Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Individual SPC Assignment

Caricato da

api-298975236Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Individual SPC Assignment

Caricato da

api-298975236Copyright:

Formati disponibili

Running head: INDIVIDUAL SPC ASSIGNMENT

Individual SPC Assignment

Bernard Godfrey

Siena Heights University

LDR 640-OA

Professor Lucas

INDIVIDUAL SPC ASSIGNMENT

Individual SPC Assignment

Question 1 Data:

A drive-in restaurant is running a new promotion, the "Route 44," named after an interstate that

runs through their primary market area. The drink is promoted as 44 ounces of pure carbonated

pleasure but the regional manager, being somewhat of a quality expert, wants to make sure that

the company's drink process can deliver 44 ounces. He decides statistical quality control is the

best way to monitor their process.

For ten consecutive days he purchases five Route 44 drinks from franchise locations on his way

to headquarters and turns them over to the testing lab for volume analysis. The data appear in the

table; all amounts are in fluid ounces as measured by the testing lab.

Sample

Drink 1

Drink 2

Drink 3

Drink 4

Drink 5

43.51

41.47

42.15

48.15

47.14

47.94

47.90

49.72

48.68

41.71

42.05

44.65

47.37

41.43

48.32

41.72

47.94

46.68

43.13

40.62

46.98

48.39

41.30

46.52

43.44

40.83

42.44

48.94

46.74

41.83

48.76

41.65

46.41

44.73

48.41

49.53

46.18

49.65

40.11

47.08

43.42

41.16

46.53

48.23

47.63

INDIVIDUAL SPC ASSIGNMENT

10

46.56

41.10

41.04

40.56

43.06

Since the regional manager is somewhat of a quality expert, he needs your help in formulating a

control chart that will monitor the process performance to target. Develop the

appropriate metrics:

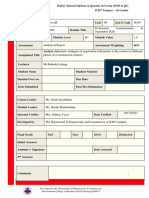

Sample Mean (X-Bar)

Grand Mean (Double X-Bar)

Sample Range (R)

Average Range (R-Bar)

Calculate Upper and Lower control limits

Is the process in control? Explain

Sample Mean (X-bar), Sample Range (R), Grand Mean (Double X-Bar), and Average

Range (R-Bar):

Sample

Drink 1

Drink 2

Drink 3

Drink 4

Drink 5

X-Bar

43.51

41.47

42.15

48.15

47.14

44.484

6.68

47.94

47.9

49.72

48.68

41.71

47.19

8.01

42.05

44.65

47.37

41.43

48.32

44.764

6.89

41.72

47.94

46.68

43.13

40.62

44.018

7.32

46.98

48.39

41.3

46.52

43.44

45.326

7.09

40.83

42.44

48.94

46.74

41.83

44.156

8.11

48.76

41.65

46.41

44.73

48.41

45.992

7.11

INDIVIDUAL SPC ASSIGNMENT

49.53

46.18

49.65

40.11

47.08

46.51

9.54

43.42

41.16

46.53

48.23

47.63

45.394

7.07

10

46.56

41.1

41.04

40.56

43.06

42.464

Grand Mean (X-Dbl Bar) = 45.0298

Average Range (R-Bar) = 7.382

Upper and Lower Control Limits:

X-Bar Upper Control Limits formula used: X-Dblbar+A2*R-Bar

X-Bar Lower Control Limits formula used: X-Dblbar-A2*R-Bar

R-Bar Upper Control Limits formula used: D4*R-Bar

R-Bar Lower Control Limits formula used: D3*R-Bar

X-bar

Chart

R chart

LCL

CL

UCL

LCL

CL

UCL

40.77039

45.0298

49.28921

7.382

15.60555

INDIVIDUAL SPC ASSIGNMENT

Sample Mean (X-bar)

51

49

47

45

43

41

39

37

35

4

X-Bar

LCL

CL

10

10

UCL

Sample Range (R)

18

16

14

12

10

8

6

4

2

0

Question 2:

The process engineers have designed our drink process with an upper tolerance of 46 ounces

and a lower tolerance of 42 ounces. I wonder what our process capability really is? I've been

reading about Six Sigma; it would be fantastic if we could add that to our already fantastic

slogan regarding this new beverage!"

INDIVIDUAL SPC ASSIGNMENT

Process Capability Formulas:

Sigma= R bar / D2

7.38 / 2.33 = 3.2

USL=46

LSL=42

Mean (x-bar) =45.03

Sigma (SD)= 3.2

Cp= (46-42) / 6*3.2

Cp= 4 / 19.2

Cp= .20

CpU= (46-45.03) / 3*3.2

CpU= .97 / 9.6

CpU= .10

CpL= (45.03-42) / 3*3.2

CpL= 3.03 / 9.6

CpL= .32

CpK= Min(45.03-42 / 3*3.10 ; 46-45.03 / 3*3.10)

CpK= Min(3.03 / 9.6 ; .97 / 9.6)

CpK= Min(.32 , .10)

CpK=.10

INDIVIDUAL SPC ASSIGNMENT

Conclusion

According to Infinity QS (nd.) Data that falls within the control limits indicates that

everything is operating as expected. Any variation within the control limits is likely due to a

common causethe natural variation that is expected as part of the process (para. 2). Because

the sample stayed within the upper control limit of 49.3 and the lower control limit of 40.8 it is in

control; however, the CpK is .10. A CpK of less than 1 is not capable of at least delivering a 3

sigma result. Therefore, deeming this not capable. Because the intended drink was to be 44

ounces and the sample yielded a grand mean of 45.03 ounces shifted the distribution off center.

With a Cpk of .10 only 10 percent of the 6 sigma ruler would fit in this curve. Also, I would add

that, in my opinion, just because the sample stayed within the upper and lower control limits

doesnt necessarily mean its in control. The grand mean was 45 ounces. The intended amount

was 44 ounces. That means the company is losing 1 ounce on every drink sold.

Follow up question on week five video:

INDIVIDUAL SPC ASSIGNMENT

What can we do to fix this issue?

According to Smith (2006) All work is a process, all processes have variability and all

processes create data that explains variability (para. 11). Because the process is not capable, we

have a variability issue. The process in place for pouring the route 44 drink at the drive-in

restaurant is clearly flawed and not consistent. I believe one can see this is a good area to utilize

the Six Sigma methodology. According to Cowman (2005) Six Sigma can be applied to any

business process where the quality of the result may be quantified and the results of each process

tracked (p.69). By analyzing the process and tracking inconsistencies, the flaws will surface and

the ability to fix those flaws will be possible. Six Sigma has processes that will track leading

indicators of problems to prevent them from happening again (HR Focus, 2007, p. 6).

Another process that could expose quality issues is Total Quality Management (TQM).

When Neave (1990) discussed Dr. Demings philosophy he talked first about the constancy of

purpose. The need to know that continually improving is necessary and second, this philosophy

needs to be maintained. The third is cease of mass inspection. If the process is constant

improvement, inspections will not be needed. The quality is always being inspected. Also, points

like improve every process, institute training on the job, institute leadership, eliminate numerical

targets, and permit pride of workmanship are all key to quality (Neave, 1990).

Dr. Juran had a three step process that runs simultaneously with each other. They are (1)

Quality planning which is where you discover what the customer needs and a system is designed

to make sure those needs are met. (2) Quality Control is the process that monitors the

performance to make sure it complies with the original design standards that were developed. If

the standards fall short, systems are put in place to deal with those short falls. (3) Quality

INDIVIDUAL SPC ASSIGNMENT

improvement is when levels of performance are made better. In other words, when previously

un-obtained levels of performance are obtained (Juran, 1986).

Getting back to the original question of what can we do to fix the route 44 drinks

capability process? I think it is clear to see that some type of quality management process is

needed. Either TQM or Six Sigma.

INDIVIDUAL SPC ASSIGNMENT

10

References

Cowman, K. (2005). Six sigma: What, where, when, why & how. Materials Management and

Distribution, 50(8), 69. Retrieved from http://search.proquest.com/docview/227981602?

accountid=28644

How six sigma may help HR to improve processes and services. (2007). HR Focus,84(12), 5-7.

Retrieved from http://search.proquest.com/docview/206801938?accountid=28644

Infinity QS. (n.d.). What is Statistical Process Control (SPC)? Retrieved April 8, 2016, from

http://www.infinityqs.com/resources/what-is-spc

Juran, J. M. (1986, May 20). The Quality Trilogy. Retrieved March 25, 2016, from

http://threadcontent.next.ecollege.com/CurrentCourse/Juran Trilogy.pdf

Neave, H. R. (1990). Deming'88 * .Part 1: Win-win, joy in work, and innovation. Total Quality

Management, 1(1), 33-48.

Smith, K. (2006, May 3). Quality Digest Magazine. Retrieved March 25, 2016, from

http://www.qualitydigest.com/may03/articles/01_article.shtml

Potrebbero piacerti anche

- Individual SPC AssignmentDocumento8 pagineIndividual SPC Assignmentapi-298002927Nessuna valutazione finora

- QS Btac Construction TechnologyDocumento6 pagineQS Btac Construction TechnologyThushanka Thimira100% (1)

- Family Secure protection with flexibility to change coverageDocumento8 pagineFamily Secure protection with flexibility to change coverageMärinël VëlmöntëNessuna valutazione finora

- MOSFET Electronics Devices AssignmentDocumento5 pagineMOSFET Electronics Devices AssignmentShaheer ShahzadNessuna valutazione finora

- Logistics Center Location OptimizationDocumento3 pagineLogistics Center Location OptimizationTôn Nữ Minh UyênNessuna valutazione finora

- g10 - Full Report Amali 3Documento26 pagineg10 - Full Report Amali 3Najied NajmieNessuna valutazione finora

- A Minor Project Report ON: Channel Development at Max New York LifeDocumento52 pagineA Minor Project Report ON: Channel Development at Max New York LifeYatin AroraNessuna valutazione finora

- Working Capital Management and Financial AnalysisDocumento9 pagineWorking Capital Management and Financial AnalysisFahmy KfNessuna valutazione finora

- BPM AssigmentDocumento15 pagineBPM AssigmentNeha YadavNessuna valutazione finora

- Global Strategy Final Assigment SubmissionDocumento18 pagineGlobal Strategy Final Assigment SubmissionJahangir Ishaq RanaNessuna valutazione finora

- Assignment 1Documento3 pagineAssignment 1kawishNessuna valutazione finora

- BCU BSC in QS CP - Assignment - July Intake 2020Documento8 pagineBCU BSC in QS CP - Assignment - July Intake 2020ලහිරු විතානාච්චිNessuna valutazione finora

- History of Construction Industry from Ancient Egypt to PresentDocumento24 pagineHistory of Construction Industry from Ancient Egypt to PresentOshadaNessuna valutazione finora

- Micro Assignment 1 PDFDocumento14 pagineMicro Assignment 1 PDFAinulNessuna valutazione finora

- Eco Assignment 1Documento17 pagineEco Assignment 1Mei Yee100% (1)

- Assignment#2Documento2 pagineAssignment#2Mavi Sang-olanNessuna valutazione finora

- BS 110 Assignment 1Documento4 pagineBS 110 Assignment 1Mario Rioux JnrNessuna valutazione finora

- Assignment 2 DR ShantalDocumento4 pagineAssignment 2 DR ShantalBishoy EmileNessuna valutazione finora

- Math Lesson Plan-WeeblyDocumento5 pagineMath Lesson Plan-Weeblyapi-489828484Nessuna valutazione finora

- Advanced Diploma in Construction Quantity Surveying - Tendering, Estimating & BOQ ProjectDocumento1 paginaAdvanced Diploma in Construction Quantity Surveying - Tendering, Estimating & BOQ ProjectDinesh KimrajNessuna valutazione finora

- Qs 4002 Bted AssignmentDocumento7 pagineQs 4002 Bted AssignmentweerasinghekNessuna valutazione finora

- Indusrial Assigment 2Documento13 pagineIndusrial Assigment 2Naima Abdikarim sirajiNessuna valutazione finora

- LSP 401 Fe q1 - Sample RCDocumento11 pagineLSP 401 Fe q1 - Sample RCHani HanimNessuna valutazione finora

- Group 3: Anggun Nurul HayatiDocumento21 pagineGroup 3: Anggun Nurul HayatiAndiGunturPratomoNessuna valutazione finora

- OmNarayanSingh CC306 IS FinalDocumento15 pagineOmNarayanSingh CC306 IS FinalOm SinghNessuna valutazione finora

- Competitive Advantage and Organizational Performance Through Supply Chain Management PracticesDocumento22 pagineCompetitive Advantage and Organizational Performance Through Supply Chain Management PracticesSwapnil JaiswalNessuna valutazione finora

- FGV Acquisition Plan: Financial Analysis On IOI and KLKDocumento48 pagineFGV Acquisition Plan: Financial Analysis On IOI and KLKAlexis ChooNessuna valutazione finora

- Fair - 13 - Internship BookletDocumento38 pagineFair - 13 - Internship BookletNoha AshrafNessuna valutazione finora

- Final Report CNIDocumento35 pagineFinal Report CNIHakimNessuna valutazione finora

- Bachelor Administrative Science Program StructureDocumento2 pagineBachelor Administrative Science Program StructureAin DhiraNessuna valutazione finora

- Design 3-Bit Binary CounterDocumento10 pagineDesign 3-Bit Binary CounterrodzdNessuna valutazione finora

- Tutorial 5 Eco 415Documento7 pagineTutorial 5 Eco 415ZhiXNessuna valutazione finora

- Assignment TwoDocumento5 pagineAssignment TwoAmal RidèneNessuna valutazione finora

- Mat523 Mini Project PDFDocumento37 pagineMat523 Mini Project PDFIzyan NabilahNessuna valutazione finora

- Afidah Binti Abu Bakar 10 - 24Documento24 pagineAfidah Binti Abu Bakar 10 - 24chithirai10Nessuna valutazione finora

- Azar Lab1 Mem564Documento9 pagineAzar Lab1 Mem564AZAR DANFUDI NAMAZINessuna valutazione finora

- Bus 500 Final ReportDocumento27 pagineBus 500 Final ReportTanay sahaNessuna valutazione finora

- Sampling Theory and Hypothesis TestingDocumento21 pagineSampling Theory and Hypothesis TestingMahendranath RamakrishnanNessuna valutazione finora

- ISO-1675 Liquid Resins - Determination of Density by The Pyknometer MethodDocumento8 pagineISO-1675 Liquid Resins - Determination of Density by The Pyknometer MethodDawn HaneyNessuna valutazione finora

- Project Proposal TemplateDocumento8 pagineProject Proposal TemplateJason ChaiNessuna valutazione finora

- Report Managerial Finance@UniklDocumento18 pagineReport Managerial Finance@UniklLee WongNessuna valutazione finora

- Akw 104Documento8 pagineAkw 104Ting Sie KimNessuna valutazione finora

- Mini Project Linear Algebra IIDocumento31 pagineMini Project Linear Algebra IINUR RABIATUL ALYA AMRULNIZAMNessuna valutazione finora

- Chapter 3 - Images (CSC 413-UiTM)Documento41 pagineChapter 3 - Images (CSC 413-UiTM)norlina90Nessuna valutazione finora

- Problem 5Documento1 paginaProblem 5Thu NgânNessuna valutazione finora

- This Coursework Should Take An Average Student Who Is Up-To-Date With Tutorial Work Approximately 40 HoursDocumento8 pagineThis Coursework Should Take An Average Student Who Is Up-To-Date With Tutorial Work Approximately 40 HoursdharshinishuryaNessuna valutazione finora

- Hand Sanitizer - PosterDocumento1 paginaHand Sanitizer - PosterDamia Azizi100% (1)

- Amir Abdullah Bin Muhamad DamanhuriDocumento45 pagineAmir Abdullah Bin Muhamad Damanhurimr5jalNessuna valutazione finora

- Personal Introduction With Photo: RD ND STDocumento5 paginePersonal Introduction With Photo: RD ND STAliNessuna valutazione finora

- Continuous Process Improvement MethodsDocumento76 pagineContinuous Process Improvement MethodsRahulNessuna valutazione finora

- Assessment 1 Instructions - Process Improvement Plan - ..Documento4 pagineAssessment 1 Instructions - Process Improvement Plan - ..Brian MachariaNessuna valutazione finora

- HW 6Documento6 pagineHW 6api-569240036Nessuna valutazione finora

- Six Sigma - The InitiativeDocumento26 pagineSix Sigma - The InitiativeCHAUDHARY BHAINessuna valutazione finora

- Total Quality Management - Cont'd: Prepared by Wiley Education Canada To Support The Textbook Chosen in This CourseDocumento40 pagineTotal Quality Management - Cont'd: Prepared by Wiley Education Canada To Support The Textbook Chosen in This CourseAmir HossainNessuna valutazione finora

- Deming, Juran & Crosby Trilogy To Tadays Business Scenario For World Class PerformanceDocumento16 pagineDeming, Juran & Crosby Trilogy To Tadays Business Scenario For World Class Performancenikhilgujar127Nessuna valutazione finora

- Sigma Presentation1Documento15 pagineSigma Presentation1elmerpabelNessuna valutazione finora

- GAP AnalysisDocumento13 pagineGAP AnalysisMrunal ShirsatNessuna valutazione finora

- Leanmap FREE Quality Processes OverviewDocumento2 pagineLeanmap FREE Quality Processes OverviewWixi MundoNessuna valutazione finora

- What Is Quality by DesignDocumento16 pagineWhat Is Quality by Designnoned273Nessuna valutazione finora

- Paul White - Oakland ConsultingDocumento49 paginePaul White - Oakland ConsultingDarpan BegdaiNessuna valutazione finora

- Final ProjectDocumento14 pagineFinal Projectapi-298975236Nessuna valutazione finora

- Business Plan MriDocumento17 pagineBusiness Plan Mriapi-298975236100% (1)

- Team A - Affordable Care Act Assignment 1Documento9 pagineTeam A - Affordable Care Act Assignment 1api-298975236Nessuna valutazione finora

- Conceptual BlocksDocumento11 pagineConceptual Blocksapi-298975236100% (3)

- Resume No AddressDocumento2 pagineResume No Addressapi-298975236Nessuna valutazione finora

- 4 24 16 SP Final Master For Team 2 1Documento39 pagine4 24 16 SP Final Master For Team 2 1api-298975236Nessuna valutazione finora

- Leadership CompetenciesDocumento5 pagineLeadership Competenciesapi-298975236Nessuna valutazione finora

- Leadership and MissionDocumento5 pagineLeadership and Missionapi-298975236Nessuna valutazione finora

- Chapter Nine Conducting The IT Audit: Lecture OutlineDocumento22 pagineChapter Nine Conducting The IT Audit: Lecture OutlineKiervin ReyesNessuna valutazione finora

- E FSS5 Attm1 General-Machine-Checklist Rev2 090330 PDFDocumento11 pagineE FSS5 Attm1 General-Machine-Checklist Rev2 090330 PDFJorge Luis MalagonNessuna valutazione finora

- OpenVox G410E On Elastix Guide ManualDocumento18 pagineOpenVox G410E On Elastix Guide ManualMarco CarvalhoNessuna valutazione finora

- Robert Fludd's Utriusque Cosmi Maioris Salicet Et Minoris Metaphysica..Documento9 pagineRobert Fludd's Utriusque Cosmi Maioris Salicet Et Minoris Metaphysica..isseauNessuna valutazione finora

- UL 2818 Certification-Greenguard 2017Documento16 pagineUL 2818 Certification-Greenguard 2017brpereira100% (1)

- Use of HTML TagsDocumento19 pagineUse of HTML Tagsishdeep singhNessuna valutazione finora

- Toshiba Satellite L55-A5299 User Manual20160419248597Documento4 pagineToshiba Satellite L55-A5299 User Manual20160419248597Jaime VanegasNessuna valutazione finora

- Kepware Manufacturing Suite PDFDocumento2 pagineKepware Manufacturing Suite PDFEdwin PariNessuna valutazione finora

- Basic Module Type PVBZ PVP With IntegratedDocumento16 pagineBasic Module Type PVBZ PVP With IntegratedHYDRAULICGURUNessuna valutazione finora

- HCI6K-07-TD-EN - Rev - A STAMFORD PDFDocumento7 pagineHCI6K-07-TD-EN - Rev - A STAMFORD PDFEduard Florez EfresNessuna valutazione finora

- FFS-SU-5274 Deepwater CALM Buoy Offloading SystemDocumento50 pagineFFS-SU-5274 Deepwater CALM Buoy Offloading SystemMinh Hong PhamNessuna valutazione finora

- NXP Elektronika LPC55 VTS ReferenceDocumento5 pagineNXP Elektronika LPC55 VTS ReferenceArun rajNessuna valutazione finora

- Piano Tuning & Repair: Developed by Francis ChilcoatDocumento8 paginePiano Tuning & Repair: Developed by Francis ChilcoatAleksandraMladenovićNessuna valutazione finora

- Def Stan 03-32 Part 2 Paint-Systems For Ferrous ArmourDocumento10 pagineDef Stan 03-32 Part 2 Paint-Systems For Ferrous ArmourDeepto BanerjeeNessuna valutazione finora

- 5000 Series Control Valves: It All Flows From ExpertiseDocumento7 pagine5000 Series Control Valves: It All Flows From Expertiseluis piNessuna valutazione finora

- A Sweet Lullaby For World Music-FeldDocumento916 pagineA Sweet Lullaby For World Music-FeldelakirNessuna valutazione finora

- Hardware UkDocumento7 pagineHardware UkLucian RobNessuna valutazione finora

- Universidad de Manila: A.J. Villegas ST., Mehan Gardens, Manila CityDocumento1 paginaUniversidad de Manila: A.J. Villegas ST., Mehan Gardens, Manila CityMayeth BotinNessuna valutazione finora

- Kenguru Catalog 2014Documento41 pagineKenguru Catalog 2014Milan DimitrijevićNessuna valutazione finora

- BS Iso 22915-1,2016Documento20 pagineBS Iso 22915-1,2016ragesh r nairNessuna valutazione finora

- Token bus network protocol explainedDocumento26 pagineToken bus network protocol explainedgauravkumawat18Nessuna valutazione finora

- Conector NeutrikDocumento4 pagineConector NeutrikPracticante AlmacenNessuna valutazione finora

- Data Sheet Speaker StrobeDocumento4 pagineData Sheet Speaker StrobeAneesh ConstantineNessuna valutazione finora

- Manual Eco 5 CompactDocumento108 pagineManual Eco 5 Compactmarcelo1315Nessuna valutazione finora

- E-RAAJA E-Rickshaw Drive System GuideDocumento18 pagineE-RAAJA E-Rickshaw Drive System GuidesksinghkgnNessuna valutazione finora

- Slave Addressing for Monochrome and Color PLCsDocumento5 pagineSlave Addressing for Monochrome and Color PLCsIsidro Igigi HernándezNessuna valutazione finora

- Elevator MANUALDocumento10 pagineElevator MANUALShankar ArunmozhiNessuna valutazione finora

- Industrial Diesel Hydraulic Crane: TIL LimitedDocumento4 pagineIndustrial Diesel Hydraulic Crane: TIL LimitedNageswara Reddy GajjalaNessuna valutazione finora

- Manual SRA L XD PlugIn 7 7Documento60 pagineManual SRA L XD PlugIn 7 7Dorobo WarubozoNessuna valutazione finora

- FedEx WebServices DevelopersGuideDocumento767 pagineFedEx WebServices DevelopersGuideSantosh TelawaneNessuna valutazione finora