Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Canon Ir2525 Trouble Error Codes PDF

Caricato da

nafeesDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Canon Ir2525 Trouble Error Codes PDF

Caricato da

nafeesCopyright:

Formati disponibili

1

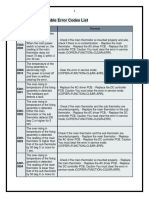

Canon iR2525 Trouble Error Codes List

Code

Description

Fixing temperature abnormal rise

The temperature detected by the

E000main thermistor does not rise to the

0001

specified value during startup

control.

Remedy

1.Go through the following to clear the error:

CLEAR > ENGIN > ERRCLR; and then turn OFF

and then ON the power. 2.Check connection of

the Connectors (Thermistor Connector and AC

Connector). 3.Replace the Fixing Main Thermistor

(Film Unit). 4.Replace the Fixing Assembly.

5.Replace the DC Controller PCB (PCB4).

1.Go through the following to clear the error:

CLEAR > ENGIN > ERRCLR; and then turn OFF

Fixing unit temperature rise detection and then ON the power. 2. Check connection of

E001- The reading of the main thermistor is the Connectors (Thermistor Connector and AC

0000 250 deg C or more continuously for Connector). 3. Replace the Fixing Main

200 msec.

Thermistor (Film Unit). 4. Replace the Fixing

Assembly. 5. Replace the DC Controller PCB

(PCB4).

Fixing unit temperature rise detection

E001- The hardware circuit detects

0001 overheating of the main or sub

thermistor for 200 msec.

1.Go through the following to clear the error:

CLEAR > ENGIN > ERRCLR; and then turn OFF

and then ON the power. 2. Replace the DC

Controller PCB (PCB4).

1.Go through the following to clear the error:

CLEAR > ENGIN > ERRCLR; and then turn OFF

Fixing unit temperature rise detection and then ON the power. 2. Check connection of

E001- The reading of the sub thermistor is the Connectors (Thermistor Connector and AC

0002 295 deg C or more continuously for Connector). 3. Replace the Fixing Main

200 msec.

Thermistor (Film Unit). 4. Replace the Fixing

Assembly. 5. Replace the DC Controller PCB

(PCB4).

Fixing unit temperature insufficient

rise

1.The reading of the main thermistor

is less than 115 deg C continuously

E002- for 400 msec 1.3 sec after it has

0000 indicated 100 deg C. 2.The reading

of the main thermistor is less than

150 deg C continuously for 400

msec 1.3 sec after it has indicated

140 deg C.

1.Go through the following to clear the error:

CLEAR > ENGIN > ERRCLR; and then turn OFF

and then ON the power. 2. Check connection of

the Connectors (Thermistor Connector and AC

Connector). 3. Replace the Fixing Main

Thermistor (Film Unit). 4. Replace the Fixing

Assembly. 5. Replace the DC Controller PCB

(PCB4).

Low fixing temperature detection

after standby

E003The reading of the main thermistor is

0000

less than 140 deg C continuously for

400 msec or more.

1. Go through the following to clear the error:

CLEAR > ENGIN > ERRCLR; and then turn OFF

and then ON the power. 2. Check connection of

the Connectors (Thermistor Connector and AC

Connector). 3. Replace the Fixing Main

Thermistor (Film Unit). 4. Replace the Fixing

Assembly. 5. Replace the DC Controller PCB

(PCB4).

Thermistor disconnection detection

error

E004When disconnection is detected with

0000

connector (J214) for 30 sec

continuously.

1. Check connection of the Connector (J214). 2.

Replace the Film Unit. 3. Replace the Fixing

Assembly. 4. Replace the DC Controller PCB

(PCB4).

Unstable rotation of the Main Motor

(M1)

1.Replace the Main Motor (M1). 2.Replace the DC

E010- Detection is executed every 100

0001 msec after the start of motor rotation; Controller PCB (PCB4).

however, the drive detection signal is

absent for 2 sec.

Unstable rotation of the Main Motor

(M1)

E010- During motor rotation, detection is

0002 executed every 100 msec; however,

the drive signal is absent 5 times in

sequence.

1.Replace the Main Motor (M1). 2.Replace the DC

Controller PCB (PCB4).

Unstable rotation of the Fixing Motor

(M2)

1.Replace the Fixing Motor (M2). 2.Replace the

E014- Detection is executed every 100

0001 msec after the start of motor rotation; DC Controller PCB (PCB4).

however, the drive detection signal is

absent for 2 sec.

Unstable rotation of the Fixing Motor

(M2)

1.Replace the Fixing Motor (M2). 2.Replace the

E014- During motor rotation, detection is

0002 executed every 100 msec; however, DC Controller PCB (PCB4).

the drive signal is absent 5 times in

sequence.

Error in Waste Toner Sensor (S17)

Warning when the sensor goes on

for 2000 consecutive sheets, and

E019error when the sensor goes on for

0000

100 consecutive sheets.

* Error occurs after the delivery if a

paper in passage exists.

1.Replace the Waste Toner Sensor (S17).

2.Replace the DC Controller PCB (PCB4).

The path between the sub hopper

and the developing assembly is

clogged with toner.

The Developing Assembly Toner

E020Sensor (TS1) detects the absence of

0000

toner,while the Sub Hopper Toner

Sensor (TS2) detects the presence

of toner. With the Developing

Cylinder Clutch (CL3) turned on, the

1.Check the rotation of hopper motor gear. (If

rotating, false detection by the sensor is doubted.

Feed the toner to the developing unit in service

mode: CLEAR>ENGIN>TNRINST.) 2.Replace the

Developing Assembly Toner Sensor (TS1).

3.Replace the Sub Hopper Toner Sensor (TS2).

4.Replace the DC Controller PCB (PCB4).

hopper feedscrew motor (M7) is

rotated for 1 sec intermittently 194

times; still, theDeveloping Assembly

Toner Sensor (TS1) does not detect

the presence of toner.

* Error occurs after the delivery if a

paper in passage exists.

The connector (J207) of Developing

Assembly Toner Sensor (TS1) is

disconnected.

The Developing Assembly Toner

E024Sensor (TS1) connection detection

0000

signal is absent for 100 msec 10

times in sequence. * Error occurs

after the delivery if a paper in

passage exists.

1.Check connection of the Connector (J207).

2.Replace the Developing Assembly Toner

Sensor (TS1). 3.Replace the DC Controller PCB

(PCB4).

The Developing Assembly Toner

Sensor (TS1) is disconnected

<At LOW SPEED> - The developing

assembly toner sensor (TS1) ON

counter is checked every 2.5

seconds, and the counter increments

1 count every 25 times when the

1.Check connection of the Connector (J207).

E024- sensor goes on, and 300 counts are

2.Correct the cable. 3.Replace the Developing

0001 reached.

Assembly Toner Sensor (TS1).

<At HIGH SPEED> - The developing

assembly toner sensor (TS1) ON

counter is checked every 1.5

seconds, and the counter increments

1 count every 15 times when the

sensor goes on, and 300 counts are

reached.

Code

Description

Remedy

The connector (J207) of Sub Hopper

Toner Sensor (TS2) is disconnected.

The Sub Hopper Toner Sensor (TS2)

E025connection detection signal is absent

0000

for 100 msec 10 times in sequence.

* Error occurs after the delivery if a

paper in passage exists.

1.Check connection of the Connector (J207).

2.Replace the Sub Hopper Toner Sensor

(TS2). 3.Replace the DC Controller PCB

(PCB4).

Failure of the Bottle Motor (M6)

The bottle motor (M6) is unlocked

E025when it goes on for 12 consecutive

0001

times at 0.1 sec. intervals.

* Error occurs after the delivery if a

1.Replace the Bottle Motor (M6). 2.Replace

the DC Controller PCB (PCB4).

paper in passage exists.

Failure of the Scanner Motor (M21)

The Scanner Motor (M21) speed lock

signal does not indicate a locked state

E110- a specific period of time after the

0001 Scanner Motor (M21) has been

started.

* The same condition is detected after

the error retry is performed.

1.Check the cable. 2.Replace the Laser

Scanner Unit. 3.Replace the DC Controller

PCB (PCB4).

Failure of the Scanner Motor (M21)

The speed lock signal indicates a

deviation 10 times in sequence at

E110intervals of 100 msec after the signal

0002

has indicated a locked state.

* The same condition is detected after

the error retry is performed.

1.Check the cable. 2.Replace the Laser

Scanner Unit. 3.Replace the DC Controller

PCB (PCB4).

Failure of the Scanner Motor (M21)

The scanner motor (M21) speed lock

signal does not indicate a locked state

for 6.5 sec. after a switchover is made 1.Check the cable. 2.Replace the Laser

E110from low to normal speed or for 8 sec. Scanner Unit. 3.Replace the DC Controller

0003

after a switchover is made from normal PCB (PCB4).

to low speed.

* The same condition is detected after

the error retry is performed.

Error in EEPROM access

20 retries failed after error occurred

E196during communication with EEPROM.

0000

* Error occurs after the delivery if a

paper in passage exists.

1.Replace the DC Controller PCB (PCB4).

Error in communication of Laser Driver

1.Check the cable. 2.Replace the Laser

E197- PCB (PCB14)

Scanner Unit. 3.Replace the DC Controller

0000 Communication error 1 with image

PCB (PCB4).

PCB

Error in communication of Laser Driver

1.Check the cable. 2.Replace the Laser

E197- PCB (PCB14)

Scanner Unit. 3.Replace the DC Controller

0001 Communication error 2 with image

PCB (PCB4).

PCB

There is an error in the detection of the

CIS home position.

1.The attempt to detect the home

E202- position fails when the CIS is moved

0000 forward.

2.The attempt to detect the home

position fails when the CIS is moved

back.

1.Disconnect and then connect the flexible

cable(Relay PCB (PCB2)-Main Controller PCB

(PCB1) 64pin). 2.Replace the flexible cable.

3.Replace the CIS HP sensor (S31). 4.Replace

the Scanner Motor (M31). 5.Replace the Relay

PCB (PCB2). 6.Replace the Main Controller

PCB (PCB1).

Error in controller communication

E240- The serial communication error such

0000 as parity error or overrun error is

constantly detected.

1.Check the Connectors. 2.Replace the DC

Controller PCB (PCB4).

Error in controller communication

E240- The serial communication error such

0001 as parity error or overrun error is

detected while printing.

1.Check the Connectors. 2.Replace the DC

Controller PCB (PCB4).

E246- Writing to the counter PCB (FRAM)

0000 failed

E247- Mismatched checksum between the

0000 Flash Rom and the FRAM

Error in Zero Cross

Zero Cross failed to be detected for

E261- 500ms or more while the relay was

0000 ON.

* The same condition is detected after

the error retry is performed.

1.Check the Connectors. 2.Replace the DC

Controller PCB (PCB4).

E350SOFT-ID PCB error

0000

ode

Description

Remedy

E354- Mismatched serial number for the

0000 SOFT-ID PCB

Mismatched serial number

E355between the SOFT-ID, the Flash

0000

Rom and the FRAM

E355System information error

0004

E355System information error

0005

Communication error

E500The communication with the host

0000

machine is interrupted.

1.Check the cable. 2.Replace the Finisher

Controller PCB (PCB1). 3.Replace the DC

Controller PCB.

EEPROM error

E505The checksum for the EEPROM

0001

data has an error.

1.Replace the Finisher Controller PCB (PCB1).

Shift Motor (M4) error

The shift roller does not leave the 1.Replace the Shift Roller HP Sensor (S2).

E520shift roller home position when the 2.Replace the Shift Motor (M4). 3.Replace the

0001

Shift Motor (M4) has been driven Finisher Controller PCB (PCB1).

for 1.2 seconds.

Shift Motor (M4) error

The shift roller does not return to

1.Replace the Shift Roller HP Sensor (S2).

E520the shift roller home position when 2.Replace the Shift Motor (M4). 3.Replace the

0002

the Shift Motor (M4) has been

Finisher Controller PCB (PCB1).

driven for 1.2 seconds.

Stapler Motor (M10) error

The stapler does not leave the

E531staple home position when the

8001

Staple Motor (M10) has been

driven for 0.5 sec.

1.Check the wiring between the Finisher Controller

PCB and Stapler. 2.Replace the Stapler. 3.Replace

the Finisher Controller PCB (PCB1).

Stapler Motor (M10) error

The stapler does not return to the

E531staple home position when the

8002

Stapler Motor (M10) has been

driven for 0.5 sec.

1.Check the wiring between the Finisher Controller

PCB and Stapler. 2.Replace the Stapler. 3.Replace

the Finisher Controller PCB (PCB1).

STP Move Motor (M1) error

The stapler does not leave the

E532stapler move home position when

0001

the STP Move Motor (M1) has

been driven for 0.25 sec.

1.Replace the Stapler Move HP Sensor (S10).

2.Check the wiring between the Finisher Controller

PCB and the STP Move Motor. 3.Check the stapler

shift base. 4.Replace the STP Move Motor (M1).

5.Replace the Finisher Controller PCB (PCB1).

STP Move Motor (M1) error

The stapler does not return to the

E532stapler move home position when

0002

the STP Move Motor (M1) has

been driven for 2.8 sec.

1.Replace the Stapler Move HP Sensor (S10).

2.Check the wiring between the Finisher Controller

PCB and the STP Move Motor. 3.Check the stapler

shift base. 4.Replace the STP Move Motor (M1).

5.Replace the Finisher Controller PCB (PCB1).

Tray Lift Motor (M11) time out

E540- error

0001 The stack tray does not move

within a specified time period.

1.Replace the Tray Lift Motor (M11). 2.Replace the

Finisher Controller PCB (PCB1).

Tray Lift Motor (M11) closing

detect switch error

E540The FG input cannot be detected

0005

when the Tray Lift Motor (M11)

has been driven for 0.1 second.

1.Replace the Stack Tray Clock Sensor (S13).

2.Replace the Tray Lift Motor (M11). 3.Replace the

Finisher Controller PCB (PCB1).

Additional Tray Lift Motor (M12)

E542- time out error

0001 The stack tray does not move

within a specified time period.

1.Replace the Additional Tray Lift Motor (M12).

2.Replace the Finisher Controller PCB (PCB1).

Code

Description

Remedy

E5420005

Additional Tray Lift Motor (M12) closing

detect switch error

The FG input cannot be detected when the

Additional Tray Lift Motor (M12) has been

driven for 0.1 second.

1.Replace the Additional Tray Clock

Sensor (S23). 2.Replace the Additional

Tray Lift Motor (M12). 3.Replace the

Finisher Controller PCB (PCB1).

E5670001

Shift Roller Release Motor (M5) error

The shift roller does not leave the shift

roller release home position when the Shift

Roller Release Motor (M5) has been

driven for 0.1 sec.

1.Replace the Shift Roller Release

Sensor (S3). 2.Replace the Shift Roller

Release Motor (M5). 3.Replace the

Finisher Controller PCB (PCB1).

E5670002

Shift Roller Release Motor (M5) error

The shift roller does not return to the shift

roller release home position when the Shift

Roller Release Motor (M5) has been

driven for 0.06 sec.

1.Replace the Shift Roller Release

Sensor (S3). 2.Replace the Shift Roller

Release Motor (M5). 3.Replace the

Finisher Controller PCB (PCB1).

E5710001

Gripper Open/Close Motor (M7) error

The gripper unit does not leave the gripper

unit home position when the Gripper

Open/Close Motor (M7) has been driven

for 0.25 seconds.

1.Replace the Grip Arm Sensor (S13).

2.Replace the Gripper Open/Close

Motor (M7). 3.Replace the Finisher

Controller PCB (PCB1).

E5710002

Gripper Open/Close Motor (M7) error

The gripper unit does not return to the

gripper unit home position when the

Gripper Open/Close Motor (M7) has been

driven for 0.15 seconds.

1.Replace the Grip Arm Sensor (S13).

2.Replace the Gripper Open/Close

Motor (M7). 3.Replace the Finisher

Controller PCB (PCB1).

E5750001

Gripper Unit Move Motor (M2) error

The gripper unit does not leave the gripper

unit home position when the Gripper Unit

Move Motor (M2) has been driven for 3.8

seconds.

1.Replace the Gripper Unit HP Sensor

(S7). 2.Replace the Gripper Unit Move

Motor (M2). 3.Replace the Finisher

Controller PCB (PCB1).

E5750002

Gripper Unit Move Motor (M2) error

The gripper unit does not return to the

gripper unit home position when the

Gripper Unit Move Motor (M2) has been

driven for 0.1 seconds.

1.Replace the Gripper Unit HP Sensor

(S7). 2.Replace the Gripper Unit Move

Motor (M2). 3.Replace the Finisher

Controller PCB (PCB1).

E6020001

The built-in SD card is not detected

E6021105

Access to the built-in SD card failed

E7110001

Error in UFDI communication

The communication system error (such as

reception timeout or checksum error)

occurred.

E7130000

Erroneous communication with finisher

1.Check the cable. 2.Replace the DC

The communication does not restart by the Controller PCB (PCB4). 3.Replace the

1.Check and Replace the cable.

2.Replace the DC Controller PCB

(PCB4). 3.Replace the Finisher

Controller PCB.

error retry after the communication failure

with the finisher.

Finisher Controller PCB.

E7160000

Erroneous communication with optional

cassette or 2-way unit

After the presence of a cassette pedestal

or a 2-way unit has been detected, the

communication fails to be normal for 5 sec.

1.Check the cable. 2.Replace the DC

Controller PCB (PCB4). 3.Replace the

Cassette Pedestal Driver PCB.

4.Replace the 2-way unit driver PCB.

E7160010

Failure of the communication with the 2way unit

When the communication with the 2-way

unit is faulty after detecting the connection

with the finisher.

1.Install the 2-way unit. 2.Check the

cable. 3.Replace the DC Controller PCB

(PCB4). 4.Replace the 2-way unit driver

PCB.

E7190000

Erroneous communication with New Card

Reader (serial communication)

E7190002

Erroneous communication with Coin

Vendor (serial communication)

Code

Description

Remedy

E736- Erroneous communication between

0000 CCU and controller.

E744- Mismatched version between the

0001 language file and the Bootable

E744Oversized language file in HDD

0002

E744- Mismatched version between the

0003 language file and the Bootable

E744Language file reading error

0004

Failure of the Power Supply Cooloing

Fan (FAN6)

When lock signal is detected for 5 sec

E804while the Power Supply Cooloing Fan

0000

(FAN6) is stopped.

* The same condition is detected after

the error retry is performed.

1.Disconnect and then connect the connector

(J205) on the DC Controller PCB (PCB4).

2.Replace the Power Supply Cooloing Fan

(FAN6). 3.Replace the DC Controller PCB

(PCB4).

Unstable rotation of the Power Supply

Cooloing Fan (FAN6)

When lock signal failed to be detected

E804for 5 sec while the Power Supply

0001

Cooloing Fan (FAN6) is driven.

* The same condition is detected after

the error retry is performed.

1.Disconnect and then connect the connector

(J205) on the DC Controller PCB (PCB4).

2.Replace the Power Supply Cooloing Fan

(FAN6). 3.Replace the DC Controller PCB

(PCB4).

Failure of the Exhaust Fan (Rear)

(FAN3)

When lock signal is detected for 5 sec

E805while the Exhaust Fan (Rear) (FAN3) is

0000

stopped.

* The same condition is detected after

the error retry is performed.

1.Disconnect and then connect the connector

(J206) on the DC Controller PCB (PCB4).

2.Replace the Exhaust Fan (Rear) (FAN3).

3.Replace the DC Controller PCB (PCB4).

Unstable rotation of the Exhaust Fan

(Rear) (FAN3) or Finisher Fan 1 (M8)

or Finisher Fan 2 (M9)

1.When lock signal failed to be

detected for 5 sec while the Exhaust

Fan (Rear) (FAN3) is driven.

E8052.When lock signal failed to be

0001

detected for 5 sec while the Finisher

Fan 1 (M8) is driven. 3.When lock

signal failed to be detected for 5 sec

while the Finisher Fan 2 (M9) is driven.

* The same condition is detected after

the error retry is performed.

1.Disconnect and then connect the connector

(J206) on the DC Controller PCB (PCB4).

2.Replace the Exhaust Fan (Rear) (FAN3).

3.Replace the Finisher Fan 1 (M8). 4.Replace

the Finisher Fan 2 (M9). 5.Replace the DC

Controller PCB (PCB4).

Failure of the Exhaust Fan (Front)

(FAN4)

When lock signal is detected for 5 sec

E805while the Exhaust Fan (Front) (FAN4)

0002

is stopped. * The same condition is

detected after the error retry is

performed.

1.Disconnect and then connect the connector

(J206) on the DC Controller PCB (PCB4).

2.Replace the Exhaust Fan (Front) (FAN4).

3.Replace the DC Controller PCB (PCB4).

Unstable rotation of the Exhaust Fan

(Front) (FAN4)

When lock signal failed to be detected

E805for 5 sec while the Exhaust Fan (Front)

0003

(FAN4) is driven.

* The same condition is detected after

the error retry is performed.

1.Disconnect and then connect the connector

(J206) on the DC Controller PCB (PCB4).

2.Replace the Exhaust Fan (Front) (FAN4).

3.Replace the DC Controller PCB (PCB4).

Code

Description

E736- Erroneous communication between

0000 CCU and controller.

E744- Mismatched version between the

0001 language file and the Bootable

E744Oversized language file in HDD

0002

E744- Mismatched version between the

0003 language file and the Bootable

Remedy

10

E744Language file reading error

0004

Failure of the Power Supply Cooloing

Fan (FAN6)

When lock signal is detected for 5 sec

E804while the Power Supply Cooloing Fan

0000

(FAN6) is stopped.

* The same condition is detected after

the error retry is performed.

1.Disconnect and then connect the connector

(J205) on the DC Controller PCB (PCB4).

2.Replace the Power Supply Cooloing Fan

(FAN6). 3.Replace the DC Controller PCB

(PCB4).

Unstable rotation of the Power Supply

Cooloing Fan (FAN6)

When lock signal failed to be detected

E804for 5 sec while the Power Supply

0001

Cooloing Fan (FAN6) is driven.

* The same condition is detected after

the error retry is performed.

1.Disconnect and then connect the connector

(J205) on the DC Controller PCB (PCB4).

2.Replace the Power Supply Cooloing Fan

(FAN6). 3.Replace the DC Controller PCB

(PCB4).

Failure of the Exhaust Fan (Rear)

(FAN3)

When lock signal is detected for 5 sec

E805while the Exhaust Fan (Rear) (FAN3)

0000

is stopped.

* The same condition is detected after

the error retry is performed.

1. Disconnect and then connect the connector

(J206) on the DC Controller PCB (PCB4).

2.Replace the Exhaust Fan (Rear) (FAN3).

3.Replace the DC Controller PCB (PCB4).

Unstable rotation of the Exhaust Fan

(Rear) (FAN3) or Finisher Fan 1 (M8)

or Finisher Fan 2 (M9)

1.When lock signal failed to be

detected for 5 sec while the Exhaust

Fan (Rear) (FAN3) is driven.

E805- 2.When lock signal failed to be

0001 detected for 5 sec while the Finisher

Fan 1 (M8) is driven. 3.When lock

signal failed to be detected for 5 sec

while the Finisher Fan 2 (M9) is

driven.

* The same condition is detected after

the error retry is performed.

1. Disconnect and then connect the connector

(J206) on the DC Controller PCB (PCB4). 2.

Replace the Exhaust Fan (Rear) (FAN3). 3.

Replace the Finisher Fan 1 (M8). 4. Replace

the Finisher Fan 2 (M9). 5. Replace the DC

Controller PCB (PCB4).

Failure of the Exhaust Fan (Front)

(FAN4)

When lock signal is detected for 5 sec

E805while the Exhaust Fan (Front) (FAN4)

0002

is stopped. * The same condition is

detected after the error retry is

performed.

1. Disconnect and then connect the connector

(J206) on the DC Controller PCB (PCB4). 2.

Replace the Exhaust Fan (Front) (FAN4). 3.

Replace the DC Controller PCB (PCB4).

Unstable rotation of the Exhaust Fan

E805(Front) (FAN4)

0003

When lock signal failed to be detected

1. Disconnect and then connect the connector

(J206) on the DC Controller PCB (PCB4). 2.

Replace the Exhaust Fan (Front) (FAN4). 3.

11

for 5 sec while the Exhaust Fan (Front) Replace the DC Controller PCB (PCB4).

(FAN4) is driven.

* The same condition is detected after

the error retry is performed.

Potrebbero piacerti anche

- Ir 6000 Code ListDocumento21 pagineIr 6000 Code ListAashish Chaudhari83% (12)

- Canon IR2535 Trouble Error CodesDocumento36 pagineCanon IR2535 Trouble Error Codesnafees100% (4)

- Ir3235 Service ManualDocumento33 pagineIr3235 Service ManualGirish KumarNessuna valutazione finora

- ERRor Code IR3245Documento7 pagineERRor Code IR3245JatmokoNessuna valutazione finora

- Error Code Ir3245 - Series-SmDocumento22 pagineError Code Ir3245 - Series-SmvikramNessuna valutazione finora

- Canon IR2530 Error CodesDocumento10 pagineCanon IR2530 Error CodesnafeesNessuna valutazione finora

- Canon Ir8070 Error Codes List PDFDocumento18 pagineCanon Ir8070 Error Codes List PDFGirish KumarNessuna valutazione finora

- Errorc Ir Advance 6055 6065 6075Documento77 pagineErrorc Ir Advance 6055 6065 6075nafeesNessuna valutazione finora

- Ir7095 Error CodesDocumento15 pagineIr7095 Error Codesnag85100% (5)

- Canon IR Advance 500 Trouble Error CodesDocumento30 pagineCanon IR Advance 500 Trouble Error CodesnafeesNessuna valutazione finora

- Canon IR Advance 4045 Trouble Error CodesDocumento94 pagineCanon IR Advance 4045 Trouble Error CodesnafeesNessuna valutazione finora

- Error Codes Canon Ir3300Documento5 pagineError Codes Canon Ir3300Ashraf Ali82% (11)

- Error Solution Canon Ir4570Documento14 pagineError Solution Canon Ir4570Abu Fatih Al Faruq50% (2)

- Ir 6570 Code ListDocumento22 pagineIr 6570 Code ListAashish Chaudhari90% (10)

- Canon Ir2200 Ir2800 Ir3300 Service ManualDocumento768 pagineCanon Ir2200 Ir2800 Ir3300 Service ManualRodrigo Carvajal100% (7)

- Error Code Copier CanonDocumento7 pagineError Code Copier Canonkaka_afie100% (12)

- Canon Ir7105 Error Code E000197 0000Documento2 pagineCanon Ir7105 Error Code E000197 0000ereslomaximo2014100% (4)

- IR 400 Error CodesDocumento4 pagineIR 400 Error Codeselan20250% (2)

- CANON Ir2200 - 2800 - 3300 SHDocumento352 pagineCANON Ir2200 - 2800 - 3300 SHjayant_gore100% (1)

- Canon IR2016 Error CodesDocumento7 pagineCanon IR2016 Error CodesnafeesNessuna valutazione finora

- Canon IR7095 Error CodesDocumento21 pagineCanon IR7095 Error CodesnafeesNessuna valutazione finora

- Xerox 7245 Fault Codes PDFDocumento28 pagineXerox 7245 Fault Codes PDFcataroxi88% (8)

- Canon Ir 7086 E 069Documento4 pagineCanon Ir 7086 E 069Abhi FaxNessuna valutazione finora

- CANON imageRUNNER 2520 Series Parts ListDocumento186 pagineCANON imageRUNNER 2520 Series Parts ListKārlis SpreslisNessuna valutazione finora

- Canon Error Codes: Brand Model Error Code Most Likely CauseDocumento8 pagineCanon Error Codes: Brand Model Error Code Most Likely CausegigypubsNessuna valutazione finora

- Ir4570 Service ManualDocumento1.008 pagineIr4570 Service ManualMarco MenaNessuna valutazione finora

- Advance Image Runner 6075Documento96 pagineAdvance Image Runner 6075vishwajitNessuna valutazione finora

- General Timing Chart / General Circuit Diagram: Ir5075/5065/5055 SeriesDocumento38 pagineGeneral Timing Chart / General Circuit Diagram: Ir5075/5065/5055 SeriesAnonymous T8I5K1nNh100% (2)

- IR3225 3235 3245 - General Circuit DiagramDocumento20 pagineIR3225 3235 3245 - General Circuit Diagramcopyhere78% (9)

- Canon IR3225 Trouble Error CodesDocumento30 pagineCanon IR3225 Trouble Error Codesnafees80% (10)

- Error Code For Canon IR4045 AdvanceDocumento30 pagineError Code For Canon IR4045 AdvanceRopsonNessuna valutazione finora

- Canon IR Advance 6075 Error Codes ListDocumento63 pagineCanon IR Advance 6075 Error Codes ListZhonny Rongsok Kendal60% (5)

- Daftar Kode Kesalahan Canon IR5000 IR6000Documento14 pagineDaftar Kode Kesalahan Canon IR5000 IR6000M MiftakhNessuna valutazione finora

- Canon IR3245 Error CodesDocumento31 pagineCanon IR3245 Error Codesnafees80% (10)

- Daftar Kode Kesalahan Canon IR5000 IR6000Documento26 pagineDaftar Kode Kesalahan Canon IR5000 IR6000desy zulfiarniNessuna valutazione finora

- Canon IR8070 Error Codes ListDocumento18 pagineCanon IR8070 Error Codes ListGirish Kumar100% (1)

- Canon IR2200 Trouble Error CodesDocumento29 pagineCanon IR2200 Trouble Error CodesnafeesNessuna valutazione finora

- Error Code: CANON Ir105 REV.0 JULY 2001Documento30 pagineError Code: CANON Ir105 REV.0 JULY 2001Willian S.Nessuna valutazione finora

- Canon IR4570 Trouble Error CodesDocumento22 pagineCanon IR4570 Trouble Error Codesnafees100% (3)

- Canon 2545i Error CodesDocumento4 pagineCanon 2545i Error CodesMoffat SavieraNessuna valutazione finora

- Canon IR9070 Error CodesDocumento19 pagineCanon IR9070 Error CodesnafeesNessuna valutazione finora

- Canon IRC1020 Trouble Error CodesDocumento9 pagineCanon IRC1020 Trouble Error CodesnafeesNessuna valutazione finora

- SELF: 3. Testcommandsusedfor The Self Diag and Cancel 1. GeneralDocumento13 pagineSELF: 3. Testcommandsusedfor The Self Diag and Cancel 1. GeneralredaNessuna valutazione finora

- KM1505 C-Errors PDFDocumento4 pagineKM1505 C-Errors PDFFrancisco LópezNessuna valutazione finora

- Canon Ir3225 Error Codes: Code DescriptionDocumento46 pagineCanon Ir3225 Error Codes: Code DescriptionnishaNessuna valutazione finora

- Error CodeDocumento99 pagineError CodeRDN Artha SentosaNessuna valutazione finora

- Canon Ir1230 Trouble Error Codes PDFDocumento4 pagineCanon Ir1230 Trouble Error Codes PDFnafeesNessuna valutazione finora

- Panasonic TroubleshootingDocumento89 paginePanasonic Troubleshootingjmarrero_3Nessuna valutazione finora

- Canon Ir Advance C5030 Trouble Error Codes PDFDocumento73 pagineCanon Ir Advance C5030 Trouble Error Codes PDFNafeesAhmad100% (1)

- Canon IR Advance C5030 Trouble Error CodesDocumento73 pagineCanon IR Advance C5030 Trouble Error Codesnafees100% (8)

- Ir 3300 Code ListDocumento44 pagineIr 3300 Code ListAashish Chaudhari84% (44)

- TMP - 11281-Error Codes - Canon - Ir3300 - Page 11424020151Documento3 pagineTMP - 11281-Error Codes - Canon - Ir3300 - Page 11424020151nichoNessuna valutazione finora

- Error Code 3030 CanonDocumento9 pagineError Code 3030 CanonsubramaniansonyNessuna valutazione finora

- Canon IR105 Trouble Error CodesDocumento32 pagineCanon IR105 Trouble Error Codesnafees0% (2)

- Canon IR5000 ErrorsDocumento3 pagineCanon IR5000 ErrorsYarnellePinedaAlvaroNessuna valutazione finora

- Technical Manual: DVD PlayerDocumento48 pagineTechnical Manual: DVD PlayeravrelecNessuna valutazione finora

- Canon IR 5075 Error-CodeDocumento9 pagineCanon IR 5075 Error-Codeslavko688% (8)

- Canon IR2022 Error CodesDocumento7 pagineCanon IR2022 Error Codesnafees100% (1)

- Kode Eror Mesin Canon 5075Documento16 pagineKode Eror Mesin Canon 5075donirahmat100% (2)

- Canon IR2030 Trouble Error CodesDocumento7 pagineCanon IR2030 Trouble Error CodesnafeesNessuna valutazione finora

- How Fat Cells WorkDocumento5 pagineHow Fat Cells WorknafeesNessuna valutazione finora

- How Helicopters WorkDocumento11 pagineHow Helicopters WorknafeesNessuna valutazione finora

- How The Digestive System WorksDocumento9 pagineHow The Digestive System WorksnafeesNessuna valutazione finora

- CanonDocumento747 pagineCanonnafeesNessuna valutazione finora

- Canon IR4570 Trouble Error CodesDocumento22 pagineCanon IR4570 Trouble Error Codesnafees100% (3)

- Ricoh Aficio MPC4000 Trouble Error CodesDocumento25 pagineRicoh Aficio MPC4000 Trouble Error CodesnafeesNessuna valutazione finora

- How The Sun WorksDocumento27 pagineHow The Sun WorksnafeesNessuna valutazione finora

- Konica-Minolta Bizhub 250 Trouble Error CodesDocumento11 pagineKonica-Minolta Bizhub 250 Trouble Error Codesnafees100% (1)

- How Circuit Breakers Work 9Documento4 pagineHow Circuit Breakers Work 9nafeesNessuna valutazione finora

- Konica-Minolta Bizhub 423 Error CodesDocumento26 pagineKonica-Minolta Bizhub 423 Error Codesnafees0% (1)

- Ricoh Aficio MPC6501 Trouble Error CodesDocumento55 pagineRicoh Aficio MPC6501 Trouble Error Codesnafees100% (1)

- Charging FaultsDocumento1 paginaCharging FaultsnafeesNessuna valutazione finora

- How Food WorksDocumento19 pagineHow Food WorksnafeesNessuna valutazione finora

- How To Install Android 4Documento39 pagineHow To Install Android 4nafeesNessuna valutazione finora

- Ricoh Aficio MPC2030 Trouble Error CodesDocumento19 pagineRicoh Aficio MPC2030 Trouble Error CodesnafeesNessuna valutazione finora

- Ricoh Aficio MPC3000 Trouble Error CodesDocumento23 pagineRicoh Aficio MPC3000 Trouble Error CodesnafeesNessuna valutazione finora

- Ricoh Aficio MPC2500 Trouble Error CodesDocumento23 pagineRicoh Aficio MPC2500 Trouble Error CodesnafeesNessuna valutazione finora

- Ricoh Alicia MPC3503SP Trouble Error CodesDocumento46 pagineRicoh Alicia MPC3503SP Trouble Error CodesnafeesNessuna valutazione finora

- Ricoh Aficio MP7000 Trouble Error CodesDocumento35 pagineRicoh Aficio MP7000 Trouble Error CodesnafeesNessuna valutazione finora

- Ricoh Aficio MPC3002 Trouble Error CodesDocumento27 pagineRicoh Aficio MPC3002 Trouble Error CodesnafeesNessuna valutazione finora

- Canon IR Advance C5030 Trouble Error CodesDocumento73 pagineCanon IR Advance C5030 Trouble Error Codesnafees100% (8)

- Ricoh Aficio MP6500SP Trouble Error CodesDocumento48 pagineRicoh Aficio MP6500SP Trouble Error CodesnafeesNessuna valutazione finora

- Canon IR Advance C2020 Trouble Error CodesDocumento62 pagineCanon IR Advance C2020 Trouble Error Codesnafees50% (2)

- Ricoh Aficio MP4500 Trouble Error CodesDocumento19 pagineRicoh Aficio MP4500 Trouble Error Codesnafees100% (1)

- Ricoh Aficio MP4002 Trouble Error CodesDocumento26 pagineRicoh Aficio MP4002 Trouble Error Codesnafees100% (1)

- Canon IR Advance C2025 Trouble Error Codes - 1Documento73 pagineCanon IR Advance C2025 Trouble Error Codes - 1nafeesNessuna valutazione finora

- Ricoh Aficio MPC2000 Trouble Error CodesDocumento20 pagineRicoh Aficio MPC2000 Trouble Error Codesnafees100% (1)

- Canon IR105 Trouble Error CodesDocumento32 pagineCanon IR105 Trouble Error Codesnafees0% (2)

- Canon IR Advance 6265 Error CodesDocumento56 pagineCanon IR Advance 6265 Error CodesnafeesNessuna valutazione finora

- Lab 1: Accessing Cloudera Distribution For Hadoop (Vmware & Cluster Environment)Documento13 pagineLab 1: Accessing Cloudera Distribution For Hadoop (Vmware & Cluster Environment)Ahmad HazzeemNessuna valutazione finora

- Final Report 3D Chocolate PrintingDocumento20 pagineFinal Report 3D Chocolate PrintingPrathamesh PatilNessuna valutazione finora

- Social Media Brings Good Than HarmDocumento2 pagineSocial Media Brings Good Than HarmSophia Micaella HermosoNessuna valutazione finora

- Ripple Curve Background PowerPoint TemplatesDocumento21 pagineRipple Curve Background PowerPoint TemplatesRamadhan AkbarNessuna valutazione finora

- Sensor Based Automated Irrigation System With Iot A Technical ReviewDocumento4 pagineSensor Based Automated Irrigation System With Iot A Technical ReviewJhanina CapicioNessuna valutazione finora

- LabUMat 2 & UriSed 3PRODocumento2 pagineLabUMat 2 & UriSed 3PROAurobindo EnterprisesNessuna valutazione finora

- Electrical Diagram Mac Series Lifting Column 1 2 A ANSIDocumento1 paginaElectrical Diagram Mac Series Lifting Column 1 2 A ANSICAD CAMNessuna valutazione finora

- Roland SPD-SX Owner's ManualDocumento80 pagineRoland SPD-SX Owner's ManualAnonymous cdQSIU03AQNessuna valutazione finora

- Distributed Systems Midterm ReviewDocumento12 pagineDistributed Systems Midterm Reviewhussiandavid26Nessuna valutazione finora

- Clinch Nut HandbookDocumento16 pagineClinch Nut HandbookRico MalibiranNessuna valutazione finora

- Computing Midterm Exams B6Documento2 pagineComputing Midterm Exams B6kobby norteyNessuna valutazione finora

- East West University: Lab Report - 02Documento10 pagineEast West University: Lab Report - 02Raisa Trade InternationalNessuna valutazione finora

- Chapter 2 - Digital Switching Systems (EEEg8254)Documento58 pagineChapter 2 - Digital Switching Systems (EEEg8254)Barnabas Fantahun100% (1)

- Cse320 Srs Awasthi FinalDocumento21 pagineCse320 Srs Awasthi Finalaggressiveboy.sharmaNessuna valutazione finora

- HSP InstructionDocumento4 pagineHSP Instruction1989vasu.pNessuna valutazione finora

- A Known Plaintext Attack On The PKZIP Stream CipherDocumento10 pagineA Known Plaintext Attack On The PKZIP Stream Cipherrobson2015Nessuna valutazione finora

- Security Automation in Information Technology: Sikender Mohsienuddin Mohammad, Surya LakshmisriDocumento5 pagineSecurity Automation in Information Technology: Sikender Mohsienuddin Mohammad, Surya LakshmisriramramNessuna valutazione finora

- EASA - SIB - 2018 - 19 - FlySmart+ Applications For Ipad - Change of Runway Entry Not Taken Into Account in Take-Off ComputationDocumento2 pagineEASA - SIB - 2018 - 19 - FlySmart+ Applications For Ipad - Change of Runway Entry Not Taken Into Account in Take-Off ComputationDimitris SarmasNessuna valutazione finora

- Optimize Your Access Risk Analysis Reports For SAP S/4HANA and SAP FioriDocumento42 pagineOptimize Your Access Risk Analysis Reports For SAP S/4HANA and SAP Fiorianbuka7Nessuna valutazione finora

- MD X2500 DatasheetDocumento6 pagineMD X2500 DatasheetJULIO LOPEZNessuna valutazione finora

- ENC OIC Mapping KS1Documento2 pagineENC OIC Mapping KS1Aliyah LuharNessuna valutazione finora

- Tostadora R20Documento30 pagineTostadora R20Abel Antonio Calderon HernandezNessuna valutazione finora

- 5000H Parts Book: Version 5 For Serial Numbers 2H-282-1455 To 2H-400Documento609 pagine5000H Parts Book: Version 5 For Serial Numbers 2H-282-1455 To 2H-400Beto José Roberto De Castro SantosNessuna valutazione finora

- OptiX OSN 9800 Operating and Maintaining Your Network (For 2nd Line Engineer) V100R005C00 - 01 20181030134623Documento21 pagineOptiX OSN 9800 Operating and Maintaining Your Network (For 2nd Line Engineer) V100R005C00 - 01 20181030134623sam samNessuna valutazione finora

- Final Exam Summit 1a PDF: Download HereDocumento4 pagineFinal Exam Summit 1a PDF: Download Heretiven garrix100% (1)

- Module 3 - Configure Computer Systems and NetworksDocumento82 pagineModule 3 - Configure Computer Systems and NetworksSheina VillarozaNessuna valutazione finora

- 9210 Commissioning ManualDocumento4 pagine9210 Commissioning ManualHarry Chan Putra. SP. MTCNA. MTCTCE. MTCRENessuna valutazione finora

- GBXX Programming Training: Augsburg (24Th and 25Th October 2006)Documento96 pagineGBXX Programming Training: Augsburg (24Th and 25Th October 2006)Edgar WamundilaNessuna valutazione finora

- Corrective Maintenance Report v1.1Documento10 pagineCorrective Maintenance Report v1.1babul1985Nessuna valutazione finora

- Access Control ProposalDocumento9 pagineAccess Control Proposalalenk91Nessuna valutazione finora