessuna valutazione finora

- Annexure-I: Physico-Chemical Properties of SoilDocumento6 pagineAnnexure-I: Physico-Chemical Properties of SoilRamesh KumarNessuna valutazione finora

- Total Caloric Intake Daily ValueDocumento4 pagineTotal Caloric Intake Daily Valueapi-397104089Nessuna valutazione finora

- 2 3 FLDocumento4 pagine2 3 FLapi-397108373Nessuna valutazione finora

- Tugaspemrogramanepisode 2Documento4 pagineTugaspemrogramanepisode 2Ilham MaulanaNessuna valutazione finora

- Jawaban Trial and ErrorDocumento6 pagineJawaban Trial and ErrorAnonymous OVXBXaNessuna valutazione finora

- Trial & Error (Master)Documento6 pagineTrial & Error (Master)Muhammad GhaisanNessuna valutazione finora

- Yield Pektin No Sampel Temperatur (°C) Waktu (Menit) Massa Bahan Baku (Gram) Massa Pektin (Gram) Yield (%)Documento4 pagineYield Pektin No Sampel Temperatur (°C) Waktu (Menit) Massa Bahan Baku (Gram) Massa Pektin (Gram) Yield (%)DewiSriNessuna valutazione finora

- SmofKabiven DetailsDocumento21 pagineSmofKabiven DetailskelgroryNessuna valutazione finora

- Atividade Moluscicidal7Documento11 pagineAtividade Moluscicidal7amensetNessuna valutazione finora

- Food Log 1 29 PDFDocumento5 pagineFood Log 1 29 PDFapi-397108373Nessuna valutazione finora

- Foodlogtemplate - Sheet1 12Documento4 pagineFoodlogtemplate - Sheet1 12api-447451274Nessuna valutazione finora

- February 1 - February 1-2Documento4 pagineFebruary 1 - February 1-2api-446188753Nessuna valutazione finora

- February 2 - February 2Documento4 pagineFebruary 2 - February 2api-446188753Nessuna valutazione finora

- Juice Nutrition Page 9Documento2 pagineJuice Nutrition Page 9Jerry DoughertyNessuna valutazione finora

- No Penilaian JumlahDocumento6 pagineNo Penilaian JumlahSaRay DHhe InNaNessuna valutazione finora

- Partial Replacement of Concentrate by Browse G Saraye 21 JN 2020Documento3 paginePartial Replacement of Concentrate by Browse G Saraye 21 JN 2020Rajesh ToolseeNessuna valutazione finora

- Tropical Feed - Summer Course 2021Documento20 pagineTropical Feed - Summer Course 2021HAMZAH JAUHARNessuna valutazione finora

- My Meal: Smoothie and MealsDocumento4 pagineMy Meal: Smoothie and MealsStella DevaniaNessuna valutazione finora

- Grams in 1 Pound 453.6 Raw Data Normalized To 1 Lb. Normalized To 8 Fluid Oz. Normalized To 100 CalsDocumento1 paginaGrams in 1 Pound 453.6 Raw Data Normalized To 1 Lb. Normalized To 8 Fluid Oz. Normalized To 100 CalsJerry DoughertyNessuna valutazione finora

- Tally Sheet Pengukuran Kurva Tinggi No. Keliling (CM) Diameter (CM) Jenis %htop %HBCDocumento25 pagineTally Sheet Pengukuran Kurva Tinggi No. Keliling (CM) Diameter (CM) Jenis %htop %HBCMWA GamingNessuna valutazione finora

- Day 6 Done - Sheet1Documento2 pagineDay 6 Done - Sheet1api-447078165Nessuna valutazione finora

- Perhitungan Pembuatan Formula Ransum Dengan Metode Trial and ErrorDocumento6 paginePerhitungan Pembuatan Formula Ransum Dengan Metode Trial and ErrorrisnawatiNessuna valutazione finora

- Foodlog Feb 5Documento2 pagineFoodlog Feb 5api-447084768Nessuna valutazione finora

- Ventas de Prod Desde 01-09 Al 26-09-2022Documento4 pagineVentas de Prod Desde 01-09 Al 26-09-2022Edwin EscárateNessuna valutazione finora

- White Gummie Jamba Ju: Total Caloric Intake Daily ValueDocumento3 pagineWhite Gummie Jamba Ju: Total Caloric Intake Daily Valueapi-397104089Nessuna valutazione finora

- FoodlogDocumento4 pagineFoodlogapi-541474235Nessuna valutazione finora

- % Daily ValueDocumento39 pagine% Daily ValueEmmanuel ManinangNessuna valutazione finora

- Antioxidant Capacity Jf0502698Documento21 pagineAntioxidant Capacity Jf0502698Fransisca PutriNessuna valutazione finora

- February 8 - February 8Documento4 pagineFebruary 8 - February 8api-446188753Nessuna valutazione finora

- Food Log 2 3 PDFDocumento4 pagineFood Log 2 3 PDFapi-397108373Nessuna valutazione finora

- Foodlogtemplate Day 2 MainDocumento4 pagineFoodlogtemplate Day 2 Mainapi-397125493Nessuna valutazione finora

- Final 11 Week ReportDocumento12 pagineFinal 11 Week ReportRaguRamanNessuna valutazione finora

- Berries and Health: A Review of The EvidenceDocumento20 pagineBerries and Health: A Review of The EvidenceAndreea CraciunNessuna valutazione finora

- Food Log 2 7 NewDocumento4 pagineFood Log 2 7 Newapi-397108373Nessuna valutazione finora

- Copy of Foodlog Date 01 31 2022 - Daily IntakeDocumento3 pagineCopy of Foodlog Date 01 31 2022 - Daily Intakeapi-595111213Nessuna valutazione finora

- FoodlogDocumento4 pagineFoodlogapi-541474235Nessuna valutazione finora

- ZZZ ZZZDocumento11 pagineZZZ ZZZNghia Phan TrungNessuna valutazione finora

- Foodlog Date 02 5 22Documento4 pagineFoodlog Date 02 5 22api-593084957Nessuna valutazione finora

- Friday 2 2f2 2f18Documento2 pagineFriday 2 2f2 2f18api-397114157Nessuna valutazione finora

- Foodlog Date 02 1 22Documento4 pagineFoodlog Date 02 1 22api-593084957Nessuna valutazione finora

- Evaluation of The Behavior of The American Genipa (Jagua) in The Dehydration Process by ConvectionDocumento7 pagineEvaluation of The Behavior of The American Genipa (Jagua) in The Dehydration Process by ConvectionPedro Felipe RiveraNessuna valutazione finora

- February 7 - February 7Documento4 pagineFebruary 7 - February 7api-446188753Nessuna valutazione finora

- 1-30 Food Log - Sheet1Documento4 pagine1-30 Food Log - Sheet1api-398291990Nessuna valutazione finora

- ED 20220805-Tabel Nilai Kontrol HematologiDocumento1 paginaED 20220805-Tabel Nilai Kontrol HematologiAhmad Rahmadi AdheNessuna valutazione finora

- 02 07 - Daily IntakeDocumento1 pagina02 07 - Daily Intakeapi-654919778Nessuna valutazione finora

- HVB-DN Follow Up WWTP Plant Balancing Tank Unit Norm Jan FebDocumento12 pagineHVB-DN Follow Up WWTP Plant Balancing Tank Unit Norm Jan FebbaoNessuna valutazione finora

- GOAT 2 Auto Feed Formulator MASTER - NRC - 100kgDocumento8 pagineGOAT 2 Auto Feed Formulator MASTER - NRC - 100kgJude EnabuluNessuna valutazione finora

- Foodlogtemplate - Sheet1Documento4 pagineFoodlogtemplate - Sheet1api-447451274Nessuna valutazione finora

- Lal Pesticidas 2017Documento228 pagineLal Pesticidas 2017Junior SanchezNessuna valutazione finora

- Wednesday Jan 30Documento2 pagineWednesday Jan 30api-447201619Nessuna valutazione finora

- Grams in 1 Pound 453.6 Raw Data Normalized To 1 Lb. Normalized To 8 Fluid Oz. Normalized To 100 CalsDocumento2 pagineGrams in 1 Pound 453.6 Raw Data Normalized To 1 Lb. Normalized To 8 Fluid Oz. Normalized To 100 CalsJerry DoughertyNessuna valutazione finora

- Mencari %mole Methanol UapDocumento3 pagineMencari %mole Methanol UapChoiriah EBNessuna valutazione finora

- Foodlog Date 1 30 22 - Daily Intake 1Documento1 paginaFoodlog Date 1 30 22 - Daily Intake 1api-594236741Nessuna valutazione finora

- January 30 - January 30Documento4 pagineJanuary 30 - January 30api-446188753Nessuna valutazione finora

- Ventas de Prod Desde 01-06 Al 30-06-2022Documento4 pagineVentas de Prod Desde 01-06 Al 30-06-2022Edwin EscárateNessuna valutazione finora

- Carbonated Soft Drinks: Formulation and ManufactureDa EverandCarbonated Soft Drinks: Formulation and ManufactureDr. David SteenNessuna valutazione finora

- Soy Proteins and Their Modifications For Food IndustriesDocumento2 pagineSoy Proteins and Their Modifications For Food IndustriesAdapa Prabhakara GandhiNessuna valutazione finora

- Oil Seed MedicinalsDocumento2 pagineOil Seed MedicinalsAdapa Prabhakara GandhiNessuna valutazione finora

- Soyfood Quality, Safety and StandardsDocumento18 pagineSoyfood Quality, Safety and StandardsAdapa Prabhakara GandhiNessuna valutazione finora

- Soymeal For Food UsesDocumento6 pagineSoymeal For Food UsesAdapa Prabhakara GandhiNessuna valutazione finora

- General Principles of Food Sanitation and Hygiene: A.P.GandhiDocumento17 pagineGeneral Principles of Food Sanitation and Hygiene: A.P.GandhiAdapa Prabhakara GandhiNessuna valutazione finora

- Soybased Aqua FeedsDocumento3 pagineSoybased Aqua FeedsAdapa Prabhakara GandhiNessuna valutazione finora

- RPF-III Alternate SolventsDocumento35 pagineRPF-III Alternate SolventsAdapa Prabhakara GandhiNessuna valutazione finora

- EdpDocumento33 pagineEdpAdapa Prabhakara GandhiNessuna valutazione finora

- Milk ProteinsDocumento2 pagineMilk ProteinsAdapa Prabhakara GandhiNessuna valutazione finora

- What Is Soy YogurtDocumento1 paginaWhat Is Soy YogurtAdapa Prabhakara GandhiNessuna valutazione finora

- Soy Entrepreneurship DvelopmentDocumento12 pagineSoy Entrepreneurship DvelopmentAdapa Prabhakara GandhiNessuna valutazione finora

- Mycotoxins: A.P.Gandhi, Th-28, E-8, Shahapura, Bharatnagar, Bhopal (MP), IndiaDocumento4 pagineMycotoxins: A.P.Gandhi, Th-28, E-8, Shahapura, Bharatnagar, Bhopal (MP), IndiaAdapa Prabhakara GandhiNessuna valutazione finora

- Biochemical Changes Associated With The Processing of FoodsDocumento4 pagineBiochemical Changes Associated With The Processing of FoodsAdapa Prabhakara GandhiNessuna valutazione finora

- TofuDocumento3 pagineTofuAdapa Prabhakara GandhiNessuna valutazione finora

- Project Report HACCPDocumento338 pagineProject Report HACCPAdapa Prabhakara Gandhi86% (14)

- SoybutterDocumento1 paginaSoybutterAdapa Prabhakara GandhiNessuna valutazione finora

- Soybeans - The WonderbeansDocumento22 pagineSoybeans - The WonderbeansAdapa Prabhakara Gandhi100% (1)

- Use of Hazard Analysis Critical Control Point PrinciplesDocumento139 pagineUse of Hazard Analysis Critical Control Point PrinciplesAdapa Prabhakara GandhiNessuna valutazione finora

- Implementing HACCP Based Food Quality and Safety Programs at IndustriesDocumento3 pagineImplementing HACCP Based Food Quality and Safety Programs at IndustriesAdapa Prabhakara Gandhi100% (2)

- The Titan School Lesson Plan Class Subject Topic 1. Incorporation of Multiple IntelligencesDocumento3 pagineThe Titan School Lesson Plan Class Subject Topic 1. Incorporation of Multiple IntelligencesanandakrNessuna valutazione finora

- Soy Food GuideDocumento24 pagineSoy Food Guideabhi_841Nessuna valutazione finora

- 407 MealplanprojectDocumento10 pagine407 Mealplanprojectapi-508953960Nessuna valutazione finora

- Bread (Composite Flour) Formulation and Study of Its Nutritive, Phytochemical and Functional PropertiesDocumento15 pagineBread (Composite Flour) Formulation and Study of Its Nutritive, Phytochemical and Functional PropertiesJamal JunaidNessuna valutazione finora

- Chapter - Ii II II II: Reivew Reivew Reivew Reivew OF OF OF OF Literature Literature Literature LiteratureDocumento38 pagineChapter - Ii II II II: Reivew Reivew Reivew Reivew OF OF OF OF Literature Literature Literature LiteratureMukesh SharmaNessuna valutazione finora

- Fnce 2021 PPT - ElenaDocumento15 pagineFnce 2021 PPT - Elenaapi-617094741Nessuna valutazione finora

- Best Management of Irritable Bowel SyndromeDocumento13 pagineBest Management of Irritable Bowel SyndromeIsaac Martinez ArevaloNessuna valutazione finora

- Stabilizers Acidified Milk Drinks PDFDocumento6 pagineStabilizers Acidified Milk Drinks PDFthanhtl_hugolataNessuna valutazione finora

- Fine Grinding and BS3 Xylanase Improve Productivity in WeanersDocumento11 pagineFine Grinding and BS3 Xylanase Improve Productivity in WeanersMilling and Grain magazineNessuna valutazione finora

- 2 PBDocumento8 pagine2 PBc76991350Nessuna valutazione finora

- 30-Second NutritionDocumento163 pagine30-Second NutritionRahul Roy100% (1)

- 20 Pro Metabolic Fat Burning SecretsDocumento31 pagine20 Pro Metabolic Fat Burning SecretsBest Com100% (1)

- Plant-Based Milk Alternatives An Emerging Segment of Functional Beverages: A ReviewDocumento16 paginePlant-Based Milk Alternatives An Emerging Segment of Functional Beverages: A ReviewRafael LuchaNessuna valutazione finora

- Physical Education and Health (H.O.P.E. 4) : Quarter 4 - Module 5: Going On TopDocumento18 paginePhysical Education and Health (H.O.P.E. 4) : Quarter 4 - Module 5: Going On TopJayson Barsana75% (8)

- Forage GlossaryDocumento5 pagineForage GlossaryAslamNessuna valutazione finora

- Nutritional Quality and Health Benefits of Vegetables: A ReviewDocumento22 pagineNutritional Quality and Health Benefits of Vegetables: A ReviewTitoNessuna valutazione finora

- Us20110313055a1 PDFDocumento13 pagineUs20110313055a1 PDFRecurso AgronomicoNessuna valutazione finora

- Haas, Don - Vegan Barbell Strength Training, Powerlifting, Olympic Lifting On A Plant Based DietDocumento79 pagineHaas, Don - Vegan Barbell Strength Training, Powerlifting, Olympic Lifting On A Plant Based DietDiegoNessuna valutazione finora

- Drying Kinetics of Green Banana FlourDocumento11 pagineDrying Kinetics of Green Banana FlourUsha BbattaNessuna valutazione finora

- 3.3 Resistant Starch As Functional Ingredient PDFDocumento12 pagine3.3 Resistant Starch As Functional Ingredient PDFAndrea GanibeliusNessuna valutazione finora

- Diatery FiberDocumento5 pagineDiatery FiberRatnaNessuna valutazione finora

- CVB Feed Table 2016 Version 1Documento713 pagineCVB Feed Table 2016 Version 1RizTambalqueNessuna valutazione finora

- Water and Fibre Lecture v1Documento44 pagineWater and Fibre Lecture v1INAKI MOYANessuna valutazione finora

- Enteral Dan ParenteralDocumento25 pagineEnteral Dan ParenteralFikaNessuna valutazione finora

- Fiber-How: Much Is Too Much?Documento2 pagineFiber-How: Much Is Too Much?Marian YuqueNessuna valutazione finora

- Romano 2021Documento11 pagineRomano 2021biancap00Nessuna valutazione finora

- Lo RPKW 2 GDocumento1 paginaLo RPKW 2 GChili NNessuna valutazione finora

- How To Use Chia Seeds To Lose WeightDocumento2 pagineHow To Use Chia Seeds To Lose WeightMax OratioNessuna valutazione finora

- GreenSmoothieDetox - PDF - Final1 (2018 - 10 - 09 17 - 50 - 25 UTC) PDFDocumento42 pagineGreenSmoothieDetox - PDF - Final1 (2018 - 10 - 09 17 - 50 - 25 UTC) PDFNatalia FuentesNessuna valutazione finora

- Feasibility StudyDocumento19 pagineFeasibility StudyGian FernandezNessuna valutazione finora