Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

T SB 0149 10

Caricato da

goombaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

T SB 0149 10

Caricato da

goombaCopyright:

Formati disponibili

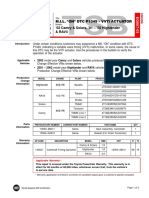

T-SB-0149-10 June 10, 2010

Clicking Noise from Transfer Case

Service

Category Drivetrain

Section Transfer/4wd/Awd Market USA

Applicability

YEAR(S) MODEL(S) ADDITIONAL INFORMATION

2010 Tacoma Drive Type(s): 4WD

VDS(s): LU4EN, MU4FN, PX4EN, UU4EN,

UX4EN

Introduction

Some 2010 model year 4WD Tacoma vehicles may exhibit a clicking or chirping noise from the

transfer case assembly when the vehicle is in motion. Production changes have been made to

eliminate this noise. Follow the procedure in the bulletin to correct this condition.

Production Change Information

This TSB applies to vehicles produced BEFORE the Production Change Effective VINs shown below.

MODEL PLANT ENGINE WHEEL BASE PRODUCTION CHANGE EFFECTIVE VIN*

TMMBC 3TMLU4EN#AM045486

Long

NUMMI 5TEUU4EN#AZ721895

1GR-FE

TMMBC 3TMMU4FN#AM018093

Tacoma Super Long

5TEMU4FN#AZ721735

NUMMI Short 5TEPX4EN#AZ721517

2TR-FE

Long 5TEUX4EN#AZ721943

* 11th digit in VIN indicates production plant: M = TMMBC, Z = NUMMI.

NOTE

This is a production-caused issue that will be present at low mileage. Vehicles that exhibit a similar

condition that began after 3,000 miles should NOT need this repair. Refer to the Repair Manual to

diagnose this issue on vehicles with greater than 3,000 miles and NO prior condition history for

transfer case noise.

2010 Toyota Motor Sales, USA Page 1 of 18

T-SB-0149-10 June 10, 2010 Page 2 of 18

Clicking Noise from Transfer Case

Repair Procedure Overview

Confirm noise is loudest from the rear transfer case output area.

Remove transfer case assembly.

Disassemble transfer case and R & R rear output shaft needle bearing.

Reassemble transfer case.

Install transfer case and confirm proper operation.

Warranty Information

OP CODE DESCRIPTION TIME OFP T1 T2

TC1006 R & R Transfer Case Needle Bearing 7.8 90364-37013 91 51

APPLICABLE WARRANTY

This repair is covered under the Toyota Powertrain Warranty. This warranty is in effect for 60

months or 60,000 miles, whichever occurs first, from the vehicles in-service date.

Warranty application is limited to occurrence of the specified condition described in this

bulletin.

Parts Information

PREVIOUS PART NUMBER CURRENT PART NUMBER PART NAME QTY

90364-37013 Same Bearing, Needle Roller 1

90311-41013 Same 1

Seal, Type T, Oil

90311-41007 Same 1

90312-23001 Same Seal, Type V, Oil 2

90179-22016 Same Lock Nut, Companion Flange* 2

* Non-reusable.

Required Tools & Equipment

REQUIRED MATERIAL QUANTITY

FIPG Sealant: Three Bond 1281, or equivalent As Needed

Sealant: Toyota Genuine Adhesive 1344, Three Bond 1344,

As Needed

Loctite 242, or Equivalent

Hypoid Gear Oil API GL-4 or GL-5, SAE 75W-90 As Needed

MP (Multi-Purpose) Grease As Needed

2010 Toyota Motor Sales, USA

T-SB-0149-10 June 10, 2010 Page 3 of 18

Clicking Noise from Transfer Case

Required Tools & Equipment (Continued)

REQUIRED EQUIPMENT SUPPLIER PART NUMBER QTY

JSPSM06606

ChassisEAR (or equivalent) ADE 1

(JS Products)

NOTE

A mechanics stethoscope or similar tool may be used in place of ChassisEAR.

ChassisEAR may be ordered by calling Approved Dealer Equipment (ADE) at 1-800-368-6787.

SPECIAL SERVICE TOOLS (SST) PART NUMBER QTY

Companion Flange Holding Tool* 09330-00021 1

Universal Puller Set B* 09950-40011

(Hanger 200, (09951-04020,

Slide Arm, 09952-04010,

Center Bolt 200, 09953-04030,

1

Arm 25, 09954-04010,

Claw No. 5, 09955-04051,

Attachment, 09957-04010,

Holder) 09958-04011)

09555-55010-01

Output Flange Remover 1

(or Equivalent)

09316-60011

Transmission Transfer Bearing Replacer Set

(09316-00011,

(Replacer Pipe, 1

09316-00071)

Replacer F)

(or Equivalent)

09554-22010

Differential Oil Seal Replacer 1

(or Equivalent)

Replacer Set 1* 09950-60010-01

1

(Replacer 32) (09951-00320)

Handle Set* 09950-70010-01

1

(Handle Assembly 100 4.25 inch) (09951-07100-01)

Steering Knuckle Tool* 09649-17010

* Essential SST.

NOTE

Additional SSTs may be ordered by calling 1-800-933-8335.

2010 Toyota Motor Sales, USA

T-SB-0149-10 June 10, 2010 Page 4 of 18

Clicking Noise from Transfer Case

Repair Procedure: Transfer Case Disassembly

1. Test drive the vehicle and confirm the condition.

2. Confirm noise is loudest from the rear output area Figure 1. .

of the transfer case using ChassisEAR or a

technicians stethoscope (or equivalent). (See

Figure 1.)

Is the noise loudest near the rear driveshaft

output area?

YES Go to step 3.

NO This TSB does NOT apply, continue

diagnosis to determine the cause of the

noise.

3. Remove the transfer case.

Refer to the Technical Information System (TIS), 2010 model year Tacoma Repair Manual:

Drivetrain Transfer/4wd/Awd VF2BM Transfer: Transfer Assembly: Removal

4. Remove the front and rear output shaft companion flange sub-assemblies.

A. Using a chisel and hammer, loosen the staked part of the output shaft lock nut.

B. Using the SST to hold the output shaft Figure 2.

companion flange, remove the output shaft

lock nut.

SST: 09330-00021

1 SST

2010 Toyota Motor Sales, USA

T-SB-0149-10 June 10, 2010 Page 5 of 18

Clicking Noise from Transfer Case

Repair Procedure: Transfer Case Disassembly (Continued)

C. Using the SST, remove the output shaft Figure 3.

companion flange sub-assembly (front side).

SST: 09950-40011 (09951-04020, 09952-04010,

09953-04030, 09954-04010, 09955-04051,

09957-04010, 09958-04011)

1 SST

5. Manual Transmission ONLY:

Remove the speedometer driven gear sub-assembly.

Remove the bolt and speedometer driven gear with sensor.

6. Remove the transfer case extension housing Figure 4. .

sub-assembly front by removing the 5 bolts.

HINT

If necessary, tap the extension housing

sub-assembly with a plastic hammer to

remove it.

7. Remove the transfer extension housing type T oil seal using a screwdriver and hammer.

8. Remove the transfer output shaft washer.

9. Remove the transfer speedometer drive gear.

Using a magnetic finger, remove the speedometer drive gear ball.

2010 Toyota Motor Sales, USA

T-SB-0149-10 June 10, 2010 Page 6 of 18

Clicking Noise from Transfer Case

Repair Procedure: Transfer Case Disassembly (Continued)

10. Remove the transfer rear case by removing the Figure 5. .

12 bolts and 2 brackets.

HINT

If necessary, tap the transfer rear case with a

plastic hammer to remove it.

11. Remove both shift detent springs and balls. Figure 6. .

Using a hexagon wrench (6 mm), remove the

2 shift detent ball spring plugs, 2 shift fork

compression springs, and 2 shift detent balls.

12. Remove the 2 snap rings from the shift forks. Figure 7. .

2010 Toyota Motor Sales, USA

T-SB-0149-10 June 10, 2010 Page 7 of 18

Clicking Noise from Transfer Case

Repair Procedure: Transfer Case Disassembly (Continued)

13. Remove the bolt and shift shaft stopper. Figure 8. .

14. Remove the rear output shaft snap ring using a Figure 9. .

snap ring expander.

2010 Toyota Motor Sales, USA

T-SB-0149-10 June 10, 2010 Page 8 of 18

Clicking Noise from Transfer Case

Repair Procedure: Transfer Case Disassembly (Continued)

15. Remove the output shaft assembly, driven Figure 10. .

sprocket assembly, drive chain, shift shaft, and

shift forks No. 1 and No. 2 as an assembly.

A. Mount the transfer rear case in a vise.

B. Using a plastic hammer, carefully tap the

transfer rear case and remove the rear output

shaft assembly, driven sprocket assembly,

front drive chain, shift shaft, and shift forks

No. 1 and No. 2.

C. Remove the driven sprocket assembly, front

drive chain, shift shaft, and shift forks No. 1

and No. 2 from the rear output shaft assembly.

NOTICE

Be careful NOT to lose the 2 interlock pins.

16. Inspect the drive sprocket thrust clearance.

Using a feeler gauge, measure the drive sprocket thrust clearance. Record measurement for

later use.

Standard clearance: 0.10 to 0.25 mm (0.0039 to 0.0098 in.)

Maximum clearance: 0.25 mm (0.0098 in.)

Figure 11.

1 Drive Sprocket Thrust Clearance

2010 Toyota Motor Sales, USA

T-SB-0149-10 June 10, 2010 Page 9 of 18

Clicking Noise from Transfer Case

Repair Procedure: Transfer Case Disassembly (Continued)

17. Using a press and the SST, remove the transfer Figure 12. .

output shaft rear radial ball bearing.

SST: 09555-55010

1 SST

18. Remove the drive sprocket and replace the rear Figure 13. .

output shaft needle bearing.

NOTE

Lubricate the bearing with new transfer case

oil before installation.

2010 Toyota Motor Sales, USA

T-SB-0149-10 June 10, 2010 Page 10 of 18

Clicking Noise from Transfer Case

Repair Procedure: Transfer Case Reassembly

1. Install the transfer output shaft rear radial ball Figure 14. .

bearing.

Using the SST and a press, install the output

shaft rear radial ball bearing with the output shaft

snap ring groove toward the rear. 1

2

SST: 09316-60011 (09316-00011, 09316-00071)

1 SST

2 Bearing

2010 Toyota Motor Sales, USA

T-SB-0149-10 June 10, 2010 Page 11 of 18

Clicking Noise from Transfer Case

Repair Procedure: Transfer Case Reassembly (Continued)

2. Inspect the drive sprocket thrust clearance.

Using a feeler gauge, measure the drive sprocket thrust clearance.

Standard clearance: 0.10 to 0.25 mm

(0.0039 to 0.0098 in.)

Maximum clearance: 0.25 mm (0.0098 in.)

NOTE

The clearance measurement should be similar to the measurement taken in step

16 of the Transfer Case Disassembly procedure.

If the clearance exceeds 0.25 mm (0.0098 in.), replace the drive sprocket sub-assembly.

Figure 15.

1 Drive Sprocket Thrust Clearance

2010 Toyota Motor Sales, USA

T-SB-0149-10 June 10, 2010 Page 12 of 18

Clicking Noise from Transfer Case

Repair Procedure: Transfer Case Reassembly (Continued)

3. Install the rear output shaft assembly, front drive chain, driven sprocket assembly, shift shaft, and

shift forks No. 1 and No. 2.

A. Install the driven sprocket assembly, front drive Figure 16.

chain, shift shaft, and shift forks No. 1 and

No. 2 onto the rear output shaft assembly.

3

NOTICE

Make sure that the shift forks No. 1 and

No. 2 are installed facing in the correct

1

direction. 2

HINT

Install shift interlock pins in shift forks No. 1

and No. 2, then slide the shift shaft in place.

1 Shift Fork No. 1

2 Shift Fork No. 2

3 Front

B. Mount the transfer rear case in a vise. Figure 17.

C. Install the rear output shaft assembly, front drive chain, driven sprocket assembly, shift shaft,

and shift forks No. 1 and No. 2 onto the transfer rear case.

NOTICE

Do NOT let the clutch sleeve or shifting key drop.

HINT

If necessary, heat the rear case to about 122 to 176F (50 to 80C).

2010 Toyota Motor Sales, USA

T-SB-0149-10 June 10, 2010 Page 13 of 18

Clicking Noise from Transfer Case

Repair Procedure: Transfer Case Reassembly (Continued)

4. Install the rear output shaft snap ring using a snap Figure 18. .

ring expander.

5. Install the shift shaft stopper with the bolt. Figure 19. .

6. Install the 2 shift shaft snap rings. Figure 20. .

2010 Toyota Motor Sales, USA

T-SB-0149-10 June 10, 2010 Page 14 of 18

Clicking Noise from Transfer Case

Repair Procedure: Transfer Case Reassembly (Continued)

7. Install the shift detent balls and springs. Figure 21. .

A. Install the 2 shift detent balls and 2

compression springs onto the shift forks No.

1 and No. 2.

B. Apply sealant to the shift detent ball spring

plug threads.

Sealant: Three Bond 1344, Loctite 242, or

equivalent

C. Using a hexagon wrench (6 mm), install the

2 shift detent ball spring plugs onto the shift

forks No. 1 and No. 2.

Torque: 18.6 N*m (190 kgf*cm, 14 ft*lbf)

8. Install the transfer extension housing type T oil Figure 22. .

seal.

A. Using the SST and a hammer, tap in a new

extension housing type T oil seal until its

surface is flush with the housing upper surface.

SST: 09554-22010 1

B. Coat the lip of the oil seal with MP grease.

1 SST

9. Install the transfer case oil seal. Figure 23. .

A. Coat the lip of a new oil seal with MP grease.

B. Using the SST and a hammer, tap in the oil

seal until its metal ring contacts the case.

SST: 09649-17010

09950-70010-01 (09951-07100-01)

1 SST

2010 Toyota Motor Sales, USA

T-SB-0149-10 June 10, 2010 Page 15 of 18

Clicking Noise from Transfer Case

Repair Procedure: Transfer Case Reassembly (Continued)

10. Install the transfer rear case.

A. Apply FIPG to the transfer rear case, as shown Figure 24.

in Figure 24.

FIPG: Three Bond 1281, or equivalent

1

NOTE

Be sure to thoroughly clean and dry the

transfer front and rear sealing surfaces

prior to applying FIPG.

1 FIPG

B. Engage the 2 brackets and install the transfer Figure 25.

rear case with the 12 bolts.

Torque: 28 N*m (286 kgf*cm, 21 ft*lbf)

2010 Toyota Motor Sales, USA

T-SB-0149-10 June 10, 2010 Page 16 of 18

Clicking Noise from Transfer Case

Repair Procedure: Transfer Case Reassembly (Continued)

11. Install the transfer extension housing sub-assembly front.

A. Apply FIPG to the extension housing Figure 26.

sub-assembly, as shown in Figure 26.

FIPG: Three Bond 1281, or equivalent 1

NOTE

Be sure to thoroughly clean and dry the

extension housing and transfer case

sealing surfaces prior to applying FIPG.

1 FIPG

B. Apply sealant to the bolt threads.

Sealant: Three Bond 1344,

Loctite 242, or equivalent

C. Install the extension housing sub-assembly Figure 27.

with the 5 bolts.

Torque: 12 N*m (122 kgf*cm, 9 ft*lbf)

12. Manual Transmission ONLY:

Install the speedometer driven gear w/ sensor with the bolt.

Torque: 11.5 N*m (117 kgf*cm, 8 ft*lbf)

2010 Toyota Motor Sales, USA

T-SB-0149-10 June 10, 2010 Page 17 of 18

Clicking Noise from Transfer Case

Repair Procedure: Transfer Case Reassembly (Continued)

13. Install the transfer output shaft companion flange Figure 28. .

oil seals.

Using the SST and a hammer, tap in new output

shaft companion flange oil seals (front and rear).

1

SST: 09950-60010-01 (09951-00320-01)

SST: 09950-70010-01 (09951-07100-01)

1 SST

14. Install the front and rear output shaft companion Figure 29. .

flange sub-assemblies.

1 2

A. Install the companion flange sub-assembly

(front side) onto the drive sprocket

sub-assembly.

B. Using the SST to hold the companion flange,

install a NEW companion flange lock nut.

SST: 09330-00021

Torque: 118 N*m (1203 kgf*cm, 87 ft*lbf)

C. Using a chisel and hammer, stake the

companion flange lock nut.

3

1 Front

2 Rear

3 SST

2010 Toyota Motor Sales, USA

T-SB-0149-10 June 10, 2010 Page 18 of 18

Clicking Noise from Transfer Case

Repair Procedure: Transfer Case Reassembly (Continued)

15. Install the transfer case in the vehicle.

Refer to TIS, 2010 model year Tacoma Repair Manual:

Drivetrain Transfer/4wd/Awd VF2BM Transfer: Transfer Assembly: Installation

16. Test drive the vehicle and confirm proper operation.

2010 Toyota Motor Sales, USA

Potrebbero piacerti anche

- Harsh 5-4 Downshift On Deceleration: T-SB-0033-08 April 15, 2008Documento3 pagineHarsh 5-4 Downshift On Deceleration: T-SB-0033-08 April 15, 2008hockeyman1584Nessuna valutazione finora

- T SB 0075 09Documento2 pagineT SB 0075 09goombaNessuna valutazione finora

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Da EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Nessuna valutazione finora

- T-SB-0088-10 Transmission Fluid Leak Through Drive Shaft YokeDocumento4 pagineT-SB-0088-10 Transmission Fluid Leak Through Drive Shaft YokeFrank Logan100% (1)

- GM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyDa EverandGM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyValutazione: 5 su 5 stelle5/5 (1)

- M.I.L. "ON" DTC P043E, P043F, P2401, P2402, and P2419: T-SB-0098-09 March 24, 2009Documento4 pagineM.I.L. "ON" DTC P043E, P043F, P2401, P2402, and P2419: T-SB-0098-09 March 24, 2009vanhostingwebNessuna valutazione finora

- T SB 0385 09Documento6 pagineT SB 0385 09goomba100% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDa EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNessuna valutazione finora

- sb0007t11 P0741Documento5 paginesb0007t11 P0741Huguito DiazNessuna valutazione finora

- T SB 0076 08Documento10 pagineT SB 0076 08goombaNessuna valutazione finora

- Defroster Air Volume: T-SB-0224-10 August 4, 2010Documento2 pagineDefroster Air Volume: T-SB-0224-10 August 4, 2010goombaNessuna valutazione finora

- Technical Service BULLETINDocumento5 pagineTechnical Service BULLETINdanieldario33Nessuna valutazione finora

- T SB 0106 10Documento3 pagineT SB 0106 10goombaNessuna valutazione finora

- Torque Converter Flex Lock-Up Shudder Toyota Rav4 2013 - 2015 RAV4Documento9 pagineTorque Converter Flex Lock-Up Shudder Toyota Rav4 2013 - 2015 RAV4boirxNessuna valutazione finora

- '02 Camry & Solara, '01 - '02 Highlander & RAV4 Technical Service BulletinDocumento3 pagine'02 Camry & Solara, '01 - '02 Highlander & RAV4 Technical Service BulletinLuis RoblesNessuna valutazione finora

- CK313 CVT P2757 Valve Body Replacement: T-SB-0150-16 Rev1 October 20, 2016Documento12 pagineCK313 CVT P2757 Valve Body Replacement: T-SB-0150-16 Rev1 October 20, 2016Gearauto Power50% (2)

- MC 10132100 9999Documento16 pagineMC 10132100 9999marranNessuna valutazione finora

- T SB 0326 08Documento4 pagineT SB 0326 08goomba100% (1)

- T SB 0132 08Documento9 pagineT SB 0132 08goombaNessuna valutazione finora

- P0440, P0441 OR P0446camry1 PDFDocumento5 pagineP0440, P0441 OR P0446camry1 PDFВИКТОР СЕВЕРNessuna valutazione finora

- Tra 026Documento7 pagineTra 026Trọng Nghĩa VõNessuna valutazione finora

- SNT Catalogue For Japanese Car and TruckDocumento745 pagineSNT Catalogue For Japanese Car and TruckMad NasirNessuna valutazione finora

- Intermitten No CrankDocumento5 pagineIntermitten No CrankIhrul FaumuiNessuna valutazione finora

- Purus FS ATFDocumento2 paginePurus FS ATFJorge ForeroNessuna valutazione finora

- Parts Manual: Rider-ScrubberDocumento138 pagineParts Manual: Rider-ScrubberАлексейNessuna valutazione finora

- Engine Oil Consumption TOYOTA 2AZ-FEDocumento24 pagineEngine Oil Consumption TOYOTA 2AZ-FEComercializadoraSesamoNessuna valutazione finora

- T SB 0142 08Documento9 pagineT SB 0142 08goombaNessuna valutazione finora

- T-SB-0316-17 Vacuum Pump Knocking NoiseDocumento3 pagineT-SB-0316-17 Vacuum Pump Knocking NoiseRhytham SoniNessuna valutazione finora

- Caution / Notice / HintDocumento15 pagineCaution / Notice / HintZouhair WahbiNessuna valutazione finora

- Dashboard Is250Documento3 pagineDashboard Is250ReaperNessuna valutazione finora

- SNT Autopart Oil Seal Catalog For MITSUBISHI FUSO PDFDocumento151 pagineSNT Autopart Oil Seal Catalog For MITSUBISHI FUSO PDFphilip connieNessuna valutazione finora

- SI0305 Lubricacion de MotoresDocumento4 pagineSI0305 Lubricacion de MotoresJose RamosNessuna valutazione finora

- Technical Service Bulletin: Combined TSB / Service Action: Forte (TD) Front Strut Noise Repair (Sa047)Documento4 pagineTechnical Service Bulletin: Combined TSB / Service Action: Forte (TD) Front Strut Noise Repair (Sa047)Trọng Nghĩa VõNessuna valutazione finora

- 4700.50 Mavors ATF ST-IDocumento3 pagine4700.50 Mavors ATF ST-ITaller MarioNessuna valutazione finora

- T SB 0274 09Documento5 pagineT SB 0274 09goombaNessuna valutazione finora

- Foreword: Toyota Motor CorporationDocumento32 pagineForeword: Toyota Motor CorporationSirine SurabayaNessuna valutazione finora

- SM-Toyota 5FG33-45, 5FD33-45, 5FGE35, 5FDE35 Forklift Service Repair Manual PDFDocumento559 pagineSM-Toyota 5FG33-45, 5FD33-45, 5FGE35, 5FDE35 Forklift Service Repair Manual PDFvadim vadim71% (7)

- Altima, Rogue, Sentra MIL "ON" W/DTC P0840 / P0845 / P0744 / P1777Documento2 pagineAltima, Rogue, Sentra MIL "ON" W/DTC P0840 / P0845 / P0744 / P1777Lalo Barajas GarciaNessuna valutazione finora

- TCM Calibration: Enhancement To Shifting Performance & SmoothnessDocumento6 pagineTCM Calibration: Enhancement To Shifting Performance & SmoothnessSyed Zeeshan ShahNessuna valutazione finora

- Titan Atf 4400: Fuchs Lubricants (Uk) PLCDocumento2 pagineTitan Atf 4400: Fuchs Lubricants (Uk) PLCAntonio FernandesNessuna valutazione finora

- M.I.L "ON" DTC P2195, P2197, P0138, P0158, P0171, P0174, P0031, or P0051Documento4 pagineM.I.L "ON" DTC P2195, P2197, P0138, P0158, P0171, P0174, P0031, or P0051a8yssNessuna valutazione finora

- 6-Speed Manual Clutch Release Bearing Squeak or Rattle NoiseDocumento9 pagine6-Speed Manual Clutch Release Bearing Squeak or Rattle NoiseinvisiblerNessuna valutazione finora

- Great Parts For Great Engines: Light/Medium Duty Diesel Engine KitsDocumento12 pagineGreat Parts For Great Engines: Light/Medium Duty Diesel Engine KitsTayfun SezişNessuna valutazione finora

- Tema 5. Motores de Corriente AlternaDocumento2 pagineTema 5. Motores de Corriente AlternaRichard ZapataNessuna valutazione finora

- TSB ToyotaDocumento2 pagineTSB ToyotaAlexis GarcíaNessuna valutazione finora

- Lo 10 3930 631 12Documento7 pagineLo 10 3930 631 12SteveNessuna valutazione finora

- 3UR-FE Accessory Drive Belt Tensioner: T-SB-0323-08 October 23, 2008Documento3 pagine3UR-FE Accessory Drive Belt Tensioner: T-SB-0323-08 October 23, 2008Ken LevinsNessuna valutazione finora

- Despiece Completo ThwaittesDocumento60 pagineDespiece Completo ThwaittesJuan Antonio Cano Diaz100% (1)

- X351 - JTB00349v2 - 5.0L Supercharger NoiseDocumento2 pagineX351 - JTB00349v2 - 5.0L Supercharger Noisebibibibibiib123123Nessuna valutazione finora

- PB Full Synthetic Multi Vehicle Automatic Transmission Fluid 20230609Documento2 paginePB Full Synthetic Multi Vehicle Automatic Transmission Fluid 20230609Dick BrosigNessuna valutazione finora

- Lexus CT200h (17") 2011-Alloy Wheel: Kit ContentsDocumento12 pagineLexus CT200h (17") 2011-Alloy Wheel: Kit ContentsFrancisco Javier MoraNessuna valutazione finora

- KZ1000 KZ1100Documento370 pagineKZ1000 KZ1100motomech100% (12)

- Yamaha XTZ750 Super Tenere Service ManualDocumento425 pagineYamaha XTZ750 Super Tenere Service ManualDhery Prieto Barrientos100% (2)

- Yamaha XTZ 750 ST Service ManualDocumento425 pagineYamaha XTZ 750 ST Service ManualAmigosek80% (5)

- 8M0084089 PICK UP ASSY + Fuel Quick Connector Mercury Mercruiser Outboard 2T 4T PDFDocumento16 pagine8M0084089 PICK UP ASSY + Fuel Quick Connector Mercury Mercruiser Outboard 2T 4T PDFMarine Parts ChinaNessuna valutazione finora

- WS ATF Level Adjustment For U660E/F & U760E/F Transmissions: Drivetrain Automatic Transmission/Transaxle USADocumento11 pagineWS ATF Level Adjustment For U660E/F & U760E/F Transmissions: Drivetrain Automatic Transmission/Transaxle USADiego GarciaNessuna valutazione finora

- Multi DCTF: Dual Clutch Transmission (DCT) Fluid Dry DCT and Wet DCT TechnosyntheseDocumento2 pagineMulti DCTF: Dual Clutch Transmission (DCT) Fluid Dry DCT and Wet DCT TechnosyntheseCarlos JuniorNessuna valutazione finora

- T SB 0141 10Documento9 pagineT SB 0141 10goombaNessuna valutazione finora

- 2013 Toyota Tacoma Model CodeDocumento1 pagina2013 Toyota Tacoma Model CodegoombaNessuna valutazione finora

- T-Cp-E0m-A510-D Toyota Spiral Cable RecallDocumento11 pagineT-Cp-E0m-A510-D Toyota Spiral Cable RecallgoombaNessuna valutazione finora

- T SB 0119 10Documento7 pagineT SB 0119 10goombaNessuna valutazione finora

- ExteriorDocumento2 pagineExteriorgoombaNessuna valutazione finora

- TS DMR 2011 WDocumento1 paginaTS DMR 2011 WgoombaNessuna valutazione finora

- Defroster Air Volume: T-SB-0224-10 August 4, 2010Documento2 pagineDefroster Air Volume: T-SB-0224-10 August 4, 2010goombaNessuna valutazione finora

- TSB - 0345 - 08Documento4 pagineTSB - 0345 - 08goombaNessuna valutazione finora

- MTS1000SDS Usa 06 Ed 00Documento109 pagineMTS1000SDS Usa 06 Ed 00goombaNessuna valutazione finora

- T SB 0373 09Documento4 pagineT SB 0373 09goombaNessuna valutazione finora

- T SB 0087 10Documento7 pagineT SB 0087 10goombaNessuna valutazione finora

- T SB 0106 10Documento3 pagineT SB 0106 10goombaNessuna valutazione finora

- 234-237 Accessory MeterDocumento4 pagine234-237 Accessory Metergoomba100% (3)

- Condensation Dripping From Around Dome Light Cover (Access Cab ONLY)Documento2 pagineCondensation Dripping From Around Dome Light Cover (Access Cab ONLY)goombaNessuna valutazione finora

- Tna Ops Map 2009Documento8 pagineTna Ops Map 2009goombaNessuna valutazione finora

- MIL "ON" DTC P0705: T-SB-0277-09 August 18, 2009Documento11 pagineMIL "ON" DTC P0705: T-SB-0277-09 August 18, 2009goomba100% (4)

- T SB 0072 09Documento18 pagineT SB 0072 09goomba100% (1)

- T SB 0274 09Documento5 pagineT SB 0274 09goombaNessuna valutazione finora

- TS El010 07Documento8 pagineTS El010 07goomba100% (2)

- T CP ZTHDocumento63 pagineT CP ZTHgoomba100% (2)

- T SB 0051 09Documento3 pagineT SB 0051 09goombaNessuna valutazione finora

- Rear Spring Harsh Ride: T-SB-0305-08 Rev1 September 30, 2008Documento16 pagineRear Spring Harsh Ride: T-SB-0305-08 Rev1 September 30, 2008goombaNessuna valutazione finora

- TS El009 07Documento3 pagineTS El009 07goomba100% (5)

- T SB 0142 08Documento9 pagineT SB 0142 08goombaNessuna valutazione finora