Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Training Report Front Page

Caricato da

Saurabh SinghTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Training Report Front Page

Caricato da

Saurabh SinghCopyright:

Formati disponibili

A

Summer training report

on

(GANGA BRIDGE & FLYOVERS PROJECT KANPUR)

Completed

at

GAMMON INDIA LIMITED,

Project Name

“Rehabilitation and Upgradation from Km. 75.00 to Km. 80.60 of NH-25 in the town of Kanpur

(including bridge across river Ganga) to 4 lane divided carriageway configuration”

Duration

12 June to 20 July, 2010

Submitted

By

Saurabh Singh

Roll No. 0704300035

B.Tech-3rd Year

Department of Civil Engineering

Bundelkhand Institute of Engineering & Technology

Jhansi (U.P.) India – 284128

July,2010

Acknowledgements

I acknowledge with gratitude the interest with which Mr. M. Biswas (Project Manager),

Gammon India Limited (Kanpur Job Unit) took in providing me valuable informations and

guide lines regarding the field training.

I extend my heartiest thanksto Mr. R.K. Singh (Admin. Manager). Acknowledgement is

no return to the cooperation and knowledge received from Mr. T.K. Chatterjee and Mr.

Prabhat Dwivedi in elevated road and highway, Mr. D.C. Naidu and Mr. Souvic

Bhattacharjee in Ganga bridge and Mr. VivekBharti in QC Lab.

I also thank to the Professor Training & Placement, B.I.E.T., Jhansi, for taking interest

and guidance in my Endeavour to get an opportunity to work at GIL.

I am also thankful to the staff of GIL, Kanpur for their help and assistance during my

training period.

July, 2010 Saurabh Singh

Roll No.-0704300035

Contents

1 About Company 1

2 Work Outline 4

3 Introduction 6

4 Machinaries used 7

5 Ganga Bridge 8

5.1 Salient features of the project 8

5.2 Material data 8

5.3 Bridge foundation 9

5.4 Well foundation 10

5.5 Well components & their function 10

5.6 Depth of Well Foundation 13

5.7 Sinking of Wells 14

5.8 Abutement 16

5.9 Abutement Cap 17

5.10 Pier 18

5.11 Pier cap 19

5.12 PSC beam casting, stressing & grouting 21

5.13 Launching & Shifting of Beams 27

5.14 Bearing 28

5.15 Diaphragm 29

5.16 Deck Slab 30

5.17 Retaining Wall 32

6 Flyover 33

6.1 Foundation for flyover : pile foundation 33

6.2 Pile cap 35

6.3 Pier & Pier cap 35

6.4 Pre stressed Concrete Beam 36

7 Production of concrete 38

7.1 Materials used 39

8 Quality Control of Concrete 40

8.1 Liquid limit & plastic limit test 42

8.2 Cube strength of concrete 43

8.3 Aggregate impact value 43

8.4 Sieve analysis for all in aggregate 44

8.5 Sieve analysis for fine aggregate 45

8.6 Flakiness index test 46

8.7 specific gravity & water absorption test 47

8.8 Modified proctor test 48

8.9 California Bearing Ratio (CBR) test 49

9 Conclusion 50

Potrebbero piacerti anche

- Six Month Training Report On Construction of Railway Overbridge PDFDocumento49 pagineSix Month Training Report On Construction of Railway Overbridge PDFGurpreet SinghNessuna valutazione finora

- Major Project Report PDFDocumento74 pagineMajor Project Report PDFGaddam Sudheer100% (1)

- Project ReportDocumento45 pagineProject ReportAbhishek Gupta81% (27)

- Mini Project ReportDocumento37 pagineMini Project ReportPRAVIN KUMAR NNessuna valutazione finora

- PWD Training Report CivilDocumento24 paginePWD Training Report CivilKushal 00725% (4)

- Thesis M.TechDocumento109 pagineThesis M.TechSonu Dhangar100% (10)

- Artificial Intelligence Seminar ReportDocumento30 pagineArtificial Intelligence Seminar Reportmohd Azhar100% (1)

- Chapter-1: 1.1 Basic IntroductionDocumento25 pagineChapter-1: 1.1 Basic IntroductionVasu Thakur100% (2)

- Final Report Spam Mail Detection 33Documento51 pagineFinal Report Spam Mail Detection 33ASWIN MANOJNessuna valutazione finora

- CATIA internship report on solid modeling and double bearing assemblyDocumento39 pagineCATIA internship report on solid modeling and double bearing assemblyManoj Sixer 13Nessuna valutazione finora

- Major Project Report FormatDocumento4 pagineMajor Project Report Formatyatendra kashyap100% (2)

- Minor Project For Civil EngineeringDocumento52 pagineMinor Project For Civil EngineeringRupesh GenesisNessuna valutazione finora

- Project Report On Electric Two WheelerDocumento5 pagineProject Report On Electric Two WheelerEIRI Board of Consultants and Publishers100% (1)

- Internship Report On CC PavementsDocumento39 pagineInternship Report On CC PavementsPrakashNessuna valutazione finora

- ITR Report FormatDocumento9 pagineITR Report FormatYogesh Bhandari100% (1)

- Project Report On Artificial IntelligenceDocumento19 pagineProject Report On Artificial Intelligencebuddunaveen92Nessuna valutazione finora

- Internship ReportDocumento35 pagineInternship ReportAli umarNessuna valutazione finora

- Micro Project Format-2Documento8 pagineMicro Project Format-2Rohit Bhamare100% (2)

- Plastic RoadsDocumento24 paginePlastic RoadsGnaneshwar DevarapagaNessuna valutazione finora

- Summer Training Project ReportDocumento26 pagineSummer Training Project ReportSHAURYA TIWARINessuna valutazione finora

- Industrial Training ReportDocumento34 pagineIndustrial Training ReportGOURAV MITTAL100% (2)

- Internship ReportDocumento31 pagineInternship ReportShashidhara AENessuna valutazione finora

- Varahi ReportDocumento5 pagineVarahi ReportbesttNessuna valutazione finora

- Final Year Project Report: Micro RefrigeratorDocumento40 pagineFinal Year Project Report: Micro RefrigeratorWaseem Aulakh100% (1)

- M Tech Projects - Engineering Project REPORTDocumento55 pagineM Tech Projects - Engineering Project REPORTmanoj phadtareNessuna valutazione finora

- Summer Internship Report PDFDocumento66 pagineSummer Internship Report PDFsri balajee71% (7)

- Training Report of Mechanical EngineerDocumento20 pagineTraining Report of Mechanical Engineerpatel ketan60% (5)

- Summer Internship FOR Autocad Report Altaf SheikhDocumento28 pagineSummer Internship FOR Autocad Report Altaf SheikhNamira KhanNessuna valutazione finora

- Major Project ReportDocumento49 pagineMajor Project ReportMohini BhartiNessuna valutazione finora

- Report On Industrial TrainingDocumento40 pagineReport On Industrial Trainingveeresh0% (1)

- Anti Sleep Alarm GlassDocumento22 pagineAnti Sleep Alarm GlassKotesh KalyanNessuna valutazione finora

- Resume M.tech EE IIT KanpurDocumento2 pagineResume M.tech EE IIT Kanpuritsnaga23100% (2)

- In-Plant Training Report at Blue Star India LimitedDocumento18 pagineIn-Plant Training Report at Blue Star India LimitedAdil AhsanNessuna valutazione finora

- Renewable Energy Sources Micro Project ReportDocumento11 pagineRenewable Energy Sources Micro Project ReportAayan mulaniNessuna valutazione finora

- Internship: A Report OnDocumento11 pagineInternship: A Report OnMuntaseem Bijapure0% (1)

- Waste Connect App for Effective Waste ManagementDocumento34 pagineWaste Connect App for Effective Waste ManagementBhagyasri Patel100% (1)

- Evs Micro ProjectDocumento19 pagineEvs Micro ProjectVaishnavi Patil Art100% (2)

- An Internship Project Report On Residential BuildingDocumento14 pagineAn Internship Project Report On Residential Buildingrupesh singhNessuna valutazione finora

- Design of Pedestrian Walkway at Vytilla JunctionDocumento47 pagineDesign of Pedestrian Walkway at Vytilla JunctionAkhil BabuNessuna valutazione finora

- Use of Plastic Waste & E-Waste in Flexible PavementDocumento48 pagineUse of Plastic Waste & E-Waste in Flexible PavementPew DiePie67% (3)

- DEEPAK KUMAR Training & Development in HERO DocumentationDocumento77 pagineDEEPAK KUMAR Training & Development in HERO DocumentationSuraj Dubey100% (2)

- A Mini Project Report On CONCRETEDocumento9 pagineA Mini Project Report On CONCRETEsuresh nenavathNessuna valutazione finora

- Internship ReportDocumento30 pagineInternship ReportAbhishek SengarNessuna valutazione finora

- NSSK Sugar Factory Bidar Intrenship ReportDocumento45 pagineNSSK Sugar Factory Bidar Intrenship Reportmukund100% (1)

- Minor Project Report On Construction of National Highway 2Documento97 pagineMinor Project Report On Construction of National Highway 2Sumit Singh58% (31)

- Construction of 4 lane segmental bridge across river Yamuna in FaridabadDocumento22 pagineConstruction of 4 lane segmental bridge across river Yamuna in FaridabadShefali Yadav100% (4)

- Project Report FinalDocumento18 pagineProject Report Finalsdfa100% (2)

- Rubber Concrete: Effects on Workability and Compressive StrengthDocumento13 pagineRubber Concrete: Effects on Workability and Compressive StrengthDhruvKandwal50% (2)

- Final Smart Traffic Management System PPT Using DipDocumento44 pagineFinal Smart Traffic Management System PPT Using DipSaloni SinghNessuna valutazione finora

- Automatic Pneumatic Stand For Two WheelerDocumento34 pagineAutomatic Pneumatic Stand For Two WheelerTanvi100% (1)

- Bituminous (Asphalt) Road: Bachelor of TechnologyDocumento22 pagineBituminous (Asphalt) Road: Bachelor of TechnologyBirjesh KumarNessuna valutazione finora

- Final Project Report PDFDocumento83 pagineFinal Project Report PDFDigvijayNessuna valutazione finora

- Specification of Hydraulic Power Pack and Pneumatic Service Unit (FRL Unit)Documento12 pagineSpecification of Hydraulic Power Pack and Pneumatic Service Unit (FRL Unit)Paren Trivedi77% (13)

- 3 4 4 Activity Report of AICTE Activity Point Program Part 3Documento149 pagine3 4 4 Activity Report of AICTE Activity Point Program Part 3riya kangralkarNessuna valutazione finora

- Automatic Street Light Control Using LDRDocumento39 pagineAutomatic Street Light Control Using LDRAyush Kumar100% (1)

- BCA Fresher Resume Sample Format in Word PDFDocumento2 pagineBCA Fresher Resume Sample Format in Word PDFGokul SaiNessuna valutazione finora

- "Pervious Concrete": Gujarat Technological UniversityDocumento26 pagine"Pervious Concrete": Gujarat Technological UniversityRutvikNessuna valutazione finora

- Development of Bundelkhand Expressway Pro Ject: 30 Days Industrial Training atDocumento98 pagineDevelopment of Bundelkhand Expressway Pro Ject: 30 Days Industrial Training atAditya KumarNessuna valutazione finora

- CFRP Compressive Strength Study of Carbon Fiber Reinforced Polymer ConcreteDocumento52 pagineCFRP Compressive Strength Study of Carbon Fiber Reinforced Polymer Concrete130 Nandini KotaNessuna valutazione finora

- Design of Self Compacting Concrete Using Crushed-Stone SandDocumento54 pagineDesign of Self Compacting Concrete Using Crushed-Stone SandSwati SharmaNessuna valutazione finora

- Field Training ProformaDocumento31 pagineField Training ProformaSaurabh SinghNessuna valutazione finora

- Track Drainage - Inspection and Maintenance RTS 3432: Engineering Practices Manual Civil EngineeringDocumento21 pagineTrack Drainage - Inspection and Maintenance RTS 3432: Engineering Practices Manual Civil EngineeringJamie MooreNessuna valutazione finora

- Examresult UPSC Engineering Services Exam 2014Documento8 pagineExamresult UPSC Engineering Services Exam 2014Arvind BajpaiNessuna valutazione finora

- Agricultural For CSEDocumento37 pagineAgricultural For CSESaurabh SinghNessuna valutazione finora

- Exam Schedule Odd2011Documento65 pagineExam Schedule Odd2011Azam RizviNessuna valutazione finora

- Airport Liner TimingsDocumento10 pagineAirport Liner TimingsNagasai ViswanathNessuna valutazione finora

- History of Tunnels in IndiaDocumento191 pagineHistory of Tunnels in IndiaSaurabh Singh100% (1)

- Mess Bill SeptDocumento1 paginaMess Bill SeptSaurabh SinghNessuna valutazione finora

- 2010-11 Admitted Students at BIETDocumento18 pagine2010-11 Admitted Students at BIETSaurabh SinghNessuna valutazione finora

- Mess Bill AugustDocumento1 paginaMess Bill AugustSaurabh SinghNessuna valutazione finora

- Open Elective SyllabusDocumento1 paginaOpen Elective SyllabusSaurabh SinghNessuna valutazione finora

- Valmet HP Cleaning System For Pulp FiltersDocumento2 pagineValmet HP Cleaning System For Pulp FiltersnotengofffNessuna valutazione finora

- Santosh ResumeDocumento4 pagineSantosh ResumeSantosh KumarNessuna valutazione finora

- Ec Council Certified Security Analyst Ecsa v8 PDFDocumento5 pagineEc Council Certified Security Analyst Ecsa v8 PDFJunaid Habibullaha0% (1)

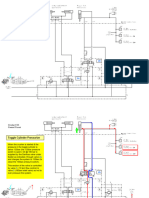

- Toggle Ram - CSS Ram Valve SetupDocumento6 pagineToggle Ram - CSS Ram Valve Setupsassine khouryNessuna valutazione finora

- Science 4, Q3, Module 6, ReyesDocumento12 pagineScience 4, Q3, Module 6, ReyesIyutaann Kantutan100% (1)

- Positive Displacement PumpsDocumento48 paginePositive Displacement PumpsSteve Carwell100% (5)

- Europass CV Aristeidis TsialosDocumento3 pagineEuropass CV Aristeidis Tsialoso_pythagoriosNessuna valutazione finora

- Mechanical Design Standards: Bending Guidelines 1Documento9 pagineMechanical Design Standards: Bending Guidelines 1ioanchiNessuna valutazione finora

- Course Outline June 2020Documento3 pagineCourse Outline June 2020nurul syafiqah12Nessuna valutazione finora

- BFC 31901 Structure LabsheetDocumento11 pagineBFC 31901 Structure LabsheetAshyra JamilNessuna valutazione finora

- OS X ShortcutsDocumento19 pagineOS X Shortcutsia_moheetNessuna valutazione finora

- Temporary Horizontal Lifeline Rope A6Documento3 pagineTemporary Horizontal Lifeline Rope A6tanu00Nessuna valutazione finora

- Chitosan - A Versatile Semi-Synthetic Polymer in BiomedicalDocumento34 pagineChitosan - A Versatile Semi-Synthetic Polymer in BiomedicalBianca Ionela DraganNessuna valutazione finora

- Buried Pipes in OLGADocumento5 pagineBuried Pipes in OLGAmotalebyNessuna valutazione finora

- jOOQ Manual 3.10Documento303 paginejOOQ Manual 3.10sifar786Nessuna valutazione finora

- Soft Box System Product Presentation 1Documento26 pagineSoft Box System Product Presentation 1jmiller9842Nessuna valutazione finora

- Microsoft Word - Dangerous Goods Declaration PDFDocumento1 paginaMicrosoft Word - Dangerous Goods Declaration PDFAlfian AnasNessuna valutazione finora

- Mahindra&mahindraDocumento95 pagineMahindra&mahindraAshik R GowdaNessuna valutazione finora

- Pet-704 704PDocumento38 paginePet-704 704Papi-3702225100% (1)

- B 330 MDocumento3 pagineB 330 MdjbobyNessuna valutazione finora

- How To Segregate The Access To MIGO Transaction Like All The Other SAP TransactionsDocumento5 pagineHow To Segregate The Access To MIGO Transaction Like All The Other SAP Transactionsolivier larocheNessuna valutazione finora

- Overview of NGV Cylinder Safety StandardsDocumento11 pagineOverview of NGV Cylinder Safety StandardsImam BuchairiNessuna valutazione finora

- Foundations For Transmission LineDocumento73 pagineFoundations For Transmission LineDato Azariani100% (2)

- Philips 32pfl2508 f8Documento118 paginePhilips 32pfl2508 f8Victor Hugo PiedrahitaNessuna valutazione finora

- MeasurementDocumento4 pagineMeasurementmuh_akbar2451Nessuna valutazione finora

- Tg0003en Ed01 ErmaDocumento16 pagineTg0003en Ed01 ErmaEduardo Pereira da SilvaNessuna valutazione finora

- Project On SamsungDocumento39 pagineProject On SamsungAbbas0% (1)

- 5 Things To Know About DB2 Native EncryptionDocumento4 pagine5 Things To Know About DB2 Native EncryptionAnup MukhopadhyayNessuna valutazione finora

- Calculation and Design of Critical Speed and Power AgitatorDocumento4 pagineCalculation and Design of Critical Speed and Power AgitatorFrendy RianNessuna valutazione finora

- LPTv4 Module 44 Penetration Testing Report AnalysisDocumento12 pagineLPTv4 Module 44 Penetration Testing Report AnalysisShanky Verma SoniNessuna valutazione finora