Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Internal Normalization Piping Project Specification for Weakly Corrosive Hydrocarbons

Caricato da

liviu_dovaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Internal Normalization Piping Project Specification for Weakly Corrosive Hydrocarbons

Caricato da

liviu_dovaCopyright:

Formati disponibili

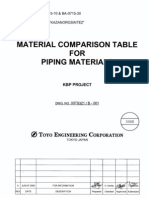

AGIP

04019.PIP.MEC.SDS

INTERNAL NORMALIZATION

Revisions

PIPING PROJECT SPECIFICATION

SERVICE : WEAKLY CORROSIVE HYDROCARBONS - BLOW

DOWN - VENTS - DRAINS (T < 120C)

Sheet

of

A 02

ITEM

REFERENCE SPECIFICATIONS

150 # RF

20377.PIP.MEC.FUN

DRIP RINGS

15011

A 105

MATERIALS (if not otherw.stated)

ASTM STANDARDS

SPECTACLE BLINDS

15038

A 105

SPACERS & BLINDS

15039

NIPPLES

A 105/3000# NPT (3)

NORMAL (from pipe)

14383

API 5L Gr.B / SMLS (3)

SWAGES (from pipe)

14382

API 5L Gr.B / SMLS (3)

THICKNESS

mm

PIPES

INCH

WALL THK.

mm

SCHEDULE

MATERIAL

FLANGES

WELDING NECK

14355

SOCKET WELD

14356

THREADED

14357

SLIP ON

14358

LAP JOINT

14359

BLIND

14360

14365

STUD BOLTS & NUTS

14368

VALVES

ON / OFF

15801

STSW

RTSW

STSW

STSW

STEE

0

0

2

DN"

HEADER SIZE

T

U

B

----

----

----

----

120

17,0

----

----

-------

-------

14"

16" 18" 20" 24" 30" 36"

7,92

7,92 7,92 9,52 9,52

80

2"

80

2"

80

40

3"

40

4"

40

6"

40

8"

-------

10" 12"

160

1"

20

20

20

20

20

20

20

20

---

---

---

---

A 105 / 150# - RF125 Ra

32 C 28

A 193 Gr.B7 / A 194 Gr.2H (ZINC COATING) (1)

VS 235 AG E24-SW

VB 511 AG 1C2 - RF 125 Ra (R.B.)

VB 515 AG 5C2 - RF125 Ra

VB 511 AG 2C2 - RF125 Ra (F.B.) (2)

VD 435 AG 7R1 - SW

VD 311 AG A04 - RF 125 Ra

VDR 711 AG 6C2 - RF 125 Ra (WAFER)

VDR 835 AG 3R1 - SW

FT 935 AG 5R1 - SW

FT 911 AG 2C3 - RF 125 Ra

90-45 ELBOWS

14370

A 234 Gr.WPB

CONC.REDUCTIONS

14372

A 234 Gr.WPB

ECC.REDUCTIONS

14372

A 234 Gr.WPB

ELLIPT.CAPS

14374

A 234 Gr.WPB

LJ STUB ENDS

14375

PIPE BENDS

15023

METER ELBWS

STEE

15020

15021

STEE

Mark

STEE

INTERSECTIONS

STEE

10

STEE

12

SLET

NLET

14

SWLT

RTEE

STEE

Components

Material

STEE STRAIGHT BW TEE

14371

A 234 Gr.WPB

RTEE REDUCTION BW TEE

14371

A 234 Gr.WPB

STSC STRAIGHT THDD TEE

14381

RTSC REDUCTION THDD TEE

14381

STSW STRAIGHT SW TEE

14380

A 105

RTSW REDUCTION SW TEE

14380

A 105

SWLT SWEEPOLETS

15003

A 105

WLET WELDOLETS

15004

30

TLET THREDOLETS

14381

36

SLET SOCKOLETS

14380

A 105

NLET NIPOLETS THDD

14381

A 105

PTOP PIPE TO PIPE

15012

STEE

16

STEE

18

STEE

20

24

STEE

STEE

1/2 3/4 1 1 2

4

F

G

18,8

17,8

-------

A 105 / 600# RF 125 Ra

15701

STSW

50

4,78 5,56 4,55 5,08 5,54 5,16 5,49 6,02 7,11 6,35 6,35 6,35

160

1"

P - bar

----

100

9,09 10,16 11,07

1/2" 3/4"

T - C

----

VB 635 AG 6R1-NPT (3)

SPECIAL USE

" Y " STRAINERS

A 105

AISI 316

P - bar

19,0

A 105 / 600# RF 125 Ra

15801

CHECK

T - C

-29 38

SMLS

A 105 / 150# - RF125 Ra

MANUAL CONTROL 15801

3/4

7,82

DESIGN CONDITIONS

API 5L Gr.B

GASKETS

1/2

7,47

TEMP. STRAINERS 15050-15007

14350

MANIFACTURE

M

E

C

----

125 Ra

Dimensions : ASME B 16.5 / B 16.34

WELDS EXAMINATION

A 105 / 6000# SW

3 mm

CODES - Design : ASME B 31.3

-----

14381

CORR.ALLOWANCE

MAT.

15017

14380

Date

A 105

RED. S.O. FLG.S

THDD FITTINGS

15016

20367.PIP.MEC.FUN

S.W. FITTINGS

RED. THDD FLG.S

PIPING CLASS

NOMINAL SIZE

M

O

D

COMPONENTS

20376 / 20368 PIP.MEC.FUN

06--97

Rating & Facing

WELDING AND HEAT TREATMENT

Compiled

6

DN"

10

12

14

16

BRANCH SIZE

18

20

24

30

36

NOTES:

1) All carbon steel bolting on flanges, valves & "Y" strainers shall be zinc coating

(hot-dip) to ASTM A-153.

2) To be used where required by P&I drawings only.

3) Threaded Ends and connections are allowed for instrument taps only (15801).

Company's sole property document . Company will protect his right by law.

Potrebbero piacerti anche

- Komatsu 6bg1t-Be2 - A4Documento166 pagineKomatsu 6bg1t-Be2 - A4George Jhonson90% (10)

- Building Your Own CNC Milling MachineDocumento19 pagineBuilding Your Own CNC Milling MachineMarius DanilaNessuna valutazione finora

- Section 26 11 13-Unit Sub-Stations PDFDocumento10 pagineSection 26 11 13-Unit Sub-Stations PDFmasoodaeNessuna valutazione finora

- Pipe JoiningDocumento248 paginePipe JoiningRam Shiv Verma100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Injection Molding Design GuidelinesDocumento28 pagineInjection Molding Design GuidelinesVinay Kumar KumarNessuna valutazione finora

- Flanged Duplex Strainers GuideDocumento1 paginaFlanged Duplex Strainers GuideRoshan ShanmughanNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- Piping Inspector QuestionsDocumento10 paginePiping Inspector QuestionsRichard Periyanayagam100% (1)

- Basic valve datasheets for inquiryDocumento21 pagineBasic valve datasheets for inquirymainur mechanical engineerNessuna valutazione finora

- Choke Manifold ManualDocumento34 pagineChoke Manifold ManualAlex RamirezNessuna valutazione finora

- Data Sheet Ball ValveDocumento1 paginaData Sheet Ball ValveIkhsan Hj SiratNessuna valutazione finora

- Piping Line List Template 2018-05-29Documento1 paginaPiping Line List Template 2018-05-29Trevor KanodeNessuna valutazione finora

- MATERIAL COMPARISONDocumento8 pagineMATERIAL COMPARISONrouquinNessuna valutazione finora

- Ucd 345Documento2 pagineUcd 345psgkanakarajNessuna valutazione finora

- Calpeda MXV-B Vertical Multistage PumpDocumento6 pagineCalpeda MXV-B Vertical Multistage PumpWayne Seaman100% (1)

- ABO Ball ValveDocumento6 pagineABO Ball ValveSunil BajpaiNessuna valutazione finora

- Customer Name Date Bid Due Date: Sweco Fab Inc. Customer RFQ FormDocumento2 pagineCustomer Name Date Bid Due Date: Sweco Fab Inc. Customer RFQ FormGustavo GarciaNessuna valutazione finora

- Specification for weakly corrosive hydrocarbon piping systemDocumento1 paginaSpecification for weakly corrosive hydrocarbon piping systemhalim_ka100% (1)

- Specification for weakly corrosive hydrocarbon piping systemDocumento1 paginaSpecification for weakly corrosive hydrocarbon piping systemhalim_ka100% (1)

- Specification for weakly corrosive hydrocarbon piping systemDocumento1 paginaSpecification for weakly corrosive hydrocarbon piping systemhalim_ka100% (1)

- Flowserve-Ball Valve Technical Manual For AKH3 IOMDocumento23 pagineFlowserve-Ball Valve Technical Manual For AKH3 IOMwholenumberNessuna valutazione finora

- Isuzu Front SuspensionDocumento28 pagineIsuzu Front SuspensionHendrianto100% (2)

- Ceiling SystemsDocumento56 pagineCeiling SystemsTheGuroid100% (1)

- Advanced Heat Exchangers: Shell & Tube Marine CondensersDocumento16 pagineAdvanced Heat Exchangers: Shell & Tube Marine CondensersMarco CambeiroaNessuna valutazione finora

- SY Series LEDEEN Actuators: Pneumatic and Hydraulic ActuatorsDocumento8 pagineSY Series LEDEEN Actuators: Pneumatic and Hydraulic ActuatorsCarla FerroNessuna valutazione finora

- Load Capacity Limits For Flanged NozzleDocumento6 pagineLoad Capacity Limits For Flanged Nozzlektjayakumar3878100% (1)

- MTU PARTS 12V4000G43 5262010910 PetrobrasDocumento197 pagineMTU PARTS 12V4000G43 5262010910 PetrobrasJoan Sebastian GaribelloNessuna valutazione finora

- Series FB: Floating Ball ValveDocumento12 pagineSeries FB: Floating Ball ValveCarlos Alberto Aguilera MendezNessuna valutazione finora

- SBC (Safety Break-Away Couplings) v140630Documento16 pagineSBC (Safety Break-Away Couplings) v140630Robert Villavicencio0% (1)

- ET de TubulacaoDocumento214 pagineET de TubulacaoClarisse MendoncaNessuna valutazione finora

- AHD186FADocumento47 pagineAHD186FAthe707100% (4)

- Hot Bolting Procedure PDFDocumento2 pagineHot Bolting Procedure PDFmasmarkun4444100% (3)

- Suction Heaters and Heating Coils Suction Heaters and Heating CoilsDocumento3 pagineSuction Heaters and Heating Coils Suction Heaters and Heating CoilsDaysianne100% (1)

- Materials Comparison DIN / EN / ASTM: Pipes / Tubes Flanges Buttwelding FittingsDocumento1 paginaMaterials Comparison DIN / EN / ASTM: Pipes / Tubes Flanges Buttwelding Fittingsnaseema1Nessuna valutazione finora

- Carbon Steel and Alloy Steel Material SpecificationsDocumento2 pagineCarbon Steel and Alloy Steel Material SpecificationsseptixNessuna valutazione finora

- Rovalve PDFDocumento4 pagineRovalve PDFWilliam ValenciaNessuna valutazione finora

- WPMP NDT Request FormDocumento7 pagineWPMP NDT Request FormVimin PrakashNessuna valutazione finora

- Pga1000998050010 01Documento1 paginaPga1000998050010 01Amit SaxenaNessuna valutazione finora

- Hoja de Datos PSVDocumento6 pagineHoja de Datos PSVMarc MarNessuna valutazione finora

- Catálogo Válvulas de Control Red Valve PDFDocumento30 pagineCatálogo Válvulas de Control Red Valve PDFFranciscoNessuna valutazione finora

- Co-Efficient of Friction For Pipe Supporting During Stress Analysis Using Caesar IIDocumento2 pagineCo-Efficient of Friction For Pipe Supporting During Stress Analysis Using Caesar IIHmd MokhtariNessuna valutazione finora

- ANSI FlangeDocumento10 pagineANSI FlangemechftpNessuna valutazione finora

- Data Sheet S7 - 2020 - ENG - Light - CavagnaDocumento12 pagineData Sheet S7 - 2020 - ENG - Light - CavagnaWND PRTMNessuna valutazione finora

- Uh Banano - V1Documento7 pagineUh Banano - V1Jose VivancoNessuna valutazione finora

- Nozzle CatalogueDocumento53 pagineNozzle CatalogueMike UpNessuna valutazione finora

- Material 11373Documento1 paginaMaterial 11373Deepak MadnaikNessuna valutazione finora

- KingdaDocumento45 pagineKingdaPascual Daga Deudor0% (1)

- SLG-0001-1b Flange Designation Chart PDFDocumento2 pagineSLG-0001-1b Flange Designation Chart PDFMohd Shafuaaz KassimNessuna valutazione finora

- Best Potable Water Pressure Tank SeriesDocumento6 pagineBest Potable Water Pressure Tank SeriesGhislaine SousaNessuna valutazione finora

- Bifold UpdatedDocumento8 pagineBifold UpdatedGopinath GunasekaranNessuna valutazione finora

- Commonly Used Piping MaterialsDocumento1 paginaCommonly Used Piping MaterialsMOHAMMAD ASIFNessuna valutazione finora

- Applicable Standard Mech Documents ReviewDocumento27 pagineApplicable Standard Mech Documents ReviewArun CPNessuna valutazione finora

- JC Catalogue Gate Valves BBDocumento24 pagineJC Catalogue Gate Valves BBMahdi DalyNessuna valutazione finora

- PIPE CLASS SPECIFICATIONDocumento138 paginePIPE CLASS SPECIFICATIONbadelitamariusNessuna valutazione finora

- MPower (Mostro) Data Sheet Gate Valve S43 NEW Edition 2009Documento9 pagineMPower (Mostro) Data Sheet Gate Valve S43 NEW Edition 2009el_apache10Nessuna valutazione finora

- Flameproof MotorsDocumento16 pagineFlameproof MotorsKiran KumarNessuna valutazione finora

- Cs Globe Valve 600#Documento1 paginaCs Globe Valve 600#Vijay GaikwadNessuna valutazione finora

- Virgo Trunnion Ball ValveDocumento16 pagineVirgo Trunnion Ball ValveKamalNessuna valutazione finora

- Material Selection GuideDocumento1 paginaMaterial Selection Guidesuresh_vikiNessuna valutazione finora

- 1100-ME-DST-001 - Rev.1A - Data Sheet Hari Pig Launcher (1194-V-101)Documento6 pagine1100-ME-DST-001 - Rev.1A - Data Sheet Hari Pig Launcher (1194-V-101)Didi Hadi RiantoNessuna valutazione finora

- Catalogue Air Handling Unit DDW Without Frame PDFDocumento27 pagineCatalogue Air Handling Unit DDW Without Frame PDFFirman AnriNessuna valutazione finora

- 6877-SM-LM-99-00-09014-A1A7 Document Number: Merlin Version 2.2 11-JAN-05 15:46:38 Detailed ReportDocumento12 pagine6877-SM-LM-99-00-09014-A1A7 Document Number: Merlin Version 2.2 11-JAN-05 15:46:38 Detailed ReportSalimNessuna valutazione finora

- IMI Remosa ValvesDocumento4 pagineIMI Remosa ValvesDhananjay B KNessuna valutazione finora

- Argus FK 76M Ball Valve Material ListDocumento2 pagineArgus FK 76M Ball Valve Material ListFelipe Gamboa Gálvez100% (1)

- Douglas Chero Catalogue Valve 6-2003Documento89 pagineDouglas Chero Catalogue Valve 6-2003Yurizki LhzNessuna valutazione finora

- AstmDocumento6 pagineAstmMasih BelajarNessuna valutazione finora

- Tidy-Aboveground Fabrication StandardsDocumento40 pagineTidy-Aboveground Fabrication StandardsarisandiyusufNessuna valutazione finora

- P-7302 - CCR 25-160 PDFDocumento1 paginaP-7302 - CCR 25-160 PDFArjun KrishnakumarNessuna valutazione finora

- SA 515 and SA 516Documento3 pagineSA 515 and SA 516yogacruiseNessuna valutazione finora

- Internal Normalization Piping Project Specification for Low Pressure Steam, Condensate & Boiler Feed Water SystemsDocumento1 paginaInternal Normalization Piping Project Specification for Low Pressure Steam, Condensate & Boiler Feed Water Systemsliviu_dovaNessuna valutazione finora

- AGIP Piping Project Specification for Non Corrosive Hydrocarbons - Glycol Blow Down - Vents - Drains (T < 120°CDocumento1 paginaAGIP Piping Project Specification for Non Corrosive Hydrocarbons - Glycol Blow Down - Vents - Drains (T < 120°Chalim_kaNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- AGIP Piping Project Specification for Non Corrosive Hydrocarbons - Glycol Blow Down - Vents - Drains (T < 120°CDocumento1 paginaAGIP Piping Project Specification for Non Corrosive Hydrocarbons - Glycol Blow Down - Vents - Drains (T < 120°Chalim_kaNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- D11Documento1 paginaD11liviu_dovaNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- Piping Project Specification for Non-Corrosive Hydrocarbon, Glycol, Blowdown, Vent and Drain SystemsDocumento1 paginaPiping Project Specification for Non-Corrosive Hydrocarbon, Glycol, Blowdown, Vent and Drain Systemshalim_kaNessuna valutazione finora

- C11Documento1 paginaC11liviu_dovaNessuna valutazione finora

- D12Documento1 paginaD12liviu_dovaNessuna valutazione finora

- C14Documento1 paginaC14liviu_dovaNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- Internal Normalization Piping Project Specification for Low Pressure Steam, Condensate & Boiler Feed Water SystemsDocumento1 paginaInternal Normalization Piping Project Specification for Low Pressure Steam, Condensate & Boiler Feed Water Systemsliviu_dovaNessuna valutazione finora

- C12Documento1 paginaC12liviu_dovaNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- Piping Project Specification for Non-Corrosive Hydrocarbon ServiceDocumento1 paginaPiping Project Specification for Non-Corrosive Hydrocarbon Servicehalim_kaNessuna valutazione finora

- A20Documento1 paginaA20liviu_dovaNessuna valutazione finora

- Piping Project Specification for Non-Corrosive Hydrocarbon ServiceDocumento1 paginaPiping Project Specification for Non-Corrosive Hydrocarbon Servicehalim_kaNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- Piping Project Specification for Non-Corrosive Hydrocarbon, Glycol, Blowdown, Vent and Drain SystemsDocumento1 paginaPiping Project Specification for Non-Corrosive Hydrocarbon, Glycol, Blowdown, Vent and Drain Systemshalim_kaNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- Piping Project Specification for Mean Pressure Steam and Steam Condensate ServiceDocumento1 paginaPiping Project Specification for Mean Pressure Steam and Steam Condensate Servicehalim_kaNessuna valutazione finora

- A35Documento1 paginaA35liviu_dovaNessuna valutazione finora

- Piping Project Specification for Non-Corrosive Hydrocarbon, Glycol, Blowdown, Vent and Drain SystemsDocumento1 paginaPiping Project Specification for Non-Corrosive Hydrocarbon, Glycol, Blowdown, Vent and Drain Systemshalim_kaNessuna valutazione finora

- Piping Project Specification for Non-Corrosive Hydrocarbon ServiceDocumento1 paginaPiping Project Specification for Non-Corrosive Hydrocarbon Servicehalim_kaNessuna valutazione finora

- Bale Command Plus MonitorDocumento62 pagineBale Command Plus MonitorSabadsag DariusNessuna valutazione finora

- 2 WaydistributorDocumento53 pagine2 WaydistributormbhaditNessuna valutazione finora

- Thông số kỹ thuật cẩu LiebherrDocumento374 pagineThông số kỹ thuật cẩu LiebherrTam_Luu_77Nessuna valutazione finora

- EjectionDocumento32 pagineEjectionsk9145Nessuna valutazione finora

- Vegetable Dicers: User ManualDocumento3 pagineVegetable Dicers: User ManualJose SavinonNessuna valutazione finora

- Portable Power Drive 700Documento2 paginePortable Power Drive 700TEODORONessuna valutazione finora

- Vertical Turbine Canal Recirculation & CT Make-Up Water PumpDocumento37 pagineVertical Turbine Canal Recirculation & CT Make-Up Water PumpSanto ENessuna valutazione finora

- Carcasa para Filtro Secador Adks Fds FDH Instrucciones de Funcionamiento 10 Pages Es Es 4686656 PDFDocumento10 pagineCarcasa para Filtro Secador Adks Fds FDH Instrucciones de Funcionamiento 10 Pages Es Es 4686656 PDFJuan Manuel EscorihuelaNessuna valutazione finora

- Stingray Mini Kart Kit: Installation ReferenceDocumento11 pagineStingray Mini Kart Kit: Installation ReferencederrickbcNessuna valutazione finora

- Shield Alarm Check ValveDocumento6 pagineShield Alarm Check ValveMd. Mominul IslamNessuna valutazione finora

- Floor CraneDocumento6 pagineFloor CranejillianixNessuna valutazione finora

- Instructions: 2 or 3 Carb Progressive LinkageDocumento5 pagineInstructions: 2 or 3 Carb Progressive LinkageJohn TrollskiNessuna valutazione finora

- Type 1066 On-Off Piston Rotary Actuator With H Mounting AdaptationDocumento16 pagineType 1066 On-Off Piston Rotary Actuator With H Mounting AdaptationapisituNessuna valutazione finora

- Prostar Solar Module Installation Manual (EN)Documento7 pagineProstar Solar Module Installation Manual (EN)Sisegusa QuitoNessuna valutazione finora

- Kumar Pumps BroucherDocumento18 pagineKumar Pumps BroucherSrikanth Kesanakurthi50% (2)

- 7-1/4 Circular Saw Instruction ManualDocumento24 pagine7-1/4 Circular Saw Instruction ManualMiguel Aguilar100% (1)

- SectionC Latching SystemsDocumento39 pagineSectionC Latching SystemsHermanNessuna valutazione finora

- V CRIMP BrochureDocumento6 pagineV CRIMP Brochureromy_piliando0% (1)