Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Thickness OF Opple As e B 31.3-2012: Calculations TEE Asme

Caricato da

chethanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Thickness OF Opple As e B 31.3-2012: Calculations TEE Asme

Caricato da

chethanCopyright:

Formati disponibili

THICKNESS CALCULATIONS OF STOPPLE TEE as uer ASME B 31.

3-2012

Project

20- STUB WITH RF PAD

Client

JSW Steel Limited

Drawing No .

PPTS-HT- 40-- 20- - 000

DATE

13-05-2015

REV

00

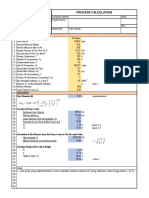

Design data:

Materia l of Construction

Allowable stress of Material

,MOe : ASTM A515 GR 50 .

s: 138 MPa

(From table A1 , Min temp to 40 Deg C)

: 1962 Kg/cm2

Design Calculation;

.

P

Internal design pressure

0.0 of header or run pipe in mm

Design temperature

Basic allowable stress for material of run pipe

I

2

3

4

5

6

Dh

S

E

Joint efficiency

Corrosion allowance for run cioe

Threadin allowance

Thinning allowance

7

8

9

10

Desion factor (from table 304.1.1)

AI

A2

A3

Y

Weld joint red uction factor ( from table 302.3.5 note (9

kgfcm2

mm

OegC

Kg/cm2

mm

mm

%

I

513

40

1962

0.85

3

0

0.25

0.72

I

Min.thk without allowances

II

AS PER ANSI B31 .3

0.92

tmin - (PXDh) I (2SxExW)+(PxY)

tmin

mm

A,

mm

0.23

mm

4.2

mm

10

,

12

Total thinning allowance

tmin

A3

Total thk with allowances

13

tmln ... At+A'+A2

14

T HICKNESS SELECTED

Conclusion :

SELECTED STUB THICKNESS [S GREATER T HAN THE REQ UIRED TH[CKNESS FOR THE

GIVEN WORKING CONDITIONS.HENCE DES [GN [S SAFE.

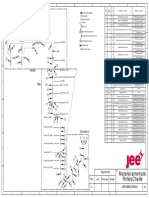

\.C\\H1CAl

~'\

~

o

'7

..0

Plottlo. 145

8.1....111,141

\116115U1" AI"

V>

Mt" wallgl\o(l : :

'{fil

~ 575011

~~

. .cd

"fJ.

~~~ ~- l)'

'ylij-...+I!

'M'

~"

': ~i

---

' 2~

O2!Itl

"I'F

1'1"

~ ~..- ..~

I _ _ _ _ _.'" _1._ _ ___ _ _

,

FRONT VIEW (TOP HALF)

~,

~._. _ J _. _._.

'<<wITH!< RF ".00

.---- - --~

1\\-+\ ! _ ____ L.:.< _

DETAIL"8"

DESIGN TEMPERATURE .o"C

CORROSION ALLOW... NCE 3 rrwn

TOP VIEW (SVMMETRIC HALF)

DESIG N F"'CTOR -0.72

PNEUMATICTEST PRESSURE _

,.

DESIGN Oo\TA.

IMX. OPERA. nNG PRESSURE -II KgIc:m

TYP~

TVP'" 10

.. - .. - ..- .. - ..- .. .. - .. - ..~.

CESIGN COOE. A$ME. 831.32012

~I

I

-~

-rulruiJ I"

TYp~

I

I,

I-A

SECTION .......

~TYP

i--j

~.

,L A

~o_

1.~

TIMES Of OPEAATIHG PRESSURE

(AS PER ASME.B32.3-2O'2)

MATERIJo.L.

BRANCH & RF PAD - ASTM ~'IIGReOIASTM ~'IIGR70

F'\..o".NGE 1MTERIAl _ IS 2052 GR It

STUB LONG SEAM WELD DET.....

FABRICATIOH

W'ELOING AS PER"'$ME 831 .3

W'ELDERSCODE "'SME. ~

NOT. IN "'CCORD... NCE ~ ASME. V

SU" W'ELDS ' ~ RA.DIOGIV.PIfY.

~/.

ALL FILLETv.LDS l OO'IIo MPI.

"",,1S'tC'~

,

,

RFPAO

'

FlANGE

$I. NO

\\~ \ ~'~YO" '.'",U

. N Mannalar.

IN SERVICE WELDING.

FLLER AWSA-61 (E701')

J...."'II

"'"

DESCRIPTION

...... o:H;_

AST .. A5.8 GROlO

... ST .. A5.8 GRell

C/GT-_'

'

IS1OII2 GR 1\

SPECS IDRG NO

DTY

MOe

_. _..

-..

- .t"LAN I-I t:.\.iM t"UVYt:.t<

BUTT WELDING EDGE PREPARATlOH SHOULD OOHEAS PERASME 831

3. PARA 328.

2

Uf

SCAI.

REMARKS

TECHNICAL SERVICES

WELOING PROCEOIJRE AS PER API 1104

FU ET WELDING EDGE PREPAIV noN SHOULD OOHE AS PER ASME 831.l. PARA 328.UD

I PAATHAME.

TESTIIiG DVE PENETRATE AND MAGNETIC P... RTlCLE INSPECTlON

THICKNESS CALCULATIONS OF STOPPLE TEE as per ASME R 31.3-2012

Project

24" STUB WITH RF PAD

Client

J$W Steel Limited

Drawing No.

PPTSHT 48"0 24" 000

DATE

13-05-2016

REV

00

Desig n data:

Materia l of Construction

MOC : ASTM A516 GR 60.

S: 138 MPa

Allowable stress of Material

(From table A-1 , Min temp to 50 Oe9 C)

: 1962 Kglcm2

Design Calculation ;

IP

I Dh

d deslon

. Design

~

7

I

I

~for run

9

10

I , factor (from table 304.1.1)

I Weld loin. ,

I

(from ..bl,:

kgk m;

mm

D'ge

I

6 16

'k:

1.8'

Al

I A2

I A3

mm

mm

0/0

"'w-

0.72

I

Min.thk without allowances

"

6S PER 6~S I DJI J

.2

Total thinning allowance

1.79

tmin "" (PXDh) I (2SxExW)+(PxY)))

tmin x A3

tJ

tmin

mm

A,

mm

0.45

mm

5.22

Total thk with allowances

tmin" At"A1 "A2

'4

TH

Conclusion:

SELECTED STUB HI ICKNESS IS GREATER HIAN THE REQUIRED THICKNESS FOR THE

GIVEN WORKING CONDITIONS.HENCE DESIGN IS SAFE.

~"

~TYP

i-----U1

PC007~. 3

,~

.~

._- II

I

~I I

~ _ _

JOII

301

"'"

1>

i1==

,

!.!L.b..-1"-..

TAPI'ING SIZE IZI!>:W

01226

"'- f

~.~"'-

CA.

i- -

I

- - - -.- I-A

--

.

---'I

"'-

FRONT VIEW (TOP HAlF)

~""PC07.$ , 3

J--.. _ .. _ . _ .. _+_ .. _ .. "----i

"'-_1

___ _

OESIGNOo/I,TA.

DESIGN CODE. " SME. 831.320,2

MAX. OPERATiNG PRESSURE. 8 KgIcm

f"

m>)2.

~.

-~--B\:::i. - _i_ ~

fYp)12.

I,

I

I

I

al

~

TYP~ 10

1()nmn.( RF PAD

._____ __ -.l

,-

TOP VIEW (SYMMETRIC HALf)

DETAJL"8"

DESIGN TEMPERATURE. 5O"C

CORROSION ALLOWANCE. 3..."

DESIGN FACTOR aQ,n

".

'\:-7

.

PNEUMATIC-TEST PRESSURE. U TIM ESOf' OPERATING PRESSURE

(AS PER 1\&.1132.3-20.2 )

61

.~ ~

j:

WoTERlAL

BRANCH & flF PAD ... STM "516 GR60 I ASTM -'516 GRlO.

FlANGE W. TERIAL IS 20&2 GR B.

STUB LONG $AM v.e.o DETM.

F"SRICATlQN

'MOlDING ... S PER "SME 831 3

VoELDERS CODe ASME. DC

NOT. IN ACCORDANCE ~Tli ASME. Y

BUTT WElDS 1em!. R.\O!OGfV.PHY.

AU FIU. ET WELDS. ' 00% MPI.

RF PAQ

ASHI -'$11 GAllO

1D- ' 22f<_ g

"'".

''''''"'

ASUI -'$" GAeO

IS 2062 GR 8

cs-G!V'SOf/'1I07

ON

DESCRIPTION

IN SERVICE v.ELOlNG:

FillER AWS "5.1 (El0,8)

v.El.O!I'OG PROCEDURE AS PER

"'"

PLANT-TECH POWER TECHNICAL SERVICES

N': l1D4

BUTT WELDING EOG PREPARATION SHOULD DONE AS PER ASME. 931.3. PAM 328. .2

FillET 'MOLDING EDGE PREPARATION SHOULO DONE AS PER ASMt: 831 ,3. PAAA

328.5,.1)

11

5CAl.E

PART NAME:

'" ..n...

24" STUB WITH RF PAD

TESTING DYE PENETR.lfE AND MAGNETIC PARTlClE INSPECTlON

THICKNESS CALCULAT IONS OF STOPPLE TEE as pcr ASME B 31.3-2012

Project

36- STUB WITH RF PAD

Client

Drawing No.

JSW Steel limited

PPTSHT 64", 36" 000

DATE

REV

13-05-2016

00

Design data:

Material of Co nstruction

MOC : ASTM A516 GR 60.

Allowable stress of MaterIal

S: 138 MPa

(From lable A1, Min temp to 50 Deg C)

: 1962 Kg/cm2

Design Calculatio n;

I

2

3

4

Internal desi n pressure

0.0 of header or run i e in mm

Desian temoeralure

Basic allolt/able stress for material of run i e

P

Dh

5

6

Joint efficiency

Corrosion allowance for run pipe

7

8

9

Threading allowance

Thinning allowance

Design factor (from table 304 .1.1)

E

AI

A2

A3

Y

10

Weld joint reduction factor ( from table 302.3.5 note (9) )

II

Min .thk without allowances

AS PER ANSI 831.3

kglcm2

mm

I

922

DcgC

SO

K cm2

1%2

0.85

3

0

0.25

mm

mm

%

0.72

0.28

tmin - (PXDh) I (2SxExW)+(PxY)))

12

tmin

Tolal thinning allowance

tmin x A3

13

mm

0.07

mm

3.4

mm

Il

Total thk with allowances

A

14

mm

TI-IICKNESS SELECTE D

Conclusion:

SELECTED STUB TH ICKNESS is GREATER TIIAN THE REQ UIRED THICKNESS FOR THE

GIVEN WORKING CONDlTiONS. HENCE DES IGN IS SAFE.

If IN DOUBT PLEASE ASK

EO<J<S

,-------

,

(]D

I,

0'~~

~j11 ~,=

I" ,

II

L ,

2

..- ..- ..- .. ~

l1MRFPAD

I,

I

~.

CA

""--

FRONT VIEW (TOP IW.F)

DETAil?

24HO_ ON PCP 11120

~ .. - .. - .. - ..- .. - ..-.~~. ..-.. - .. .._ .. _ .. _ .._ .._ .. _ .. J

DESIGN DATA.

~L _ __ '

DESIGN CODE "'8ME. 831 .32012

MAX. OPERATING PRESSURE - ,

KWtm'

DES IGN TE '-IP ERATURE ~"c

CORROSION ALLOWANCE 3 tMI

DESIGN FACTOR -0.72

PNEUMATICTEST PRESSURE . , 5 TIMES OF OPeRAnNG PRESSURE

(AS PER ASME.832.l-2012)

~

'

7 ,~'

".

T ~

,,~

1,5

~+ ~'

srue LONG SEAM """LO DETAIL

TOP VIEW (SYMIJIETRIC HI\lF)

MATERlo'L

BRANCH & RF PAD _ "'SYM AS1ISGReO/.t.STM Mlt1GR70

FLANGE MATeRIAL - IS 20&2 GR 8 ,

SPECIAL NOTE :FLANGE 10 SHOULD BE 922+2 mm

FABRlCAl'lOtt

WElOINGASPERASMEB313

'MOlDRS CODE ASME. I)(

NOT. IN ACCORIMNCE v.tTM ASME. V

8UTTWElOS 1~1VoDIOGRAPHY

All Fl.lET WELDS 100"",1>,

RFPAO

rn.o

MTWA5,&GfIIlO

'''''''''

IS2OlI2GRB

SL NO_I oeSCRIPTlON

IN SERVICE WELDING;

Fl.lER : "WS "'~ . 1 (t:70I8)

i\ST1l A51e GfIIlO

_'~-'I

on

"""

PLANT-TECH POWER TECHNICAL SERVICES

WELDING PROCEDURE AS PER APlll()o1

BUTT WELDING EDGE PREPARATlO+I SHOULD OONEAS PER.o.sME 831 .3, PARA 328.4.2

FlLlETWELOING EDGE PREPAAATtON SHOULD OONEAS PER ASME 831 ,3. PARA 328.5.4{)

PAATNAME.

. 36" STUB 'MTH RF PAD

TESTING: DYE PENETRATE AND M.*:GNET1C P.-sTlCLE INsPECTION

THICKNESS CALCULATI ONS OF STOPPLE TEE as pcr ASME B 31.3-201 2

Project

40' STUB WITH RF PAD

Client

JSW Steel limited

Drawing No.

PPTS-HT56" 40", 000

DATE

REV

00

13-05-2016

Design data:

Material of Construction

MOC: ASTM A516 GR 60.

Allowable stress of Mate ria l

S: 138 MPa

: 1962 Kg/cm2

(From table A" Min temp to 50 Deg C)

Design Calculation :

I

2

J

4

5

6

,

7

10

Internal design pressure

0.0 of header or run pipe in mm

Design temperature

Basic allowable stress for material of run pipe

Joint efficiency

Corrosion allowance for run ;e

Threadin allowance

Thinnin allowance

Oesiqn factor (from table 304 .1.1)

Weld 'oint reduction factor fro m table 302.3.5, note 9))

kglcm2

Dh

mm

DegC

S

E

AI

K glcm 2

A2

AJ

I

1000

SO

1962

0.85

mm

mm

0/0

0

0.25

0.72

I

Min.thk without allowances

11

AS PEB. A~S: I B3q

0.30

tmin - (PXDh) I (2 SxExW)+(Pxy)))

12

A,

mm

0.075

mm

3.375

mm

12

Total thk with allowances

tmln + AI+A1+A2

14

mm

TOlallhinning allowance

Imin x A3

13

tmin

T HIC KNESS SELECTED

Conclusion:

SELECTED STUB THICKNESS IS GREATER THAN THE REQUIRED THICKNESS FOR THE

GIVEN WORKING CONDITIONS.DESIGN IS SAFE.

500

"' 17~

"~

12

~.,,~

;;

,.-T-..

...... I "'.

I/'

0 1.027

HOT TAPPII

~-

iIOO

~A

_

2

1000

r"-"-"-'

_.. _.. ,,._.. -

-_.. _.. _."

c~ ____________ ____ ~~______________ j ~

SECTION "AA"

FRONT VIEW (TOP HALF)

.._.. _.. _.. _..../

_~1

DET....."8"

OH PCO 1120

DESIGN O... T,,:

DESIGN COOE" ASME. 931.32012

M.OJC , OPERATING PRESSURE " 1 KWOT>'

DESIGN TEMPRA~E" 5O"C

CORROSION ALLOWANCE " 3 .......

DESIGN FACTOR -0.72

CA

PttEUW.TlCTEST PRESSURE" \ S TIMES ~ OPERATING PRESSURE

(AS PER ASME,B323-2012)

STUe LONG SEAM WELO DETAR.

8.28'

TOP VIEW (SYMMETRIC HALF)

MATERIAl;

BRANCH & RF PI\O AST'" ,t.,510 GRI/...sTN MI&GRlo.

Fuo,NGE MATERIAL IS 20&2 OR B.

FABRICATION;

WELDING AS PER ASUE 831 .3

WELDERS CODE ASME. IX

NOT IN M:CORDAHCE 'Ml1i ASME. V

BUTTWELDS I()(1%RAOIQGRAPHY

ALL FILLET WELDS 100'lI0 MPI.

IN SERVICE WELDING:

fI. LBI AWS " 5 1 (El018)

WELDiNG PROCEDURE AS PER /\P I 11()o1

RF p.w

ASUIi'<518GRfIO

Doo I.u7;-'12

''',.

"A"'"

Sl. NO. 1 DESCRIPTION

ASTIlli'<518GA1O

IS 20&2 GRB

1IIOr->-"

NO. I ClY

MOe

PlANT-TECH POWER TECHNICAL SERVICES

BUTTWELD1NG EDGE PREPI<RATION SHOULD DONEAS PER ASME 831 3, PAFtA 328 ....2

FILLET WELDING EOGE PREPAA.o\TION SHOULD CONE AS PER ASME 831 .3, PARA :t18.MD

l1;$llNG DYE PEJ\lETAA fE ANO MAGNETIC PARTICLE INSPECTION

""",

40" STUB WITH RF PAD

THICKNESS CALCULATIONS OF STOPPLE TEE as pcr ASME 8 31.3-2012

Project

48" STUB WITH RF PAD

Client

JSW Steel Limited

Drawing No.

PPTS-HT-9S" 48"000

DATE

13-05-2016

REV

00

Design data:

Material of Construction

MOC : ASTM A5 16 GR 60 .

S: 134 MPa

Allowable stress of Material

(From table A-t , Min temp to 100 Oeg C)

: 1905 Kg/cm2

Design Calculation j

P

Dh

k cm2

mm

K om2

I

2

3

4

5

Internal desi n ressure

0.0 of header or run i einmm

6

7

Corrosion allowance for ron ;e

AI

Threading allowance

Thinning allowance

A2

mm

mm

A3

Design factor (from table 304.1.1)

0.25

0.72

10

Weld joint reduction factor ( rrom table 302.3.5, note (9) )

Design temperature

Basic allowable stress for malerial of run ;

Joint efficienc

DcgC

E

I

1220

100

1905

0.85

3

0

Min.thk without allowances

II

6Sf EBANS! UJ I,J

0.38

lInin - (PXDh) I (2SxExW)+(PxY)))

12

A3

A,

mm

0.095

mm

3.5

mm

18

Total thk with allowances

tmin + AI+Al+A2

14

mm

Total thinning allowance

tmin X

Il

lmin

THI CKNESS SEL.ECTED

Conclusion:

SELECTED STUB THICKNESS IS GREATER THAN THE REQUIRED THICKNESS FOR THE

GIVEN WORKING CONOITIONS.IIENCE DESIGN IS SAFE.

.,~

IF IN

~,~

I.

1~4

~

_.~!k._~

18

18 THII !IF P,\o

,/

',.

'\

~4V

(MOTHEA PF)

cj_______ ~___L~

f-A

,-------

!014

Ql12lO

I

!-.. _ .. _.

~ ,

,

rAPPtNGIiIZE'11M

Mol

._.. _ -!

I,

I,

r___________ L' __________~

~~

j~

f-A

SECTION "A-A"

FRONT VIEW (TOP I-W.F)

., ~

32No_34 ON PeD 1)00

!-.. - - - - ~ - - - - - ..- - , _ _ .. _ _ -!

DESIGN CODE '

"'S ~E _

DESIGN OATA.:

831 .3 2012

DESIGN TEMPERATURE ' lOOOC

CORROSION ALLOWANCE ' 3 mm

DESIGN FACTOR a() n

~---

PNEUMATICTEST PRESSURE - 1.5 TIMS OF OPERATING PRESSURE

lAS PER A$ME.B32.3-2012 )

".

MAX. OPERATING PRESSURE ' 1 1(QII:m'

OETAllT

~+ ~ '

, _

__ j!L

STUB LONG SEAM WELD DETAJI.

TOP VIEW (SYMMETRIC tw..F)

MATERIAL:

BRANCH & RF PAD "'STM .0.5111 GRGOIASll.lA5UI ~70.

FlANGE MATERIAL IS~ GR B

FA8RICAT1ON"

WELDING AS PER A5ME 831 3

WELDE RS COOEASME. IX

NOT. IN ACCORO...NCE IMTH~ . \I

BUTT WELDS lC1O'1o RAOIOGRAF'IiY

SPECIAL NOTE :FLANGE ID SHOULD BE 1220+2 mm

,

2

!IF PAD

I

_2027:_

_ 11

A.Sfll A51eO"'lO

STUB

A.Sl' 1I ,0,51'O..o

'''''''''

IS2OQGR8

....,;;::~

ALl FIt.LET weLDS. 100'1' MPI.

51. NO. I DESCRIPTION

IN SERVICE WELOI N<l

FU El<: ....WSA-s.l (E7018)

ON

MOC

PLANT-TECH POWER TECHNICAL SERVICES

WELDING PROCEDURE AS PER API 1104

BUTT WELDING EDGE PREPAAATlON SI-lO\Jl.O DONEAS PER A.SME 031 3, PARA 328.' .'

FILLET WELD IN G EDGE PREPARATION SHOULD OONE AS PER ASME 831,3. PARA 328.5.'0

PART NAME:

48" STUB 'MTH RF PAD

TESTING ' DYE PE NETRATE AND t AGNETlC PARTICLE INSPECTION

THI CKNESS CALCULATIONS OF STOPPLE TEE as per ASME B 3 1.3-2012

Project

56" STUB W ITH RF PAD

Client

JSW Steel Limited

Drawing No.

PPTS-HT-80"-56"000

DATE

REV

13-05-20 16

00

Design data:

Material of Construction

Allowable stress of Material

MOC : ASTM A516 GR 60.

S: 134 MPa

(From table A-1, Min temp to 100 Deg C)

: 1905 Kg/cm2

Design Calculation ;

I

Internal design pressure

0 .0 of header or run pipe in mm

3

4

Design temperature

Basic allowable stress for material of run pipe

Joint efficien.fY

10

11

Min.thk without allowances

AS rER 6~S I B31.J

7

8

9

kglcm2

mm

DcgC

Corrosion allowance for run ;e

Threadin allowance

ThinninQ allowance

Desicm factor (from table 304 .1. 1)

Weld jOint reduction factor ( from table 302.3.5, nole (9))

P

Dh

S

E

AI

Kglcm2

A2

mm

mm

A3

I

14 16

100

190'

0.85

3

0

0.25

0.4

I

0.44

tmin " (PXDh) I (2SxExW)+(PxY)))

12

A,

mm

0. 1

mm

3.8

mm

14

Total thk with allowances

tmin + At+Al+A2

14

mm

Total thinning allowance

tmin x A3

13

lm in

T HICKNESS SELECTE D

Conclusion :

SELECTED STUB TH ICKNESS IS GREATER THAN THE REQUIRED THIC KNESS FOR THE

GIVEN WORKING CONDITIONS.HENCE DES IGN IS SAFE.

.,-

~4

I" '

~~.,~

o;ofti02

TA,PPING SIZE 1111312

~-

,I

,

14 THK RI' PAD

~_C<

.,

1418

REMOVE ALL SHARP EDGES

: - ---~J;;\J i

1-'

, _. I

.L,.

t .. _oo_ ..-

_ _ _

IF IN DOU BT PLEASE ASK

I,

I,

I

._....1'

, ______ __________ ~

I ___ _________ ___ J~

'

c~~

1-'

SECllON -,,-It"

FAONT VIEW (TOP HA1F)

OESIGNOATA

DESIGN CODE. A5ME. 831.32012

MAX. OPERATING PRESSURE .. 1 KgIcm 1

oeSlGN TEMPERA-lURE " 10crc

C()I;IAOSION AllOWANCE " 3mon

DESIGN F.o,CTOR oo(l72

PN EUMATIC_TEST PRESSUR E" 1 5 TIMES OF OPeRATING PRESSURE

V<S PER ASME.832.3-2012)

..-..-..-

C,!- I

. _. -..'\.._..-

~.

..-..-..-..-..

OETAIL"B"

,.

~ c.

STUB LONG SE.o\M weLD OETAI.

TOP VIEW (SYMMETRIC HAlF)

MATERIAl..:

BRANCH & RF PAO ASn.. ASI &GReO IASTMA5 1&GR70,

FlANGE MATERIAL 15 2062 GR B

FA8RICATIOH.

SPECIAL NOTE :FLANGE 10 SHOULD BE 1416 mm

'Io'ELDING AS PER ASME 831 .3

, I

, I

WEL DERS CODE "8"'E , IX

NOT. IN ACCORDANCE WlTHASME. V

BUTT WELDS 1~ RADIOGRAPHY

ALL FIllET WELDS. 100'lI0 MPl

IN SE RVIC E WELDING:

FUER ' AWSA-5.1 (E701 8)

WELDING PROCEOURE AS PER API 11001

Sl

RF PAD

'"'"

,WtGe

NO.1 DESCRIPT10N

.....

__.,.

OO-I""__

'~

Q-<II-'' ' ' SPECSI ORG NO.

,

,

,

ON

A.ST MAlIl'GReO

AST IoI A51.GRlIO

1520&:011.

MOC

PlANT-TECH POWER TECHNICAL SERVICES

BUTT WELDING EDGE: PREPARA no,.. SMOUlO DONE AS PEA ASME 831.3. PARA 32$,. 2

FILLE"TWELDI NG EOGE PREPARATION SHOULD QONEAS PER ASIdE 831.3, PARA m.UD

TESTING OYE PE NETIi" T"; ANO WlGNETlC PAATICLE INSPECTION

56'" STUB 'MTH RF PAD

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Pad Eye Designwww - Thenavalarch.com Rev B SI UnitsDocumento10 paginePad Eye Designwww - Thenavalarch.com Rev B SI UnitsndesigngmailNessuna valutazione finora

- Lifting Shakle DesignDocumento1 paginaLifting Shakle DesignchethanNessuna valutazione finora

- Apu Aps500rDocumento100 pagineApu Aps500romarmasaquizaNessuna valutazione finora

- Puncture ValveDocumento2 paginePuncture ValveSanjeev SainiNessuna valutazione finora

- Virtual Pipeline Projects Around The World - GNC GalileoDocumento76 pagineVirtual Pipeline Projects Around The World - GNC GalileoMariano Gandulfo CastillaNessuna valutazione finora

- P I F 3000 PSI B A: Recharging Nstructions OR Ladder CcumulatorsDocumento2 pagineP I F 3000 PSI B A: Recharging Nstructions OR Ladder CcumulatorsRonaldNessuna valutazione finora

- Inventory Record - FinalDocumento6 pagineInventory Record - FinalParag WadekarNessuna valutazione finora

- Metal Valves StandardsDocumento5 pagineMetal Valves StandardsheitorgmsNessuna valutazione finora

- RS 3.0 - 75.0 KW: RENNER Screw CompressorsDocumento5 pagineRS 3.0 - 75.0 KW: RENNER Screw CompressorstitiNessuna valutazione finora

- Process Calculation: Flare Diameter (D)Documento2 pagineProcess Calculation: Flare Diameter (D)kristian08Nessuna valutazione finora

- United States Patent: (12) (10) Patent No.: US 8,360,155 B2 Avery Et Al. (45) Date of Patent: Jan. 29, 2013Documento19 pagineUnited States Patent: (12) (10) Patent No.: US 8,360,155 B2 Avery Et Al. (45) Date of Patent: Jan. 29, 2013chethanNessuna valutazione finora

- Mechanical Locking Cylinders: Dimensional DataDocumento4 pagineMechanical Locking Cylinders: Dimensional DatachethanNessuna valutazione finora

- Hydroleduc Micro en PDFDocumento24 pagineHydroleduc Micro en PDFchethanNessuna valutazione finora

- Sample Sealing Element PDFDocumento1 paginaSample Sealing Element PDFchethanNessuna valutazione finora

- Hydroleduc Micro en PDFDocumento24 pagineHydroleduc Micro en PDFchethanNessuna valutazione finora

- O-Ring Compression Force: Figures 2-4 2-5 2-6 2-7, 2-8Documento1 paginaO-Ring Compression Force: Figures 2-4 2-5 2-6 2-7, 2-8chethanNessuna valutazione finora

- Sample Assy of Jack - PDF PDFDocumento1 paginaSample Assy of Jack - PDF PDFchethanNessuna valutazione finora

- Maryland Metrics: Technical Data ChartDocumento10 pagineMaryland Metrics: Technical Data ChartchethanNessuna valutazione finora

- Lenovo Wrokstation Product PresentationDocumento19 pagineLenovo Wrokstation Product PresentationchethanNessuna valutazione finora

- Eriks Epdm 70 Compound 55985Documento2 pagineEriks Epdm 70 Compound 55985chethanNessuna valutazione finora

- FFGGGDocumento5 pagineFFGGGchethanNessuna valutazione finora

- Engineering Properties of Laterite Stone Scrap Blocks: S.K. Jain, P.G. Patil, N.J. ThakorDocumento11 pagineEngineering Properties of Laterite Stone Scrap Blocks: S.K. Jain, P.G. Patil, N.J. ThakorchethanNessuna valutazione finora

- Turbo CompressorsDocumento8 pagineTurbo CompressorskhibusinessdevelopmentNessuna valutazione finora

- Schneider Documentation - Hook-Up11sDocumento1 paginaSchneider Documentation - Hook-Up11sgenih44348Nessuna valutazione finora

- Types of Manual ValvesDocumento12 pagineTypes of Manual ValvesDuy Nguyen DucNessuna valutazione finora

- Chapter 1 GeneralitiesDocumento24 pagineChapter 1 GeneralitiesPuwa CalvinNessuna valutazione finora

- Bernoulis TheoremDocumento14 pagineBernoulis TheoremKhairulAzwanizamNessuna valutazione finora

- Revision Question Bank ME 2204Documento11 pagineRevision Question Bank ME 2204Rajendra Kumar YadavNessuna valutazione finora

- R Randen Engg - Bhushan - Valves Enq - 18Documento3 pagineR Randen Engg - Bhushan - Valves Enq - 18Vinayak PujariNessuna valutazione finora

- OpenDocumento9 pagineOpenchristian1777Nessuna valutazione finora

- Fisher N551 ESVDocumento2 pagineFisher N551 ESVWynn ChoNessuna valutazione finora

- Transonic Wind TunnelDocumento6 pagineTransonic Wind TunnelIsaiThamizhNessuna valutazione finora

- NicholsonDocumento177 pagineNicholsonParth AggarwalNessuna valutazione finora

- Manual Rosemount 1495 Orifice Plate 1496 Orifice Flange Union en 76098 PDFDocumento74 pagineManual Rosemount 1495 Orifice Plate 1496 Orifice Flange Union en 76098 PDFKamalNessuna valutazione finora

- Ives Keir Bassey Hamad Vol 10 Iss 1Documento10 pagineIves Keir Bassey Hamad Vol 10 Iss 1RomizNessuna valutazione finora

- Bisep Hot Tapping Plugging 1Documento7 pagineBisep Hot Tapping Plugging 1mospt100% (1)

- Centrifugal Pump Vs Centrifugal CompressorDocumento1 paginaCentrifugal Pump Vs Centrifugal CompressorMuhammad Rakha A.P.MNessuna valutazione finora

- Lab Experiment # 03: ObjectiveDocumento4 pagineLab Experiment # 03: ObjectiveSayam AliNessuna valutazione finora

- Emerson Centrifugal Oil SeparatorsDocumento2 pagineEmerson Centrifugal Oil SeparatorsEtienne AyigahNessuna valutazione finora

- Type HSR Pressure Reducing Regulator For Residential, Commercial, or Industrial ApplicationsDocumento20 pagineType HSR Pressure Reducing Regulator For Residential, Commercial, or Industrial ApplicationsVirgilMaroNessuna valutazione finora

- To Be Del Eted: Anchor Bolt M24 Scale 1/4Documento4 pagineTo Be Del Eted: Anchor Bolt M24 Scale 1/4dhiaa mohammedNessuna valutazione finora

- Forties Charlie Material Schematic: TopsideDocumento1 paginaForties Charlie Material Schematic: TopsidesnamprogNessuna valutazione finora

- Basics of Rotating Machines: Energy TransferDocumento11 pagineBasics of Rotating Machines: Energy Transfernico NicoNessuna valutazione finora

- Pumping of FluidDocumento12 paginePumping of Fluidramazan.00265477Nessuna valutazione finora