Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

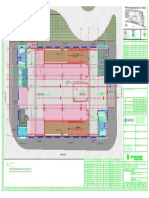

345-001071-1007 - R0 Beam & Slab Formworks First Aid Bldg.17

Caricato da

Satya kaliprasad vangaraTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

345-001071-1007 - R0 Beam & Slab Formworks First Aid Bldg.17

Caricato da

Satya kaliprasad vangaraCopyright:

Formati disponibili

Safety Advice

NO HEAVY LOADS

CROSS BEAMS

PRIMARY BEAMS

855

700

1695

1695

700

CO

580

1005

BA

RW

A

2095

300

932

1 BRACING CHAIN OR CABLE WIRE

-PROVIDE BRACING CHAIN OR CABLE WIRE FOR

ALL CROSS BEAMS (@2.40m MAX.)

AND TO BE FIXED TO THE EXISTING CONCRETE

SLAB. [BY THE CLIENT]

950

800

800

M

PLE

X

2095

330 700

EX

IS

TIN

980

6650

500

700

800

318 500

6500

1695

6650

1695

19800

700

U

AB kv

R /11

FO 6

E 20/6

SIT R 2 N

ED PE ATIO

OS SU ST

OP UR UB

S

PR MO

A

H

880

KEY PLAN

2 EXTERNAL PLANKS STOPPER

-PROVIDE EXTERNAL PLANKS STOPPER OR

EQUIVALENT TO AVOID PROPS SLIDING OUTSIDE

THE BUILDING. [BY THE CLIENT]

Date Received:

3 EXTERNAL RAILINGS

1250

1250

-PROVIDE EXTERNAL RAILINGS,

PIPE OR EQUIVALENT. [BY THE CLIENT]

1000

1250

1000

-LUMBER (BY SITE) CAN BE ATTACHED TO THE

FLOOR PROPS AS A DIAGONAL BRACE USING THE

BRACING CLAMP B

1000

-CROSS BEAM WITH EDGE FORMS MUST BE

SECURED AGAINST HORIZONTAL PULL-OUT AND

TIPPING OVER. THEREFORE PLYWOOD MUST BE

SECURE BY NAILS OR SCREWS.

DOKA MAIN BEAM PARALLEL

TO SLAB/BEAM EDGE

REFERENCE DRAWINGS

NO HEAVY LOADS

CROSS BEAMS

1333

1333

PRIMARY BEAMS

700

800

330 700

2095

2095

700

580

800

700

2650

2650

700

685

2650

TITLE

1981-ST-B17-1-001

PLAN

1981-ST-B17-1-002

PLAN

1981-ST-B17-2-001

DETAILS

1981-ST-B17-2-002

DETAILS

3

2

650

1 BRACING CHAIN OR CABLE WIRE

THIS REVIEW IS TO VERIFY GENERAL

CONFORMANCE WITH THE DESIGN CONCEPT

AND IT DOES NOT RELIEVE THE CONTRACTOR

OF HIS OBLIGATIONS UNDER THE CONTRACT.

-PROVIDE BRACING CHAIN OR CABLE WIRE FOR

ALL PRIMARY BEAMS AND TO BE FIXED TO THE

EXISTING CONCRETE SLAB. [BY THE CLIENT]

683

683

DRAWING NO.

648

2500

650

14900

648

685

A

700 150

A - APPROVED.

B - APPROVED WITH COMMENTS.

C - REVISED & RESUBMIT.

D - REJECTED.

N - NOTED.

5 SECURE EDGE FORM

1333

1000

1333

7450

1250

4 BRACING CLAMP B

2 EXTERNAL PLANKS STOPPER

Co-ordination Table

Date

1333

1333

Structural

Electrical

3 EXTERNAL RAILINGS

Mechanical

-PROVIDE EXTERNAL RAILINGS,

PIPE OR EQUIVALENT. [BY THE CLIENT]

Infrastructure

1333

-CROSS BEAM WITH EDGE FORMS MUST BE

SECURED AGAINST HORIZONTAL PULL-OUT AND

TIPPING OVER. THEREFORE PLYWOOD MUST BE

SECURE BY NAILS OR SCREWS.

DOKA MAIN BEAM PERPENDICULAR TO SLAB/BEAM EDGE

maximum

(range)

EXTENSION

RANGE

ECO 20 250

ECO 20 300

152-250 cm

172-300 cm

ECO 20 350

ECO 20 400

EUREX 20 550

197-350 cm

227-400 cm

297-550 cm

20.05.2015

AS

REV. No.

DATE

BY

ISSUED FOR APPROVAL

DESCRIPTION

RA

JL

CH'KD APP'D

CLIENT

CONSULTANT

LEGEND :

300

800

DOKA TIMBER BEAM H20 ECO N

500

800

950

minimum

1250

1250

950

800

SHOP DRAWING

5 SECURE EDGE FORM

1250

1333

1000

1250

1000

Building Coordination

-LUMBER (BY SITE) CAN BE ATTACHED TO THE

FLOOR PROPS AS A DIAGONAL BRACE USING THE

BRACING CLAMP B

PROPS MODEL

500 300

7450

4 BRACING CLAMP B

1000

Sign

Architectural

-PROVIDE EXTERNAL PLANKS STOPPER OR

EQUIVALENT TO AVOID PROPS SLIDING OUTSIDE

THE BUILDING. [BY THE CLIENT]

1000

Name

Trade

4-WAY HEAD H20

880

700

1695

1695

700

980

330 700

2095

2095

700

580

855

700

1695

1695

700

1005

MAIN CONTRACTOR

LEIGHTON

CONTRACTING

SUPPORTING HEAD H20 DF

REMOVABLE FOLDING TRIPOD

P.O. Box 11346 DOHA-QATAR, Tel. 44059444 Fax. 44410494

SUBCONTRACTOR

DOKA QATAR WLL.

FIRST AID BUILDING-17

BEAM FORMWORK - DOKAFLEX 20

MAIN BEAM + PROPS ARRANGEMENT PLAN

GENERAL NOTES FOR DOKAFLEX

EMAIL: qatar@doka.com

ALL FLOOR PROPS HAVE TO BE PLACED CENTRALLY UNDER THE MAIN BEAMS.

PROJECT

ALL FLOOR PROPS HAVE TO BE ERECTED VERTICALLY.

DISTANCES BETWEEN BEAMS AND DISTANCES BETWEEN FLOOR PROPS HAVE TO CORRESPOND WITH THE DRAWING.

SCALE 1 : 50A1

OVERLAPPING OF THE MAIN BEAM MEASURED FROM THE CENTRE OF THE MAIN BEAM TO THE FLOOR PROPS

WITH TRIPOD MAX. 50 CM.

Drawn:

Romeo Apolinario

20.05.2015

Drawing-No.:

Rev.:

Checked:

Jerico Lanto

20.05.2015

345-001037-1007

Scale:

Revised:

RISK OF FORMWORK BEAM

TIPPING OVER!

ONLY ATTACH THE HANDRAIL CLAMP-S TO

FORMWORK BEAMS IF THESE CANNOT TIP OVER.

NEVER MOUNT GUARD-RAIL BOARDS IN THE

LONGITUDINAL DIRECTION OF THE FORMWORK

BEAMS.

RISK OF BREAKING THE

FORMWORK SHEETS!

IT IS FORBIDDEN TO FASTEN THE CLAMP-S TO THE

FORMWORK SHEETING ONLY.

P.O. BOX 23439, DOHA, QATAR

PHONE: +974 44500628, FAX: +974 44500608

MAXIMUM ALLOWABLE

LIVE LOAD:

xx

INTERMEDIATE FLOOR PROPS WITHOUT TRIPOD SHOULD BE PLACED AT EQUAL DISTANCES BETWEEN THE FLOOR

PROPS WITH TRIPOD. THE NUMBER OF INTERMEDIATE FLOOR PROPS HAS TO BE TAKEN FROM THE DRAWING.

AS SHOWN

Safety instruction:

Do not weld or heat tie rods!

USE OF INTERMEDIATE FLOOR PROPS BY COSTUMER: THE DESIGN CONSIDERS PROPS WITH A LOAD CAPACITY

OF 20kN. THE NUMBER OF PROPS HAS TO BE INCREASED IN THE RATIO OF ITS ALLOWABLE LOAD CAPACITY.

ALL INTERMEDIATE FLOOR PROPS HAVE TO BE SECURED

AGAINST TIPPING OVER.

ALL MEASUREMENTS OF THE STRUCTURE HAVE

TO BE CHECKED!

ALL HORIZONTAL FORCES MUST BE BORNE WITH APPLIANCES.

ALL MEASUREMENTS IN MM!

BEFORE PLACING LOADS ON THE SLAB FORMWORK (PLYWOOD,

TIMBER BEAMS, REINFORCEMENT ETC.( INTERMEDIATE FLOOR

PROPS HAVE TO BE PLACED.

TO AVOID RISKS REGARDING HEALTH & SAFETY OF USERS OR THIRD PERSONS, "USER INFORMATION",

"OPERATING INSTRUCTIONS" AND "FITTING INSTRUCTIONS" HAVE TO BE NOTED IN ADDITION TO THE INFORMATION

GIVEN ON THE DRAWINGS.

IF REQUIRED ASK YOUR DOKA PARTNER FOR THESE DOCUMENTS.

IF FLOOR PROPS WITH MOUNTED LOWERING HEADS, 4-WAY HEADS

OR SUPPORTING HEADS ARE MOVED, THEY HAVE TO BE SECURED

AGAINST FALLING OUT WITH SPRING LOCKED CONNECTING PINS 16 MM.

SCAFFOLD BOARDS FOR PLATFORMS AND RAILING ARE TO BE PROVIDED BY SITE AND MUST BE FIXED ACCORDING

TO HEALTH & SAFETY REGULATIONS AND LOCAL LAW!

TO PROTECT THE FORMWORK SHEET AGAINST DAMAGING USE VIBRATORS WITH PROTECTIVE CAPS.

CONSTRUCTION OF KAHRAMAA

CENTRAL WORKSHOP

TITLE

FIRST AID - BUILDING 17

BEAM FORMWORKS

DOKAFLEX20 SYSTEM

MAIN BEAM + PROPS PLAN

PROJECT No. SCALE

DRAWN BY CHECKED BY APPROVED BY

DRAWING No.

GTC517-17-S-S-D-501

DATE

SHT.

REV.

2/6

Potrebbero piacerti anche

- Rough DA Arrear Calculation For 2 IncrementsDocumento9 pagineRough DA Arrear Calculation For 2 IncrementsSatya kaliprasad vangaraNessuna valutazione finora

- EcE Text Bio M&CA3Documento82 pagineEcE Text Bio M&CA3Satya kaliprasad vangaraNessuna valutazione finora

- ALL FLOOR PLAN PRINT ph-DRAINAGE PDFDocumento1 paginaALL FLOOR PLAN PRINT ph-DRAINAGE PDFSatya kaliprasad vangaraNessuna valutazione finora

- 0Documento15 pagine0Satya kaliprasad vangaraNessuna valutazione finora

- Content Sheet - V-2Documento1 paginaContent Sheet - V-2Satya kaliprasad vangaraNessuna valutazione finora

- 07 - Linepipe FabricationDocumento21 pagine07 - Linepipe FabricationMetwally NaserNessuna valutazione finora

- 01 - Course IntroductionDocumento25 pagine01 - Course Introductionsathish_iyengarNessuna valutazione finora

- 08.m.e. Comm & NWDocumento44 pagine08.m.e. Comm & NWVasuNessuna valutazione finora

- 2Documento12 pagine2Satya kaliprasad vangaraNessuna valutazione finora

- 22Documento37 pagine22Satya kaliprasad vangaraNessuna valutazione finora

- Cover Sheet - V - 2Documento17 pagineCover Sheet - V - 2Satya kaliprasad vangaraNessuna valutazione finora

- 3Documento8 pagine3Satya kaliprasad vangaraNessuna valutazione finora

- 16 - Bottom Roughness PDFDocumento20 pagine16 - Bottom Roughness PDFSatya kaliprasad vangaraNessuna valutazione finora

- Bahrain Tender Docs Vol 2 2008Documento1 paginaBahrain Tender Docs Vol 2 2008Satya kaliprasad vangaraNessuna valutazione finora

- 03 - Pipeline HydraulicsDocumento34 pagine03 - Pipeline Hydraulicsvb_pol@yahooNessuna valutazione finora

- Project: Doubling of Madar-Palanpur Section Client: RVNL Job: Design of Substructure For BR - No 831Documento2 pagineProject: Doubling of Madar-Palanpur Section Client: RVNL Job: Design of Substructure For BR - No 831HaymanAHMEDNessuna valutazione finora

- StaadDocumento3 pagineStaadMark Kenneth P. OntejoNessuna valutazione finora

- Staad Model Word CheckDocumento6 pagineStaad Model Word CheckSatya kaliprasad vangaraNessuna valutazione finora

- Vertical Capacity of PileDocumento6 pagineVertical Capacity of PileSatya kaliprasad vangaraNessuna valutazione finora

- Checking of Load On Pile 100111Documento41 pagineChecking of Load On Pile 100111satydevsinghnegiNessuna valutazione finora

- Retaining Wall Technical GuidanceDocumento12 pagineRetaining Wall Technical GuidanceSatya kaliprasad vangaraNessuna valutazione finora

- StaadDocumento3 pagineStaadsatydevsinghnegiNessuna valutazione finora

- 1652 Acc For Piling WorkDocumento4 pagine1652 Acc For Piling WorkSatya kaliprasad vangaraNessuna valutazione finora

- Memorandum: (Enclosure To Form of Tender) Ref.: Tender For: Initial Load Testing of Pile IncludingDocumento3 pagineMemorandum: (Enclosure To Form of Tender) Ref.: Tender For: Initial Load Testing of Pile IncludingSatya kaliprasad vangaraNessuna valutazione finora

- 1609 06370v1Documento90 pagine1609 06370v1Satya kaliprasad vangaraNessuna valutazione finora

- 1609 06370v1Documento90 pagine1609 06370v1Satya kaliprasad vangaraNessuna valutazione finora

- Andrew J. Fox, Nicolas Lehner, Felix J. Lockman, Bart P. Wakker, Alex S. Hill, Fabian Heitsch, David V. Stark, Kathleen A. Barger, Kenneth R. Sembach, & Mubdi RahmanDocumento6 pagineAndrew J. Fox, Nicolas Lehner, Felix J. Lockman, Bart P. Wakker, Alex S. Hill, Fabian Heitsch, David V. Stark, Kathleen A. Barger, Kenneth R. Sembach, & Mubdi RahmanSatya kaliprasad vangaraNessuna valutazione finora

- A SQUID-based Microwave Cavity Search For Dark-Matter AxionsDocumento4 pagineA SQUID-based Microwave Cavity Search For Dark-Matter AxionsSatya kaliprasad vangaraNessuna valutazione finora

- Early Theories On The Distance To The SunDocumento10 pagineEarly Theories On The Distance To The SunSatya kaliprasad vangaraNessuna valutazione finora

- What Is Quantum Computation?: 1 MotivationDocumento17 pagineWhat Is Quantum Computation?: 1 MotivationSatya kaliprasad vangaraNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5783)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- GCAF Online Inspector Practice ExamDocumento5 pagineGCAF Online Inspector Practice Examcamwills2100% (1)

- Piping and Equipment IsolationDocumento8 paginePiping and Equipment IsolationBilal Mustafa Siddiqui100% (1)

- Bla Irv RanchDocumento84 pagineBla Irv RanchArturo Palma RamírezNessuna valutazione finora

- AbolethDocumento3 pagineAbolethjlewis_4Nessuna valutazione finora

- Business-Process Integration: Supply-Chain Management 2.0 (SCM 2.0)Documento8 pagineBusiness-Process Integration: Supply-Chain Management 2.0 (SCM 2.0)nidayousafzaiNessuna valutazione finora

- Ticket Frankfurt Berlin 3076810836Documento2 pagineTicket Frankfurt Berlin 3076810836farzad kohestaniNessuna valutazione finora

- Action and Budget Plan For The Boys Scouts of The PhilippinesDocumento2 pagineAction and Budget Plan For The Boys Scouts of The PhilippinesJohn Paul ViñasNessuna valutazione finora

- Horses To Follow: Ten To Follow From Timeform'S Team of ExpertsDocumento12 pagineHorses To Follow: Ten To Follow From Timeform'S Team of ExpertsNita naNessuna valutazione finora

- A Light Sculling Training Boat PDFDocumento8 pagineA Light Sculling Training Boat PDFLuis BraulinoNessuna valutazione finora

- Anectodal RecordsDocumento10 pagineAnectodal RecordsSchahyda ArleyNessuna valutazione finora

- Boiler Instrumentation and Control SystemsDocumento68 pagineBoiler Instrumentation and Control Systemstagne simo rodrigueNessuna valutazione finora

- Vào 10 - Sở L NG Sơn 2022-2023Documento5 pagineVào 10 - Sở L NG Sơn 2022-2023Lan HuongNessuna valutazione finora

- Dof Omm Ss Skirting Sk-02Documento8 pagineDof Omm Ss Skirting Sk-02Ideal DesignerNessuna valutazione finora

- Engineering Standard for Rolling Stock Minimum In-Service ConditionsDocumento19 pagineEngineering Standard for Rolling Stock Minimum In-Service Conditions4493464Nessuna valutazione finora

- Next-Generation Widebody Conversion: in Service From 2017 ONWARDSDocumento6 pagineNext-Generation Widebody Conversion: in Service From 2017 ONWARDSAgusNessuna valutazione finora

- Emily Act 3 GraficoDocumento13 pagineEmily Act 3 Graficoemily lopezNessuna valutazione finora

- Deed of Sale for 2009 Toyota PickupDocumento1 paginaDeed of Sale for 2009 Toyota PickupRheal P Esmail100% (3)

- European Management Journal: Pawel Korzynski, Grzegorz Mazurek, Michael HaenleinDocumento9 pagineEuropean Management Journal: Pawel Korzynski, Grzegorz Mazurek, Michael HaenleinkharismaNessuna valutazione finora

- Project Close OutDocumento12 pagineProject Close OutWeel HiaNessuna valutazione finora

- Philips Solar+LED Marketing StrategyDocumento15 paginePhilips Solar+LED Marketing StrategyrejinairNessuna valutazione finora

- Key plan and area statement comparison for multi-level car park (MLCPDocumento1 paginaKey plan and area statement comparison for multi-level car park (MLCP121715502003 BOLLEMPALLI BINDU SREE SATYANessuna valutazione finora

- TMP 841704 RL 2023-03-13 Relieving LetterDocumento1 paginaTMP 841704 RL 2023-03-13 Relieving Letterxop0887Nessuna valutazione finora

- How COVID-19 Affects Corporate Financial Performance and Corporate Valuation in Bangladesh: An Empirical StudyDocumento8 pagineHow COVID-19 Affects Corporate Financial Performance and Corporate Valuation in Bangladesh: An Empirical StudyInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Chapter 2 (Teacher)Documento19 pagineChapter 2 (Teacher)ajakazNessuna valutazione finora

- 1404 Pratul Singhal Ideal Gas Equation Density StoichiometryDocumento22 pagine1404 Pratul Singhal Ideal Gas Equation Density StoichiometryYang ChoudhuryNessuna valutazione finora

- Dimensions of Comparative EducationDocumento5 pagineDimensions of Comparative Educationeminentsurvivor9Nessuna valutazione finora

- Introduction To Computer Graphics: Version 1.3, August 2021Documento456 pagineIntroduction To Computer Graphics: Version 1.3, August 2021Sharan K.KNessuna valutazione finora

- Joou No Gohoubi - Tate No Yuusha No Nariagari 288869 Doujin - EdoujinDocumento25 pagineJoou No Gohoubi - Tate No Yuusha No Nariagari 288869 Doujin - Edoujinaura.nazhifa10020% (1)

- Acc121 Exam1 ProblemsDocumento4 pagineAcc121 Exam1 ProblemsTia1977Nessuna valutazione finora

- Final VeganDocumento11 pagineFinal Veganapi-314696134Nessuna valutazione finora