Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pipe Branch Calculations Example

Caricato da

Ahmed YusufCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pipe Branch Calculations Example

Caricato da

Ahmed YusufCopyright:

Formati disponibili

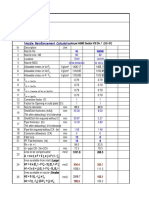

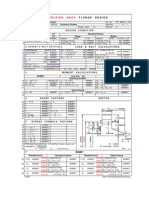

CALCULATION FOR BRANCH REINFORCEMENT

The equations provided below is used to determine the reinforcement requirements for a set-on branch

connection (6header & 1 Branch) using the methods prescribed by ASME B31.3 paragraph 304.3.3. The

acceptable details that can be used with these equations are shown in figures.The equations below are

based on no reinforcement pad at the branch connections. The equations are used to determine the

requirements for additional reinforcement. These equations are only applicable when the branch opening in

the header pipe is a projection of the branch pipe inside diameter (i.e. the branch pipe is set on the header

pipe).

Inputs

Design pressure = 113.129 psi.

Material allowable stress (S) = 16679.3 psi

Joint quality factors Eh = 1

Joint quality factors Eb = 1

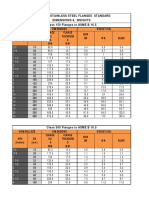

Outer Diameter for 6 Header (Dh) = 6.625 Inch

Nominal wall thickness for 6 Header (Tnom,h) =0.280 Inch

Outer Diameter for 1 Branch (Db) =1.315 Inch

Nominal wall thickness for 1 Branch (Tnom,b) = 0.179 Inch

Angle () between the branch and the header = 90

Minimum Leg Dimension of Fillet Weld =Tc/0.707=0.1253/0.707=0.177

Where ,Tc=0.7 (Tnom,b)

Calculation for the required pressure design wall thicknesses using the equations

N-1 and N-2.

(Thickness for 6Header) t h

PD h

=0.01739 Inch

2(SE 0.4P)

(N-1)

(Thickness for 1Branch) t b

PD b

=0.00284 Inch

2(SE 0.4P)

(N-2)

Calculation for the required reinforcement area (A1)

where

A1= th X d1 X (2-sin )

(N-3)

d1= [Db-2(Tb-c)]/ sin

(N-4)

Tb= 0.875 Tnom,b

(N-5)

Tb =0.875xTnom,=0.875x0.179=0.156inch

d1= 5.8[1.315-2(0.156-0)] / Sin90= 1.00175

Required reinforcement area (A1)=0.280 x 1.00175 x (2 sin 90)= 0.28049 Sq Inch

A1= 0.28049. Sq Inch

CALCULATION FOR BRANCH REINFORCEMENT

Calculation for the available reinforcement area (A2) and (A3)

Reinforcement area for Run Wall

A2=(2d2-d1)(Th-th-c)

Reinforcement area for Branch Wall A3=2L4(Tb-tb-c)/sin

(N-6)

(N-7)

where

d2=max[d1,(Tb-c)+(Th-c)+d1/2]

(N-8)

Th=0.875Tnom,h

(N9)

L4=min[2.5(Th-c), 2.5(Tb-c)]

(N-10)

d2=max[d1,(Tb-c)+(Th-c)+d1/2] = [1.00175 (0.179-0)+(0.280-0)+1.00175/2]

d2= 0.960

Th=0.875Tnom,h=0.875 x 0.280=0.245

Th=0.245

L4=min[2.5(Th-c), 2.5(Tb-c)]=[2.5 x (0.156-0)=0.39

L4=0.39

A2=(2d2-d1)(Th-th-c)= (2x0.960-1.00175) (0.245-0.01739-0)=0.209

A2=0.209 Sq Inch

A3=2L4(Tb-tb-c)/sin = 2 x 0.39 x (0.156-0.00284-0)/sin 90=0.11946

A3=0.11946 Sq Inch

Calculation for the available reinforcement area (A4). Area A4 is the area of other

metal provided by welds .See B31.3 paragraph 328.5.4 for minimum required weld sizes.

A4 = 2 (1/2) (0.177) =0.031 Sq Inch

A4 = 0.031 Sq Inch

Where, Minimum Leg Dimension of Fillet Weld= 0.177

CALCULATION FOR BRANCH REINFORCEMENT

Calculation for the required reinforcement area (Ar).

If Ar is positive, additional reinforcement is required. If Ar is less than or equal to

zero, no additional reinforcement is required.

Ar= A1 (A2 + A3 + A4)

(N-11)

Ar= 0.280489 (0.209+0.11946 +0.031)

Ar = - 0.078 (-ve) Sq Inch

NO ADDITONAL REINFORCEMENT IS REQUIRED.

Pipe to Pipe Weld can be done without any additional reinforcement pad or piping

components (Olets or Coupling).

Potrebbero piacerti anche

- 39.pipe Cap Thickness Calculation: EVS-DC-AR-001 REV.01Documento2 pagine39.pipe Cap Thickness Calculation: EVS-DC-AR-001 REV.01masaminathanNessuna valutazione finora

- Coupling Calculations and Ug-32 Unstayed Head CalculationsDocumento9 pagineCoupling Calculations and Ug-32 Unstayed Head CalculationsLcm TnlNessuna valutazione finora

- Branch (1) Calculations: Pipe Branch Reinforcement Per ASME B31.1b - 2009 Power Piping CodeDocumento2 pagineBranch (1) Calculations: Pipe Branch Reinforcement Per ASME B31.1b - 2009 Power Piping Codedeua2004Nessuna valutazione finora

- New Storage Tanks Design GuidelinesDocumento6 pagineNew Storage Tanks Design GuidelinespaaryNessuna valutazione finora

- 7-12-0005 Rev6 (Skirt Opening Details)Documento2 pagine7-12-0005 Rev6 (Skirt Opening Details)sumit kumarNessuna valutazione finora

- Calculation For Reinforced PadDocumento4 pagineCalculation For Reinforced Padjsridhar_34750% (2)

- Stress Sample Calculation On Base EllDocumento1 paginaStress Sample Calculation On Base EllLionel TorradoNessuna valutazione finora

- SIF ExcelDocumento3 pagineSIF ExcelaravindhcamNessuna valutazione finora

- Mitered BendsDocumento1 paginaMitered BendsTsouki TsoukiNessuna valutazione finora

- Flange Weight ChartDocumento4 pagineFlange Weight ChartDayo IdowuNessuna valutazione finora

- Blind Flange Thickness CalculationDocumento3 pagineBlind Flange Thickness CalculationKannapiran Krishnamoorthy75% (4)

- Check 18Documento6 pagineCheck 18Anonymous qBwHKusNessuna valutazione finora

- IBR CalculationsDocumento20 pagineIBR CalculationsSivi NallamothuNessuna valutazione finora

- 7-12-0006 Rev6 (Angle Leg Support)Documento2 pagine7-12-0006 Rev6 (Angle Leg Support)sumit kumarNessuna valutazione finora

- Nozzle Reinforcement Calculation Excel SheetDocumento3 pagineNozzle Reinforcement Calculation Excel Sheetramesh punjabiNessuna valutazione finora

- TEMA Shell Bundle Entrance and Exit AreasDocumento3 pagineTEMA Shell Bundle Entrance and Exit AreasArunkumar MyakalaNessuna valutazione finora

- Body Flange Thkickness CalculationDocumento2 pagineBody Flange Thkickness CalculationsachmayaNessuna valutazione finora

- ASME PipingOffice - Piping CalculatorsDocumento5 pagineASME PipingOffice - Piping CalculatorsJohn PaulNessuna valutazione finora

- Trunnion Calculation - MasterDocumento92 pagineTrunnion Calculation - MasterSrisaran Srinivas ArasavelliNessuna valutazione finora

- Pipe Reinforcement Calculation (ASME-B31.3)Documento3 paginePipe Reinforcement Calculation (ASME-B31.3)jenshid100% (2)

- Annexure - Bolt Torque CalculationDocumento4 pagineAnnexure - Bolt Torque CalculationDarshan PanchalNessuna valutazione finora

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocumento5 pagineASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNessuna valutazione finora

- Hydrostatic Test Pressure CalculationDocumento1 paginaHydrostatic Test Pressure Calculationmohd as shahiddin jafriNessuna valutazione finora

- Branch Reinforcement Pad Requirement CalculationDocumento1 paginaBranch Reinforcement Pad Requirement Calculations.mladinNessuna valutazione finora

- Calculation of Pipe Support Mercury Removal Inlet Filter Coalescer 180kg CAPACITY, 1.533 M LENGTHDocumento2 pagineCalculation of Pipe Support Mercury Removal Inlet Filter Coalescer 180kg CAPACITY, 1.533 M LENGTHRidho Ziska0% (1)

- Piping Engineering - Tank Nozzle Loads 1Documento1 paginaPiping Engineering - Tank Nozzle Loads 1Nasrul AdliNessuna valutazione finora

- Branch Reinforcement Per Asme B31.4 PipelineDocumento1 paginaBranch Reinforcement Per Asme B31.4 PipelinegateauxboyNessuna valutazione finora

- API 650 RF Pad Calculation PDFDocumento1 paginaAPI 650 RF Pad Calculation PDFRakeshNessuna valutazione finora

- Pipe Saddle Support CalculationsDocumento1 paginaPipe Saddle Support CalculationsAbir Baran HandaNessuna valutazione finora

- Flange DesignDocumento6 pagineFlange DesignDinesh VaghelaNessuna valutazione finora

- Impact Test Exemptions PEDDocumento7 pagineImpact Test Exemptions PEDoberaiNessuna valutazione finora

- ASTM A53 Vs A500 EquivalenceDocumento6 pagineASTM A53 Vs A500 Equivalenceemmanuilmoulos6339Nessuna valutazione finora

- Tailing LugDocumento2 pagineTailing Lugjagannadha varmaNessuna valutazione finora

- Jacketed Piping CalculationDocumento9 pagineJacketed Piping CalculationKamran Shaikh0% (1)

- Bolt TorqueDocumento3 pagineBolt TorqueHeri KurniawanNessuna valutazione finora

- Piping Stress Critical Lines - Basis For Piping Critical Line ListDocumento4 paginePiping Stress Critical Lines - Basis For Piping Critical Line Listashish.mathur1Nessuna valutazione finora

- TrunnionDocumento5 pagineTrunnionTanvirNessuna valutazione finora

- The Tangent LineDocumento1 paginaThe Tangent LinealokbdasNessuna valutazione finora

- Rectangular Tank SizingDocumento8 pagineRectangular Tank Sizingvofaith100% (16)

- Anchor FlangeDocumento2 pagineAnchor Flangeannu300100% (1)

- Flange CalculationsDocumento5 pagineFlange CalculationsswapnavattemNessuna valutazione finora

- Pipe Support IndexDocumento4 paginePipe Support IndexxkokarcaxNessuna valutazione finora

- 2 - 1 Ellipsoidal Head Blank DiameterDocumento1 pagina2 - 1 Ellipsoidal Head Blank Diameterdownloadmonster100% (2)

- Pressure & Temperature ClassificationDocumento1 paginaPressure & Temperature Classificationkeo85100% (1)

- Trun CalcDocumento215 pagineTrun CalcmohamedeliasNessuna valutazione finora

- Design of Flanges - Full-Face Gasket 2010Documento29 pagineDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- Bolt Torque Calculations 1 PDFDocumento1 paginaBolt Torque Calculations 1 PDFshazanNessuna valutazione finora

- EN1591 Flange DesignDocumento9 pagineEN1591 Flange DesignmadodandembeNessuna valutazione finora

- Modification Thickness of A FlangeDocumento3 pagineModification Thickness of A FlangePeter PerezNessuna valutazione finora

- Miter Bend CalculationDocumento4 pagineMiter Bend CalculationRavindra S. Jivani100% (3)

- Nozzle Design CalculationDocumento1 paginaNozzle Design CalculationSachin55860% (1)

- Asme b31 3 03 PDFDocumento3 pagineAsme b31 3 03 PDFAtallah BoufatahNessuna valutazione finora

- Steel Structure ST 37Documento11 pagineSteel Structure ST 37aliNessuna valutazione finora

- Expansion Loop CalculationDocumento1 paginaExpansion Loop Calculationalvinchuan100% (1)

- SPREADSHEETS SERIES No. 0009S - 2Documento4 pagineSPREADSHEETS SERIES No. 0009S - 2Emma DNessuna valutazione finora

- RC Design Spreadsheets - Working SheetDocumento49 pagineRC Design Spreadsheets - Working SheetKiran AcharyaNessuna valutazione finora

- Miter B1 ADocumento55 pagineMiter B1 AFarid TataNessuna valutazione finora

- Calculo de Derivaciones Asme b31.8Documento18 pagineCalculo de Derivaciones Asme b31.8Wilson Castellón BarrancosNessuna valutazione finora

- Pipe Thickness & RF Pad Calculations As Per Asme b313Documento3 paginePipe Thickness & RF Pad Calculations As Per Asme b313Gaurav BhendeNessuna valutazione finora

- Design of Beam Aci 11-01-05Documento23 pagineDesign of Beam Aci 11-01-05MuhammadMuzammilNessuna valutazione finora

- Ethernetwebserver For Wt32 - Eth01 (Esp32 + Lan8720) : FeaturesDocumento6 pagineEthernetwebserver For Wt32 - Eth01 (Esp32 + Lan8720) : FeaturestraiandNessuna valutazione finora

- Emerson Automation Solutions Process Systems and Solutions Product Support GuidelineDocumento6 pagineEmerson Automation Solutions Process Systems and Solutions Product Support Guidelineandres garciaNessuna valutazione finora

- Philips TV Software Upgrade With USB Portable MemoryDocumento4 paginePhilips TV Software Upgrade With USB Portable MemoryAmin AsawabNessuna valutazione finora

- Sales Navigator: Introducing Linkedin For NonprofitsDocumento2 pagineSales Navigator: Introducing Linkedin For NonprofitsAlex RamónNessuna valutazione finora

- Preparation For Speaking 2Documento3 paginePreparation For Speaking 2Em bé MậpNessuna valutazione finora

- Enable Hyper-V On Windows 10 - Microsoft DocsDocumento3 pagineEnable Hyper-V On Windows 10 - Microsoft DocsDương Khởi ThạchNessuna valutazione finora

- The China Continental Scientific Drilling Project CCSD-1 Well Drilling Engineering and Construction PDFDocumento375 pagineThe China Continental Scientific Drilling Project CCSD-1 Well Drilling Engineering and Construction PDF杨建政Nessuna valutazione finora

- 0aa000005 h.248 Protocol Issue2.0Documento27 pagine0aa000005 h.248 Protocol Issue2.0Cristhian OñaNessuna valutazione finora

- TOMBSTONING AT-221CM5 FlysheetDocumento2 pagineTOMBSTONING AT-221CM5 FlysheetManjunatha Swamy VNessuna valutazione finora

- ASB 2011 12 09 TCR Containment-1Documento3 pagineASB 2011 12 09 TCR Containment-1K MNessuna valutazione finora

- C-Bus Basics Training Manual - Vol 1Documento64 pagineC-Bus Basics Training Manual - Vol 1jakkyjeryNessuna valutazione finora

- The Blender Quick Start Guide: by Darrin LileDocumento23 pagineThe Blender Quick Start Guide: by Darrin LileMiguel Alberto Dávila SacotoNessuna valutazione finora

- DCNM - Wliion - Dicentis Battery PackDocumento3 pagineDCNM - Wliion - Dicentis Battery PackAndrew Halim RamadanNessuna valutazione finora

- Problem Gambling Worldwide: An Update and Systematic Review of Empirical Research (2000 - 2015)Documento22 pagineProblem Gambling Worldwide: An Update and Systematic Review of Empirical Research (2000 - 2015)Adre CactussoNessuna valutazione finora

- Dimplex Cadiz Dry Radiator UKDocumento8 pagineDimplex Cadiz Dry Radiator UKDaniel AdebayoNessuna valutazione finora

- XI - Maths - Chapter 8 - BINOMIAL THEOREM - (95-122)Documento29 pagineXI - Maths - Chapter 8 - BINOMIAL THEOREM - (95-122)NdjskaNessuna valutazione finora

- Output Leetcode Questions PDFDocumento224 pagineOutput Leetcode Questions PDFvNessuna valutazione finora

- Bosch Leisure Batteries L4 PDFDocumento4 pagineBosch Leisure Batteries L4 PDFsimon_someone217Nessuna valutazione finora

- Drive Gearboxes GPT ENDocumento24 pagineDrive Gearboxes GPT ENZaqi SatchNessuna valutazione finora

- ISO-28591-2017 - PreviewDocumento13 pagineISO-28591-2017 - PreviewGuven MarangozNessuna valutazione finora

- Chapter 1 Introduction To HTML5Documento46 pagineChapter 1 Introduction To HTML5alhinai676Nessuna valutazione finora

- Tds Total Fluidmatic LV MV Tcs 202111 enDocumento2 pagineTds Total Fluidmatic LV MV Tcs 202111 enMartín BaezaNessuna valutazione finora

- Cryptography and Network Security: Seventh Edition by William StallingsDocumento34 pagineCryptography and Network Security: Seventh Edition by William StallingsvanithaNessuna valutazione finora

- 1oracle SCM Cloud (Purchasing, Order Management)Documento340 pagine1oracle SCM Cloud (Purchasing, Order Management)AhmedNessuna valutazione finora

- General Catalogue 2012Documento120 pagineGeneral Catalogue 2012Irina AureliaNessuna valutazione finora

- Computer Training Institute: Project Report ofDocumento9 pagineComputer Training Institute: Project Report ofEMMANUEL TV INDIANessuna valutazione finora

- Master of Arts in Education Major In: CurriculumDocumento2 pagineMaster of Arts in Education Major In: CurriculumJuvelyn Gutierrez MonteroNessuna valutazione finora

- 5 ITE403 Whitman Ch04 W4C2Documento32 pagine5 ITE403 Whitman Ch04 W4C2namo nrtNessuna valutazione finora

- Chapter 12 - Fluid MachineriesDocumento98 pagineChapter 12 - Fluid MachineriesWaw0% (1)

- 2021.02.19.lyons Valve Designers HandbookDocumento440 pagine2021.02.19.lyons Valve Designers Handbookparallax19570% (1)

- The Cyanide Canary: A True Story of InjusticeDa EverandThe Cyanide Canary: A True Story of InjusticeValutazione: 4 su 5 stelle4/5 (52)

- Waste: One Woman’s Fight Against America’s Dirty SecretDa EverandWaste: One Woman’s Fight Against America’s Dirty SecretValutazione: 5 su 5 stelle5/5 (1)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDa EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterNessuna valutazione finora

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionDa EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionValutazione: 3 su 5 stelle3/5 (1)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDa EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNessuna valutazione finora

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDa EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesValutazione: 4.5 su 5 stelle4.5/5 (21)

- Electric Motor Control: DC, AC, and BLDC MotorsDa EverandElectric Motor Control: DC, AC, and BLDC MotorsValutazione: 4.5 su 5 stelle4.5/5 (19)

- A Practical Handbook for Drilling Fluids ProcessingDa EverandA Practical Handbook for Drilling Fluids ProcessingNessuna valutazione finora

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionValutazione: 5 su 5 stelle5/5 (1)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDa EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentValutazione: 4.5 su 5 stelle4.5/5 (21)

- Electric Motors and Drives: Fundamentals, Types and ApplicationsDa EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsValutazione: 4.5 su 5 stelle4.5/5 (12)

- Shorting the Grid: The Hidden Fragility of Our Electric GridDa EverandShorting the Grid: The Hidden Fragility of Our Electric GridValutazione: 4.5 su 5 stelle4.5/5 (2)

- Well Control for Completions and InterventionsDa EverandWell Control for Completions and InterventionsValutazione: 4 su 5 stelle4/5 (10)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsDa EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNessuna valutazione finora

- Well Integrity for Workovers and RecompletionsDa EverandWell Integrity for Workovers and RecompletionsValutazione: 5 su 5 stelle5/5 (3)

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingDa EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingNessuna valutazione finora

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ADa EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANessuna valutazione finora

- Photovoltaic Solar Energy: From Fundamentals to ApplicationsDa EverandPhotovoltaic Solar Energy: From Fundamentals to ApplicationsNessuna valutazione finora

- Handbook on Battery Energy Storage SystemDa EverandHandbook on Battery Energy Storage SystemValutazione: 4.5 su 5 stelle4.5/5 (2)

- Pipeline and Energy Plant Piping: Design and TechnologyDa EverandPipeline and Energy Plant Piping: Design and TechnologyValutazione: 5 su 5 stelle5/5 (2)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontDa EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontValutazione: 4.5 su 5 stelle4.5/5 (18)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsDa EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNessuna valutazione finora

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsDa EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsValutazione: 4.5 su 5 stelle4.5/5 (2)

- Power Electronics Diploma Interview Q&A: Career GuideDa EverandPower Electronics Diploma Interview Q&A: Career GuideNessuna valutazione finora

- Flow Analysis for Hydrocarbon Pipeline EngineeringDa EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNessuna valutazione finora

- Thermal Power Plant: Design and OperationDa EverandThermal Power Plant: Design and OperationValutazione: 4.5 su 5 stelle4.5/5 (23)