Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Checklist For Routine Maitenance

Caricato da

Mohd Kazi Abd Rahman0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

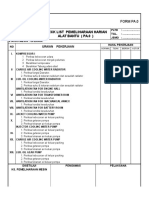

17 visualizzazioni1 paginaThe document is a routine maintenance checklist for a D3 injection system with 3 sections:

1) The injection skid section checks the strainer, piping integrity, system operation, pressure relief valves, pulsation dampener, and calibration column.

2) The heater section checks the heater panel temperature settings and integrity of the heater body connections.

3) The injection line section checks the piping integrity and condition of the nozzle on a monthly basis.

The checklist provides items to inspect weekly along with notes on action and completion.

Descrizione originale:

sa

Titolo originale

Checklist for Routine Maitenance.xlsx

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThe document is a routine maintenance checklist for a D3 injection system with 3 sections:

1) The injection skid section checks the strainer, piping integrity, system operation, pressure relief valves, pulsation dampener, and calibration column.

2) The heater section checks the heater panel temperature settings and integrity of the heater body connections.

3) The injection line section checks the piping integrity and condition of the nozzle on a monthly basis.

The checklist provides items to inspect weekly along with notes on action and completion.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

17 visualizzazioni1 paginaChecklist For Routine Maitenance

Caricato da

Mohd Kazi Abd RahmanThe document is a routine maintenance checklist for a D3 injection system with 3 sections:

1) The injection skid section checks the strainer, piping integrity, system operation, pressure relief valves, pulsation dampener, and calibration column.

2) The heater section checks the heater panel temperature settings and integrity of the heater body connections.

3) The injection line section checks the piping integrity and condition of the nozzle on a monthly basis.

The checklist provides items to inspect weekly along with notes on action and completion.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

Form No:

D3 INJECTION SYSTEM

Date:

RM-D3IS-16 (rev.0)

Checklist No:

Routine Maintenance Checklist

No

1.0

Check Item

Page: .........of......

Mill Name:

Observation / Result

Action To Be Taken

Completed

Description

Date

Injection Skid

1.1

Strainer Check for the presence of trapped solids and

clean as necessary.

1.2

Piping/Tubing Integrity Line check piping, tubing,

isolation valves and connections for any leakages.

System Operation Perform flow calibration regularly

1.3 to ensure that dosing chemical is being added at the

proper rate.

1.4

Pressure Relief and Back Pressure Valves Check to

ensure connections are tight.

1.5

Pulsation Dampener Check air pressure versus

recommended set point.

1.6

2.0

Calibration Column Check for sticky substance in the

column and perform internal cleaning if necessary in

order to have a clear view of liquid level inside.

Heater

Heater Panel Visually check the value of limit

2.1 temperature and setting temperature to ensure it still

on the setting range.

2.2

3.0

Check the integrity of the Heater Body and all related

connections.

Injection Line

3.1 Piping/Tubing Integrity Routinely check piping,

tubing, isolation valves and connections for leakages.

Nozzle Check the condition of nozzle and clean as

3.2 necessary. (Monthly check - every first week of the

month)

Note: All of the above items need to be checked on weekly basis except for item 3.2 which to be checked on monthly basis.

By

Potrebbero piacerti anche

- Major Works To Be DoneDocumento6 pagineMajor Works To Be DoneAustin UdofiaNessuna valutazione finora

- Pocket Guide to Preventing Process Plant Materials Mix-upsDa EverandPocket Guide to Preventing Process Plant Materials Mix-upsNessuna valutazione finora

- InstrumentDocumento8 pagineInstrumentfructoraNessuna valutazione finora

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- FAT ProcedureDocumento6 pagineFAT Procedurebmanojkumar16100% (2)

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesDa EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesValutazione: 1 su 5 stelle1/5 (2)

- Re 07900Documento2 pagineRe 07900lizbethdiosesNessuna valutazione finora

- DAC-REQ-08: Accreditation Requirements of Inspection Bodies For Pressure EquipmentDocumento21 pagineDAC-REQ-08: Accreditation Requirements of Inspection Bodies For Pressure EquipmentMetallurgist007100% (1)

- K & T Style Hydraulic System Test Analysers - ManualDocumento16 pagineK & T Style Hydraulic System Test Analysers - Manualpravesh bhartiNessuna valutazione finora

- EG 15-14-1.1 Inspection and Testing of InstrumentsDocumento3 pagineEG 15-14-1.1 Inspection and Testing of Instrumentsamin100% (1)

- Introduction To Static PressureDocumento4 pagineIntroduction To Static Pressure63ragtop100% (2)

- Maintenance and TroubleshootingDocumento3 pagineMaintenance and TroubleshootingOkta AdityaNessuna valutazione finora

- Preventive Maintenance Check:: Sample ProbeDocumento2 paginePreventive Maintenance Check:: Sample ProbeHANessuna valutazione finora

- Testing Procedure SprinklerDocumento2 pagineTesting Procedure SprinklerBea RullanNessuna valutazione finora

- Cooling System: Shutdown SIS Previous ScreenDocumento10 pagineCooling System: Shutdown SIS Previous ScreenMiharb FinouakefNessuna valutazione finora

- P&ID SeminarDocumento66 pagineP&ID Seminar蔡蕲82% (11)

- Split Air Conditioner TrainerDocumento2 pagineSplit Air Conditioner TrainerAhmed AzadNessuna valutazione finora

- DDC System Commissioning Acceptance Procedure: Example Project/Building DescriptionDocumento21 pagineDDC System Commissioning Acceptance Procedure: Example Project/Building DescriptionAbdul Mohid SheikhNessuna valutazione finora

- Appendix C2-Preventive Maintenance ChecklistDocumento10 pagineAppendix C2-Preventive Maintenance Checklisteeit_nizamNessuna valutazione finora

- TIMAS-PR-PI-005 - Piping Pressure Test, Flushing, BLW & Reinstate ProcedureDocumento16 pagineTIMAS-PR-PI-005 - Piping Pressure Test, Flushing, BLW & Reinstate ProcedureMechanical Static WRKNessuna valutazione finora

- Hydranautics TAB142 LDocumento9 pagineHydranautics TAB142 LMax JunghannsNessuna valutazione finora

- Pressure Testing & QC Test PackDocumento10 paginePressure Testing & QC Test Packravi00098Nessuna valutazione finora

- AC Presisi UniflairDocumento32 pagineAC Presisi UniflairBayu Hermawan0% (1)

- Functional Performance Test: FT: 15990-2 Item: Calibration and Leak-By Test Procedures ID: Area ServedDocumento4 pagineFunctional Performance Test: FT: 15990-2 Item: Calibration and Leak-By Test Procedures ID: Area Servedvin ssNessuna valutazione finora

- Clarifier and RSCDocumento6 pagineClarifier and RSCMuhd Fadzli HadiNessuna valutazione finora

- Sop Pressure TestDocumento5 pagineSop Pressure TestRichard Adolf100% (1)

- HTP-ER-OM-B-4 Maintenance Regulation For Chemistry SystemDocumento31 pagineHTP-ER-OM-B-4 Maintenance Regulation For Chemistry SystemJorge Luis Vera AlmeidaNessuna valutazione finora

- Reactor Control System & Reactor SafetyDocumento23 pagineReactor Control System & Reactor SafetyAmol MagarNessuna valutazione finora

- C: P: D: Factory Acceptance Test Procedure For Control Valve C - D N .: - Ptcs D N .: FCS-SOP-001. R 01 S: 1 10Documento13 pagineC: P: D: Factory Acceptance Test Procedure For Control Valve C - D N .: - Ptcs D N .: FCS-SOP-001. R 01 S: 1 10Hicham BelmaatiNessuna valutazione finora

- Hvac ToolsDocumento12 pagineHvac Toolsavicohvacr100% (2)

- Extendedsheet 5Documento2 pagineExtendedsheet 5osama hamadaNessuna valutazione finora

- Domestic Water Booster Test ProcedureDocumento6 pagineDomestic Water Booster Test ProcedureEduardo ChvaNessuna valutazione finora

- What Is Instrument Hook Up Diagram ? Instrument Hook Up Diagram Is Also Called Installation Drawing, Specifies The ScopeDocumento31 pagineWhat Is Instrument Hook Up Diagram ? Instrument Hook Up Diagram Is Also Called Installation Drawing, Specifies The ScopevrajakisoriDasiNessuna valutazione finora

- PPM CHECK LIST - Format 1Documento26 paginePPM CHECK LIST - Format 1Conrad WaluddeNessuna valutazione finora

- Chiller Testing Procedure Rev 3Documento11 pagineChiller Testing Procedure Rev 3Ali AimranNessuna valutazione finora

- Balancing of A Water and Air SystemsDocumento114 pagineBalancing of A Water and Air SystemselconhnNessuna valutazione finora

- Pre Action Fire Protection SystemDocumento117 paginePre Action Fire Protection SystemMohamed Aboobucker Mohamed IrfanNessuna valutazione finora

- Compressor Water Wash SystemDocumento10 pagineCompressor Water Wash SystemCarlos GonzálezNessuna valutazione finora

- PLCDocumento5 paginePLCAika CatalanNessuna valutazione finora

- MNT 016-04 AC Compressor OperationDocumento6 pagineMNT 016-04 AC Compressor OperationAniket kopateNessuna valutazione finora

- Start Up UnitDocumento40 pagineStart Up UnitchrisNessuna valutazione finora

- Compressed Air Distribution SystemDocumento12 pagineCompressed Air Distribution SystemPeterson muchiriNessuna valutazione finora

- Laboratory Activity 1 - Pages-2-3Documento2 pagineLaboratory Activity 1 - Pages-2-3WyndellRioNessuna valutazione finora

- Prefunctional ChecklistsDocumento37 paginePrefunctional Checklistsrenjithv_4100% (1)

- Instrumentations Symbols Diagrams Technologies: Maintenance and Repair Work. Instrument P&ID'sDocumento31 pagineInstrumentations Symbols Diagrams Technologies: Maintenance and Repair Work. Instrument P&ID'sAngeel MalicseNessuna valutazione finora

- Best Practice Guide For Power Transformer Maintenance EEPDocumento1 paginaBest Practice Guide For Power Transformer Maintenance EEPashutosh ambeyNessuna valutazione finora

- UREA PRODUCTION REPORT FinalDocumento17 pagineUREA PRODUCTION REPORT FinalAmir Javed officialNessuna valutazione finora

- PidDocumento85 paginePidvermaakash22Nessuna valutazione finora

- Control ValveDocumento16 pagineControl ValvedileepNessuna valutazione finora

- Piping Hydrotest ProcedureDocumento9 paginePiping Hydrotest Procedurewendypost73100% (1)

- Check List Pemeliharaan Harian Alat Bantu (Pa.0) : Sektor Tell0Documento35 pagineCheck List Pemeliharaan Harian Alat Bantu (Pa.0) : Sektor Tell0rahmanNessuna valutazione finora

- Breathing Air Quality IMPDocumento18 pagineBreathing Air Quality IMPMangesh KorlekarNessuna valutazione finora

- ZTE Macro BTS IntroDocumento15 pagineZTE Macro BTS IntroJohn EarleyNessuna valutazione finora

- Rmprtbiddoc PREFUNCTIONALCHECKLISTSDocumento37 pagineRmprtbiddoc PREFUNCTIONALCHECKLISTSDani HambalinaNessuna valutazione finora

- ObjectivesDocumento7 pagineObjectivesPeeka booNessuna valutazione finora

- Plant Testing Acceptance and Commissioning InstructionsDocumento1 paginaPlant Testing Acceptance and Commissioning InstructionssivavalaiNessuna valutazione finora

- Check ListDocumento6 pagineCheck Listiman2222Nessuna valutazione finora

- General Firefighting Wet Systems Method Statement For Testing & CommissioningDocumento11 pagineGeneral Firefighting Wet Systems Method Statement For Testing & CommissioningAhmad Omar100% (3)

- Air Cooled Package Units Roof Top Unit - AnnuallyDocumento2 pagineAir Cooled Package Units Roof Top Unit - AnnuallyDreamlinerNessuna valutazione finora

- Mechanical Engineering-Hydraulic Machines Important MCQ PDFDocumento10 pagineMechanical Engineering-Hydraulic Machines Important MCQ PDFJunaid KhanNessuna valutazione finora

- Applied Aerodynamics BookDocumento213 pagineApplied Aerodynamics BookYasser NogoudNessuna valutazione finora

- F1-20 Issue 6 Instruction ManualDocumento28 pagineF1-20 Issue 6 Instruction ManualWafaa AimanNessuna valutazione finora

- WORK 2 Gas Dyn - 2019-1Documento3 pagineWORK 2 Gas Dyn - 2019-1Victor RodriguesNessuna valutazione finora

- Valvulas AlivioDocumento64 pagineValvulas AlivioJose Andres Jimenez CasallasNessuna valutazione finora

- Vortex-Induced Oscillation-A Selective ReviewDocumento18 pagineVortex-Induced Oscillation-A Selective ReviewWade ZhouNessuna valutazione finora

- Density&Viscosity CalculatorDocumento15 pagineDensity&Viscosity CalculatorDennis Angelo PablicoNessuna valutazione finora

- DegummingDocumento41 pagineDegummingTan Han Kiat100% (2)

- Putting It All Together: OperationsDocumento34 paginePutting It All Together: OperationsIbrahim FaqaihNessuna valutazione finora

- MPFM Virtual Training June 2021 All Slides-1Documento247 pagineMPFM Virtual Training June 2021 All Slides-1hussein.talib.kadumNessuna valutazione finora

- TecHidro-L3 Watbal ManualDocumento44 pagineTecHidro-L3 Watbal ManualJoko NugrohoNessuna valutazione finora

- Fluid Mechanics ApplicationsDocumento29 pagineFluid Mechanics ApplicationsHASSAN ARSHADNessuna valutazione finora

- Heat ExchangerDocumento22 pagineHeat ExchangerYashwant SinghNessuna valutazione finora

- CFX MultiphaseDocumento2 pagineCFX MultiphaseNiamul Baqui100% (1)

- DRAINSDocumento11 pagineDRAINSAgus SugihartoNessuna valutazione finora

- 01 - Introduction To Well Testing PDFDocumento32 pagine01 - Introduction To Well Testing PDFviralrajgorNessuna valutazione finora

- Cavitation Apparatus FM 1849 21Documento15 pagineCavitation Apparatus FM 1849 21Alyan YousafNessuna valutazione finora

- HPLC Pump Spares Price List: January 2020Documento20 pagineHPLC Pump Spares Price List: January 2020mardonioandradeNessuna valutazione finora

- FLOWSHEET Minyak Ikan PenampungDocumento2 pagineFLOWSHEET Minyak Ikan PenampungdausykNessuna valutazione finora

- MBR Presentation For Filter InnovationsDocumento18 pagineMBR Presentation For Filter InnovationsGiang Huu Tai100% (1)

- 4796-09a52301 - Transport Phenomena in BioprocessesDocumento4 pagine4796-09a52301 - Transport Phenomena in BioprocessesNanditha MNessuna valutazione finora

- Live Control Valve Sizing Using Sizing ProgramDocumento14 pagineLive Control Valve Sizing Using Sizing ProgramnagarjunNessuna valutazione finora

- Water Treatment For Beverages and Soft Drinks IndustryDocumento7 pagineWater Treatment For Beverages and Soft Drinks IndustryAlysia PrinceNessuna valutazione finora

- Heat Transfer: Lecture 22: External Flow Forced ConvectionDocumento10 pagineHeat Transfer: Lecture 22: External Flow Forced ConvectionDavico MartinezNessuna valutazione finora

- A Mechanistic Model For Cuttings Transport PDFDocumento16 pagineA Mechanistic Model For Cuttings Transport PDFPaul Carlin SeminarioNessuna valutazione finora

- Bismillah RABDocumento144 pagineBismillah RABVerandinawina100% (1)

- PMC Projects (India) Pvt. LTD.: Adani Mormugao Port Terminal (P) LTDDocumento31 paginePMC Projects (India) Pvt. LTD.: Adani Mormugao Port Terminal (P) LTDrenger20150303Nessuna valutazione finora

- CFD Application in Fixed Bed Reactor InternalsDocumento22 pagineCFD Application in Fixed Bed Reactor InternalsSubhasish Mitra100% (2)

- Difloat - BrochureDocumento8 pagineDifloat - Brochurejpsingh75100% (1)

- Landfill LeachateDocumento32 pagineLandfill LeachateAzmi Pitt100% (2)