Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pad Eye Failure

Caricato da

malawanyDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pad Eye Failure

Caricato da

malawanyCopyright:

Formati disponibili

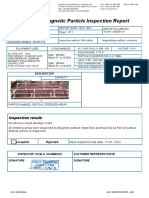

Safety Alert

From the International Association of Drilling Contractors

ALERT 09 02

DROPPED OBJECT PAD EYES FAIL CAUSING NEAR MISS

WHAT HAPPENED:

When lifting a newly constructed mud cleaning equipment skid for installation on a mud tank, three of the four

lifting lug pad eyes failed at the welds located on the top of the Mud Cleaning System Lifting Frame. The skid

fell to the ground. The shaker skid was approximately two feet off the ground when the welds failed.

Fortunately, the crew members were using tag lines on the equipment and were at a safe distance from the

lift. No injuries sustained and no equipment damaged.

WHAT CAUSED IT:

Lack of quality control during fabrication permitted a substandard product to enter into service.

Weld penetration on the pad eyes was found to be unacceptable by standard welding specifications.

After construction of the skid, inspection of the welds was not thorough nor complete.

CORRECTIVE ACTIONS: To address this incident, this company did the following:

Instructed construction supervisors that all pad eyes used for lifting purposes need to be stamped with a

unique identity mark or number to enable tracing of the pad eye to the inspection and certification

documents.

Personnel in charge of reconstruction or construction of skids were instructed to contract a third party

qualified welding inspector to visually inspect and verify that all welding of lifting lugs and pad eyes meet

the quality standards for welding.

The company revised engineering and drafting procedures for drawings to include the wording that all

critical welds on lifting lugs and base plates as well as other critical welds associated with lift and support

structures be inspected by a qualified welding inspector for cracks, fatigue, penetration, etc.

The company instructed quality control personnel that the Quality Control System needs to be improved

and closely monitored.

The company instructed company personnel in charge of rig construction projects to develop a Lifting

Equipment Register and use it to log all pad eyes on the rig as they are welded, inspected and

documented prior to leaving the rig up facility.

The Corrective Actions stated in this alert are one companys attempts to address the incident,

and do not necessarily reflect the position of IADC or the IADC HSE Committee.

This material is presented for information purposes only. Managers & Supervisors should

evaluate this information to determine if it can be applied to their own situations and practices

Copyright 2008 International Association of Drilling Contractors All rights reserved.

Issued January 2009

Potrebbero piacerti anche

- Ted Blanton Na CB PresentationDocumento15 pagineTed Blanton Na CB PresentationmalawanyNessuna valutazione finora

- Method Statement - Erection of Main TrussDocumento2 pagineMethod Statement - Erection of Main TrussAli WaqasNessuna valutazione finora

- ScreenwritingDocumento432 pagineScreenwritingkunalt09100% (4)

- Overhead Crane Inspection ProcedureDocumento2 pagineOverhead Crane Inspection ProcedureEphraim John Tangelon AquinoNessuna valutazione finora

- Vc-Api 650 PDFDocumento6 pagineVc-Api 650 PDFShinta ShowiantariNessuna valutazione finora

- LOLER Guidance For Mgr.Documento16 pagineLOLER Guidance For Mgr.Cris SuyamNessuna valutazione finora

- Lifting Lug Design-MrDocumento5 pagineLifting Lug Design-MrMiguelRagasNessuna valutazione finora

- Cytogenectics Reading ListDocumento2 pagineCytogenectics Reading ListHassan GillNessuna valutazione finora

- Failure of Fabricated Test Blind FlangeDocumento6 pagineFailure of Fabricated Test Blind FlangeHamdan Rifai100% (1)

- Scaffold Classes and Duties CalsDocumento20 pagineScaffold Classes and Duties CalsMohideenAlhaseb100% (1)

- TubestarDocumento29 pagineTubestarPernando Saga100% (1)

- More Med Surg Practice QuestionsDocumento14 pagineMore Med Surg Practice QuestionsmisscoombsNessuna valutazione finora

- Mpi Pipe Rack PR 03-1.Documento1 paginaMpi Pipe Rack PR 03-1.Khalil ChabbouhNessuna valutazione finora

- HSE Alert 07-16 Damage To Drilling Mast IncidentDocumento1 paginaHSE Alert 07-16 Damage To Drilling Mast IncidentSajid HussainNessuna valutazione finora

- Calculation Sheet: Design of PadeyeDocumento7 pagineCalculation Sheet: Design of PadeyeIkade SuartanaNessuna valutazione finora

- Man Basket Profile and Specification Details: Schedules of Man BasketsDocumento8 pagineMan Basket Profile and Specification Details: Schedules of Man Basketssandip khardeNessuna valutazione finora

- L6.25 Scaffold Check List 40 FTDocumento1 paginaL6.25 Scaffold Check List 40 FTAbhiyan Anala ArvindNessuna valutazione finora

- Sec.2-61 Sky Climbers & Suspended Power PlatformsDocumento6 pagineSec.2-61 Sky Climbers & Suspended Power Platformsbravo2uniform2736Nessuna valutazione finora

- Tank Builders ScaffoldDocumento40 pagineTank Builders ScaffoldEhab SaadNessuna valutazione finora

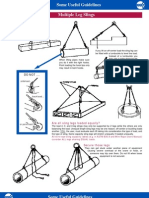

- Sling: Rigging DepartmentDocumento1 paginaSling: Rigging DepartmentmalawanyNessuna valutazione finora

- Sling: Rigging DepartmentDocumento1 paginaSling: Rigging DepartmentmalawanyNessuna valutazione finora

- Daily Erection Progress Report-15!07!2018Documento2 pagineDaily Erection Progress Report-15!07!2018SAIDNessuna valutazione finora

- Safety Alert Space HeatersDocumento2 pagineSafety Alert Space HeatersRamadan KareemNessuna valutazione finora

- SOP 03 SP Painting Procedure PDFDocumento5 pagineSOP 03 SP Painting Procedure PDFBalaji Guru100% (2)

- Douglas Frayne Sargonic and Gutian Periods, 2334-2113 BCDocumento182 pagineDouglas Frayne Sargonic and Gutian Periods, 2334-2113 BClibrary364100% (3)

- Industries in 2023Documento36 pagineIndustries in 2023malawany100% (1)

- Sop Iii-300 R00Documento13 pagineSop Iii-300 R00Bepdj100% (1)

- FrankensteinDocumento24 pagineFrankensteinLisa WardNessuna valutazione finora

- Case Study No. 11 - Hydroelectric Power Plant in The PhilippinesDocumento26 pagineCase Study No. 11 - Hydroelectric Power Plant in The PhilippinespicefeatiNessuna valutazione finora

- Ms Clamshell Operating ManualDocumento28 pagineMs Clamshell Operating ManualEhsan50% (2)

- Latihan Soal Recount Text HotsDocumento3 pagineLatihan Soal Recount Text HotsDevinta ArdyNessuna valutazione finora

- ICAO Environmental Report 2016Documento250 pagineICAO Environmental Report 2016vigneshkumar rajanNessuna valutazione finora

- Avanto Magnet System Error MessagesDocumento21 pagineAvanto Magnet System Error MessagesMuhammad Ahmad75% (4)

- RA Elevator ManualDocumento8 pagineRA Elevator ManualBahman MatouriNessuna valutazione finora

- WPS Format For Asme Ix - Wps - Fcaw GmawDocumento1 paginaWPS Format For Asme Ix - Wps - Fcaw GmawThe Welding Inspections CommunityNessuna valutazione finora

- Crane 3612 LoadChartDocumento6 pagineCrane 3612 LoadChartZura RamliNessuna valutazione finora

- WPS FGPDocumento1 paginaWPS FGPShabbir HussainNessuna valutazione finora

- SDLINC NDT Level II Certification CourseDocumento8 pagineSDLINC NDT Level II Certification CourseNkwor AndersonNessuna valutazione finora

- PT Bhaita Wire Rope Inspection ProcedureDocumento4 paginePT Bhaita Wire Rope Inspection ProcedureSugianto TanNessuna valutazione finora

- Industrial Rope Access ChecklistDocumento12 pagineIndustrial Rope Access ChecklistPaulNessuna valutazione finora

- Memo To: Memo No: From: Date: Prep. By: Copied ToDocumento3 pagineMemo To: Memo No: From: Date: Prep. By: Copied Tojogi oscar sinagaNessuna valutazione finora

- Scaffold Checklist LocationDocumento2 pagineScaffold Checklist LocationMikael NaqibNessuna valutazione finora

- st44 2 PDFDocumento1 paginast44 2 PDFAraby Gamal GamalNessuna valutazione finora

- Method of Statement PDFDocumento7 pagineMethod of Statement PDFSakib AyubNessuna valutazione finora

- CHG 55B2Documento1 paginaCHG 55B2Nhien ManNessuna valutazione finora

- Report of Ultrasonic Flaw Detection Test of Weld JointDocumento1 paginaReport of Ultrasonic Flaw Detection Test of Weld Jointkevin desai100% (1)

- Chain Block & Puller Inspection ChecklistDocumento1 paginaChain Block & Puller Inspection Checklistibrahim100% (1)

- Eye Bolt Inspection Report: Last of ExaminationDocumento7 pagineEye Bolt Inspection Report: Last of ExaminationRonniNessuna valutazione finora

- EN 12079-1:2006 (E) Forklift Pocket DimensionsDocumento3 pagineEN 12079-1:2006 (E) Forklift Pocket Dimensionsdsn_sarmaNessuna valutazione finora

- Steel Section Fire Resistant-HpA ValueDocumento14 pagineSteel Section Fire Resistant-HpA Valuekingson719Nessuna valutazione finora

- Wps PQRDocumento6 pagineWps PQRneelson_099Nessuna valutazione finora

- Securing Straps & RatchetsDocumento2 pagineSecuring Straps & RatchetsKhurram S. MuzammilNessuna valutazione finora

- Universal Beams PDFDocumento2 pagineUniversal Beams PDFbrodieNessuna valutazione finora

- Techsonic EZ III Rev 4 092010 PDFDocumento70 pagineTechsonic EZ III Rev 4 092010 PDFandresgomez10Nessuna valutazione finora

- Structural Design Calculation Structural Design CalculationDocumento107 pagineStructural Design Calculation Structural Design CalculationQadeer AhmedNessuna valutazione finora

- Material Safety Data Sheet: Poly Cell AdhesiveDocumento8 pagineMaterial Safety Data Sheet: Poly Cell AdhesiveMinh BảoNessuna valutazione finora

- Gantry Crane Rail Inspection Form NAVFACDocumento6 pagineGantry Crane Rail Inspection Form NAVFACTracy JohnsonNessuna valutazione finora

- MS For Fabrication of Above-Ground Storage TankDocumento8 pagineMS For Fabrication of Above-Ground Storage Tankdadz mingiNessuna valutazione finora

- Slinging Tubulars, Scaffold, BeamsDocumento3 pagineSlinging Tubulars, Scaffold, BeamsAngel AngeleyeNessuna valutazione finora

- Anchor bolt pull-out test method statementDocumento1 paginaAnchor bolt pull-out test method statementMorris KwokNessuna valutazione finora

- Aac Spec 377003Documento25 pagineAac Spec 377003JakesNessuna valutazione finora

- Lot Inspection Report For LPG New CylindersDocumento3 pagineLot Inspection Report For LPG New CylindersJagannath MajhiNessuna valutazione finora

- Tube and CouplerDocumento1 paginaTube and CouplerShams TabrezNessuna valutazione finora

- Webbing Sling - SWLDocumento4 pagineWebbing Sling - SWLChandrasekhar SonarNessuna valutazione finora

- Penguard ZP AO - English (Uk) - Issued.06.12.2007Documento3 paginePenguard ZP AO - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- RADIANT NDT SERVICES REPORT PROVIDES ULTRASONIC TESTING RESULTSDocumento1 paginaRADIANT NDT SERVICES REPORT PROVIDES ULTRASONIC TESTING RESULTSGoutam Kumar Deb100% (1)

- Magnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)Documento2 pagineMagnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)Khalil ChabbouhNessuna valutazione finora

- QIP of Boiler For ErectionDocumento6 pagineQIP of Boiler For ErectionUmair Awan100% (2)

- Introducing Tg20-13 Presentation February March 2014Documento18 pagineIntroducing Tg20-13 Presentation February March 2014Azharuddin_kfupmNessuna valutazione finora

- Wca-27 - Heien Larssen - Fire Alarm and Extinguisher SystemDocumento97 pagineWca-27 - Heien Larssen - Fire Alarm and Extinguisher SystemANessuna valutazione finora

- Prorox WM 960 Sa PDFDocumento1 paginaProrox WM 960 Sa PDFr afriantoNessuna valutazione finora

- Safety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingDocumento5 pagineSafety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingvietnampetrochemicalNessuna valutazione finora

- QC Fit Sheaves Final ReportDocumento23 pagineQC Fit Sheaves Final ReportJuan Manuel Ortiz RoseroNessuna valutazione finora

- Plan Preventative Actions for Weather-Related FailuresDocumento2 paginePlan Preventative Actions for Weather-Related FailuresmalawanyNessuna valutazione finora

- AIES Fokus 2020 10Documento5 pagineAIES Fokus 2020 10malawanyNessuna valutazione finora

- Weighing The Impact of The Cost of Living Crisis On Media and Entertainment PDFDocumento5 pagineWeighing The Impact of The Cost of Living Crisis On Media and Entertainment PDFmalawanyNessuna valutazione finora

- Business Suite PADocumento11 pagineBusiness Suite PAmalawanyNessuna valutazione finora

- Relevant Standard October 2018Documento1 paginaRelevant Standard October 2018malawanyNessuna valutazione finora

- Body Shape PPSDocumento6 pagineBody Shape PPSpradipNessuna valutazione finora

- Body Shape PPSDocumento6 pagineBody Shape PPSpradipNessuna valutazione finora

- Relevant Standard October 2018Documento1 paginaRelevant Standard October 2018malawanyNessuna valutazione finora

- Prif 2204Documento38 paginePrif 2204malawanyNessuna valutazione finora

- Relevant Standard October 2018Documento1 paginaRelevant Standard October 2018malawanyNessuna valutazione finora

- Relevant Standard October 2018Documento1 paginaRelevant Standard October 2018malawanyNessuna valutazione finora

- Body Shape PPSDocumento6 pagineBody Shape PPSpradipNessuna valutazione finora

- Apple Environmental Responsibility Report 2016Documento50 pagineApple Environmental Responsibility Report 2016SergioNessuna valutazione finora

- Family TaxDocumento29 pagineFamily TaxmalawanyNessuna valutazione finora

- Manual ReportDocumento198 pagineManual ReportmalawanyNessuna valutazione finora

- Master Link SpecificationDocumento1 paginaMaster Link SpecificationmalawanyNessuna valutazione finora

- Preventive Maintenance 1 Hydraulic Cylinder1Documento2 paginePreventive Maintenance 1 Hydraulic Cylinder1HalimPratamaNessuna valutazione finora

- Crosby Bolt-Type Shackle InfoDocumento1 paginaCrosby Bolt-Type Shackle InfomalawanyNessuna valutazione finora

- Confidental ReportDocumento1 paginaConfidental ReportmalawanyNessuna valutazione finora

- Pad Eye FailureDocumento1 paginaPad Eye FailuremalawanyNessuna valutazione finora

- Fast Craft RecoveryDocumento26 pagineFast Craft RecoverymalawanyNessuna valutazione finora

- Wrs Rigging PracticeDocumento4 pagineWrs Rigging PracticeZulfikar HassanNessuna valutazione finora

- Crosby Bolt-Type Shackle InfoDocumento1 paginaCrosby Bolt-Type Shackle InfomalawanyNessuna valutazione finora

- LA4EDocumento2 pagineLA4EmalawanyNessuna valutazione finora

- Aemses Sof Be LCP 2021 2022Documento16 pagineAemses Sof Be LCP 2021 2022ROMEO SANTILLANNessuna valutazione finora

- Eco 301 Final Exam ReviewDocumento14 pagineEco 301 Final Exam ReviewCảnh DươngNessuna valutazione finora

- 1.an Overview On Membrane Strategies For Rare Earths Extraction and Separation - 2017Documento36 pagine1.an Overview On Membrane Strategies For Rare Earths Extraction and Separation - 2017Vasile AlexandraNessuna valutazione finora

- Plano Electrico 785CDocumento2 paginePlano Electrico 785CLuis MartínezNessuna valutazione finora

- College Physics Reasoning and Relationships 2nd Edition Nicholas Giordano Solutions ManualDocumento36 pagineCollege Physics Reasoning and Relationships 2nd Edition Nicholas Giordano Solutions Manualshippo.mackerels072100% (22)

- Yayasan Pendidikan Ramadanthy Milad Anniversary SpeechDocumento6 pagineYayasan Pendidikan Ramadanthy Milad Anniversary SpeechDina Meyraniza SariNessuna valutazione finora

- Fci FC CotsDocumento25 pagineFci FC CotsMatthew DuNessuna valutazione finora

- Polifur 1K Synthetic Top Coat MSDS Rev 2 ENDocumento14 paginePolifur 1K Synthetic Top Coat MSDS Rev 2 ENvictorzy06Nessuna valutazione finora

- 2000 T.R. Higgins Award Paper - A Practical Look at Frame Analysis, Stability and Leaning ColumnsDocumento15 pagine2000 T.R. Higgins Award Paper - A Practical Look at Frame Analysis, Stability and Leaning ColumnsSamuel PintoNessuna valutazione finora

- School newspaper report teaches Present PerfectDocumento2 pagineSchool newspaper report teaches Present PerfectMiro MiroNessuna valutazione finora

- Hope 03 21 22Documento3 pagineHope 03 21 22Shaina AgravanteNessuna valutazione finora

- My RepublicDocumento4 pagineMy Republicazlan battaNessuna valutazione finora

- Gender and Other Cross Cutting Issues Mental HealthDocumento6 pagineGender and Other Cross Cutting Issues Mental HealthJamira Inoc SoboNessuna valutazione finora

- Advisory Circular: Aircraft Maintenance Engineer Licence - Examination Subject 2 Aircraft Engineering KnowledgeDocumento44 pagineAdvisory Circular: Aircraft Maintenance Engineer Licence - Examination Subject 2 Aircraft Engineering KnowledgejashkahhNessuna valutazione finora

- Giampietro 2019 Circular Bioeconomy Decoupling Implications For Sustainable Growth PDFDocumento14 pagineGiampietro 2019 Circular Bioeconomy Decoupling Implications For Sustainable Growth PDFcarlos mario marin avendañoNessuna valutazione finora

- Oposa vs. Factoran 224 Scra 792Documento28 pagineOposa vs. Factoran 224 Scra 792albemartNessuna valutazione finora

- Final Exam IN Sample QuestionsDocumento27 pagineFinal Exam IN Sample QuestionsJI TEN100% (1)

- Hireena Essay AnsDocumento2 pagineHireena Essay AnsTasniiem ChandraaNessuna valutazione finora

- Mechanics of Materials: Combined StressesDocumento3 pagineMechanics of Materials: Combined StressesUmut Enes SürücüNessuna valutazione finora

- Format For Handout - Comparative Models of EducationDocumento5 pagineFormat For Handout - Comparative Models of EducationAdrian AsiNessuna valutazione finora

- BCMEDocumento9 pagineBCMEVenkateshwaran VenkyNessuna valutazione finora