Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lab1 3-Step Synthesis

Caricato da

api-3142008140 valutazioniIl 0% ha trovato utile questo documento (0 voti)

147 visualizzazioni1 paginaTetraphenylcyclopentadienone was made from oxidizing benzoin with nitric acid. The melting point of the purified product was 86-91. DegC. Few crystals were recovered resulting in a low yield of 18.17%.

Descrizione originale:

Titolo originale

lab1 3-step synthesis

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoTetraphenylcyclopentadienone was made from oxidizing benzoin with nitric acid. The melting point of the purified product was 86-91. DegC. Few crystals were recovered resulting in a low yield of 18.17%.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

147 visualizzazioni1 paginaLab1 3-Step Synthesis

Caricato da

api-314200814Tetraphenylcyclopentadienone was made from oxidizing benzoin with nitric acid. The melting point of the purified product was 86-91. DegC. Few crystals were recovered resulting in a low yield of 18.17%.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

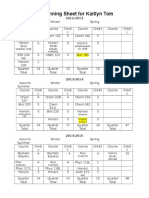

Kaitlyn Tom AH

3-Step Synthesis Lab

Discussion:

In step 1 of this 3-step synthesis, I made benzil by oxidizing benzoin with nitric acid. Progression of

the reaction was monitored using TLC. After crystallization in an ice bath followed by vacuum

filtration, a melting point of the crude product was taken to determine its purity. The products

melting point, 64.4-71.0 C, was wide-ranging and depressed. The crude product was then

recrystallized with 95% ethanol. The melting point of the purified product, 86-91.9 C, was much

closer to the literature value of benzil (94.4-95.1 C). Few crystals were recovered however,

resulting in a low yield of 18.17%.

In step 2, I prepared tetraphenylcyclopentadienone from the aldol reaction of benzil (step1) and

dibenzylketone. Due to my low yield from day 1, I supplemented my product with additional

prepared benzil to make 0.1 g. After heating and refluxing the reaction, crystallization and filtration

were performed to isolate the crude product. The crude melting point, 213.6-215 C, was slightly

depressed. After recrystallization with 95% ethanol and toluene, a melting point of the purified

product was taken and determined to be 218.6-219 C. This value is sharp, narrow, and very close to

the expected melting point of tetraphenylcyclopentadienone (219-220 C). My % recovery was

determined to be 25.16%.

In the last step, I synthesized tetraphenylnaphthalene from the diels-alder reaction of

tetraphenylcyclopentadienone (day 2) and benzyne. Due to my low yield from day 2, I

supplemented my product with additional prepared tetraphenylcyclopentadienone to make 0.1 g

After heating and refluxing the reaction, I noticed a color change from deep purple to orange

(signifying completion of the reaction). The melting point of the crude product (crystallized and

filtered) was revealed to be 199.6-201.5 C, which, compared to tetraphenylnaphthalenes expected

melting point value of 199-201 C, is sharp, narrow, and nearly identical. My calculated % recovery

was 47.11%.

Conclusion:

Despite my low % yields, the overall reaction was a success. The expected color changes were

observed, and the relative sharpness and proximity of my melting points to the literature values of

the expected products indicated few impurities were present and that benzil,

tetraphenylcyclopentadienone, and tetraphenylnaphthalene were produced (respectively). The one

exception was the depressed and wide-ranging melting point of my crude benzil product from step

1, which indicated that impurities remained. Recrystallization, however, successfully removed these

impurities (thus explaining the sharper melting point of the purified product). In step 1, my low

yield may have resulted from removing the reaction mixture from the heat prematurely (before all

of the red gases disappeared). This would have resulted in lesser product being formed. In step 2,

my low yield may have been due to dissolving my product in too much solvent (this would have

resulted in more product staying in solution) and secondly, some of my solid escaping the filter

paper and ending up in the bottom of the filter flask. My low yield from step 3 may have resulted

from the loss of product in the transfer from the funnel to the watch glass. In the future, I can

improve my recrystallization technique and chances of % recovery by using a minimum amount of

solvent, waiting until the entire reaction has run to completion, and transferring product carefully to

minimize loss.

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- 4 YearplanDocumento3 pagine4 Yearplanapi-314200814Nessuna valutazione finora

- Critical Incident EssayDocumento2 pagineCritical Incident Essayapi-314200814Nessuna valutazione finora

- Honors 394 Music Presentation-2Documento14 pagineHonors 394 Music Presentation-2api-314200814Nessuna valutazione finora

- Henrietta Lacks PaperDocumento7 pagineHenrietta Lacks Paperapi-314200814Nessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Drinking Straw From Coconut Leaf A Study of Its Ep PDFDocumento11 pagineDrinking Straw From Coconut Leaf A Study of Its Ep PDFKathiravan Rajendran100% (1)

- Standard Spec FAME-EBTKE+PETDocumento1 paginaStandard Spec FAME-EBTKE+PETMuhamad Firmansyah Hermana PutraNessuna valutazione finora

- Long Answer Questions A LEVEL BIOLOGYDocumento205 pagineLong Answer Questions A LEVEL BIOLOGYakil75% (4)

- Cau Hi TRC Nghim Co Dap AnDocumento25 pagineCau Hi TRC Nghim Co Dap AnAbdelfattah Mohamed OufNessuna valutazione finora

- Pizza Digestion High School ReportDocumento4 paginePizza Digestion High School ReportBrad KNessuna valutazione finora

- Physical Science Grade 12 Definitions Paper 2 Free StateDocumento114 paginePhysical Science Grade 12 Definitions Paper 2 Free StateKenneth100% (1)

- Taste of Amino Acids, Peptides, and ProteinsDocumento3 pagineTaste of Amino Acids, Peptides, and ProteinsCarson ChowNessuna valutazione finora

- Importance of Microorganism in Municipal Solid Waste AssigntDocumento6 pagineImportance of Microorganism in Municipal Solid Waste AssigntGabriel TambweNessuna valutazione finora

- Rotor vs2 Preventive Care Profile PlusDocumento16 pagineRotor vs2 Preventive Care Profile PlusMoisés RodríguezNessuna valutazione finora

- Assignment 25 Carboxylic AcidsDocumento8 pagineAssignment 25 Carboxylic Acidsbob jizzleNessuna valutazione finora

- Kinetic Models For Nonelementary Reactions: Non Chain ReactionDocumento6 pagineKinetic Models For Nonelementary Reactions: Non Chain ReactionXxxNessuna valutazione finora

- MODULE 2 IUPAC System NomenclatureDocumento18 pagineMODULE 2 IUPAC System NomenclatureJude's TimeNessuna valutazione finora

- Treatment of Waste Generated From Cement Industry and Their Treatment-A ReviewDocumento12 pagineTreatment of Waste Generated From Cement Industry and Their Treatment-A ReviewCharles RichardNessuna valutazione finora

- Biological P and N RemovalDocumento13 pagineBiological P and N RemovalDr. Akepati Sivarami Reddy100% (2)

- Sprint 5S / SVAGP 5S MANUALDocumento60 pagineSprint 5S / SVAGP 5S MANUALNERI80% (5)

- Imp Questions 12-Chemistry 2022 (EM) - WingofeducationDocumento17 pagineImp Questions 12-Chemistry 2022 (EM) - WingofeducationVickyNessuna valutazione finora

- Stainless Steel (Ss316L/En2348) Chemical Compatibility ChartDocumento12 pagineStainless Steel (Ss316L/En2348) Chemical Compatibility ChartEntropay UserNessuna valutazione finora

- Biochem Reviewer (Enzymes)Documento6 pagineBiochem Reviewer (Enzymes)VicentaAngeloudeLeonNessuna valutazione finora

- Green Polymer Chemistry Biobased Materials and BiocatalysisDocumento471 pagineGreen Polymer Chemistry Biobased Materials and BiocatalysisGorginNessuna valutazione finora

- Enzyme HandbookDocumento1.037 pagineEnzyme HandbookLe Dinh NamNessuna valutazione finora

- M.F.SC & PHD Programs in - Syllabus: Fish BiotechnologyDocumento24 pagineM.F.SC & PHD Programs in - Syllabus: Fish BiotechnologyRinku AroraNessuna valutazione finora

- Innovia FilmsDocumento20 pagineInnovia FilmsHOANGVUNL1988Nessuna valutazione finora

- Chem1011 Exam Practice Test 2Documento27 pagineChem1011 Exam Practice Test 2Chirisuu PantsuNessuna valutazione finora

- Chitosan Citric Acid CrosslinkDocumento10 pagineChitosan Citric Acid CrosslinkWayne LeungNessuna valutazione finora

- Minesite Water Management HandbookDocumento128 pagineMinesite Water Management Handbookedatgka100% (1)

- 2010-10 Pollution Control BiotechnologyDocumento25 pagine2010-10 Pollution Control BiotechnologyCesa MofunoutNessuna valutazione finora

- Energy Resources: Energy Can Be Defined As The Capacity To Do WorkDocumento26 pagineEnergy Resources: Energy Can Be Defined As The Capacity To Do WorkSenthilkumar KrishnamoorthyNessuna valutazione finora

- Pentens E-610CR Data SheetDocumento2 paginePentens E-610CR Data Sheetamelinda jocelinNessuna valutazione finora

- Catalogue Lagon Viton enDocumento20 pagineCatalogue Lagon Viton enhiren_mistry55Nessuna valutazione finora

- Selective Oxidation of Secondary AlcoholsDocumento24 pagineSelective Oxidation of Secondary AlcoholsFernando Silva BetimNessuna valutazione finora