Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Calibracion Stanadine

Caricato da

Andres ContrerasTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Calibracion Stanadine

Caricato da

Andres ContrerasCopyright:

Formati disponibili

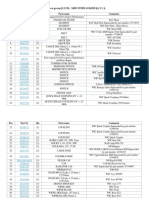

diesel systems

EDITION

NO.

MODELD

INJECTION PUMP

SPECIFICATIQN

CUSTOMER

SEW1 cE/rnLY

DATED

6.2 LiTER C,K.D

APWC*TION HEAVYDUTYTRUCK

ENGINE

CUSTOMER-S

4000

RPM

9YL42

67

OB2B29YL4305

PART NO. 14077179

NAME

ADDRESS

DETROIT DIESEL/ALLISON

MDRRAINE,OHIO

&+gO

FULL LOAD

B2 82

SUPERSEDES MODEL

ISSI 1 OY G. DUPONT

NOTE: ALL SPEEDSARE IN ENGINE .P.M. UNLESSOTHERWISENOTED

TEST

1.

SAE31418/1SC~4093:

DNG.

/IS0 7440:

OPENING?RESSURE

S SPECIFIED AT 1700 PSI OPENINGPRESSURE

MUSTUSE SPRING P/N WSF2044 A 5X OR EOUIVALENT.

3. CALIBRATIONFlULD...SAE 5967/1SO 4113 (REF. S.B.201)

A. TEMPERATURE

Al :NLET: 110"-115F (4?-4kQrl

B. SUPPLYPRESSURE(5.8.334):

5.0i0.5

bSi"(ja.5

kPa)

AT PUMPI.&LET.

4. CAMMOVEMENT.

READOLT

DEVICE /23795.

5. ALL FUEL RFMINGS CRE1OOOSTROKES.

PUMPOPERATING$EED._..lhLF.. .ENGINE SPEED

__

PUMPACCESSORIES:

1. ELECTRICSHUT-OFF (12V ETR)

2. M/LL ADVANCE

5. HOUSINGPRESS. COLDADV.

3. DELIVERYVALVE

6. TRAILING PORTROTOR

4. MIN.-MAX. GOVERNOR

II

PUMPCALIBRATIONCHECKS:-ASRECEIVEDFOR SERVICE.

(REF. s.~.222)

i. OPERATEPUMPAT 2000 RPM (HOT) FOR 10 MINUTESTO

i%;L;MTO OPERATINGTEMPERATURE

AND CLEARAIR FROM

2.

3.

4.

a.

IF-FUEL IS NOT lD.5-1B.5mn3/STRDKE Q 600 RPM.

RESETUSING LOWIDLE SCREW.

b. WITH HOUSINGPRESSURECOLDADVANCESOLENDID

ENERGIZEDWITH 8.8 VOLTS. HOUSINGPRESSURE

)ULD BE O-l PSI.

CHEC: :.S.O. FOR PULL-IN WITH 8.8 VOLTSMAX. WITH

THROTl .f IN LOWIDLE POSITION AT 400 RPM.

CHECK 'OINTS:

epM

150

600

600

1500

2000

3200

4000

32Do

4400

5.

THRTL.

pas.

WOT

L.I.

m3/

STROKE

26.

!z:*

CAM

VAR: MOVEMENT!$::;:E

;

5:

!&:

WOT

WOT

1.5: MIN.

z:;* ;::

21.fki3.5

; ;:::"-&

47.5-52.0

p 0.5'-2.5'

"w :i2;~-7.:5"

:;I:*

WOT

;8;5;;N.

.

.

'

O-l*+

'

*+H.P.C.A. ENERGIZED

CHECKAIR TIMING USING GAUGE523715, SET

TO 0.25 t 1' (REF. S.6. 334)

PUMPSETTINGS: (FOLLOWINGPUIP SERVICE

1. ROLLERTO ROLLERDIMENSION 1.93 7"* .ooD5"'

l M4xIMUMECCfNfRICITY:

2.

3.

9.

5.

6.

i:

9.

10.

.008" TIR

WITH OVERSIZECAM RING * ROLLERTO ROLLER

DIMENSIONTO BE 1.983 i.0005 (REFER 5.6.338).

LINKAGEG4P .13D" TO .175" PER 5.8.95 6342,.

a. USE GAGE123716, SET THROTTLEWiTH LDw IDLE

SCREWAT 34' f 2' AS MEASURE0BETWEEN

VERTICAL CENTERLINEOF THROTTLESHAFT

BUSHINGBOREAND THROTTLECONNECTION

STUD.

b. ADJUSTLOW IDLE SCREWUNTIL THROTTLE

CONNECTIONSTUD MAKESCONTACTWITH GAGE.

OPERATEPUMPAT 2000 RPM (HOT) FOR 10 MINUTES

TO BRING TO OPERATINGTEMPERATURE

AND CLEAR

AIR FROMSYSTEM.

SET T. PUMPPRESSUREAT 2000 RPM (WOT) FOR

58-64 PSI (TEST STANDBOOSTSET AT 5 i 0.5 P.S.I.)

SET RETURN OIL 225-375cc/min.

AT 2000 RPM (WOT)

a. CHECKHOUSINGPRESSURE

AT 600 RPM (WITH

THROTTLEIN LOU IDLE POSITION) FOR 8-12 PSI.

b.: WITH HOUSINGPRESSURE

COLDADVANCESOLENOID .

ENERGIZEDWITH 8.6 VOLTS, HOU5JNGPRESSURE

SHOULDBE O-1 PSI.

WITH GOVERNOR

COVERREMDVED

ANDTHROTTLESHAFT IN

LOWIDLE POSITION (STEP 4b). SET MJN.-MAX.

GOVERNOR

ASSEMBLYFOR 14.5 9c 2 mn /STROKEAT 600 ,

RPM (FUEL READINGWITH COVERINSTALLED.)

a.

FOR PULL-IN WITH 8.8 VOLTSMAX.

-. CHECK

_. E.S.D.

_

VITH THROTTLELEVER IN LOW IDLE POSITION AT

400 RPM.

b. CHECKFOR MINIMUMLIFT OF 18" HG AT 400 RPM.

11.

12

.-

ADVANCESfTTING PROCEDURE:

4. CONTROLFACE CAM-TO-THROTTLE

SHAFTEND PLAY

DURINGAND AT THE COMPLETIONOF ALL SETTINGSTO

.DDb"-.006" MEASURED

%ETUfENSPACER122900 6

HOUSING.

b. WITH THROTTLEIN A NOT POSITION, ROTATEFACE CAM

TO ITS MAXIMUMLIFT POSITION IN CONTACTWITH THE

CAMROLLER.

c. AT 2000 RPM, ADJUSTTRIMMERSCREW(No. 22642)

FOR 1.5O CA!! ADVANCE.(RANGE

#.5=2.5O).

d. SET THROTTLEFOR 22.5 i 1 nri /STROKE AT 1500 RPM.

ROTATEFACE CAMTO OBTAIN 3.5.CAN ADVANCEORANGE2.5*-9.5.

1.

e. AFTER SfTTING IS OBTAINED, SCREWND. 2239% IS

TORQUED;AND FACE CAMRETENTIONCHECKEDPER 5.6.361.

SET TOTAL THROTTLETRAVEL:

a. SET THROTTLEFOR 22.5 i 3 am3/STROKEAT 1500 RPM.

b. LOCKTHROTTLELEVER IN POSITION AND INSTALL THROTTLE

LEVER PROTRACTOR

NO. 22089 ONTOSHAFT.

c. ALIGN 0' ON PROTRACTOR

WITH CENTEROF RIB ON ROCKER

LEVER 22721. UNLOCKTHROTTLELEVERAND ROTATE

TO :HOTPOSITION. ADJUSTM4X. TRAVELSCREWTO 56.5'

d. CHECKTOTAL THROTTLETRAVEL: WITH THROTTLEIN LOWIDLC

POSITION, ALIGN Do ON PROTRACTOR

WITH CENTEROF RI% ON

ROCKERLEVER. MOVETHROTTLETO HOT, READINGSHOULDBE

BfThlfEN 73' AND 82'.

NOTE: ANY CHANGES

AFTERTHIS POINT WILL REQUIRERETESTSNG

OF

PUMP, STARTINGWITH STEP 11.

13.

CHECKPDINTS:

a. AT 1500 RPM (WgT, DE-ENERGIZEELECTRIC SHUT-OFF.FUEL

SHOULDBE b IMR/STROKE, MAXIMIRk RE-ENERGIZEE.S.O.

RPM

lnr

600

600

1500

2000

3200

3200

4000

4400

THRTL.

POS.

v_lT-m

?4B3/

12.5-16.6

1-I.

ALiJ:

MOT

MOT

kk

WOT

21.5-23.5

47.5-51.5

40 MIN.

4.0 Hkx.

MAX.

CYL.

YAR.

CAM.

PRESSURE

MOVEMENT1. PUMP HSG,

.

MD-1

B-12

8-12

8-12

8-12

125 M4X.

'*H.P.C.A.

ENERGIZED

AIR-TIME PUMPUSING &AGE123715 SET TOO.25 i 0.50'

SPECIAL NOTES:

a. TORDUEALL FASTENERSPER 5.8.106.

b. SECUREMAXIMUMTRAVELADJUSTINGSCREW,ADVANCETRIMMER

SCREWAND FACE CAMSCREWWITH RETAINING COMPOUND

62191:5.

c. OPENPETCOCKFOR PRESSURECHECKONLY.

d. MAXIMUMCYLINDERVARIATION SHOULDBE f 6 rtn3 FROMTHE

AVERAGEFLOWOF ALL CYLINDERS.

SEAL PUMPFASTENERSPER S.B. 365.

FURTHERINFORMATION SUPPLEMENTING

THE ABOVEPROCEDURES,

SHOULDBE OBTAINED{ROM S.B. 375.

DB2829YL4267

DfSCRlPTION

SCREW,cover hold-down

LOCKWASHER,

cover screw

3

3

ASHER, cover screw

CONN. ASSY., return line

SEAL; return line connectcjr

GASKET, governor cover

SHAFT;drive assembly l *

or 24625 o/s

PIN, dowel

SPRING, thrust button

SEAL,.drive shaft (BLACK)

BUTTON, thrust

SEAL, drive

1

127607

27244

26386

1

:

ABEL, pump identification.

OVER, governor control

23100

10541

sCREWASSY.,

vent or 21661

22733 or 22734 as reo'd.

sCREW, head locking

and

10453

22064

shaft(RE0)

12186Ot*~~@

* APPLY A LIBERAL COATINGOF SYN-KUT BASE 1241 COMPOUND

TO SEALS REFOREASSEMBLINGTO SHAFT AND

COVER, timing line

SCREW, timing line cover

SCREW, name Plate.

PLATE, name

.ING. shaft

23107

21194

24419

10394

:

2

1

retaininq

IOUSING ASSY. or 27075 0.5~

or 23105.23106 O.S.

'EARING. needle

ASKET, timing

ROLLER, cam

SHOE, cam roller

OESCRIPTION

I1

only

SCREW,hydraulic head plug

CONNECTOR,fuel line

REW, locking plate

ATE. locking

SE>

AL, locking plate s

VALVE. delivery

SB143R

or 23135 (O'size) as Req'd.

SCREW, delivery valve

l

INDENTED ITEMS INCLUDED

27245

i

1

::::;.

26071

26070

iiIL

I

ZT

!Lt

TRANSFERPUMPGROUP

II Il.

--I=

SPRING, trans.

ROLLPIN

pump blade

2

1

ETAINER, rotor

INER. transfer oumo

LADE; transfer pump

r 20512 per 58304

ING, liner locating

EGULATOR

ASSY., trans.

1

1

PRING, regulating

LATE, trans. pump pressure

,AP, transfer

IPISTON, regulating

PLUG ASSY., end plate

SCREEN. inlet

DESCRIPTION

pump

:

.SEAL. transfer

cover

HY0. HEAD 6 ROTORASSEMBLY

l

PLUNGER,rotor (Basic)

us E 11057 THRU 11060 STD.)

0 R 11062 THRU 11065 I O'SIZE)

as indicated on rotor SB 60R

SCREW,hydraulic head plug

2

2

CAM RING or 27833

or 23120 (O'sire)

O.E,M.

increase R-R by .006"

SEAL hydraulic head

SPRIl!G, leaf

SCREW, leaf spring adj.

line

-_

23915

pump

adj.

1

=

filter

SPRING, idling

GDV. ARM AND TEMPERATURE

COMPENSATOR-ASSEMBLY

GOVERNOR

GROUP

1

1

1

i

SLEEVE, min-max. governor

ROD, min-max. gov. push

SLEEVE, thrust

WASHER, thrust sleeve

WEIGHT, governor

RING, gov. cage reatining

i

1

shaft

NUT, max. travel

screw

SCREW, low idle

SPRING, low idle screw

SHAFT ASSEMBLY, throttle

1

1

SCREW, max. throttle

travel

IASHER, max. speed spring

,PRING, min.-max.

ILOCKASSEMBLY

;TUD, guide

IASHER guide stud

IRM A&.,

metering valve

;PRING, metering valve arm

/ALVE metering or 22256

IETAIltER ASSY., gov. weight

'1201

2285

=

SPACER, throttle

pump end

1

;

:

243451-&&

***

LUBRICATEPER 70027

or 50387. -

:

1

1

1

WASHER,throttle

shaft seal

SCREW,face cam

PIN. vacuum module drive

FACE CAM

SEAL, throttle

shaft

HOOKASSY.. gov. 1 inkage

LINKAGEASSY., governor

SCREW, gov. linkage hook

WASHER, gov. linkage hook

HOOK, governor linkage

SPRING. aov. linkaae hook

_ _._____ ..-._ _---- DB2829YL4267

-.

ZZ

2291j

RUTOMATICAOVANCEGROUP JEi

22%

LUBRICATE PER 70027

or 5.8.387

LEVER ASSY., rocker

PIN, rocker lever pin

RING, retaining

2608;

SCREW, servo advance adj.

2269:

47605

1

1

27602

26787

PLUG ASSY., sprinq side

SEAL, piston hole plug

SEAL, head locating

screw

SCREW, head locating

22721

PLUNGER, servo advance

SPRING, mech. light

load adv

VALVE, servo advance

PISTON ASSY., servo adv.

;

1

<i,

PIN,

piston hole plug

_

cam advance

23171

22367

26382

23426

;

=

27609

2392f

=

27610

23051

&

;

=

SEAL, adv.

PLUG. adv.

screw hole plug

screw hole

ELECTRIC SHUT-OFF GROUP

._

21618

14760

22985

-.--

PLUG, power side

3 of 3

-'-

STRAP, terminal

grounding

LOCKWASHER.cover screw

NUT, terminal

contact

WASHER, terminal

contact

;

2

2

18493

20951

:::;;

SOLENOID FRAME & ARM ASSY.

26214

23190

.TuBE, insulating

:;z;

12500

,249Ol

12049

14760

'1%

12500

23861

:

1

1

:

:

[NSULATOR, terminal

_OCKNUT, terminal

contact

rERMINAL. elect.'shut-off

LOCKWASHER.term. contact

IASHER. terminal

contact

dASHER, term. insulating

TERMINAL. cold advance

LOCKWASHER,term. contact

LOCKNUT, terminal

COdaCt

NUT, terminal

contact

WASHER, terminal

contact

WASHER, term. insulating

SOLENOID ASSY., cold adv.

.I

.--

FOR SERVICE USE ONLY

APPLICABLE SERVICE ASSEMBLIES

GASKET KIT

ES0 mount t rd. Kit

THROTTLE SHA!& BUSHING

DRIVE SHAFT ASSY. (O/S)

USE SHAFT NO. 24625 WITH PIN NO.23685

PILOT TUBE REPLACEMENT

ADVANCEPISTON REPLACEMENT.

(S.B.393)'

SUPERSESSION

INFORMATION

toMIN

4267

M/N 4305

Ghan esl)Housing

(23105t027002

or

2310%to27015) 2)Seals-BunaN to Vitor

Recalibration Required QYES ON0

ChangeRequlredl)Onlv

2)Only as part of other repairs

PubllcationsReferences:2)P'B'

NOTES:

lo2

r24370

124625

ONLY)

127106

1127869

_. ___~~

9-16-88

lL11-89

3Q?Zg

18949

19227

19509

I9227 (iss.

2)

:

7

8

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- 6.4 Power Stroke Manual de MotorDocumento103 pagine6.4 Power Stroke Manual de MotorAndres Contreras95% (44)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- 93 94 7.3 IDI Turbocharged Diesel EngineDocumento72 pagine93 94 7.3 IDI Turbocharged Diesel EngineAndres ContrerasNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Turbo Holset He351ve PDFDocumento2 pagineTurbo Holset He351ve PDFAndres Contreras0% (1)

- Service Manual Manitou R7 - Platinum1cDocumento27 pagineService Manual Manitou R7 - Platinum1cCostin GPNessuna valutazione finora

- DIAGRAMA ELECTRICO CAT 3126 IndustrialDocumento1 paginaDIAGRAMA ELECTRICO CAT 3126 IndustrialAndres Contreras100% (2)

- Transmision H300Documento24 pagineTransmision H300Andres ContrerasNessuna valutazione finora

- dt40w p40 018 (9900b-45403) PDFDocumento103 paginedt40w p40 018 (9900b-45403) PDFDiego ChamorroNessuna valutazione finora

- Manual Newhollan L220Documento242 pagineManual Newhollan L220Dario100% (1)

- J23-016B ManualDocumento12 pagineJ23-016B ManualCarmen Méndez AnTonyNessuna valutazione finora

- Calibracion StanadineDocumento3 pagineCalibracion StanadineAndres ContrerasNessuna valutazione finora

- Bomba StanadineDocumento3 pagineBomba StanadineAndres ContrerasNessuna valutazione finora

- Catalogo NavistarDocumento36 pagineCatalogo NavistarAndres Contreras75% (8)

- Calibracion de BombaDocumento3 pagineCalibracion de BombaAndres ContrerasNessuna valutazione finora

- Sistema de Aire Motor Ford 6.4L Air Management SystemDocumento18 pagineSistema de Aire Motor Ford 6.4L Air Management SystemAndres Contreras100% (1)

- TonyduramaxDocumento173 pagineTonyduramaxAndres Contreras93% (15)

- TH700-R4 / 4L60E / 4L65E / 4L70E: RWD 4 SpeedDocumento14 pagineTH700-R4 / 4L60E / 4L65E / 4L70E: RWD 4 SpeedByung C Kim100% (1)

- School of Maritime Studies Vels University Thalambur: Overhauling of Centrifugal Pump AimDocumento2 pagineSchool of Maritime Studies Vels University Thalambur: Overhauling of Centrifugal Pump AimДмитроNessuna valutazione finora

- Kebutuhan Oli (LAMA)Documento23 pagineKebutuhan Oli (LAMA)ArifinNessuna valutazione finora

- Yard Location 91 Series (59th) 1Documento366 pagineYard Location 91 Series (59th) 1mehedeNessuna valutazione finora

- Design and Fabrication of Pneumatic Quick Return MechanismDocumento43 pagineDesign and Fabrication of Pneumatic Quick Return MechanismvinothNessuna valutazione finora

- C5 (X7) - SteeringDocumento86 pagineC5 (X7) - SteeringpurysanNessuna valutazione finora

- Parts Book D46Documento49 pagineParts Book D46Julio ChapilliquenNessuna valutazione finora

- Katalog Proizvoda Product Catalogue WarenkatalogDocumento267 pagineKatalog Proizvoda Product Catalogue WarenkatalogStrahinjaNessuna valutazione finora

- Jss 2 Basic Technology JSS 2 Third Term Examination - Marvel LearnDocumento1 paginaJss 2 Basic Technology JSS 2 Third Term Examination - Marvel LearnTriple Jay COC100% (1)

- Yash Gear Cutting ToolsDocumento22 pagineYash Gear Cutting Toolsmagiva873Nessuna valutazione finora

- MMM Spare Parts STERIVAPDocumento17 pagineMMM Spare Parts STERIVAPNestor ArteagaNessuna valutazione finora

- 12 Hofmann Self Aligning Drives Brochure A4Documento2 pagine12 Hofmann Self Aligning Drives Brochure A4Jorge VillalobosNessuna valutazione finora

- Experiment No. 12: ObjectiveDocumento4 pagineExperiment No. 12: ObjectiveMoiz AamirNessuna valutazione finora

- Parts Cat Mhi Alog For Centranz Parts and ManufacturingDocumento64 pagineParts Cat Mhi Alog For Centranz Parts and ManufacturingSebastián Fernando Canul MendezNessuna valutazione finora

- ISSA2013Ed CabinStores v100 Часть190Documento2 pagineISSA2013Ed CabinStores v100 Часть190Александр ВласовNessuna valutazione finora

- Baithi AVCN 2Documento37 pagineBaithi AVCN 2Khanh ĐinhNessuna valutazione finora

- Current Revision Approved: Power Rotate Sensor AssemblyDocumento1 paginaCurrent Revision Approved: Power Rotate Sensor Assemblycapslive_001Nessuna valutazione finora

- MF5400 Manual 09-EnDocumento372 pagineMF5400 Manual 09-EnJānis GrabisNessuna valutazione finora

- Numeros de ParteDocumento8 pagineNumeros de ParteJulio GarciaNessuna valutazione finora

- Name: - Section: - Schedule: - Class Number: - DateDocumento11 pagineName: - Section: - Schedule: - Class Number: - DateSir COCNessuna valutazione finora

- Volvo Ew 160BDocumento60 pagineVolvo Ew 160BApexiNessuna valutazione finora

- Zapex - ZN DentadoDocumento14 pagineZapex - ZN DentadoJose Patricio Obreque RiosNessuna valutazione finora

- Saudi Arabian Oil Company: DA-704879 005 P 0A3 K13 RestrictedDocumento1 paginaSaudi Arabian Oil Company: DA-704879 005 P 0A3 K13 RestrictedWaqarNessuna valutazione finora

- 722 5infoDocumento34 pagine722 5infoGypsyR75% (4)

- Engine 4JG2 PDFDocumento233 pagineEngine 4JG2 PDFАлексNessuna valutazione finora