Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Civil JSA Form Block Work

Caricato da

drmuhsin86%(7)Il 86% ha trovato utile questo documento (7 voti)

5K visualizzazioni3 paginejob safety assessment

Copyright

© © All Rights Reserved

Formati disponibili

DOC, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentojob safety assessment

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

86%(7)Il 86% ha trovato utile questo documento (7 voti)

5K visualizzazioni3 pagineCivil JSA Form Block Work

Caricato da

drmuhsinjob safety assessment

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

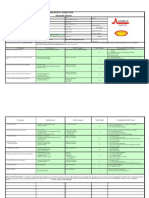

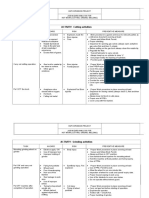

Job Safety Analysis

Project Name:

Maaden Alumina Refinery Project

Location:

Raz Al-Khair Industrial City

Reviewed By: -

Date:

Company:

Hyundai Engineering & Construction Co. LTD

Prepared By:

Approved By:-

Block Work

Sequence of Basic Job

Steps / Activity

Concrete surface

preparation

Potential Accidents or Hazards

Personnel Injury due to Slip/Trip/Fall

Risk Rating

Recommended Safe Job Procedures

Eye and hand injury due to chipping

work

Barricade around foundation trench.

Adequate lighting to be provided if work at night

Maintain high standard of house keeping

Initial Inspection by Work shop Supervisor and daily

equipment check to be carried out.

Regular maintenance programme to be made and

implemented to reduce any chance of repair.

Operator shall wear dust mask, cotton hand gloves, light

eye protection and Overall.

Compressed air line to be properly rated for pressure

involved and fitted with whip-checks.

Dead man switch is to be equipped with the air hose.

All large objects shall be removed by hand.

Provide shelter and sufficient drinking water

Use goggles, Cotton hand gloves and correct tools

No home made tools used.

Setting out

Survey equipment falls due to wind

or by hitting vehicle.

Legs of the tripod shall be well inserted into ground.

No activity at the time of heavy wind, sand storm.

Employ trained Banks man / traffic controller.

Preparation of cement

mortar / Grout.

Inhale / burn due to exposure to

cement

Use Rubber gloves, Dust mask , gum boot and safety

glass

Ensure availability of First aid at site.

Initial Inspection by Site Supervisor and daily equipment

check to be carried out as per check list

Regular maintenance programme to be made and

Failure of compressor / High

pressure air injury

Heat stress

Mechanical failure of mixer machine

/ Fire

Personnel hit with Rotating drum or

moving parts of mixer.

Pollution of soil by cement or mortar

Cement splash on eyes

Laying of Hollow block

Personnel Injury due to handling

blocks and flying fissures while

cutting

Collapse of scaffolding

Fall of men from scaffolding

implemented to reduce any chance of repair.

Provide fire extinguisher near the machine.

Keep minimum 60cm distance from the machine while

loading material.

All moving parts of machine to be guarded

Provide metal sheet / Polythene sheet at the place of

cement handling and mortar transferring.

Remove any cement or mortar fall or balance waste

immediately to designated dumping area

Trained Mixer operator

Ensure adequate supply of water to wash off any concrete

splashes.

Wear goggle with side shield. Also arrange eyewash

nearby.

Use leather gloves, Safety boot, Overall, Safety glass and

hard hat

Layman handling mortar shall use rubber gloves.

Blocks shall be lifted by bending ones knees and carrying

close to his body (straight back).

One block shall be lifted at a time manually.

Scaffolding erected by qualified scaffolder

Scaffolding is inspected by certified scaffolding supervisor

and signed in approved scaffolding tag.

Make sure soil below scaffolding legs are firm enough.

Provide wall ties and restrict the load to maximum

allowable as indicated on scaffolding tag.

Restrict the number of blocks conforming max.allowable

Wt. (300kg/m2 15 nos.)

Adequate barricading for working platform.

Wear full body harness belt and hook on top bracing

Placing steel

Personnel injury hitting rebar edge,

fissures or binding wire

Wear leather hand gloves, Safety glass, Overall, safety

shoes and hardhat.

Grout filling

Environmental pollution

Splash on eyes and injury to hand

or feet during pouring / levelling.

Plastic sheet should be used for waste collection disposal

of waste material as per RCER waste management policy.

Pour the grout from low height

Provide plywood sheet on both sides of block to prevent

splashing of the mix at the time of pour.

Wear Rubber hand gloves, safety glass, hardhat, Overall

Eyes, Hand/body injury from

protruding rebar

and polythene/disposable apron.

Mechanical failure of grout pump /

Fire

Secure Rebar extremes with wooden caps

Initial Inspection by work shop supervisor and daily

equipments check to be carried out as per check list

Regular maintenance programme to be made and

implemented to reduce any chance of repair.

Provide fire extinguisher near the machine.

Switch off while refuelling

Potrebbero piacerti anche

- JSA-Water Proofing WorksDocumento8 pagineJSA-Water Proofing Worksfrancis_e_tan100% (9)

- JSA CarpentryDocumento2 pagineJSA Carpentrysubhanmusadiq91% (11)

- Jsa For Installation of Fence & Area GradingDocumento11 pagineJsa For Installation of Fence & Area GradingKhuda Buksh80% (10)

- JSA PlumbingDocumento2 pagineJSA Plumbingsubhanmusadiq71% (7)

- Excavation and Back Filling Works JsaDocumento3 pagineExcavation and Back Filling Works Jsarashid zaman76% (17)

- Job Safety Analysis for Concrete WorksDocumento8 pagineJob Safety Analysis for Concrete Worksfrancis_e_tan93% (27)

- HARADH AND HAWIYAH FIELD GAS COMPRESSION PROJECT SAFETY ANALYSISDocumento8 pagineHARADH AND HAWIYAH FIELD GAS COMPRESSION PROJECT SAFETY ANALYSISsathakathulla100% (3)

- 003 JSA All Civil WorksDocumento5 pagine003 JSA All Civil WorksMohammed Minhaj100% (11)

- Jsa ExcavationDocumento33 pagineJsa Excavationlal5012002390782% (17)

- Job Safety Analysis PlumbersDocumento5 pagineJob Safety Analysis Plumbersallen2912100% (1)

- JSA - Fire Proofing WorksDocumento5 pagineJSA - Fire Proofing WorksAnis Uddin100% (3)

- JHA - Installation of Pipe & Support For Fire Protection 1Documento7 pagineJHA - Installation of Pipe & Support For Fire Protection 1Ralph Castillo100% (2)

- JSA - Cable Trench ExcavationDocumento9 pagineJSA - Cable Trench Excavationfrancis_e_tan75% (4)

- Job Safety Analysis (Jsa)Documento11 pagineJob Safety Analysis (Jsa)Noraini Binti Osman50% (2)

- Job Safety Analysis for Relay ConfigurationDocumento4 pagineJob Safety Analysis for Relay Configurationfrancis_e_tan100% (2)

- JSA Template 5 - Plumbing and Wastewater System InspectionsDocumento13 pagineJSA Template 5 - Plumbing and Wastewater System InspectionsSayed Darwish100% (2)

- SGD SAIPEM CAMP LOADING AND UNLOADINGDocumento2 pagineSGD SAIPEM CAMP LOADING AND UNLOADINGsubhanmusadiq82% (55)

- Australian StandardDocumento37 pagineAustralian StandardkrainajackaNessuna valutazione finora

- JSA-009a Drilling and Mon Well Construction-SonicDocumento4 pagineJSA-009a Drilling and Mon Well Construction-SonicDedi Apriadi83% (6)

- 7 - Civil WorkDocumento12 pagine7 - Civil WorkPerwez21100% (1)

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDocumento9 pagineHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- NWC Corporate Projects Risk Assessment Forms: Job / TaskDocumento3 pagineNWC Corporate Projects Risk Assessment Forms: Job / TaskNowfal HabeebNessuna valutazione finora

- JSA - CABLE TERMINATION TITLEDocumento4 pagineJSA - CABLE TERMINATION TITLESyed Yousuf Ali100% (1)

- Jsa For Civil Confined Space EntryDocumento11 pagineJsa For Civil Confined Space EntryKhuda BukshNessuna valutazione finora

- JSA Fitting and Welding Work For Pipe Trench InstalationDocumento6 pagineJSA Fitting and Welding Work For Pipe Trench InstalationAzmi Fauzi78% (9)

- Grinding Equipment Risk AssessmentDocumento3 pagineGrinding Equipment Risk Assessmentdroffilcz270% (1)

- Jsa For Tile FixingDocumento4 pagineJsa For Tile FixingMohammed Minhaj100% (1)

- Enterprise Data Management PDFDocumento18 pagineEnterprise Data Management PDFRajesh MurugesanNessuna valutazione finora

- Configuration of FSCM Dispute ManagementDocumento36 pagineConfiguration of FSCM Dispute Managementsapfico2k875% (4)

- Aboveground Piping Installation Works 2016Documento7 pagineAboveground Piping Installation Works 2016Aldrin75% (4)

- JHA Civil WorksDocumento2 pagineJHA Civil Worksethelchudi100% (11)

- JSA For False CeilingDocumento4 pagineJSA For False CeilingJaved100% (3)

- Jsa For Arc WeldingDocumento3 pagineJsa For Arc Weldingtnssbhaskar100% (5)

- JSA For Cutting, Grinding and WeldingDocumento4 pagineJSA For Cutting, Grinding and Weldingyc safety100% (3)

- JSA Cable LayingDocumento2 pagineJSA Cable Layingnishanth100% (2)

- Typical JHA FormDocumento5 pagineTypical JHA FormNasrullah Jan100% (4)

- DOCUMENT Loop Checking Activities JHADocumento8 pagineDOCUMENT Loop Checking Activities JHAFrancis Enriquez Tan83% (6)

- Tie in Hot Work JHADocumento4 pagineTie in Hot Work JHAmalik jahan100% (2)

- Jsa CraneDocumento3 pagineJsa Cranenattwa201075% (24)

- JSA WeldingDocumento2 pagineJSA WeldingSigint Sides0% (3)

- Job Steps Potential Hazards Recommended Safe Job ProceduresDocumento3 pagineJob Steps Potential Hazards Recommended Safe Job ProceduresDJadee Anuppur AmlaiNessuna valutazione finora

- Concrete Surface Coating JSA-027Documento5 pagineConcrete Surface Coating JSA-027shivgovind pal100% (1)

- JSA Earthwork Receiving BasinDocumento4 pagineJSA Earthwork Receiving BasinHilbrecht De Pedro100% (1)

- JSA Ladders Working at Heights 001Documento2 pagineJSA Ladders Working at Heights 001Raman SawNessuna valutazione finora

- Installation Safety AnalysisDocumento5 pagineInstallation Safety AnalysisLeo PascualNessuna valutazione finora

- Cement Plaster JSADocumento4 pagineCement Plaster JSAMohammed Minhaj50% (2)

- Concrete Cutting and Drilling PDFDocumento2 pagineConcrete Cutting and Drilling PDFcityofdarwingis100% (1)

- Coast Aluminum Catalog, 2019Documento200 pagineCoast Aluminum Catalog, 2019roberto silvaNessuna valutazione finora

- FactoryTalk® Batch Software SuiteDocumento8 pagineFactoryTalk® Batch Software SuiteVÕ QUỐC HIỆUNessuna valutazione finora

- Stockdale Method Roundabout PDFDocumento50 pagineStockdale Method Roundabout PDFAnonymous O7BzqVvmINessuna valutazione finora

- Civil JSA Form Application of Protective Coating On Sump PitsDocumento1 paginaCivil JSA Form Application of Protective Coating On Sump PitsdrmuhsinNessuna valutazione finora

- Jsa SKDocumento10 pagineJsa SKEngr Tahir UL Haq100% (2)

- Job Safety Analysis for Trench WorksDocumento1 paginaJob Safety Analysis for Trench Worksmurali100% (3)

- JSA For Material ShiftingDocumento3 pagineJSA For Material ShiftingMohammed Minhaj100% (1)

- JHA For Excavation Backfilling and Compaction R 01Documento6 pagineJHA For Excavation Backfilling and Compaction R 01Sreekumar100% (2)

- JSA MasnoryDocumento4 pagineJSA Masnorysubhanmusadiq100% (1)

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDocumento4 pagineJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- Lifting Operatio in Progress PDFDocumento1 paginaLifting Operatio in Progress PDFsubhanmusadiq100% (1)

- Jsa Installation of Supports and Cable Racks1Documento16 pagineJsa Installation of Supports and Cable Racks1loveson709100% (3)

- Jsa-Jha For Using of Hand ToolsDocumento2 pagineJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- JSA Unloading & SHIFTING by Manually 10-01-2017Documento16 pagineJSA Unloading & SHIFTING by Manually 10-01-2017PAVANKUMAR100% (1)

- Construction Site Health and Safety ProceduresDocumento3 pagineConstruction Site Health and Safety ProceduresArianne Mae De Vera GallonNessuna valutazione finora

- Safety Precautions Durring Dismentling of StructresDocumento83 pagineSafety Precautions Durring Dismentling of StructresshujaNessuna valutazione finora

- Pha ExcavationDocumento13 paginePha ExcavationirshadNessuna valutazione finora

- Concrete Manufacturing Hazards & SolutionsDocumento6 pagineConcrete Manufacturing Hazards & SolutionslilibethNessuna valutazione finora

- Piling Safety PlanDocumento8 paginePiling Safety PlanBalogun Isaac100% (1)

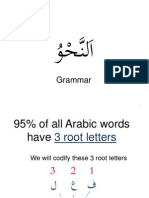

- Homework: Unit 7.1: Introduction To Arabic WordsDocumento9 pagineHomework: Unit 7.1: Introduction To Arabic Wordsdrmuhsin100% (1)

- Worksheet 1: Single IsmDocumento9 pagineWorksheet 1: Single IsmdrmuhsinNessuna valutazione finora

- Nahwu 003 3rd Feb Sound Male Plural1Documento22 pagineNahwu 003 3rd Feb Sound Male Plural1drmuhsinNessuna valutazione finora

- 09 Embryo Quran 110426082226 Phpapp01Documento46 pagine09 Embryo Quran 110426082226 Phpapp0107985Nessuna valutazione finora

- Section One: One Word (ND Casing)Documento4 pagineSection One: One Word (ND Casing)drmuhsinNessuna valutazione finora

- The Prophet Muhammad (Saw) - The Best of All HusbandsDocumento93 pagineThe Prophet Muhammad (Saw) - The Best of All Husbandsshug_bNessuna valutazione finora

- Nahwu 001 21st Jan Intro Single DualDocumento5 pagineNahwu 001 21st Jan Intro Single DualdrmuhsinNessuna valutazione finora

- Nahw 007 03rd Mar 2013Documento15 pagineNahw 007 03rd Mar 2013drmuhsin100% (1)

- Nahwu 004 10th Feb Sound Female PluralDocumento20 pagineNahwu 004 10th Feb Sound Female PluraldrmuhsinNessuna valutazione finora

- Week 005 Nahw 16th Feb 2014Documento8 pagineWeek 005 Nahw 16th Feb 2014drmuhsinNessuna valutazione finora

- Nahw Test PG 2 012 21st Apr 2013Documento1 paginaNahw Test PG 2 012 21st Apr 2013drmuhsinNessuna valutazione finora

- Week 013 Nahw 20th April 2014Documento12 pagineWeek 013 Nahw 20th April 2014drmuhsinNessuna valutazione finora

- Week 005 Nahw 16th Feb 2014Documento8 pagineWeek 005 Nahw 16th Feb 2014drmuhsinNessuna valutazione finora

- Nahw Test PG 2 012 21st Apr 2013Documento1 paginaNahw Test PG 2 012 21st Apr 2013drmuhsinNessuna valutazione finora

- Nahw 018 25th May 2014Documento6 pagineNahw 018 25th May 2014drmuhsinNessuna valutazione finora

- Nahw 006 24th Feb 2013Documento23 pagineNahw 006 24th Feb 2013drmuhsinNessuna valutazione finora

- Finding the doer and object (done uponDocumento10 pagineFinding the doer and object (done upondrmuhsinNessuna valutazione finora

- Nahw 006 24th Feb 2013Documento23 pagineNahw 006 24th Feb 2013drmuhsinNessuna valutazione finora

- Nahw 015 3rd May 2014 Root LettersDocumento6 pagineNahw 015 3rd May 2014 Root LettersdrmuhsinNessuna valutazione finora

- Nahw 007 03rd Mar 2013Documento15 pagineNahw 007 03rd Mar 2013drmuhsin100% (1)

- Nahw 014 27th April 2014 Root LettersDocumento19 pagineNahw 014 27th April 2014 Root LettersdrmuhsinNessuna valutazione finora

- Noun Basics: Verb ParticleDocumento15 pagineNoun Basics: Verb ParticledrmuhsinNessuna valutazione finora

- Arabic Vocabulary Bank: (Madinah Book 1 Chapter 1-23)Documento29 pagineArabic Vocabulary Bank: (Madinah Book 1 Chapter 1-23)mazad1985Nessuna valutazione finora

- In The Name of Allah, The Completely Merciful The Eternally MercifulDocumento13 pagineIn The Name of Allah, The Completely Merciful The Eternally MercifuldrmuhsinNessuna valutazione finora

- Lesson 41 Nahw RevisionDocumento10 pagineLesson 41 Nahw RevisiondrmuhsinNessuna valutazione finora

- 001 Nahwu 19th Jan Noun BasicsDocumento10 pagine001 Nahwu 19th Jan Noun Basicsdrmuhsin100% (1)

- AVS Sevice Desk and Desk Side Support SOODocumento28 pagineAVS Sevice Desk and Desk Side Support SOOCuong Duong DinhNessuna valutazione finora

- Add-On Scenery For MS FS2004, FSX & Prepar3D: InstallationDocumento10 pagineAdd-On Scenery For MS FS2004, FSX & Prepar3D: Installationrondon9897Nessuna valutazione finora

- Aviation Paperbacks 2012Documento4 pagineAviation Paperbacks 2012tomas.kujal8455Nessuna valutazione finora

- AgailDocumento34 pagineAgailnarasakuru79Nessuna valutazione finora

- Authorization Objects: Bi SecurityDocumento3 pagineAuthorization Objects: Bi SecurityDheeraj ReddyNessuna valutazione finora

- Nokia: FDD and TDD LTE Radio Planning (FL15A/TL15A)Documento6 pagineNokia: FDD and TDD LTE Radio Planning (FL15A/TL15A)tooma123Nessuna valutazione finora

- Training On Industrial Engineering Basics For RMGDocumento2 pagineTraining On Industrial Engineering Basics For RMGSalil BiswasNessuna valutazione finora

- Torneado del peón: Procesos de manufactura en el laboratorioDocumento14 pagineTorneado del peón: Procesos de manufactura en el laboratorioDanny Urtecho Ponte100% (1)

- ALGINATE ProductionDocumento14 pagineALGINATE ProductionMarnel Roy MayorNessuna valutazione finora

- Discharge Nozzle 360º Fedrxxx: DescriptionDocumento2 pagineDischarge Nozzle 360º Fedrxxx: Descriptionhatem hbibiNessuna valutazione finora

- SCHLENKER Katalog 2022 EN - WEBDocumento136 pagineSCHLENKER Katalog 2022 EN - WEBhosseinNessuna valutazione finora

- KrisEnergy LTD - Appendix D - Volume2Documento194 pagineKrisEnergy LTD - Appendix D - Volume2Invest StockNessuna valutazione finora

- Jerbi ResumeDocumento6 pagineJerbi ResumeLeah Nadine QuimzonNessuna valutazione finora

- Operation Management AssigementDocumento11 pagineOperation Management AssigementYogendra RathoreNessuna valutazione finora

- Abhishek Kumar SinghDocumento3 pagineAbhishek Kumar SinghAshutosh UpadhyayNessuna valutazione finora

- Jha of PaintingDocumento3 pagineJha of PaintingAllan Camacho Regalado100% (1)

- Tube Cutter: MS-TC-308Documento1 paginaTube Cutter: MS-TC-308Claudio SavazziNessuna valutazione finora

- Topic 2 - Cargo Handling and StowageDocumento17 pagineTopic 2 - Cargo Handling and StowageHemonNessuna valutazione finora

- Problem Set Ee8205 PDFDocumento4 pagineProblem Set Ee8205 PDFksajjNessuna valutazione finora

- 487 - 1 - MSSL Press Release-August 2018Documento2 pagine487 - 1 - MSSL Press Release-August 2018Varun SidanaNessuna valutazione finora

- Pass RulesDocumento40 paginePass Ruleslvsaru50% (2)

- Gyrolok CatalogDocumento58 pagineGyrolok CatalogmartinvandoornNessuna valutazione finora

- Guidelines For HOLES in BONDEK II SheetDocumento4 pagineGuidelines For HOLES in BONDEK II SheetSK ChauNessuna valutazione finora

- Sudhakar ProjDocumento71 pagineSudhakar ProjsureshexecutiveNessuna valutazione finora