Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

InspectionTest Plan Sample

Caricato da

WONG TSCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

InspectionTest Plan Sample

Caricato da

WONG TSCopyright:

Formati disponibili

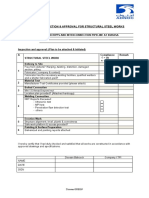

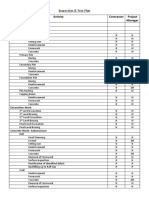

INSPECTION & TEST PLAN

MANUFACTURE NAME:

CLIENT JOB NO:

P.O. NO.

SHEET NO: 1 OF 3

ITP DOC NO.:

ABC XXX XXX

DESCRIPTION:

PRODUCT / ITEM TITLE

ACTIVITY

NO

QUALITY ACTIVITY

REFERENCE

DOCUMENT

CHARACTERISTIC

TO BE VERIFIED

ACCEPTANCE

CRITERIA

XYZ

DESIGN,

DRAWINGS &

OTHERS DOCS.

DESIGN BY

Manufacturer Name

DESIGN &

DRAWING INSP.

PROCEDURE

DESIGN

REQUIREMENT

A1

1(b)

REVIEW OF

DRAWINGS

STANDARDS

APPLICABLE

DESIGN &

DRAWING

DETAILS

DESIGN

REQUIREMENTS

A1

RAW MATERIAL

INSPECTION. EG:

STEEL PLATES

STEEL PIPES

STEEL PIPE

FITTINGS

OTHERS

MANUFACTURER

SPECS SHEET

SPECIFICATIONS

FROM MFG DATA

STANDARDS &

SPECIFICATIONS

A1

REVIEW OF SHOP

RECORDS, FOR

CONTROL &

MATERIALS ISSUE.

WORKS ORDER

AND INVENTORY

ORDER

DOCUMENT

FLOW &

CONTROL

INTERNAL QC

DOC.

A1

WELDING

PROCEDURES

SHOP QC

DOCUMENTS

APPROVAL SHOP

DOC

AWS / ASME

TESTS

REQMENTS

A1

SHOP FITTING

PROCEDURES

INSPECTION

SHOP MFG DOC

APPROVED FOR

CONSTRUCTION

APPROVED SHOP

REQUIREMENTS

A1

RE.NO/DATE

CERTIFIED COMPLETE

PREARED BY:

APPROVED BY:

H: Holding Point

M: Monitoring

1 = 100%

2 = min. 10%

HOLD POINTS ETC.

1(a)

AR: Approval Required

A: Actual Inspection

W: Witnesses Inspection

S: Operation Surveillance

R: Review of Documentation

T/C: Test Certificate Required

ABC

A1

A1

A1

A1

AP

EFG

TPI

123

SP

AR1

AR1

R1

W1

YES

A1

A1

A1

A1

TC

A1

A1

A1

ENDORSEMENTS

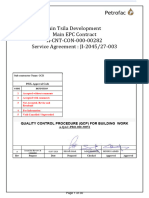

INSPECTION & TEST PLAN

MANUFACTURE NAME:

CLIENT JOB NO:

P.O. NO.

ITP DOC NO.:

ABC-XXX-XXX

DESCRIPTION:

PRODUCT / ITEM TITLE

ACTIVITY

NO

QUALITY ACTIVITY

SHEET NO: 2 OF 3

AR: Approval Required

A: Actual Inspection

W: Witnesses Inspection

S: Operation Surveillance

R: Review of Documentation

T/C: Test Certificate Required

REFERENCE

DOCUMENT

CHARACTERISTIC

TO BE VERIFIED

ACCEPTANCE

CRITERIA

XYZ

ABC

AP

HOLD POINTS ETC

WELDERS LIST

QA MANUAL

--

--

A1

A1

A1

PRODUCTION TEST PCE

TESTING

ASTM

VISUAL RESULTS

LAB REPORT

ASTM

A1

A1

A1

THICKNESS

INSPECTION

DESIGN

CALCULATION

THICKNESS

MEASUREMENTS

ASME VIII Div 1

A1

A1

VISUAL INSPECTION OF

FABRICATED

COMPONENTS

ASTM

SHOP DWG

VISUAL LY

CHECKED FOR

DEFECTS.

ASTM

A1

A1

10

DIMENSIONAL CHECKS

FLATNESS, SHAPE,

ORIENTATION OF

COMPONENTS

MEET SPECIFIED

TOLERANCES

CONTRACT DOC

ASTM

A1

A1

SHOP QC

DOCUMENTS

SHOP DWG

A1

ASTM

A1

A1

A1

VISUAL

A1

A1

A1

A1

A1

A1

BARCOL HARDNESS

TEST

ASTM

TEST RECORDS

ASTM

12

WELDED JOINTS

Inspection

AWS

TEST RESULTS

VISUAL,

13

SHELL/CONE/BASE

NOZZLES MARKING

NOZZLES OPENINGS

ASME VIII Div1

14

NOZZLES FIT UP

PREARED BY:

SHOP APPRD

PROCEDURES

APPROVED BY:

A1

A1

11

H: Holding Point

M: Monitoring

1 = 100%

2 = min. 10%

EFG

123

SP

W1

A1

A1

W2

W2

W2

S,R

W2

S,R

H

W1

W2

W1

H

W2

W1

H

W1

A1

TPI

A1

A1

VISUAL

VISUAL

RE.NO/DATE

CERTIFIED COMPLETE

ENDORSEMENTS

TC

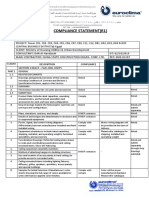

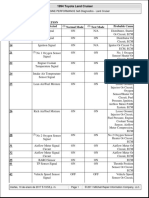

INSPECTION & TEST PLAN

MANUFACTURE NAME:

CLIENT JOB NO:

P.O. NO.

ITP DOC NO.:

ABC-XXX-XXX

DESCRIPTION:

PRODUCT / ITEM TITLE

ACTIVITY

NO

QUALITY ACTIVITY

REFERENCE

DOCUMENT

CHARACTERISTIC

TO BE VERIFIED

ACCEPTANCE

CRITERIA

VISUAL RESULTS

POSTION

DIMENSION

15A

15B

15C

FINAL PRODUCT INSPEC

NOZZLE ORIENTATION,

NOZZLE PROJECTION,

NOZZLE STIFFENNING

MEMBERS

ASME VIII Div 1

16

LIFTING LUGS

INSPECTION AND LOAD

TEST

DESIGN

CALCULATION

17

HYDROSTATIC TEST

ASME VIII Div 1

18

AIR LEAK TEST

APPROVED

METHODS

19

MATERIALS MECH

PROPERTIES LAB TEST

ASTM STDS

20

20A

DELIVERY

PROTECTION Flange

Face, OPENINGS etc

CLEANLINESS CHECK

ACCESSORIES CHECK

20B

20C

REVIEW of MDR

21

PREARED BY:

BUYERS SPECS

& APPROVED

PROCEDURES

APPROVED BY:

SHEET NO: 3 OF 3

AR: Approval Required

A: Actual Inspection

W: Witnesses Inspection

S: Operation Surveillance

R: Review of Documentation

T/C: Test Certificate Required

HOLD POINTS ETC.

XYZ

ABC

AP

EFG

ASME VIII Div1

FABRICATION

DRAWINGS

A1

A1

A1

FINISHING AFTER

TEST CONDITION

DESIGN

CALCULATIONS

A1

A1

WATER

TIGHTNESS,

VISUAL RESULT

CUSTOMER

SPECIFICATION

APPROVED

PROCEDURES

ASME

A1

A1

TENSILE AND

FLEXURAL

PROPERTIES

BUYERS SPECS

APPROVED

PROCEDURES

PLACEMENTS,

PROPER

SUPPORTS,

BLANKS, VISUAL

ACCESSMENT

RE.NO/DATE

H: Holding Point

M: Monitoring

1 = 100%

2 = min. 10%

A1

TPI

123

SP

A1

A1

W1

R1

W1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

A1

CERTIFIED COMPLETE

ENDORSEMENTS

TC

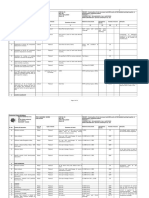

Potrebbero piacerti anche

- ITP ErectionDocumento3 pagineITP Erectionjanpaul2481Nessuna valutazione finora

- Docslide - Us - Itp Structural WorkDocumento4 pagineDocslide - Us - Itp Structural Workomda4wadyNessuna valutazione finora

- Structural Steel Work Check ListDocumento1 paginaStructural Steel Work Check ListAhmad Bilal100% (1)

- Anchr Bolt RefDocumento9 pagineAnchr Bolt ReferleosNessuna valutazione finora

- Counter flow induced draft tower model LBC-125 specsDocumento1 paginaCounter flow induced draft tower model LBC-125 specsastiadi engineeringNessuna valutazione finora

- A Qac Pro 000 38951Documento30 pagineA Qac Pro 000 38951Amin GNessuna valutazione finora

- Main - Product - Report-Tangshan Shengcai Steel Co., Ltd.Documento10 pagineMain - Product - Report-Tangshan Shengcai Steel Co., Ltd.hbookNessuna valutazione finora

- FQP 2Documento25 pagineFQP 2Kuldeep ChakerwartiNessuna valutazione finora

- Instrumentation and ControlsDocumento2 pagineInstrumentation and ControlsTrí NguyễnNessuna valutazione finora

- QCF113 Structural Steel Pre-Fabrication CertificateDocumento1 paginaQCF113 Structural Steel Pre-Fabrication CertificateminhnnNessuna valutazione finora

- Checklist For Fabrication & Erection of Structural Steel WorkDocumento1 paginaChecklist For Fabrication & Erection of Structural Steel Workbetelehem hailuNessuna valutazione finora

- Quality Control Plans for Shop FabricationDocumento7 pagineQuality Control Plans for Shop FabricationIr FankovicNessuna valutazione finora

- Larsen & Toubro underground piping inspection planDocumento4 pagineLarsen & Toubro underground piping inspection planBhavani PrasadNessuna valutazione finora

- Quality Control Procedure for Bored Pile WorkDocumento5 pagineQuality Control Procedure for Bored Pile WorkBudoy SmithNessuna valutazione finora

- Scaffold ChecklistDocumento5 pagineScaffold ChecklistMohamed GhariebNessuna valutazione finora

- Quality assurance plan for steel structure constructionDocumento1 paginaQuality assurance plan for steel structure constructionRamesh F SinghNessuna valutazione finora

- Installation Checklist Adhesive BondingDocumento1 paginaInstallation Checklist Adhesive BondingGogulu KumarNessuna valutazione finora

- Non-Conformance Report: DescriptionDocumento8 pagineNon-Conformance Report: DescriptionHirushan MenukaNessuna valutazione finora

- F-Qa-04 General Inspection ReportDocumento1 paginaF-Qa-04 General Inspection ReportHilal mohamedNessuna valutazione finora

- Dong Gwang Lighting Installation Inspection ReportsDocumento10 pagineDong Gwang Lighting Installation Inspection ReportsReynante AlimNessuna valutazione finora

- Skid Mounted Unit InstallationDocumento2 pagineSkid Mounted Unit Installationric leonisoNessuna valutazione finora

- Fiberglass and Foster - Inspection Test Plan - ITPDocumento4 pagineFiberglass and Foster - Inspection Test Plan - ITPAlaa Ali100% (1)

- Fit Up ReportDocumento41 pagineFit Up ReportFendik NewbieNessuna valutazione finora

- Attachment 12.4 - QA - QC Checklist - FDBDocumento3 pagineAttachment 12.4 - QA - QC Checklist - FDBehteshamNessuna valutazione finora

- Essentials Electrical Quality Control Plan Sample PDFDocumento13 pagineEssentials Electrical Quality Control Plan Sample PDFSalman HameedNessuna valutazione finora

- 2 HOUR HIGH PRESSURE LEAKAGE TEST CALCULATIONSDocumento2 pagine2 HOUR HIGH PRESSURE LEAKAGE TEST CALCULATIONSmanojNessuna valutazione finora

- Field inspection plan for structural steel erectionDocumento1 paginaField inspection plan for structural steel erectionDelta akathehusky100% (1)

- STR No. CORE-STR-01 For Fabricated & Galvanized Steel Structures For Ohe & Tss Effective From-21.05.2021Documento79 pagineSTR No. CORE-STR-01 For Fabricated & Galvanized Steel Structures For Ohe & Tss Effective From-21.05.2021Sharad SinghNessuna valutazione finora

- Project Internal Audit Procedure: SheetalkumarDocumento4 pagineProject Internal Audit Procedure: SheetalkumarTwin BullsNessuna valutazione finora

- Sample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Documento2 pagineSample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Dhvanit JoshiNessuna valutazione finora

- Purlins Load Tables 1Documento72 paginePurlins Load Tables 1Mohit NatuNessuna valutazione finora

- Attachment 12.5 - QA - QC Checklist - SMDBDocumento6 pagineAttachment 12.5 - QA - QC Checklist - SMDBehteshamNessuna valutazione finora

- Quality Assurance Plan for Structural FabricationDocumento1 paginaQuality Assurance Plan for Structural FabricationproxywarNessuna valutazione finora

- Hydraulic crash barriers ITPDocumento4 pagineHydraulic crash barriers ITPmoytabura96Nessuna valutazione finora

- Fan-Coil Units Compliance Statement for Egypt Tower ProjectsDocumento9 pagineFan-Coil Units Compliance Statement for Egypt Tower ProjectsLi Liu100% (1)

- Checklist-Structural Concrete Post PouringDocumento1 paginaChecklist-Structural Concrete Post Pouringajit karandikarNessuna valutazione finora

- FQP GeneralDocumento21 pagineFQP GeneralgaladrialNessuna valutazione finora

- JFD 100Documento1 paginaJFD 100ecsuperalNessuna valutazione finora

- M-Storm Drainage System - IC-M-SDS-00Documento2 pagineM-Storm Drainage System - IC-M-SDS-00achusanachuNessuna valutazione finora

- Qcs 2010 Part 27.03 Fences and GatesDocumento4 pagineQcs 2010 Part 27.03 Fences and GatesRotsapNayrbNessuna valutazione finora

- Itp FinalDocumento5 pagineItp Finalchristopher Adajo100% (1)

- Fire & Safety Lab and Generator Building Testing Laboratory On Modon-3-Dammam, KSADocumento7 pagineFire & Safety Lab and Generator Building Testing Laboratory On Modon-3-Dammam, KSAMiqdadNessuna valutazione finora

- Installation of LV Cables: Inspection and Test Plan ForDocumento1 paginaInstallation of LV Cables: Inspection and Test Plan ForHussainShabbirNessuna valutazione finora

- Manufacturing Quality Plan For Tank: FGD Sysyem, 2X550 MW TpsDocumento4 pagineManufacturing Quality Plan For Tank: FGD Sysyem, 2X550 MW TpsBhanu Pratap ChoudhuryNessuna valutazione finora

- LV Panel Weight ComparisionDocumento6 pagineLV Panel Weight ComparisionAsaru DeenNessuna valutazione finora

- Inspection and Test Plan For Steel StructureDocumento1 paginaInspection and Test Plan For Steel Structureeva maniceNessuna valutazione finora

- ITP For PlasteringDocumento2 pagineITP For PlasteringPrasanna KumarNessuna valutazione finora

- Inspection and Tests Plan: OPGW 60mm, 24coresDocumento3 pagineInspection and Tests Plan: OPGW 60mm, 24coresErika Rafani WibowoNessuna valutazione finora

- Quality PlanDocumento40 pagineQuality PlanSakthi Kasi RajanNessuna valutazione finora

- QA Inspector Job DescriptionDocumento2 pagineQA Inspector Job DescriptionnorlieNessuna valutazione finora

- Inspection and Test Plan (ITP) for Suspending Ceiling InstallationDocumento2 pagineInspection and Test Plan (ITP) for Suspending Ceiling Installationexia1992Nessuna valutazione finora

- ACG 22 Requirements For Lifting Equipment Inspection BodiesDocumento14 pagineACG 22 Requirements For Lifting Equipment Inspection BodiesramodNessuna valutazione finora

- Pump House Inspection & Test PlanDocumento5 paginePump House Inspection & Test PlanShabeer Shaarim Abdul JabbarNessuna valutazione finora

- ACI 207.1R-96 Mass ConcreteDocumento42 pagineACI 207.1R-96 Mass ConcreteAc2140Nessuna valutazione finora

- Inspection & Test Plan (Itp) : Road WorkDocumento1 paginaInspection & Test Plan (Itp) : Road WorkLOPA THANDARNessuna valutazione finora

- Execution of Sewer Network Submittal of Structural Design DocumentsDocumento1 paginaExecution of Sewer Network Submittal of Structural Design DocumentsEng hassan hussienNessuna valutazione finora

- Itp GuidelinesDocumento5 pagineItp GuidelinesSilla ShameerNessuna valutazione finora

- Approved ITP 06012023 For WT6Documento1 paginaApproved ITP 06012023 For WT6mohamed irsath100% (1)

- Scope: General Inspection Guidelines For Inspection of FittingsDocumento3 pagineScope: General Inspection Guidelines For Inspection of Fittingszahid_497Nessuna valutazione finora

- Pressure Relief Valves Procurement GuideDocumento11 paginePressure Relief Valves Procurement GuideJasbir ChaudharyNessuna valutazione finora

- Activated Sludge Calculations With ExcelDocumento22 pagineActivated Sludge Calculations With ExcelKaustav Patnaik88% (8)

- Sodium Determination ComparisonDocumento8 pagineSodium Determination ComparisonWONG TSNessuna valutazione finora

- Chemical Oxidation Organics FentonDocumento10 pagineChemical Oxidation Organics FentonBa Khoa TranNessuna valutazione finora

- 08.1PressureReliefSystems TofinishDocumento16 pagine08.1PressureReliefSystems TofinishdhavaleshNessuna valutazione finora

- Ozone in Drinking Water Process TPDocumento31 pagineOzone in Drinking Water Process TPAFLAC ............100% (3)

- Food Biochemical Oxygen Demand and Chemical Oxygen DemandDocumento2 pagineFood Biochemical Oxygen Demand and Chemical Oxygen DemandWONG TSNessuna valutazione finora

- Field Measurement of ORPDocumento21 pagineField Measurement of ORPWONG TSNessuna valutazione finora

- Performance of Hybrid Adhesives vs. Traditional Structural AdhesivesDocumento8 paginePerformance of Hybrid Adhesives vs. Traditional Structural AdhesivesJesus N RodriguezNessuna valutazione finora

- Solvents AlternativesDocumento8 pagineSolvents AlternativesWONG TSNessuna valutazione finora

- Four Questions Centrifuge SelectionDocumento4 pagineFour Questions Centrifuge SelectionWONG TSNessuna valutazione finora

- PTFE Bushing Seating WhitepaperDocumento5 paginePTFE Bushing Seating WhitepaperWONG TSNessuna valutazione finora

- Floating Roof TanksDocumento123 pagineFloating Roof TanksSalman BhattiNessuna valutazione finora

- Determining Applicability of the Risk Management Program RuleDocumento19 pagineDetermining Applicability of the Risk Management Program RuleWONG TSNessuna valutazione finora

- Mine Process Waste - Several Metals: ConclusionDocumento2 pagineMine Process Waste - Several Metals: ConclusionWONG TSNessuna valutazione finora

- Methods & Calculation Required For Ventilation in Confined SpacesDocumento4 pagineMethods & Calculation Required For Ventilation in Confined SpacesLisNessuna valutazione finora

- Fan Selection Total PressureDocumento4 pagineFan Selection Total PressureWONG TSNessuna valutazione finora

- 3 UEq Book Excerpt PDFDocumento38 pagine3 UEq Book Excerpt PDFEleonoraNessuna valutazione finora

- Chromium Treatment: ConclusionDocumento4 pagineChromium Treatment: ConclusionWONG TSNessuna valutazione finora

- Piping design basics seriesDocumento16 paginePiping design basics seriesManas KotruNessuna valutazione finora

- Buried PipeDocumento83 pagineBuried PipePlalvarezcelis100% (3)

- AkIAQ AirMovementAirFlowDocumento4 pagineAkIAQ AirMovementAirFlowkozmik54Nessuna valutazione finora

- Absorption (FGD)Documento62 pagineAbsorption (FGD)Chaidir FajariNessuna valutazione finora

- Large-Scale Pyrolysis Oil ProductionDocumento93 pagineLarge-Scale Pyrolysis Oil ProductionKarez Marto100% (1)

- Estimate Purge TimeDocumento1 paginaEstimate Purge TimeWONG TSNessuna valutazione finora

- The Mathematics of Pumping Water PDFDocumento9 pagineThe Mathematics of Pumping Water PDFOualid LamraouiNessuna valutazione finora

- AbsorptionDocumento16 pagineAbsorptionFabio Sala0% (1)

- Electrocoagulation in Wastewater TreatmentDocumento31 pagineElectrocoagulation in Wastewater TreatmentWONG TSNessuna valutazione finora

- ArachchigeEJSR87 1Documento10 pagineArachchigeEJSR87 1Trina HaqueNessuna valutazione finora

- Rapid Sand Filter Design Example PDFDocumento2 pagineRapid Sand Filter Design Example PDFWONG TS95% (21)

- Panas LebihDocumento51 paginePanas LebihRinggo Reog100% (1)

- Ps 1 SolDocumento3 paginePs 1 SolPang XsNessuna valutazione finora

- List of Linkages2016Documento74 pagineList of Linkages2016engrwho0% (1)

- Course OutlineDocumento14 pagineCourse OutlineTony SparkNessuna valutazione finora

- EGIG - 10th - Report - Final - 09-03-2018 - v1Documento50 pagineEGIG - 10th - Report - Final - 09-03-2018 - v1Paulo Marcos Cabral JuniorNessuna valutazione finora

- Civil Engineering Reference BooksDocumento2 pagineCivil Engineering Reference Booksdevbrat boseNessuna valutazione finora

- Tabla 1 Engine ControlDocumento2 pagineTabla 1 Engine Controljulio montenegroNessuna valutazione finora

- SRDK Cryocooler Service Manual: For Service Personnel OnlyDocumento151 pagineSRDK Cryocooler Service Manual: For Service Personnel OnlyOtávio PagnoncelliNessuna valutazione finora

- SRSUNTOUR General Fork GlossaryDocumento23 pagineSRSUNTOUR General Fork GlossaryThomas JunkersfeldNessuna valutazione finora

- Crompton Greaves LimitedDocumento3 pagineCrompton Greaves LimitedNitish SinghNessuna valutazione finora

- Thu Thiem Tunnel Construction - Sequence - Immersed - Tunnel PDFDocumento36 pagineThu Thiem Tunnel Construction - Sequence - Immersed - Tunnel PDFThông PhanNessuna valutazione finora

- CUCM Intracluster Port Usage GuideDocumento3 pagineCUCM Intracluster Port Usage GuideAbhinayMylavarapuNessuna valutazione finora

- ARRIMAX New Service Manual ENDocumento20 pagineARRIMAX New Service Manual ENMohammed IsmailNessuna valutazione finora

- Coco Press KitDocumento55 pagineCoco Press KitPaula RiddenNessuna valutazione finora

- Easygen-3000 Series (Package P1) Genset Control: InterfaceDocumento102 pagineEasygen-3000 Series (Package P1) Genset Control: InterfacejinameNessuna valutazione finora

- Online Institute Reporting Slip of The Application Number - 200310422837 PDFDocumento1 paginaOnline Institute Reporting Slip of The Application Number - 200310422837 PDFRohith RohanNessuna valutazione finora

- Manual 800 KvaDocumento87 pagineManual 800 Kvavicvarg100% (3)

- Airflex 728 Vinyl Acetate-Ethylene Copolymer Modified With Vinyl ChlorideDocumento2 pagineAirflex 728 Vinyl Acetate-Ethylene Copolymer Modified With Vinyl ChlorideNissim Hazar CasanovaNessuna valutazione finora

- Fajs FSXDocumento8 pagineFajs FSXJunhy Bandeira CassandraNessuna valutazione finora

- 83 - Detection of Bearing Fault Using Vibration Analysis and Controlling The VibrationsDocumento12 pagine83 - Detection of Bearing Fault Using Vibration Analysis and Controlling The VibrationsmaulikgadaraNessuna valutazione finora

- ReleDocumento3 pagineRelevitor4santos_6Nessuna valutazione finora

- Strength and Insulating Properties of Building Blocks Made From Waste MaterialsDocumento7 pagineStrength and Insulating Properties of Building Blocks Made From Waste Materialsmjrobust05Nessuna valutazione finora

- Lotus 1-2-3 For WindowsDocumento75 pagineLotus 1-2-3 For Windowskennedy_saleh100% (1)

- Ornl 2465Documento101 pagineOrnl 2465jesusNessuna valutazione finora

- NIKI V4 Infusion Pump Service ManualDocumento54 pagineNIKI V4 Infusion Pump Service ManualIgor Simonelli BermudesNessuna valutazione finora

- PDVSA Engineering Design Manual Volume 9–I Process AnalyzersDocumento25 paginePDVSA Engineering Design Manual Volume 9–I Process AnalyzersAlberto Enrique De Santa Anna CampderáNessuna valutazione finora

- Inventory Management PreetDocumento28 pagineInventory Management PreetKawalpreet Singh MakkarNessuna valutazione finora

- 2 CAD Connecting Rod ForgingDocumento56 pagine2 CAD Connecting Rod ForgingIsrar EqubalNessuna valutazione finora

- Setting vpn1Documento10 pagineSetting vpn1Unink AanNessuna valutazione finora

- Network What To ReadDocumento2 pagineNetwork What To ReadTauseef AhmadNessuna valutazione finora

- Stokes' theorem simplifies integration of differential formsDocumento6 pagineStokes' theorem simplifies integration of differential formssiriusgrNessuna valutazione finora